No, I'm not suddenly paddling a personal water craft.

I fell in love with the Eames Aluminum Group chairs (too many) years ago when I bought a few at auction and ended up using them as my office chairs. The chair I sit in every day is almost 30 years old now and is still super comfy and looks cool. Well, a few years ago - maybe like five or more years actually - a friend called me and said that the warehouse we rented space in had tossed one out when cleaning out a tenant's space. I ran down there and snagged it. It wasn't just any chair, it was a leather soft pad lounge chair, not common and NOT cheap. It was disgusting with mildew covering it and a broken base but I figured it would at least be useful for parts for someone.

Fast forward five (or more) years of it kicking around the garage half disassembled and going through a move or two. Yesterday when cleaning the garage I decided this being out of the way would be nice.

Unfortunately I didn't take any before pictures. I really regret that now since the transformation was so striking. But here's what I did:

First I needed to make sure the base was repaired at the right angle. This was complicated by the fact that, being a "sling" chair, the base isn't flat on top. It's also not an easy angle, it's something like 20 degrees. On top of that, the chair has an interesting torsion spring recline mechanism with a set bolt that allows you to adjust the tension. It depends on having the horizontal tube be both straight and smooth inside. To make sure it was straight and the angle of the base was right, I needed to make a jig.

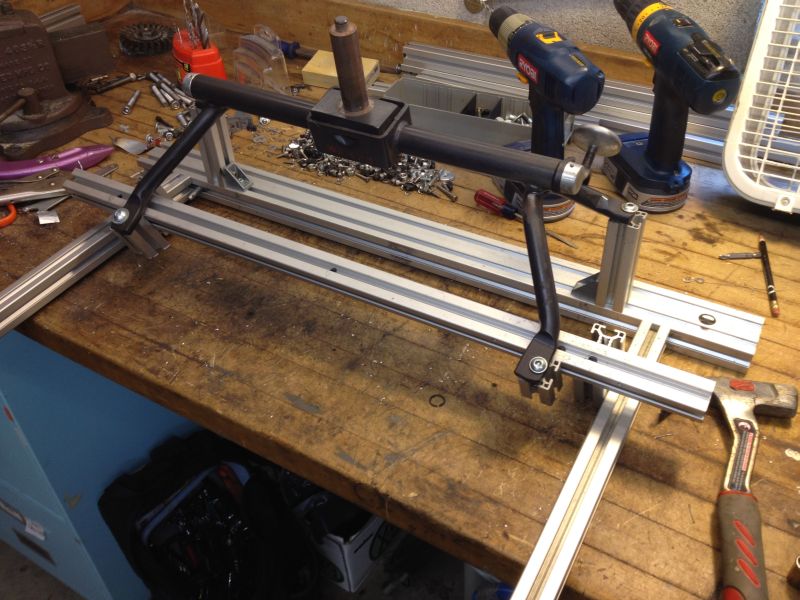

So I busted out some 80/20 aluminum that I salvaged from an old network scanner rig. An hour or two later I had this:

Probably overkill but I'm known for that. The sad part is I used it for maybe 10-15 minutes to do this:

Which isn't my prettiest weld ever but I'm using a flux core so it's never going to be pretty. But since this is well hidden under the chair I'm just worried about strong, not pretty. And that it is. In order to try to protect the inside of the tube I cut up some sheet aluminum (also known as a soda can) and slipped it inside. That both did and didn't work. The didn't work part is that a bit of the aluminum melted and so the soda can is stuck in there permanently. The did work part is that it kept the weld from intruding on the inside of the tube and so the recline mechanism works well.

Now the next part is where I really regret not having before photos because this was the biggest visual impact part. My secret for cleaning up leather is "Leather Magic." It cleans up mildewy leather just great and conditions it well. I didn't bother reading the ingredients before yesterday - water, lanolin, and siloxane. Siloxane is used as a masonry sealer and skin moisturizer in lotion. What fun!

So an hour or so of cleaning and conditioning netted me this:

The arms are polished aluminum so tend to get little pits and such. Right now I don't have the patience for re-polishing them but they look about 90% right after a good cleaning.

A couple more shots, this time in the house:

For the cost of an afternoon's time and a foot or so of welding wire and some cleaning products I have a spiffy lounge chair for the living room. It was made in 1978, looks cool, and is comfy.

Now, for fun, go look on eBay at what these sell for. I will always wonder if the people that tossed this in the dumpster had any idea what they were throwing out or if they just thought it was an old ratty chair. Most people will never own a chair this valuable - new these are north of $3000! Ouch.

I would love to have a matching ottoman but doubt I'll luck upon the right one. Although this is my third dumpster rescue of an Eames chair, and my twelfth Eames chair in total. Who knows, maybe I'll get another call and it'll turn out to be the ottoman. ;-)