In reply to volvoclearinghouse :

This is only a rumor I've heard so don't quote me.

Apparently the Pontiac ohc 6 shares it's block with the Chevy 6.

Again, might be internet lore but it may have more potential than the stock head.

In reply to volvoclearinghouse :

This is only a rumor I've heard so don't quote me.

Apparently the Pontiac ohc 6 shares it's block with the Chevy 6.

Again, might be internet lore but it may have more potential than the stock head.

In reply to volvoclearinghouse :

I take it racing is off the table? Fair enough.

Power comes from compression, breathing, cams.

You can mill the head for additional compression but then you will use additional fuel. And probably more expensive fuel. In fact almost any change that actually gains power will require more fuel and probably more expensive fuel.

Breathing is port work Match the gasket and remove anything obstructing flow. Every time you force air around something you loose power Do not go too big or you will kill power down low.

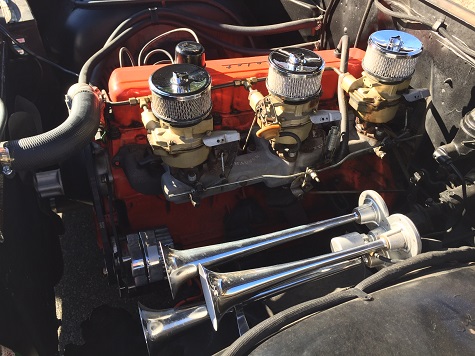

And/or conversion from one central vertical carb to several horizontal carbs. Same thought process every time you force air to curve or turn you loose power.

Use 2 or 3 SU's? You don't have to own a aluminum manifold. Make it like a set of headers with carb flanges on the ends. Have the carbs out past the exhaust manifold. So if they leak it doesn't drop on the hot manifold.

The selection is simple. Either a pair of 1& 3/4's or three 1 & 1/2 I should be able to get you close on the needles.

You can make headers but real header's sizes should be made to the formula based on displacement and cam timing. That tends to wind up very long. Skilled welders go nuts fabricating headers especially if space is tight. Remember your goal is to time the exhaust pulses to exit at the right time. All while keeping tubes equal length. But since the front tube can be as much as 30 inches ahead of the rear tube that forces the back tubes to curl around like a bunch of drunken snakes. ( and remember what I said about air likes to move in a straight line).

I've seen a skilled fabricator spend close to 200 hours making them. Only to gain very little power.

Cams won't add power at the bottom end.

CrustyRedXpress said:frenchyd said:A cam is a trade off device. Trade bottom end power to gain more at the top end.

*VTEC has entered the chat*

Sorry, couldn't resist. Carry on!

On an old stove bolt? While there is power potential in playing with LSA I can't visualize any way to do it on a cam in block pushrod engine.

That's probably left to the DOHC engines.

But I suspect you were just. checking to see if the old Geezer even knew what it is.

Just picked up the 4 bbl manifold the PO of the engine promised.

Not sure if I mentioned, but there was also a set of lightly used headers that came with it. I'm basically a 4 barrel away from a running engine. Now I just need to slap a gearbox on this thing and go hunting for a powerplant recipient.

Yes, I'm doing this all sorts of backwards. ![]()

What was the smallest 4 barrel carb used by an OEM? I don't want to spend $400 for a new 500 CFM unit. I've had pretty good luck with Quadrajets, but I think the smallest came in 750 CFM- far too big. I think the manifold needs a square bolt pattern carb.

EDIT: I know cam profiles are a trade off. But with peak HP on these things stock topping out at 3600 RPM, I'm wondering if that's the cam, the carb, or both. How high will the stock reciprocating assembly actually rev without coming apart? Will a simple intake and exhaust get me to 140-150 HP and 5500 RPM or so? Or is the bumpstick too dinky to do anything at that RPM?

A Qjet would work, but would require an adapter being a spread bore. The secondary air door has to be pulled open by the engine so it will only open fully if the engine can pull enough.

OEM small 4-bbls might be harder to find, they tended to use 2-bbls for low airflow engines. See if you can find a good deal on a used Edelbrock 500 or Holley 450, either one would be a good choice.

In reply to 81cpcamaro :

You are right. The 2 barrels may not be as sexy as a 4 barrel but there are some pretty decent sized 2 barrels out there. I used 3 of them on a vintage race car in an attempt to be proper.

When others cheated using modern Holley's I went to a Hilborn mechanical fuel injection. And remarkably the 3 two barrels was better out of the hole than the early 1&11/16's Hilborn system. At 7000rpm it made 11 more horsepower.

ShawnG said:In reply to volvoclearinghouse :

This is only a rumor I've heard so don't quote me.

Apparently the Pontiac ohc 6 shares it's block with the Chevy 6.

Again, might be internet lore but it may have more potential than the stock head.

It may have had a different block but at the very least it was based on the Chevrolet engine and shares internal dimensions. It was made for many more years in Brazil and apparently lotus did a version for there too and also apparently a prototype dohc head.

https://www.curbsideclassic.com/blog/the-chevy-250-six-was-built-in-brazil-until-1998-with-fuel-injection-and-tuning-by-lotus/

GM put q-jet's on 3.8 Buick V6en as well as the 4.1 variant of that engine. Seems like between the 3.8, 4.1, and Olds 307 q-jet's there should be plenty of examples of making that work.

I kind of like the idea of a Holley 500cfm two-barrel or similar instead of a four barrel, if sticking with carbs is part of the scope of the project.

I will just leave this here.

BTW, I think these things went into boats for a while also. You might be able to pick up a "custom" valve cover.

Those are stupid money online.

Holley made a few 390cfm 4-barrels if a Q-jet is not to your liking.

Otherwise, put a Rochester TBI unit on it and megasquirt it.

According to my Mercruiser manual the WOT for a MCM 165 is 3900 - 4300 RPM

I can't find any specs of what rpm the Mercruiser 165 hp 250 ci Chevy made it's rated power at but it could do it all day long in a boat. It would be interesting to see the cam profile data.

In reply to VolvoHeretic :

You do realize we are talking about different ways to measure horsepower? The 250 cu in 6 probably is rated at 100 hp net SAE

Marine engines are rated at Advertized horsepower. Like back in the 1960/70's hence the are probably the same net power.

volvoclearinghouse said:Just picked up the 4 bbl manifold the PO of the engine promised.

Not sure if I mentioned, but there was also a set of lightly used headers that came with it. I'm basically a 4 barrel away from a running engine. Now I just need to slap a gearbox on this thing and go hunting for a powerplant recipient.

Yes, I'm doing this all sorts of backwards.

What was the smallest 4 barrel carb used by an OEM? I don't want to spend $400 for a new 500 CFM unit. I've had pretty good luck with Quadrajets, but I think the smallest came in 750 CFM- far too big. I think the manifold needs a square bolt pattern carb.

EDIT: I know cam profiles are a trade off. But with peak HP on these things stock topping out at 3600 RPM, I'm wondering if that's the cam, the carb, or both. How high will the stock reciprocating assembly actually rev without coming apart? Will a simple intake and exhaust get me to 140-150 HP and 5500 RPM or so? Or is the bumpstick too dinky to do anything at that RPM?

The engine you have probably has very weak valve springs since peak horsepower is so low. Then if you get a bigger camshaft you'll need to add ZDDP to avoid ruining the camshaft. Plus the stiffer springs. I'm guessing the push rods may not be up to the task either. Then valve stem issues?

Then there is the cylinder head. Most GM in line 6's used the Buick style head to improve fuel mileage. But while the fuel mileage is better the air flow is far worse this requiring real work to improve ( and you'll lose the good fuel mileage).

I'm only guessing, I know the few I worked on had that raised exhaust valve platform which forces the intake charge across the exhaust valve to heat up the charge in order to eliminate misfiring of lean mixtures ( better fuel mileage)

I do know there were guys who solved all of those problems. And got some real power out of sixes.

Of course if you want real power those Jaguar engines you already have can make over 400 horsepower and have a real bark to them.

Then the Trailblazer in line six starts with 270/290 horsepower and can make up to 824 horsepower with a stone stock bottom end. Those cost about $200 in junkyards.

In reply to VolvoHeretic :

I’m guessing around 4,000 RPM. I haven’t run a Mercruiser 6 / 165 in a bit but I’m very familiar with its 485 ( 4 cylinder, 185 HP) replacement (Dads boat) and the 260 HP 350 4 barrel in my boat. Both the 485 and the 350 are rated at 4,200-4,400 RPM at WOT. My understanding is that they’re set up similar to truck engines with camshafts optimized for a flat torque curve; there’s no down hill on the water.

When sizing carburetors, don't forget that 2V and 4v carburetors are flowed at different atmospheric pressures.

A 500 CFM two-barrel does not flow the same amount of air as a 500cfm 4-barrel. It's easier to quote than to explain: "The cubic feet per minute, CFM, rating for 2 BBL and 4 BBL carburetors can not be directly compared. 2 BBL carburetors (and 1 BBLs) are tested with a 3 inch vacuum while 4 BBLS are tested with a 1.5 inch vacuum. In other words the CFM tests for 1 and 2 BBL carburetors are done with the testing equipment sucking twice as hard. If you want to compare the CFM rating of a 2 BBL to that of a 4 BBL multiply the 2 BBL rating by 0.707. ".

Also, the 250 does not use the same chamber design as it's pre-war cousin, the stove bolt six.

These are all new engines for the 1970s

Putting some thought into this...

If it ran well, I'd not bother opening the engine until I put it in something and drive it. You might hate it, who knows.

So, with that in mind, here's what I would do to stuff it in something and make it go.

It's a Chevy engine so it shares it's parts bin with all the other Chevy engines.

Go find a HEI distributor for it from a later 250. It should drop in. This gives you access to all the weight and spring kits, vacuum advance cans and the like that are available to tune the V8 distributors. HEI ignition stuff is cheap, lasts forever and will be more than you will ever need for that thing.

It probably uses SBC rocker arms. Do a little checking, then go buy some high lift rockers for it. Check to make sure you don't run into coil bind on the valve springs. You'll get a little more airflow for little cash without doing a full-on cam swap.

Use the 4-barrel manifold but go buy an Edelbrock carburetor for it. They're a perfectly ok carburetor, they're easily tuneable and they use an air door system almost like a Q-jet. They will bolt directly to your manifold, tuning parts are easy to get, they're usually close right out of the box and, best of all, no gaskets below the fuel level unlike a Holley.

Put the T5 transmission behind it. That gives you an overdrive so now you can use a 3.73 or lower rear end to give you some go off the line but still keep the revs low on the highway.

Add headers if you feel they're necessary. The Clifford ones I've installed have had thin flanges. I'd see if I could find some free-flowing cast iron manifolds from somewhere. Sanderson might make some Chevy 6 iron shorty headers.

That will make it run about as well as it can without some work to the internals.

I like I6 engines, they're a lot of fun to drive and don't sound like anything else.

I wonder if it would fit in a Vega?

In reply to ShawnG :

The Vega takes a small block. In fact the factory put a 262 small block in the Monza version with the longer water pump. So you've got about 33-35 inches to play with.

But rather than the 250 pushrod 6 which is extremely heavy and not that snarfy.

I'd use the Atlas 4200. It's all aluminum. Makes either 270 (2001-2005) or 290 ( 2006-2009) horsepower stock and with just an Amazon turbo for about $130 makes 500 horsepower. No internal work at all required. They even make an exhaust manifold set up for it.

Go to NIVLAC57 on U tube to see him stick it in a little Fiat, his old Studebaker, Ford Fox body, Datsun 260, Volvo PV 544, etc.

frenchyd said:In reply to ShawnG :

The Vega takes a small block. In fact the factory put a 262 small block in the Monza version with the longer water pump. So you've got about 33-35 inches to play with.

But rather than the 250 pushrod 6 which is extremely heavy and not that snarfy.I'd use the Atlas 4200. It's all aluminum. Makes either 270 (2001-2005) or 290 ( 2006-2009) horsepower stock and with just an Amazon turbo for about $130 makes 500 horsepower. No internal work at all required. They even make an exhaust manifold set up for it.

Go to NIVLAC57 on U tube to see him stick it in a little Fiat, his old Studebaker, Ford Fox body, Datsun 260, Volvo PV 544, etc.

Every SINGLE member on this forum knows about the Nelsons and what they've done with the 4200. Please stop cluttering up any vaguely I6 thread with posts about them.

You'll need to log in to post.