I'm about to start on an M20 head. Stroked to 2.9 liters, with an ITB setup, 272 cam. Most likely keeping the stock valves. Do you guys have any advice specific to this head? It's going in a street car, megasquirt tuned.

I've watched this a few times, the guy seem to have pretty good general advice. Is there anything very wrong with his suggestions? https://www.youtube.com/watch?v=iejDWSQEsqI

I'm not a fan or using the sanding rolls he uses. I use sanding bands, far more control (jmho). I use 1/2", 3/8", and 1/4" bands.

Note all the sanding drums on the left - varying lengths (3 different lengths) also note gold tone bands... they are diamond bands and produce a very nice finish

Very cool. What grinder do you recommend? Everything cheap seems to use a 1/8" arbor, and that seems to make the grinding bits harder to find (and more expensive)

I have no problem finding the 1/8 inch carbide cutting/grinding bits. Have you tried hobby stores rather than hardware/Lowes Depot for a larger selection?

No, been looking online and mostly, prices are much much cheaper than the hobby stores around here. I found:

An inexpensive grinder http://www.harborfreight.com/flexible-shaft-grinder-and-carver-40432.html

A 1/4" chuck handle that will work with the grinder http://www.ebay.com/itm/190548764985

And some sanding wheels https://www.amazon.com/gp/product/B009Q72U56/ref=ox_sc_act_title_1?ie=UTF8&psc=1&smid=ATVPDKIKX0DER

I think this will be my setup unless there's something better for ~$160

for part time... Dremel with a flex shaft works quite nicely... my only issue with them... I went through 6.... ![]()

so I jumped up to a Foredom SR (1/6hp)

As to bits....

http://www.toolzone.com/acatalog/1_8__Shank.html

http://www.kingsleynorth.com/skshop/product.php?id=88791&catID=101

http://www.burrs4less.com/

http://www.globalindustrial.com/c/metalworking-tools/carbide-burr

http://www.e7cuttingtools.com/category-s/1832.htm

http://cets.com/store/catalog/burrs.html

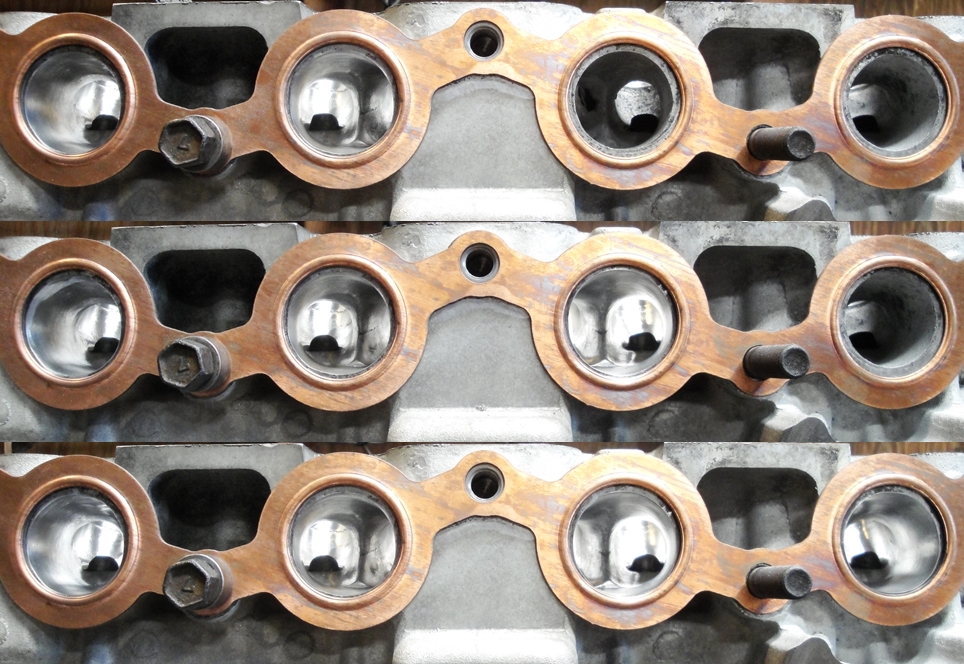

Go big, or go home......... ![]()

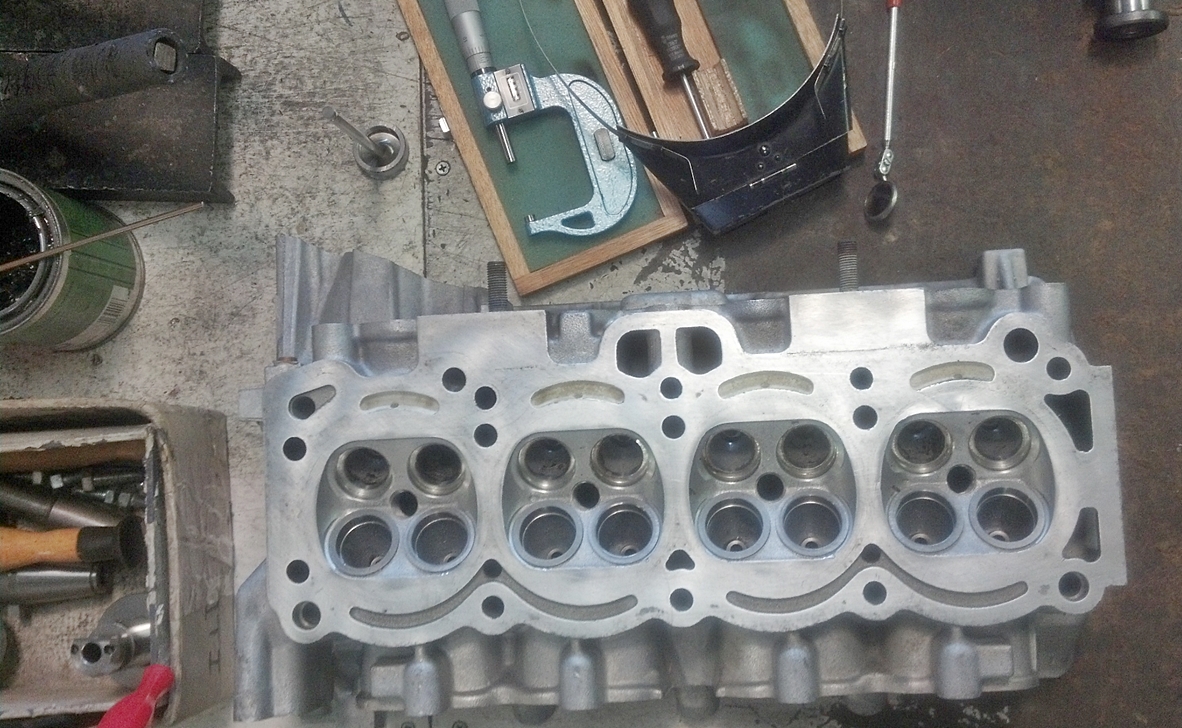

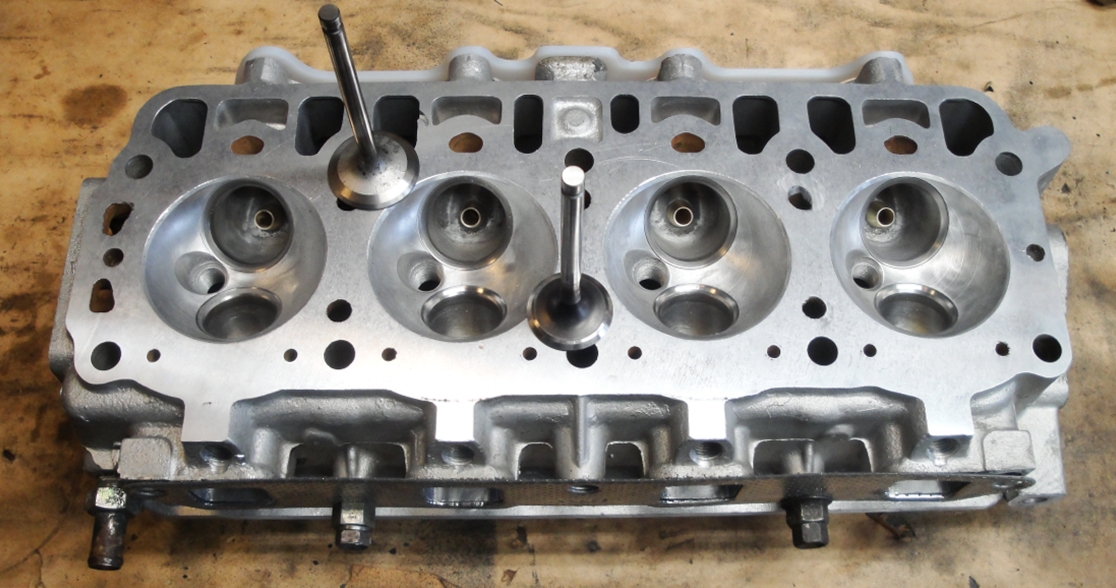

Valves that is... This head in mid surgery getting OS valve seats fitted so it can run OS valves.......... ![]()

With the extra flow at low lift will that help the whole rpm range? Aka please give us a lesson in how to read flow numbers.

Stampie wrote: With the extra flow at low lift will that help the whole rpm range? Aka please give us a lesson in how to read flow numbers.

Yes - improved low lift filling works over the entire rpm range... but so does filling at peak lifts. Remember engine speed(rpm) has nothing to do with how much lift the cam produces. The cam opens the valve the same amount @ 1000 rpm as it does at 7000. What is different is the time frame.

Ah a lesson in reading flow... an entire section of a library could be filled with this.........

The goal: more cylinder filling - the more you fill a cylinder with air/fuel, the bigger the power output.

variables: volume, and velocity... in an N/A car overall cylinder filling is almost entirely created by the downward motion of the pistons.

Too small a hole - the velocity is high, but volume is restricted. Too big of a hole - volume is good, but velocity falls.

Ideally you increase volume, without hurting velocity. This is typically accomplished by reducing, or eliminating eddy points - irregular flow patterns, as well as "fixing" mass produced castings to be more equal.

Ok, as to reading what you see.... it depends, but what you are looking for is change.

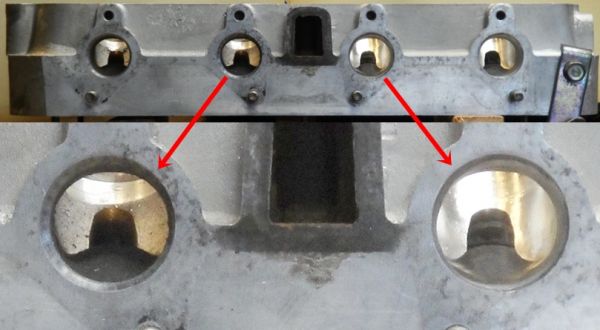

The immediate above example doesn't make it easier because it is like comparing apples, to oranges - as the client's engine is already prepared for the larger valve head. What you can glean... is O/S valves do improve filling at most lift points over stock valves. But you can kind of get that - bigger holes, flow more.

if you look back @ the June 21st 2016 post above. In that case there is little or no improvement, until lifts go up. This is because the valve size hasn't changed - but the port has - the port is more efficient.

What to be wary of - Port flow(volume) that doesn't seem to taper off as lifts go up.

What would one do to improve the very low lift flow of that port - or is that just part of the compromise? Does it even matter?

SkinnyG wrote: What would one do to improve the very low lift flow of that port - or is that just part of the compromise? Does it even matter?

Does it matter - it can. In this case the losses are small, and only encompass the lowest lift points, while the gains in the remainder of the lift points is substantial. What we are after is the correct mixture between volume and velocity - maximizing cylinder filling. What my goal here was to maximize volume while minimizing velocity loss.

I'm pretty familiar with Toyota's "A" heads and the port opening into the head versus the valves diameter is significantly different between this "F" head and the "better performing", aka smallport, "G" head. The smallport "G" heads have a significantly larger port opening then the "F" head does, yet the "F" head has a better port shape, and a .020" (.5mm) larger intake valve.

This told me that while the port velocity may have dropped some, the overall port velocity is still higher then a smallport "G" head - based on flowbench #s

Wow! Those are some numbers out of a 4AGZE!

I too would like to know what induction it's got. And what boost? Stock SC12? SC14? Twinscrew? Turbo?

I have an off the wall porting question. How do you ensure that all the little metal bits are cleaned out before putting it back on the engine?

engine retains the SC12, but has oversize crank pulley, and later S/C pulley, as well as double size intercooler. Also has aftermarket management. Engine build was based on retaining the SC12 and making the best power from it possible. Port work was specific to this end. Not sure of peak boost, but likely around 15#s

Typically I do port work before the final valve job... so the machine shop clears out any residue. On the few occasions that I've worked around the valve job, I used a can, or two of brake clean, along with compressed air to keep the particulate at bay.

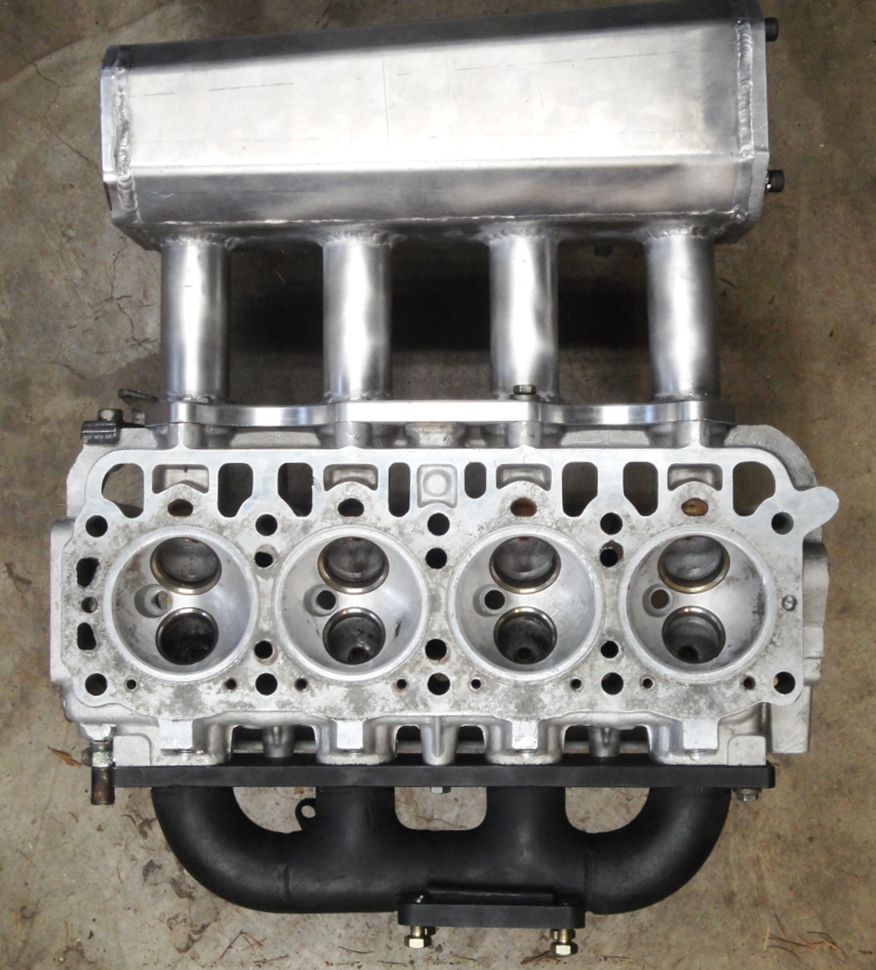

sometimes I see other heads... here a bit of vintage Toyota - 1974 2TC - to be used with boost.

Before....

some of the changes...

You'll need to log in to post.