drmike

Reader

3/11/12 10:05 p.m.

My 2003 MINI Cooper S has had an oil leak that has gotten a little worse over time. After changing various gaskets and a couple of sensors, I had rid the engine of all but one of them. Lately, the leak got to the point where it was getting annoying, so I took the front of the car apart looking for it.

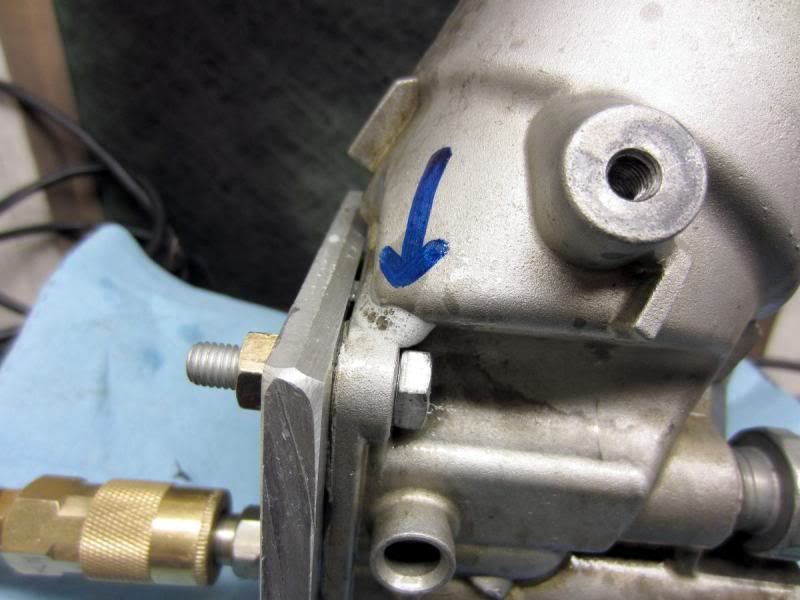

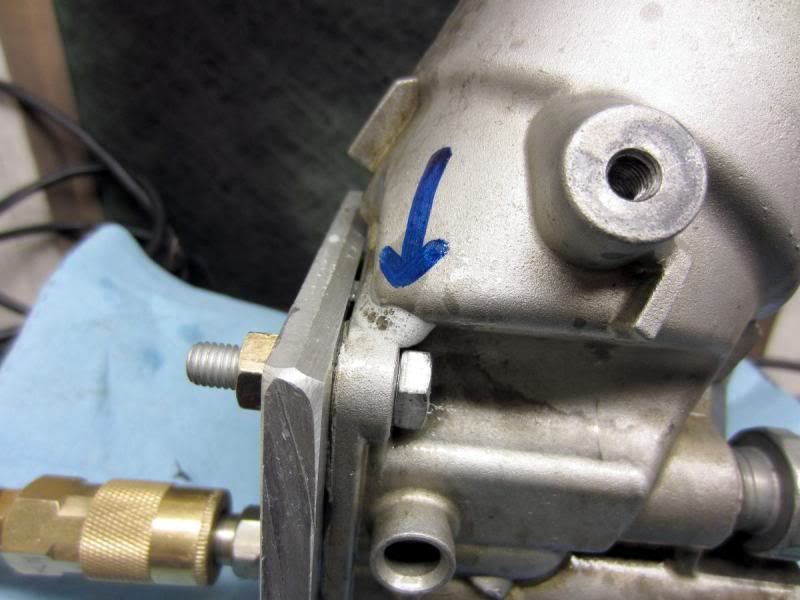

FINALLY found the leak after making a couple of block-off plates and pressurizing the oil filter housing. Windex bubbles mark the spot:

There is a pinhole leak where the bubbles are.

Is there any fix other than finding another housing, or perhaps getting the leaky area welded up?

Ian F

SuperDork

3/11/12 10:24 p.m.

Well... I commend your efforts. Just about every R53 engine I've wrenched on with a reasonable amount of miles on it has a pretty oil-soaked backside.

Fixing it... Use your rig to put the casting under vacuum and then smear the area with JB Weld?

drmike

Reader

3/11/12 10:59 p.m.

I'm thinking something like that. We have a vacuum chamber at work - I could put a product on one side, then pull a vacuum to encourage capillary action.

This is a product recommended for such things:

Seal-Lock Fluid Weld

A new part is nearly $300.00, so repairing this one seems like a good thing to try.

OUCH! too much $$$

http://www.youtube.com/watch?v=jijW310xvp4

drmike

Reader

3/11/12 11:24 p.m.

In reply to ditchdigger:

I have had no luck with aluminum brazing rods. I can gas weld, TIG weld, MIG weld, even braze stainless steel... but those dang aluminum brazing rods kicked my butt.

Me too. Perhaps it is our experience that holds us back. I see kids with little more than a propane torch and enthusiasm turn out some awesome results with the HF rods and moped cases.

Only because I'm not familiar with the Seal-Lock fluid and how it is effected by the expansion-contraction inheat, I would rather root out the crack with a die grinder and TIG it.

Congrats on your CSI skills.

Dan

Ian F

SuperDork

3/12/12 7:03 a.m.

The suggested uses for Seal-Lock would seem to imply it can handle the temperature changes well enough. Please keep us (me) updated on how this goes. Have you posted this on any of the MINI forums - NAM or Motoring Alliance?

I'd be interested in drawings for the parts you made to seal the housing as I predict I'll be doing this project myself in the not too distant future.

drmike

Reader

3/12/12 7:56 a.m.

In reply to Ian F:

No drawings - just took pieces of posterboard and rubbed them on the flange faces. Instant pattern! I hacked a couple of chunks of aluminum out of a scrap plate (with a Sawzall, no bandsaw at home), and transferred the holes with a center punch.

As for NAM or even MA, I'm quite tired of the self-elected "expert" trolls who turn every discussion into a chest-beating contest. So, no, I didn't bother.

Ian F

SuperDork

3/12/12 8:00 a.m.

drmike wrote:

In reply to Ian F:

No drawings - just took pieces of posterboard and rubbed them on the flange faces. Instant pattern! I hacked a couple of chunks of aluminum out of a scrap plate (with a Sawzall, no bandsaw at home), and transferred the holes with a center punch.

Hmm... ok... So it's just the one plate where the housing mounts to the engine?

Ian F

SuperDork

3/12/12 8:03 a.m.

Waitaminute...

Dr. Mike... That sounds familiar... Do I know you? At least from the forums. I've been on (and mostly off) NAM since it was MCO. MA, not so much... I'm not on the MINI forums much anymore either.

drmike

Reader

3/12/12 8:09 a.m.

Ian F wrote:

drmike wrote:

In reply to Ian F:

No drawings - just took pieces of posterboard and rubbed them on the flange faces. Instant pattern! I hacked a couple of chunks of aluminum out of a scrap plate (with a Sawzall, no bandsaw at home), and transferred the holes with a center punch.

Hmm... ok... So it's just the one plate where the housing mounts to the engine?

You need a second plate to block off the oil cooler ports (if you leave the cooler on the car to avoid draining the coolant).

And yeah, it's me.

Great, now my R53 will start leaking there, just because I know about it....

I had the same kind of problem with the plastic induction tube between the throttlebody and the SC - a thin spot in the cast eventually broke through.

Apparently no one at MINI does any QA on ANY of their casting...

I used to surf NAM a good bit but never posted much. There's just so little real mechanical content over there it's disappointing.

drmike

Reader

3/18/12 11:14 a.m.

Reporting back:

I went through the following (excessive, probably unnecessary) procedure to prepare the leaky housing:

- Wash and rinse housing in ultra-high-grade mineral solvent (Exxol) for 30 minutes.

- Submerge housing in isopropyl alcohol and place in ultrasonic cleaner for 30 minutes.

- Dry off housing.

- Place housing in a vacuum chamber for one hour to remove all traces of solvent and IPA.

I then brushed Seal-Lock Fluid Weld on the inside of the casting, and screwed the oil filter cap in place. The housing was pressurized to 100psig for 12 hours to encourage the product to fill the pores in the casting. I then pulled the cap back off, and left the housing sitting on my desk overnight.

Next, I brushed the product on the outside of teh casting, over the leaking area. I let that sit on my desk for a couple of days.

This morning, I reinstalled the housing, and started the car. I let it run for 10 minutes at idle to warm up, then I ran it at 3000RPM for five minutes to keep the oil pressure at 55psig.

NO MORE LEAK.  At least for now.

At least for now.  Now to put the car back together.

Now to put the car back together.

T.J.

UberDork

3/18/12 12:51 p.m.

Sounds like you did a thorough job on that repair. I could use your help to fix the oil leaks on my Mini. I had it totally leak free a few years ago, then pulled the engine for a clutch and flywheel replacement. It has leaked ever since, but it seems like it leaks from new places if I bother to track down and stop the current one.

drmike

Reader

3/17/13 10:32 p.m.

Just following up - the leak came back last week. Nearly a year to the day!

So, the Seal-Lock Fluid Weld repair didn't survive more than about 300 heat cycles. Boo.

I've set up a search on eBay to look for an R53 oil filter housing to buy. There are several in the UK, but I'm worried about the shipping cost from the UK to California.

just my $.02 , but if it is leaking from the exact same spot, I would try to weld it, or take it to someone that knows what they are doing, and have them weld it. Honestly I would be worried that a used housing might have the same, or worse leaking problems, if that is known to be a common trouble spot with those engines.

again, just my $.02. YMMV. good luck.

![]()