Short version of my question:

What is the "ideal" set up for a strut front suspension? I of course, know ideal doesn't exist, but would love any insight the hive may have.

The longer question:

I am working on a Fiat X1/9 Challenge car. There is already surgery that needs to happen in the suspension arm location, so this would be the ideal time to build it right. Variables that are nailed down so far are Aw11 struts, cut down for rear inserts and coil overs, 1/2 inch heim joints, and I'd like to keep the locating point of the stock front strut arm.

So, I have a pretty decent grip on A-arm suspension geometry.

The rack width and steering rod length should fall within the quadrilateral described by the upper and lower A-arms:

The thing is, struts just describe long arcs. I believe job #1 is to make the control arm as close to horizontal at ride height, also, have some negative camber dialed in. Then I get a bit lost. Watching Binky, I know raising/lowering rack height will change the situation. There is a limited amount of space where the rack can fit, but I have control arm length and rack width to play with.

I have heard it said that, for instance, if I used a rack like this:

and lower control arms that almost meet in the center of the car, I could get "zero bump steer". Note the tie rod attachment points for the rack above are very close together.

I do have books on this somewhere, but am having difficulty laying hand to them.

Here's another rack option:

, but having those mounting points so close together looks suspect. Lots of force going through a front suspension.

Most of my knowledge is for double wishbone as well so this could be wrong. But I would think the tie rod sizing is the same concept, but instead of a quadrilateral of the four control arm joints, it's the triangle defined by the two control arm joints and the strut top pivot point.

For a strut suspension I like the lower arm to angle downward towards the ball joint if at all possible. Ride height requirements may require that to not happen. Then the alternative is to either raise the inner mounting point of the lower arm up so the arm still has the desired slope. You can also move the mounting point outward to build in neg. camber. Alternatively you can lower the outer end of the arm by getting a longer ball joint stud. These are not easy to find on many not so popular vehicles. They can be made but it requires access to machine tools which not everybody has.

A spherical bearing, a housing, and a stud are the major parts needed. The first two can be bought, the last one needs to be machined.

There really isn't one. Due to the design, the "upper link" aka strut is constantly changing in length so dialing it out at one length changes when under compression or extension.

There is a narrow range where it's ok or manageable and there are setups that are really not.

Your best bet is to replicate the locations and angles of the donor pieces as much as possible as they've done most of the engineering for you. Keep the suspension travel within reason and keep the desired amount of static camber in mind when configuring it in the car.

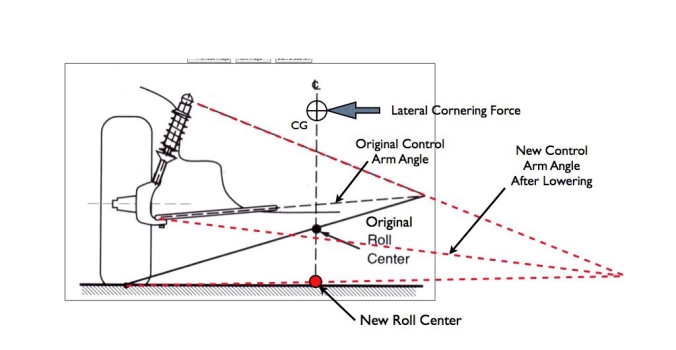

Stole this from google. But you can see how as you lower the vehicle and the lower control arm levels out the roll center drops down closer to the pavement. This increases the distance between the RC and CG (roll couple) and essentially the car is going to roll more in the corners. You want some downward angle on the control arm if possible.

Afaik there is no way to totally eliminate bump steer in a macstrut but you can control its window of motion to limit it as much as possible. I can see how the first rack would be beneficial but I would need to dig into this all again to say more than that. However, I've never seen an OEM rack like that and I suspect there is a reason.

Nice conversation fellas, responses appreciated.

The conversation mirrors what I largely had in mind. To be clear, this will be a low vehicle, with very little suspension travel, and very stiff springs. I am realistic about not having Zero bump steer. I just wondered about the theory.

I have a book that details moving the inner control arm pivots up a corresponding amount to what the car was lowered. Makes sense, and other people correct the same problem by putting spacers between the bottom of the strut and ball joint to re-establish the factory arc described by the control arm.

What I'm wondering is does a longer control arm help? Clearly, it would need a shorter rack to go with it. Spandak- excellent point about never seeing a OEM rack like the one I pictured.

All else equal for the situation you're describing, yes a longer control arm would be an improvement because the same amount of vertical travel of the outer joint results in less of a change in the angle of the control arm, which results in less horizontal movement of the joint. However, if you draw it out for the situation you describe of a stiff suspension with minimal movement and a roughly horizontal control arm, I would expect you'll find that the change is pretty small. I'd guess it would be worth a lot more to put the same amount of effort into moving the inner joints up than in, unless there's some reason moving up is substantially more difficult.

The minimum bump steer on a strut system is accomplished by making the tie rod the exact length as the control arm as well as keeping it in the same plane in both axis. Look at Volvo 240 to see the best production setup I have seen. The AW11 is probably very close to the same, but I have never been under the front of one.

TurnerX19 said:The minimum bump steer on a strut system is accomplished by making the tie rod the exact length as the control arm as well as keeping it in the same plane in both axis. Look at Volvo 240 to see the best production setup I have seen. The AW11 is probably very close to the same, but I have never been under the front of one.

So, to work backwards, the distance between inner control arm mounts should equal inner ball joint to inner ball joint length, including rack? That would make things easy.

Picture of Volvo 240 suspension:

It appears the rack is nearly in the same plane as the lower control arm. This would not be an option in my situation. The rack has to live 4-6" above the LCA mount,

Feedback greatly appreciated, as always, people.

In reply to wheelsmithy :

Draw a line between the inboard control arm pivot point, and outboard ball joint pivot point. The distance between those to points should match the distance between the pivot points of the inner & outer tie rod ends.

Then you need to setup the steering so the control arm & tie rods stay parallel to each other both horizontally & vertically...or as close as you can get.

In reply to wheelsmithy :

Why does the rack have to live above the LCA mounts? There is plenty of room down there in the X1/9 chassis.

If you're trying to get the inner tie rod pivots as close to the center as possible, look up 'center take off rack and pinion' .

TurnerX19 said:In reply to wheelsmithy :

Why does the rack have to live above the LCA mounts? There is plenty of room down there in the X1/9 chassis.

Well, that may be true. Beard scratching to ensue...

Thanks Vigo, I'm not sure what I'm trying to do. I don't understand the benefits of the center take off rack. As of right now, nothing is convincing me it is worth the hassle.

In reply to wheelsmithy :

Center rake off rack is for cars with control arms that meet in the middle of the car. The earliest example I know of was the Rootes Imp. which had a swing axle front end. I worked surprisingly well when de-cambered, but oh how crude!

As of right now, nothing is convincing me it is worth the hassle.

That's my overall impression of overthinking suspensions on cars that will never have their changes objectively measured. If there's no data before AND after you just have to do what will give you the right mix of 'feeling better afterwards for no objective reason' and actual seat of the pants result. My .02..

As far as center take off racks, they ARE used in otherwise normal cars. Hondas, old mopar LH cars, etc. It may be more for packaging than for anything related to bumpsteer, but suffice to say that having the inner tie rod and lower control arm pivots in wildly different places didn't make anyone jump out of one of those cars and yell "there is an obvious geometry issue here!". Meh

In reply to Vigo :

Thank You, I thought I remembered some of them (center steer racks), but wasn't sure if I was thinking golf carts, or what. I finally found the passage in my Herb Adams Chassis Engineering book. His take on strut suspension: Don't Bother.

Still, something good gas come from this conversation- It made me realize that the closer the rack is to the LCA, the more favorable the geometry- Thanks for that TunerX1/9.

This all gets me in a good place to start designing the suspension. I'll still whack the MR2 struts apart-it's got to be done anyway, and start trying to see what I can see.

The rack height is largely dictated by the ratio of distances between the upper and lower balljoints and the outer tie rod location.

The rack width is largely dictated by the inner pivots of the upper and lower control arms, and the rack height.

I briefly touch on this with some graphic figuring out in this video queued at the right spot HERE.

Try to pick a rack width that will work at the place you need it, and then move the rack up or down to fine-tune any toe changes in (mostly) bump, and (some) droop. Try to focus at and around ride height.

On various projects, I've winged it, I've done rudimentary estimates, I've done careful measurements, and I've run numbers through SusProg3D. Get close, it'll work.

One car was totally winged, and it drove fine, though there was something about the steering you just couldn't quite put your finger on. Then I re-did it using SusProg3D and shortend the rack considerably, and the steering was a whole lot better.

I also did some work on a business customer's X1/9, and I found the toe change to be absolutely horrific. Like: I would have wanted to cut it all out and do it all again. MASSIVE toe changes.

I drive an X1/9 every day. With the original suspension the only way to prevent bump steer is to prevent bump travel! Fortunately the motion is in the benign direction, I.E. it toes out with compression. Wheelsmithy has the opportunity here to improve the situation massively.

Thanks, Skinny, I had watched before, but wasn't in suspension design mode at the moment. Very helpful.

This conversation has helped my analysis paralysis, and I appreciate you all. I knew about keeping the rack as close to inline as possible with the LCA on a double wishbone, but now recognize its benefit on as strut suspension. You guys are the best.

Bringing this one back as I've been getting into it some more.

#1. As Spandak wrote, the lower control arm should be higher at its mount to the body than its mount to the upright. I have yet to determine how much, but I'm thinking I'll shoot for an inch over the approx 12 or 13" length of the LCA.

#2, As SkinnyG said, the tie rod must point at the Instant center. In my case, this means the tie rod will point down at ride height. I was having a really hard time getting my mind around both #1 and #2

#3. I am trying to build to an amalgamation of MR2 and X1/9 suspensions, but I have to correct the roll center while I'm doing it, because my car is lowered.

I've been studying, and will use this thread as a notebook. All input is appreciated.

Here's a lowered setup , with compromised roll couple as pointed out by Spandak:

I'm starting to get my head around this, with no small help from this Motoiq article

I had a B13 Sentra that I lowered for autocross many moons ago, and it was diabolical in handling. This was the car that started me learning about suspension.

MacStruts seem to plummet the roll center when lowered significantly. I would not be surprised to see a roll center below ground. In the case of the first set of springs in my B13, the front roll center vanished below ground, and the rear hardly moved at all, resulting in a wicked imbalance that was almost impossible to control - the thing would oversteer at the drop of a hat. When you could keep it reeled in, the front with a below-ground-roll-center felt..... weird. I don't know if I could describe it, it was like the car moved wrongly. It wasn't confidence inspiring, it felt... like something was backwards.

I later ran different springs that didn't lower the front anywhere near as much (and had MUCH stiffer rates), and it was a joy to drive again. Probably because it kept the roll center closer to ground.

I'm a big fan of having the front roll center at or around ground height.

The rear roll center higher, but not wildly so. I'd -like- to see it around the bottom of the chassis height, but it will largely depend on what the car wants, and (as always) packaging. I -do- like low rear roll centers, and tune the oversteer/understeer with sway bar. Lots of opinion on this.

I think this is what it ended up as with the first set of springs, after having lopped a coil and a half off the back to bring the rear roll center down.

Just for fun, if you raise the car considerably the roll couple decreases and you can end up with a car that is a mile off of the ground but doesn't have any body roll. Weird stuff.

You'd have some interesting jacking issues (unweighting the inside tires significantly). Might just tip over, no?

Yeah, this stuff is new to me, because I never studied up on how to make this "why bother" suspension right. I threw some lowering springs, struts, bushings, and a bigger rear bar at my Swift GTi, and loved how it handled. I am a bit of a heathen, though.

Re-watching Skinny's video helped. More stuff rang true.

After a full day of research yesterday, I think I'm ready to start cutting. The plan is to re-locate the lower ball joint as much as I reasonably can, and start building. I', prepared to narrow the rack I've got (it's got to be disassembled to de-power anyway.

You'll need to log in to post.