I have a project that calls for some stainless steel rods to be threaded. 5/16"-18 will probably be my thread of choice. Is this doable with regular thread dies or will this make me hate life?

I need about 3/4" of thread on 2 rods and I have quality, USA made dies.

Chas_H

New Reader

6/21/11 8:15 p.m.

Depends on the alloy of the SS. If you have 18-8 rods, which is a common alloy, I wish you luck. otherwise it should not be a big deal if you use the correct lubricant.

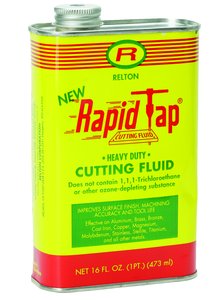

Go slow, because if the SS heats up too much it can work harden and get brittle. Will stick to the sharp edges of the die and cause all kinds of grief. Try to find some 'Tap Magic' or similar.

This is apparently a common question, based on my Google search, here are some typical responses:

http://www.streetrodding.com/forums.view/32615

http://www.practicalmachinist.com/vb/general-archive/threading-stainless-steel-hex-bolts-146456/

Make absolutely sure that the diameter of your rod is less than the major (outside) diamater of the thread you want to cut by at least 5-10%. Choose a thread size accordingly, consult machinist chart for the true dimensions of the threads. Yes, a few thousandths big is too big.

I've threaded A BIT of stainless. Of course, start out with the OD the correct major diameter of whatever you're thread is going to be. Next, clamp it in the vice. Use tap oil. I like "Tap Magic" brand. It is truly magic. I buy it at the nut and bolt store. I've tapped and threaded a bunch of 304 with cheap Chinese HF taps/dies and with pretty good quality ones. The good ones are the way to go, of course, but use what you got. Then again, my cheap HF ones are actually better than the ones I have marked "Craftsman," which suck. Anyway, I turn the tap or die about 1/8th to 1/4 turn, back it off, turn it again, etc, and work my way around.

Castrol Moly-Dee cutting fluid is the stuff for stainless, Ti, inconel, all the tough stuff.

I used to make a lot of custom precision skateboard truck axles for slalom and downhill racers, subsequently there were a lot of 5/16-24 and 8x1.25mm threads to cut on heat treated 4140 and 8640 CrMo and CP and 6.4 Ti. I have a couple automatic die heads I've picked up specifically for the job, which helps a lot, but switching to Moly-Dee made all the difference.

Warning - it's incredibly expensive. That said, breaking off a tap in something irreplaceable is ~more~ expensive.

yamaha

Reader

6/22/11 12:27 a.m.

I'd recommend tap magic for stainless lubricant as well, some of the best stuff out there. Also, IDK about dies, but with taps, you want cobalt or carbide with tin coating if possible. Hope that helps

I've always used greenfield/widia for all my tap/die needs good professional stuff that holds up well