i have been trying to gather information over the last couple days for this project. im trying to find out what manufacturer's generally use for thread diameter for there rod ends; 3/4"? knowing this i may source one size larger.

the next question is in regards to the center section. as of now i plan on using 1.25" ~ .125 wall aluminum. would you use 7075 or be okay with 6061? i will then weld on some threads, like imaged below.

to help better assess what forces these may be susceptible to i will include what information i can.

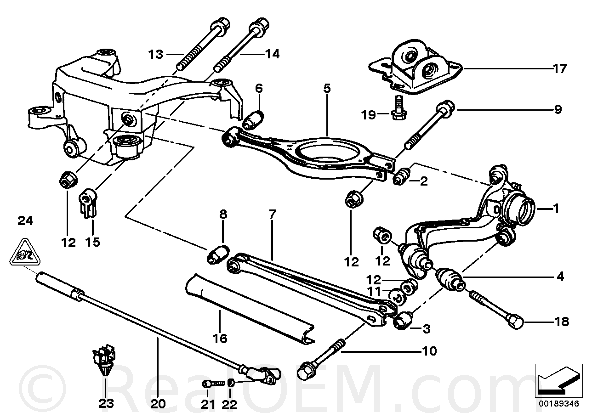

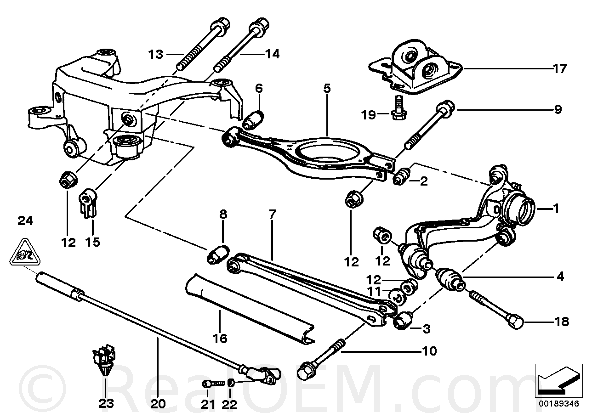

in the above diagram i would like to make parts #5 and #7. the rear will become true coil-over so no need to mention anything additional on this subject.

in the above diagram i would like to make parts #5 and #7. the rear will become true coil-over so no need to mention anything additional on this subject.

vehicle weighs ~ 2000lbs and the maximum grip will likely come from 225 tires.

so here are my questions:

what size and grade aluminum would you use? do you have experience empirical or anecdotal to help convince me of your advice?

i plan on using steel rod ends and replace yearly to limit corrosion and wear.

any other advice on this project is welcome.

here is one of the few discussions i could find on aluminum vs. steel. the conversation is about rod ends but the concerns apply to all applications.

if you come in here saying i would never use aluminum please provide some additional literature for me to read.

http://www.thirdgen.org/techboard/suspension-chassis/567357-tie-rod-sleeves-aluminum.html

Your going to weld a steal insert to an aluminum tube?

The threaded inserts you picture are steel... and I have not seen them in aluminum.

If you weld aluminum, you should probably find a place that can re-heat treat it because annealed aluminum is not particularly strong.

I've built control arms like that, but for small school formula hybrid cars.

No real problems, but I wouldn't do it for my street car... Those things hold the wheels on, and wheels are important to the basic functionality of the car.

You COULD just over build the hell out of it... But by the time you up from heim joint from 3/4 to 7/8ths and use steel tubing your going to weight more then an OEM stamped steel control arm, at a pretty huge cost (looking at Mc MasterCarr one 7/8in high strength rod end is ~$75), with a fair amount of work and a lower level of confidence.

I wouldn't use aluminum for control arms.

i often choose my words carefully to help prevent any ambiguity.

obligatory "thanks"

http://www2.hawaii.edu/~bsb/me372/docs/fatigue_curves_6061.pdf

obligatory "don't be a dick"

mw

HalfDork

1/30/11 6:40 p.m.

I thought there was some thick walled aluminum tubing that had the I D ready to tap for rod ends. I thought it was used by circle track guys so they could just take a length of tubing to the track and be able to cut to size spare arms. I'm not sure if the is really exists or if it's something I dreamed up.

Speedway has all sort of this type of stuff. I'd agree with DIY dave... easy on the dickness.

Day Motorsports also sells pre cut and threaded aluminum tubing for control arms. I'm with Dave, though: I'd prefer not to weld aluminum in this type of application. Steel tubing with inserts ('bungs') in the ends are not much heavier than aluminum and the safety factor is much higher. That's how I built the 3 link/Panhard setup on my car.

Wally

SuperDork

1/30/11 8:27 p.m.

Curmudgeon wrote:

Day Motorsports also sells pre cut and threaded aluminum tubing for control arms. I'm with Dave, though: I'd prefer not to weld aluminum in this type of application. Steel tubing with inserts ('bungs') in the ends are not much heavier than aluminum and the safety factor is much higher. That's how I built the 3 link/Panhard setup on my car.

As long as you check the parts any time there is contact with another car or curb Aluminum should be fine, although I've only every used threaded tubing, I've never seen the weld in pieces like you can get for steel parts.

He said "bungs"

He said "bungs"

I would not want to use aluminum for the control arms. You say 225 tires. What kind of tires full race slicks, Ultra High performance summers or ....? Honestly I don't think you are going to lose that much weight compared to the steel.

The aluminum tubing sold by most stock car suppliers is intended for steering links and not suspension comtrol arms. If used in a suspension it would be for trailing links and not lateral links.

If your LCA is going to be just heim joints and a tube why don't you just buy swedged steel tubing and the correct size heims. No welding needed. Links to pages showing both tubes & heims.

https://www.lefthanderchassis.com/v2a/viewproduct_group.asp?idgroup=2512077

https://www.lefthanderchassis.com/v2a/viewproduct_group.asp?idgroup=2513296

The lowers are inexpensive on ebay with heim joints and ajustability, you couold probably make a second pair into uppers with a little modification if you are not going to put the springs in the factory location.

You might want to consult with the rock-crawler/heavy-duty off road guys who deal with tube frame chassis's control rods, arms, rod ends, etc...all the time. And they might have some god pricing or ideas on what to use.

Try Rustsy's offroad to start, and go from there.

thank you for the replies.

machining question:

what is the maximum recommended hole to be machined into a bar? it would be nice to find a table with such data so i could reference for various materials and diameter bars.

the only suggestion i can recall seeing over the last couple days has been a 3/4" thread in a 1" bar or hexagon.

anyone have additional data to submit for consideration?

Depends on the material. It is more of a strength question then a can you do it question. I have thin walled the E36 M3 out of some stuff.

^ can you share some guidelines based on your experiences?

Ian F

SuperDork

2/3/11 2:08 p.m.

93EXCivic wrote:

Depends on the material. It is more of a strength question then a can you do it question.

^^^^

Ok... I'll be the dick everyone else is trying not to be:

If you have to ask these questions, then you probably shouldn't be doing this.

The questions you are asking involve a lot of engineering analysis regarding fatigue strengths and loads. None of which can be answered here without a lot more information about what you're trying to do (providing an engineer with the knowledge would be stupid enough to actually answer).

This is why the grass-roots builders use steel for these applications - it's easier to over-build for a better safety factor when using thumb-nail (or even calculated) engineering.

That said, if you are dead-set on using aluminum, I'd use 6000 series over 7000 (going by my experience with bike frames) since it's easier to weld and get re-heat treated. Of course, the chances are if you gave any of these pieces to a heat-treating facility they may not even touch then due to the potential liability. It will have to be re-heat treated. Otherwise, it'll likely fail at the first corner.

logicfactory wrote:

^ can you share some guidelines based on your experiences?

Well we used aluminum to make the frame of the NASA Great Moonbuggy Race vehicle. We had 3/4" of inch plugs which we drilled a 1/2" holes into. I think that is the thinness I have actually drilled and tapped aluminum for a structural things. I made a display piece which had maybe a 1/16" inch wall. I wouldn't put E36 M3 for weight on it though. I haven't had much experience machining steel. 99% of machining has been with composites and aluminum.

Ian F wrote:

93EXCivic wrote:

Depends on the material. It is more of a strength question then a can you do it question.

^^^^

Ok... I'll be the dick everyone else is trying not to be:

If you have to ask these questions, then you probably shouldn't be doing this.

The questions you are asking involve a lot of engineering analysis regarding fatigue strengths and loads. None of which can be answered here without a lot more information about what you're trying to do (providing an engineer with the knowledge would be stupid enough to actually answer).

This is why the grass-roots builders use steel for these applications - it's easier to over-build for a better safety factor when using thumb-nail (or even calculated) engineering.

That said, if you are dead-set on using aluminum, I'd use 6000 series over 7000 (going by my experience with bike frames) since it's easier to weld and get re-heat treated. Of course, the chances are if you gave any of these pieces to a heat-treating facility they may not even touch then due to the potential liability. It will have to be re-heat treated. Otherwise, it'll likely fail at the first corner.

I agree with this advice though. I would do steel A-arms. They did aluminum a-arms on the 2009 UAH Great Moonbuggy Race Vehicle and with the shocks removed and the suspension locked and someone standing on the vehicle, the vehicle would deflect about an 1" downward. So not only is there a possibility of the aluminum A-arms failing but they also will more then likely not be as stiff which is not a good thing when it comes to the suspension.

JoeyM

SuperDork

2/3/11 3:42 p.m.

I'll just muddy up the conversation with a quote

"Make the suspension adjustable and they will adjust it wrong -- look what they can do to a Weber carburetor in just a few moments of stupidity with a screwdriver." - Colin Chapman

Aluminum is not as rigid as steel, but since it is less dense it takes up more space than an equivalent weight of steel. Therefore, it can be much stiffer for the same weight with the tradeoff of taking up more space. When shaped properly, it can be much stiffer than a heavier steel frame. For an excellent example, check out Honda's twin spar motocross bike frame:

The heavier and more flexible steel frame it replaced:

That's the product of about five years of engineering by one of the most technologically adept companies on the planet. Unless you have their capabilities, overbuild!

Trying to thinwall aluminum tubing to save weight does not take advantage of its properties and will end badly. It's always a good idea to pick the right material for the job.

Hex and Octagon tap tube is available from the fine folks at Left Hander.

https://www.lefthanderchassis.com/v2a/viewproduct_group.asp?idgroup=2512542

Great for radius rods etc but not for lower control arms with spring attachment.

in the above diagram i would like to make parts #5 and #7. the rear will become true coil-over so no need to mention anything additional on this subject.

in the above diagram i would like to make parts #5 and #7. the rear will become true coil-over so no need to mention anything additional on this subject.

He said "bungs"

He said "bungs"