My birthday is thursday, it would be a great gift to see a youtube vid of the first start!

Incredible thread by the way, love it!

My birthday is thursday, it would be a great gift to see a youtube vid of the first start!

Incredible thread by the way, love it!

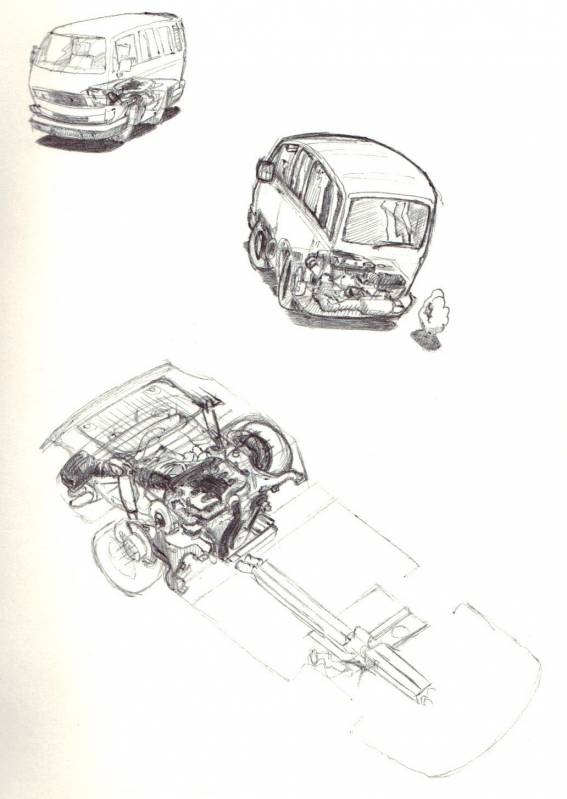

Ah yes, the 'spaghetti system'. ![]() That's the screeching halt point of many an engine swap, folks are scared they'll let the smoke out.

That's the screeching halt point of many an engine swap, folks are scared they'll let the smoke out.

I'm curious: what's up with the can of beans? Snack for when you run low on inspiration (which this thread is full of, BTW)?

stray fasteners -- I actually got most of those wires tagged today so i know what I"m cutting. luckily, most of them are plugged on the ends and already are tagged. so I'll assemble just what I need to get it to turn over- that will kill the spiders in the muffler. this will just take longer. its my first rewire project. patience, allowing yourself to be slow is faster than the other way around. I have the chrysler dash harnass almost ready to lay in. theres little room for the rope it is, we'll see.

does anyone know of a factory book that labels every wire and plug in the lh harness? my body diagnostic book only does the flow chart trouble shooting and isnt comprehensive.

https://www.factoryautomanuals.com/p-84845-1994-chrysler-concorde-new-yorker-lhs-dodge-intrepid-eagle-vision-service-manual.aspx

I am still labelling wires-- getting to know the systems--then I'll start integrating things and splice my ass off

this stuff always looked like voodoo to me- true, there is a certain depth you must go to to orchestrate it all. a macro understanding.

I rewired a Spitfire with an aftermarket harness. That was a tedious project and nowhere near as complicated as an EFI car. I bow to you. Whenever I dream of swaps like this, I think "painless harness + megasquirt".

Awesome build so far. ![]()

thummmper wrote: thanks doc! I used to say that in the academy, they ran you until you either fainted, cried like a little girl or quit, and I never fainted or quit! glad you like it.

This is so cool. What academy? I had similar experience at the Coast Guard academy.

thank you everyone

I completed 24 weeks at a high stress police academy in huntington beach, ca., in 2003. At age 42 though, and 32 interviews/fences jumped over, I was too old to be of use anywhere.

So, I began manufacturing my next occupation, truck driving, which lead me to inventing again. It's where I belong anyway.

I actually started pulling wires north to the dash yesterday, going under with the vw bundles. the vw wires still need tagging and the bentley book isnt as forthcoming as the chrysler book is, so it's ongoing.

I have a little anxiety about this part--okay, a lot of anxiety. I drink at five everyday like clockwork now and keep chipping until dark. when I fiddle with it, it starts progressing. sometimes I have to step away simply because I don't know what to do next, so i go to a donut shop south on the coast and have a coffee break, talking to anyone that will have it.

there are still a few little things that I don't know the function of, but if it was mistakenly cut out, I can always splice it back in. I accidently cut the twisted pair that the computer communicates with to the dash, but I added it back in with abs sensor wire that reached back on the sedan. almost long enough.

outstanding work so far! I love this project. is "i drink at five everyday like clockwork now" a result of this project, or just a statement that you have a predictable schedule?

this project has destroyed the tea totler in me. But I keep coming back to "just have a look" and next thing you know, i am getting some other issue out of the way--and I sketch a bit

got my halvies too

got my halvies too

the wiring has become fun now that i am over half way. when you finally understand the field you are in, you can navigate with impunity. I find that drawing the circuits out helps to understand them and familiarize to boot. I have redesigned the horn circuit. It had one vw horn and I replaced it with the dual sedan horns, so It will require the sedan horn relay, located in the white junction/fuse block at the steer wheel. the brake lights stay the same. I added the sedan brake switch for the electronics and it only needs 3 wires. the hazard turn signal system is redesigned to use only vw exterior lights. the wiper/washer system is a stickler--it has a front set and a rear hatch set as well, all controlled from a stem switch on the right of the vw column, which is gone now. I can operate the wipers from the sedan switch, but I will have to add a 3 position toggle sw for the rear set. not horrible, I suppose.

the headlights are in process now with a large roadmap sized drawing I am adding to today-- I draw on a large poster sized sheet, placing systems along side each other. then I start connecting the terminals where they have to go- some get left disconnected. [depending on what feature I am adding or deleting. It took 2 days to complete a large drawing of just the chrysler ign sw system and all that it reaches--it makes sense on one sheet. I dont get lost in the 6 to 8 pages they are on in the book. vw has the whole electrical system on 12 pages or so- but theres a lot less information as well. chrysler has over 80 electrical schematics.

Wiring. One of my least favorite jobs to do.

Sounds like you've made it to the half way point - the finish line is coming up soon.

after procrastinating on the reach-up dash wiring [connecting the e/t to the dash] I decided that I wasnt going to do anything specific with the stereo amp tail, so I deployed it today for the extension. I need 24 wires and it has 27, although I hope they are as heavy or more for the extra distance.

and the penetration grommets define the need for a bunch of single spades to pour through them. L F hdlt well

and the penetration grommets define the need for a bunch of single spades to pour through them. L F hdlt well

Great progress! Looking forward to vid of it running.

Something I learned the hard way: when tackling a big wiring job like this, do one circuit at a time. Like when I rewired my XS 650, I deleted a LOT of crap that wasn't needed. Then, did (not in this order, just for illustration purposes) low beam, high beam, running light, brake light, etc and left them unwrapped until I was able to verify that they all worked.

Same with my 13B in the Jensenator; I wired each individual injector and sensor, etc, then left the harnesses unwrapped till I heard it run.

I knew I would EAT time up with this segment. started with the intro, then the overview, then assessment of systems, intent, personal reguirements, designing hybrid circuitry after throwing out the bits I had to, and finally, inventory assurance and splicing. I find some of the first wire labels in hand, written before the labelling fully evolved, and set to relabelling them. I want to hold a wire and know what it does and where its going. It hasnt even occurred to me that this system could work, just that it connects correctly. once the blueprint is dry, the splicing will be much faster. it's like walking your way out of the deep end the first time.

up they go

under the drivers floor using the same route as the stock wires

under the drivers floor using the same route as the stock wires

and repair of the burned tail lite harness

and repair of the burned tail lite harness

You'll need to log in to post.