I've been reading outside the box lately and I keep coming across bits of information about tuning circle track cars using spring rubbers and bump stops. There's not much out there about tuning using these on street/autocross cars with the exception of Fat Cat Motorsports. That guy is really messing with this stuff and it's fascinating, though he sells a solution and not process for exploration. He also is mainly a Miata guy. I don't have a Miata and I'm more interested in the process of learning how use theses tools than just having something that works. I'm kind of an idiot. Bump stops are cheap and spring rubbers are sort of cheap and this all sounds like good fun and I'm easily amused. I'm going to try so stuff and record it in this thread partly because someone else might find it interesting, but mostly because I tend to lose things in the real world but the internet keeps them forever.

I'm starting with spring rubbers. Spring rubbers are big doughnuts of squishy stuff that you jam between the coils of a coil spring. Depending on how stiff the rubber is, you range from partially to completely isolating that coil and you stiffen the spring rate. Circle track racers use this to tune the car by easily changing the stiffness of springs. They can just pop into the pits and either push in or yank out a rubber depending on what they're trying to do. You can't change the rate a lot, but you can make pretty significant handling changes, or so they say. My Mazda 2 only has 3.5 active coils of spring in the front. If I put a really hard rubber in there and completely isolated one coil then my spring rate would go up about 40%. That's enough math to convince me to try it, so I did.

Spring rubbers are only sort of cheap, at $30-$50 each, so $60-$100 per end of the car if you're trying to do things symmetrically, which you are in a street/autocross car, not so much on a circle track car. It's sort of cheap, but in the experimental phase of this, I'm cheaper. The civilian version of spring rubbers are coil spring boosters, and instead of being $30 each, they're $8. Not a tuning tool so much as a proof of concept tester.

They're built just like spring rubbers, a split doughnut of rubber with a deep double groove. You're supposed to jack up your truck, slide these in between a previously collapsed coil and gain back an inch of height. Word is that they work.

They're built just like spring rubbers, a split doughnut of rubber with a deep double groove. You're supposed to jack up your truck, slide these in between a previously collapsed coil and gain back an inch of height. Word is that they work.

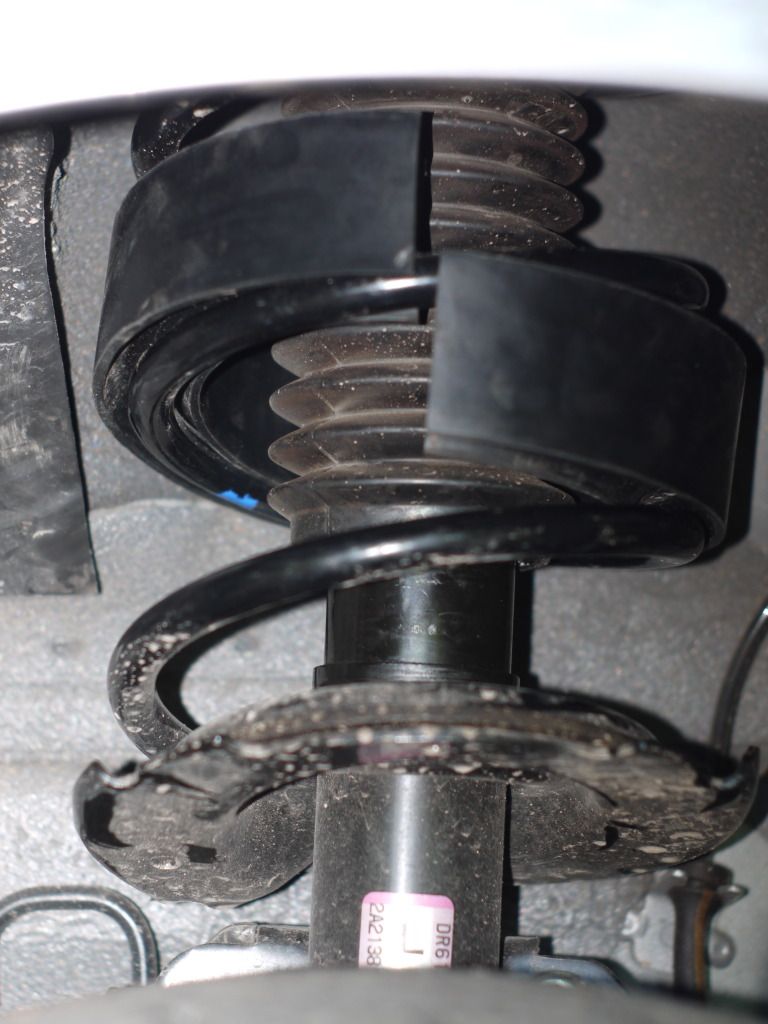

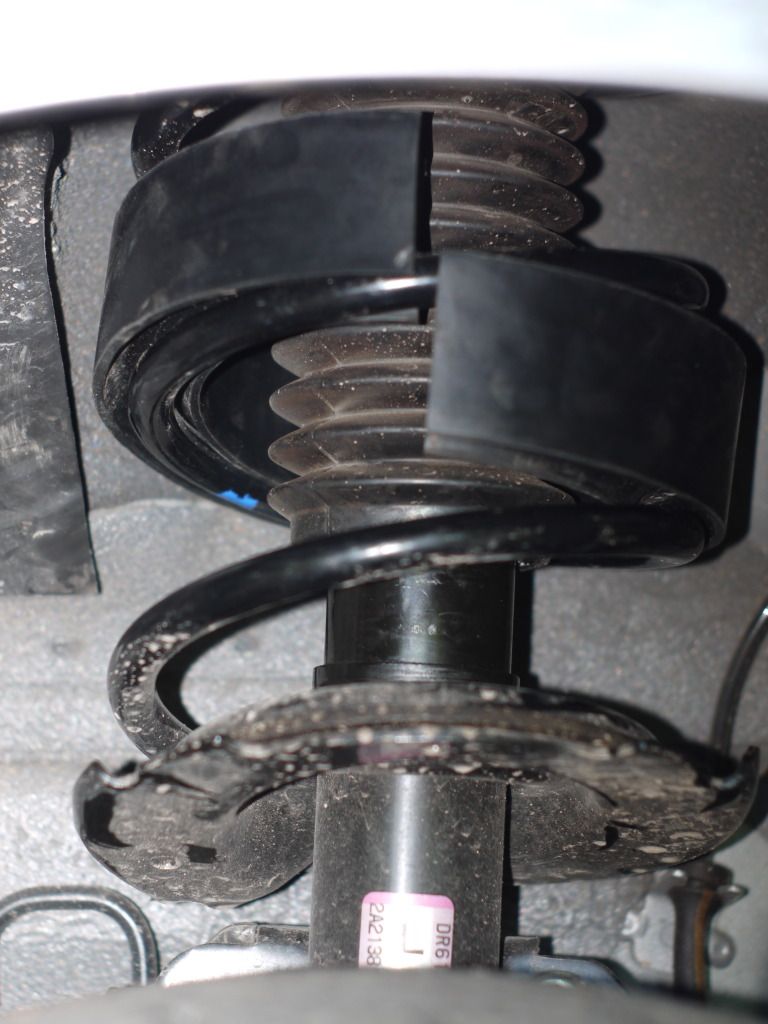

For my application, I'm sliding them in the middle, where the coils are open. Yes, I did a bit of research to find a set of these that are just about the exact thickness as the space between my coils at ride height. I don't want to lift the car, but I don't want them to flop around as I drive. The picture is of the car jacked up with them just hanging in there, but with the car on the ground the can wiggle just the tiniest bit.

For my application, I'm sliding them in the middle, where the coils are open. Yes, I did a bit of research to find a set of these that are just about the exact thickness as the space between my coils at ride height. I don't want to lift the car, but I don't want them to flop around as I drive. The picture is of the car jacked up with them just hanging in there, but with the car on the ground the can wiggle just the tiniest bit.

Well, they work. The car is stiffer. Enough that it noticeably changes the balance toward understeer. I just drove around on them for 10 minutes or so last night and then yanked them back out. That's the plan, I can drive the car normally to an autocross, stiffen it up for my runs, yank them back out and go on my way. I'm not sure I'd consider daily driving them due to the point loading on the springs where the end of the spring rubber is. For four autocross runs, I think I'll be fine. I still might die a firey death, and I'm comfortable with that risk.

I'm looking forward to your results. I also may have something to add as I will also be trying an unconventional bumpstop setup on the front of my fwd McStrut machine.

interesting, I liek this thread already. subscribed.

I'm thinking the $8 are much stiffer than the ones the circle track guys use. That's based upon a recollection from the same type of posts on another forum a long time ago.

I assume you are using them only in the front and is the reason for more understeer.

Put some in the rear and it will balance things up.

Or try them in the rear only and have fun.

ransom

Dork

4/25/12 10:07 a.m.

Interesting. I think the spring rubbers have promise. I'm guessing we'll hear shortly about how it behaves with full-coil isolators on the rear and a fragment on the front?

It's clear that people with more experience and understanding than I have achieved success with the bump stops. I'm still dubious, and would prefer to avoid any form of tuning that introduces discontinuities into the spring rates during operation.

The latest issue of circle track actually semi-addresses this with an article on an experiment using those new Hypercoil bellows springs to avoid using a nonlinear bump-stop midcorner and using these springs instead. You still get a bizarre step from the outer coil spring rate to the rate of the outer coil spring PLUS the rate of the bellows spring, but at least it doesn't ramp up asymptotically once it starts.

Though I think that was for a car designed to basically fall onto its bump stops for aero reasons once the corner is initiated. I'm guessing that bump stops in circle track are also used more like the Fat Cat approach, even on flatter corners and where only the outer wheel(s) are on the stops?

cghstang wrote:

I'm looking forward to your results. I also may have something to add as I will also be trying an unconventional bumpstop setup on the front of my fwd McStrut machine.

Please post your results. I've got a box of bumpstops and spacers that are supposed to be here on Friday. I'm going to start on the rear of the car only because it's easier to take apart and change things. I think the biggest potential benefits are on the front of cars.

ransom wrote:

Interesting. I think the spring rubbers have promise. I'm guessing we'll hear shortly about how it behaves with full-coil isolators on the rear and a fragment on the front?

Though I think that was for a car designed to basically fall onto its bump stops for aero reasons once the corner is initiated. I'm guessing that bump stops in circle track are also used more like the Fat Cat approach, even on flatter corners and where only the outer wheel(s) are on the stops?

The rear of the car has 8 open coils and they are smaller which is why I started in the front, it's easier and has a larger effect. The real spring rubbers come in a variety of hardnesses, I think the cheapos that I have are going to be closest to the hard end. Things look promising enough that I may end up spending the money to experiment with good ones.

An interesting fact about a lot of modern cars is that they're already designed to fall onto the bump stops in hard cornering. I know my 2 is doing it. That was part of what led me down this path. If it's going to corner on the bumps anyway, I might as well try and make it better. Non linearity is an issue and might end up being a significant issue. A number of the circle track bump sellers have force plots for the bumps they sell. They're actually quite linear within a given range, at which point things go all wacky. I wish I had shock position sensors to log where I am in travel to work this all out. I may need to rig up some sort of tell tale to at least tell me what my maximum travel was.

My Mazda2, like a lot of modern cars, is designed to corner on the bump stops. It's done so well that you don't feel it, but putting a tell tale on the shock shaft lets you know what's up. Bump stop isn't really the proper term for these guys, they're function more as a secondary spring. They're designed to add spring rate gently when needed. The work well, but any active part of the suspension is fair game for mucking about with to make it better.

For now, I'm changing things in the rear of the car for a couple of reasons. The first is that it's easier to take the rear shocks off and apart than the front struts. The second is that I need more spring rate in the rear more than the front. The third is the behavior of the car when loaded. If I put three kids in the back (120 lbs or so, small kids) and another 75 lbs of gear for their soccer games, the rear of the car rides significantly lower. Acceleration is less, but rear cornering grip is way way way higher and balance in the car is better. You can feel it. Which part of that is because of the extra weight and which part is because I'm on the factory bumps so much sooner in the corners giving me a higher spring rate? I don't know.

The experiment has two parts, the first is making pucks to take up travel and force the bumps to engage earlier. You can buy these from circle track suppliers, but I made with a hole saw, a drill bit, and a cutting board. $2 in cutting board will get me more spacers than I have space for.

The second part of the experiment uses a little spring math. When you stack two springs together the final rate is always lower than either spring individually. It sounds weird at first, but if you had two 6 inch coil spring that were 100 lbs/in each and you stacked them on top of each other, you would have a 12 inch spring at 50 lbs/in. This works because you've kept the spring wire the same, but effectively doubled the number of free coils. You can mix and match spring weights and lengths to make custom rates, it's pretty cool and works right up until coil collapse. If you have two springs of different weights, the lighter one will always collapse first, at that point the rate will jump to the rate of the higher spring. This can be good or bad depending on what you're trying to accomplish. Bump stops work the same general way, but due to their increased non-linearity over coil springs, the math isn't so easy. Without a spring tester we're basically guessing. What we do know, is that when we add squishy things, the two together are always softer than either one alone.

Knowing that I want my bump stops to come into contact a lot sooner in travel than stock, I suspect that I might also want them to be softer when then come in contact. Maybe I'm right. Maybe not, but I can always tune the rate decrease by changing the hardness of the extra bumps I have, in theory. I started knowing that I wanted to take up over an inch of the 2 inches of travel that I have before I start contact. I ordered up four of the softest puck style bump stops that I could get from a circle track supplier. They're 20 durometer and 1/2 an inch thick each. They feel just a firmer than the stock rear bump stop, but much softer than the front. I put them on below the stock bump stop added a spacer puck above it to take up about 1.25 inches. I've still got around 3/4 of an inch of free travel left before I contact the bumps with an empty car. With my kids in, I'm on the bumps sitting still.

Results will have to wait for the autocross this Sunday but I think the effect is real. Empty I'm coming onto the bumps sooner in cornering and it's increasing the overall roll stiffness of the car. It feels a bit like I upgraded the rear sway bar. Loaded the car still rides fine, you can't even tell I did anything while driving down the road, but the increase in stiffness in cornering is even more pronounced. There's more experimenting to do here, but this is a good first step down the road of learning.

The second part of this bump stop stuff is the ability to change the point that the car comes onto the bump stops. In normal driving I'd like to have 1-1.5 inches of up travel before that happens, at least. When autocrossing, I'd like to reduce that. I want to be on the bumps sooner to increase the wheel rate faster and prevent roll and the bad part of the camber curve, the same stuff I'd be trying to do with stiffer springs. To make things easily adjustable I'm stealing another idea from circle track, packers.

With these little pack man shaped guys I can adjust bump travel in about a second. If I want to take up that inch of free travel, I just snap 2 or 3 of them on and I'm right there on the bumps. Easy peasy.

With these little pack man shaped guys I can adjust bump travel in about a second. If I want to take up that inch of free travel, I just snap 2 or 3 of them on and I'm right there on the bumps. Easy peasy.

I should be able to test these this weekend as well. I'm going to start with as little free shaft as I can. If the rear is too stiff and the car is oversteering I can pop out a packer between runs and see how it goes. I still think the biggest potential gains are to be had on the front of the car, and that's where I'll be moving next.

I should be able to test these this weekend as well. I'm going to start with as little free shaft as I can. If the rear is too stiff and the car is oversteering I can pop out a packer between runs and see how it goes. I still think the biggest potential gains are to be had on the front of the car, and that's where I'll be moving next.

T.J.

UberDork

5/2/12 7:44 p.m.

I had some of those spring rubbers (cheap version above) on my 2002 when I bought it. They were installed to actually raise the ride height a bit because the car had the wrong tires size on it and without the spacers things would rub. After fitting a more appropriate tire size I removed them all to find that the rear end sagged a bit. I just cut the front springs a coil or so to lower the front to match.

Interesting thread, by the way.

I autocrossed on the setup mentionioned above. I added spacers until I was in contact with the bumps. It was still too soft. Time for round two.

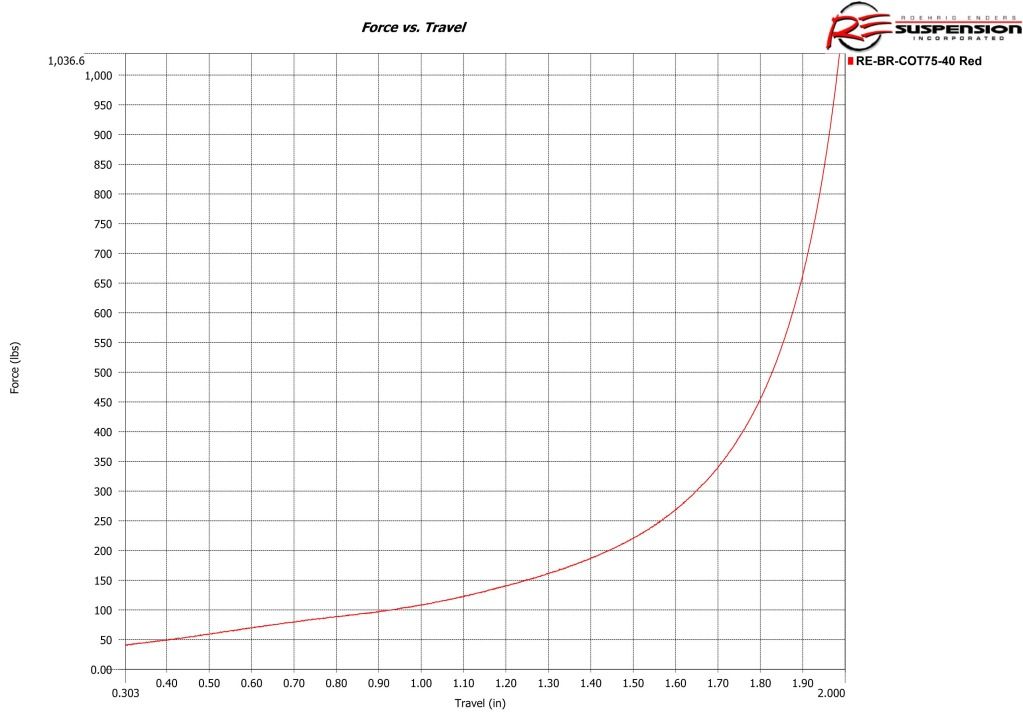

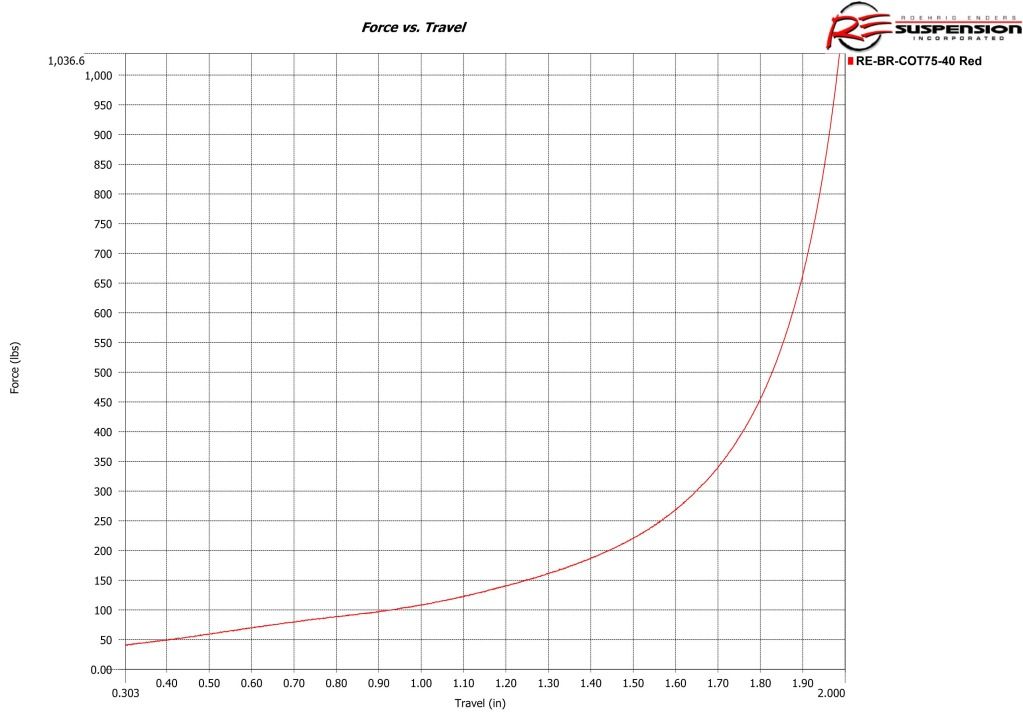

I bought two sets of COT bump stops from RE Suspension. I'm not sure that they are better or worse than any other bumps, but what they do have is plots of force vs. distance right there online when you order. This is the plot of the lighter force set:

I bought two sets, the lighter one in the plot above and the medium one that I can't get the force/distance plot to save an image of. The lighter set is for the front of the car at right around 110lbs of force at one inch compression. It's quite linear through 1.3 inches or so and then starts to ramp up to 225lbs at 1.5 inches and it's at infinity by two. I don't know what the stock stop is, but just smashing it in my hand I can feel that it's lighter thorough the first half inch or so. The bump stop is working with spring, and the rates are additive, so even though 110 lbs per inch isn't a lot, when combined with the spring of about 160 lbs per inch, it's quite a lot more than it sitting on stock. That's the other part of this, I added one spacer when I switched out bump stops and I'm going to make a bunch of C shaped one to slide in at the upcoming autocross so that I'm on the bumps sooner and I end up with less suspension travel. This is a picture of the stock bump stop next to the new one and the spacer that I added.

The rear of the car was switched around again (I'm getting quick at this). I swapped out the really long rear bump for a COT bump with 170 lbs at one inch ramping up to 400 at 1.5 inches. It's stiffer and is linear over less distance. This is ok because the motion ratio in the rear is different than the front (1.3 vs .9) and I want to rear to be stiffer. I did add two relatively soft 1/2 inch puck style bumps as well because I was worried it would be too stiff. I also added two spacers to get back to the length of the stock bump.

I've also added about an inch of C shaped spacers to reduce travel to the bumps. The rear is noticeably stiffer on the bumps. Big hits with all of the kids in the back can be felt but aren't uncomfortable. I also still can't feel any transition onto the bumps, it's still smooth.

Just driving around day to day I have somewhere between 1/2 and 3/4 inch less travel than stock before I hit the bumps in front and about the same in the rear. The car still rides very well, just like stock when driving around and it feels like a bit less lean when I'm hard in a corner. In fact, the car behaves a lot like it did on the stock tires. With the star specs it was clear that the suspension was being over worked by the increased grip, now it feels able to handle it again.

I still don't know how this will all work out and it was a little painful to disassemble the stock struts this weekend and not put new springs on. It sort of felt like a waste of three hours time. It's been cheap though and I've gotten to learn and think a lot about how the suspension is doing what it's doing. Factory engineers aren't building perfect cars, but they're pretty clever.

I have nothing really to add besides that i know of a ChumpCar Miata that actually doesn't run springs at all and just runs bumpstops.

Very cool thread!

The original Mini used various pieces of shaped rubber instead of springs and F500 cars use rubber pucks for their springs, so it's been done before. I still think there's something to be said for the linearity of real springs and I suspect that's why everything currently made uses them. I think I'm most likely to run into damping issues doing things this way, but we'll see. It would be nice to be able to drive around with a comfortable ride, and then roll up to an autocross, add a few spacers and double the effective spring rate.

I was able to autocross the car today on a familar site against familiar drivers. The bad news is that I wasn't any faster. The good news is that it was much much easier to drive. I had spacers in so that I was engaging the bump stops at about 1/2 inch of travel front and rear. The car was much flatter in cornering both in feel and in the abuse that it dished out to the tires. I'm finally not fighting the car on the Star specs and I can concentrate on driving again. I'm quite sure that the potential of the car is higher with this bump stops set up like this. The best part is that after the event I spent less than 5 minutes popping out the spacers and I'm back to the car riding completely like stock.

It's funny, cause I'm in the opposite direction - my suspension is way too much for the stock tires. I am, of course, well aware that I need to get some decent rubber on mine. Once I do, it'd be interesting to see if there's any way to compare my streetable springs and your bump stop/spacer setup.

By the way, at least some F1 cars used rubber "springs". I was just reading an article earlier today about the car James Hunt won his first F1 race in and they mentioned them.

Did you autocross with the front rubbers in? If so any odd effects?

We got a set for our Lemons/Chumpcar but haven't been able to test it yet.

Greg - I haven't autocrossed with them yet, mostly because I got wrapped up in this whole bump stop thing and I've been trying not to change too many things at once. The other reason I haven't done it is because I think they'll be most useful/linear when they can be slightly pre-loaded between the coils. I think you want them just a bit snug which would have a tendency to add just a bit of height. If you're lowered, or ideally if you have adjustable perches, this isn't a problem. With my stock springs, extra height, even a little, is not something I need. There are a few other sets of shocks that might be on the market by fall that will allow me to experiment with rubbers and different springs.

Max - You really need to figure out how much travel you have before you hit the bumps right now. With the car at ride height you should be able to pull up the shock boot in front and see. The stock front bumpstop is 2 3/4 inches long. It wouldn't be a bad plan to cut the top ring off of it which would shorten it by 3/4 of an inch. By cutting the thick part and leaving the nose you'll be keeping the progressive nature of the bump while stiffening it overall at the same time. You'll also get back a bit over 3/4 of an inch of free travel up front which would probably double what you have now. If you have limber hands, you might even be able to do it with everything still bolted to the car.

Vigo

SuperDork

5/21/12 8:09 p.m.

Great thread! Ive been planning to do basically the same thing to the front end of my 1g Insight, which, as you can imagine, doesnt have much of an aftermarket.

Necrobump.

I don't know how yall take to people reviving super old, dead threads but I am interested in the final result of this.

Mazdeuce how did this work out for you? Did you keep running it for awhile or did time prove it to be an ineffective way to setup your suspension? Would you recommend this or are aftermarket springs really the end all be all of performance suspension?

Daeldalus wrote:

Necrobump.

I don't know how yall take to people reviving super old, dead threads but I am interested in the final result of this.

Mazdeuce how did this work out for you? Did you keep running it for awhile or did time prove it to be an ineffective way to setup your suspension? Would you recommend this or are aftermarket springs really the end all be all of performance suspension?

I think it's a terrific idea for fine tuning of balance. It certainly could be used in conjunction with aftermarket springs to produce the balance that you are looking for. It's also a cheap way to test things and see how it changes things in the real world. It's not a be all end all, but a tool for fine tuning.

Also I never understood the hate and vitriol that reviving old threads creates on some other forums. It makes no sense and makes me want to punch people in the face.

SkinnyG

SuperDork

8/20/17 2:55 p.m.

On some of my lowered vehicles, I've run full-length factory bumpstops, but I've cross-drilled them to make them softer. Yes, you hit the bumpstops early, but they are much more progressive as they add to the spring rate.

Gm did this with the zq8 s10. The bump stops are soft and contact at barely any travel and are progressive rate. They are taller than i'm used to, and they were an excellent addition to my impala ss. I'm looking to use similar parts to help the front of my challenge car turn without changing springs because there is zero budget left for that

They're built just like spring rubbers, a split doughnut of rubber with a deep double groove. You're supposed to jack up your truck, slide these in between a previously collapsed coil and gain back an inch of height. Word is that they work.

They're built just like spring rubbers, a split doughnut of rubber with a deep double groove. You're supposed to jack up your truck, slide these in between a previously collapsed coil and gain back an inch of height. Word is that they work. For my application, I'm sliding them in the middle, where the coils are open. Yes, I did a bit of research to find a set of these that are just about the exact thickness as the space between my coils at ride height. I don't want to lift the car, but I don't want them to flop around as I drive. The picture is of the car jacked up with them just hanging in there, but with the car on the ground the can wiggle just the tiniest bit.

For my application, I'm sliding them in the middle, where the coils are open. Yes, I did a bit of research to find a set of these that are just about the exact thickness as the space between my coils at ride height. I don't want to lift the car, but I don't want them to flop around as I drive. The picture is of the car jacked up with them just hanging in there, but with the car on the ground the can wiggle just the tiniest bit.

With these little pack man shaped guys I can adjust bump travel in about a second. If I want to take up that inch of free travel, I just snap 2 or 3 of them on and I'm right there on the bumps. Easy peasy.

With these little pack man shaped guys I can adjust bump travel in about a second. If I want to take up that inch of free travel, I just snap 2 or 3 of them on and I'm right there on the bumps. Easy peasy.  I should be able to test these this weekend as well. I'm going to start with as little free shaft as I can. If the rear is too stiff and the car is oversteering I can pop out a packer between runs and see how it goes. I still think the biggest potential gains are to be had on the front of the car, and that's where I'll be moving next.

I should be able to test these this weekend as well. I'm going to start with as little free shaft as I can. If the rear is too stiff and the car is oversteering I can pop out a packer between runs and see how it goes. I still think the biggest potential gains are to be had on the front of the car, and that's where I'll be moving next.