bluej

UltraDork

8/11/17 9:26 a.m.

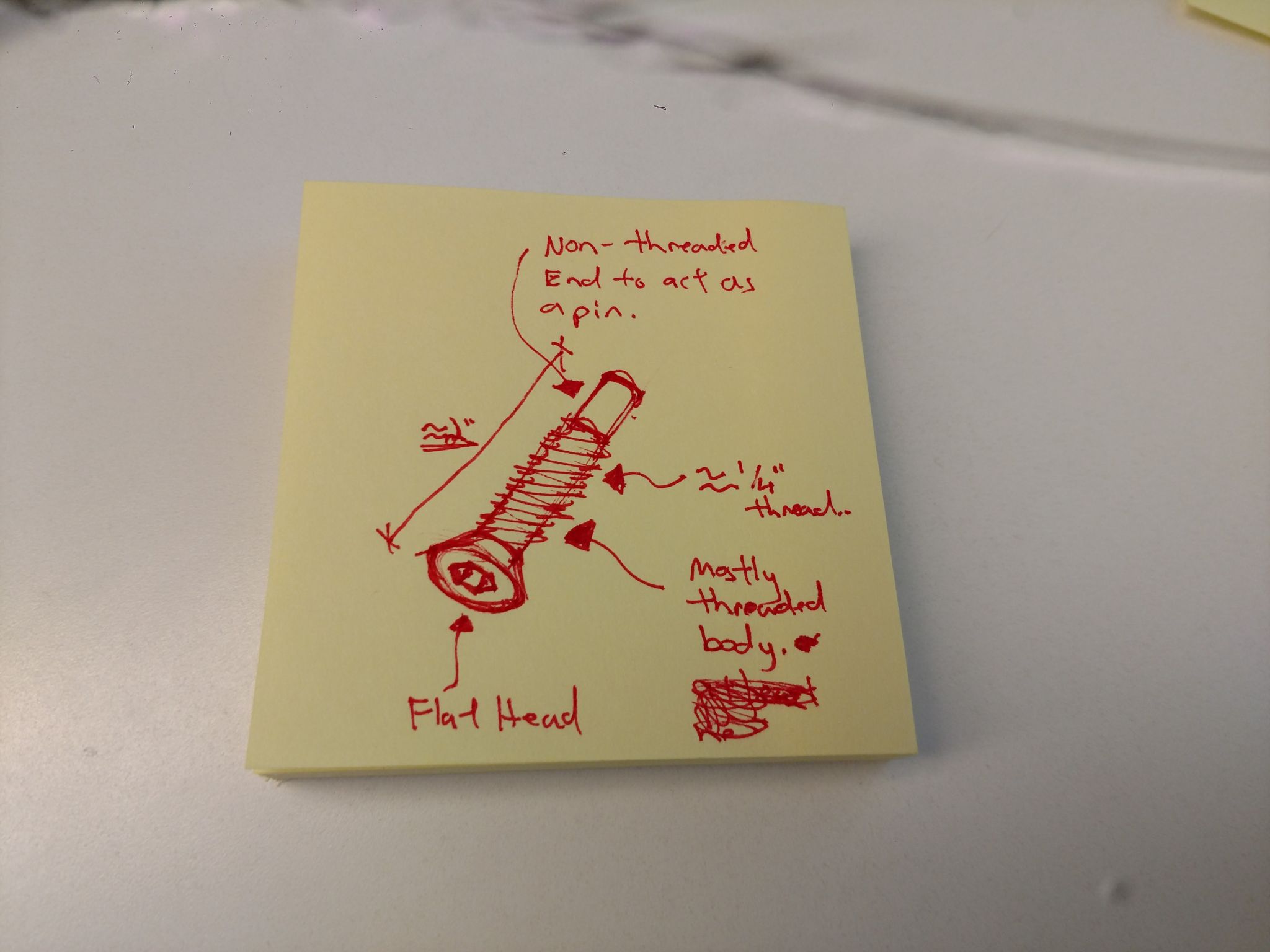

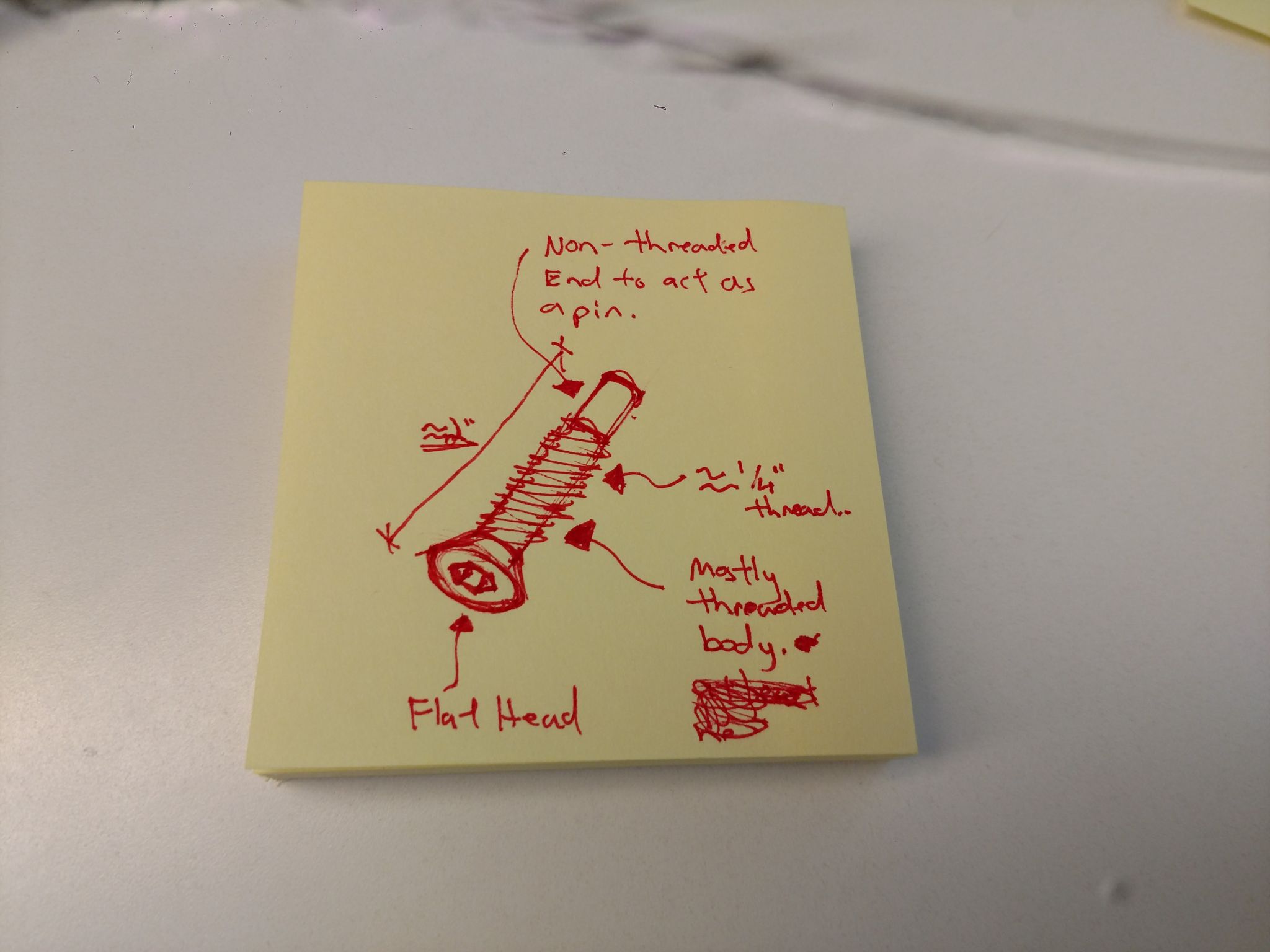

I need this:

Yes, easy button would be to grind the thread off the end of a regular ol flat head bolt, but this is in a work application and the work to grind it off would be prohibitive for the quantity needed.

Does it exist? other thoughts? I have some other ideas, but figured I'd see what you hardware geniuses (srsly) could come up with.

You need what? Is there supposed to be a picture?

There's not even a blank X to me.

bluej

UltraDork

8/11/17 9:34 a.m.

alfadriver wrote:

You need what? Is there supposed to be a picture?

There's not even a blank X to me.

hmm, that's weird. It's from photoberkit. Anyone else see it?

lets try a link to pic:

clicky

Could you have someone put the appropriate Allen bolt in a lathe and turn down the threads?

I can see it. I'll be surprised if you can get that off the shelf. Looks kind of like a Samurai's shifter locator pin.

tuna55

MegaDork

8/11/17 9:39 a.m.

Appleseed wrote:

Could you have someone put the appropriate Allen bolt in a lathe and turn down the threads?

That's probably the best bet. I don't think it's a standard thing, though like Gameboy said, other manufacturers have solved that problem with custom hardware before, depending on how sourcing works and what size/specs you need.

How many do you need? I have seen similar hardware before, but I don't think you'll find it off the shelf. You probably just want to talk to a hardware manufacturer and make your own. Or find an alternative way of accomplishing what you need.

T.J.

MegaDork

8/11/17 9:49 a.m.

Search for dog point bolt or dog point screw.

How long does the pin need to be and is this a bolt or more of a wood screw?

Seems that something like this is usually inserted from the side that the pin is on, then it would be something more like a screw in dowel.

There is a pic on Berkit. If youre not seeing it, here is a link

http://216.92.53.23/photoberkit.com/copper/albums/userpics/10017/IMG_20170811_092012431.jpg

Bluej, Ive seen those before, but they were always in a bag of hardware that came with something. IDK where you could find them off the shelf. Sorry, I know thats not much help.

Depending on your machining skills and tool availability, I could see setup where you have a cylindrical slug of steel, with a hole thru the center, tapped to accept an off-the-shelf flathead machine bolt. If youre using 2" screws, the cylinder would need to be 1.75" tall, so that a quarter of an inch is protruding. Tighten the screw into the slug, and chuck it in a lathe. Grind off the thread, and boom.

No Lathe, you could chuck up the screw, threads first, in a drill press, and grind quickly with an angle grinder, then cut off the threaded end with a cuttoff wheel.

Either way, you could probably churn out 2-3 a min if you had to. Not sure how many you would need? A few dozen would be possible in a short amount of time, but if you need hundreds or more, youre right, probably time prohibitive. Also, the lathe route would make the pin-end dims repeatable. Obviously, hand grinding with a grinder would not be as exact.

bluej

UltraDork

8/11/17 9:55 a.m.

T.J. wrote:

Search for dog point bolt?

How long does the pin need to be and is this a bolt or more of a wood screw?

Ooh! that could work! Quick search of dog point bolts is promising.

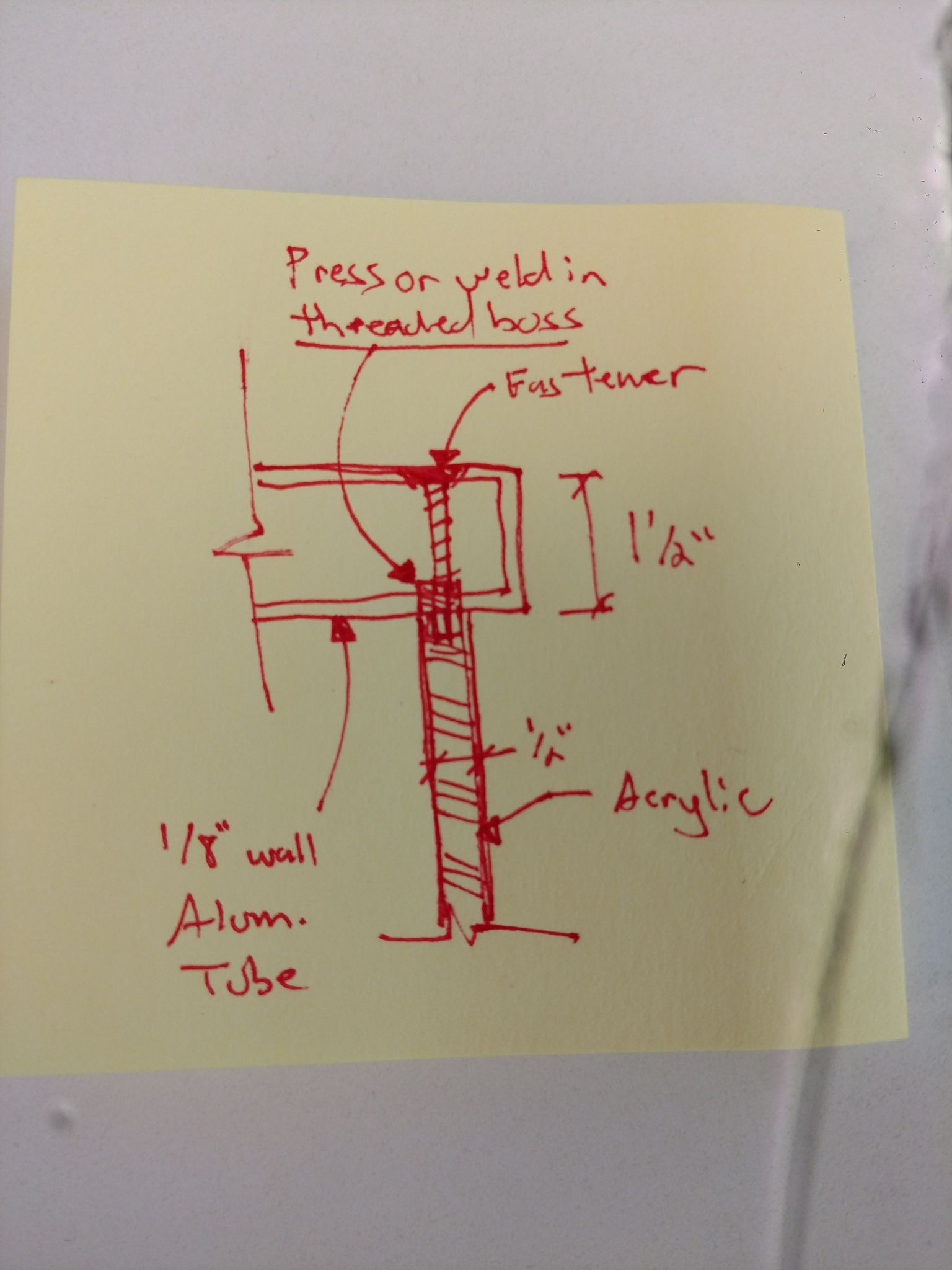

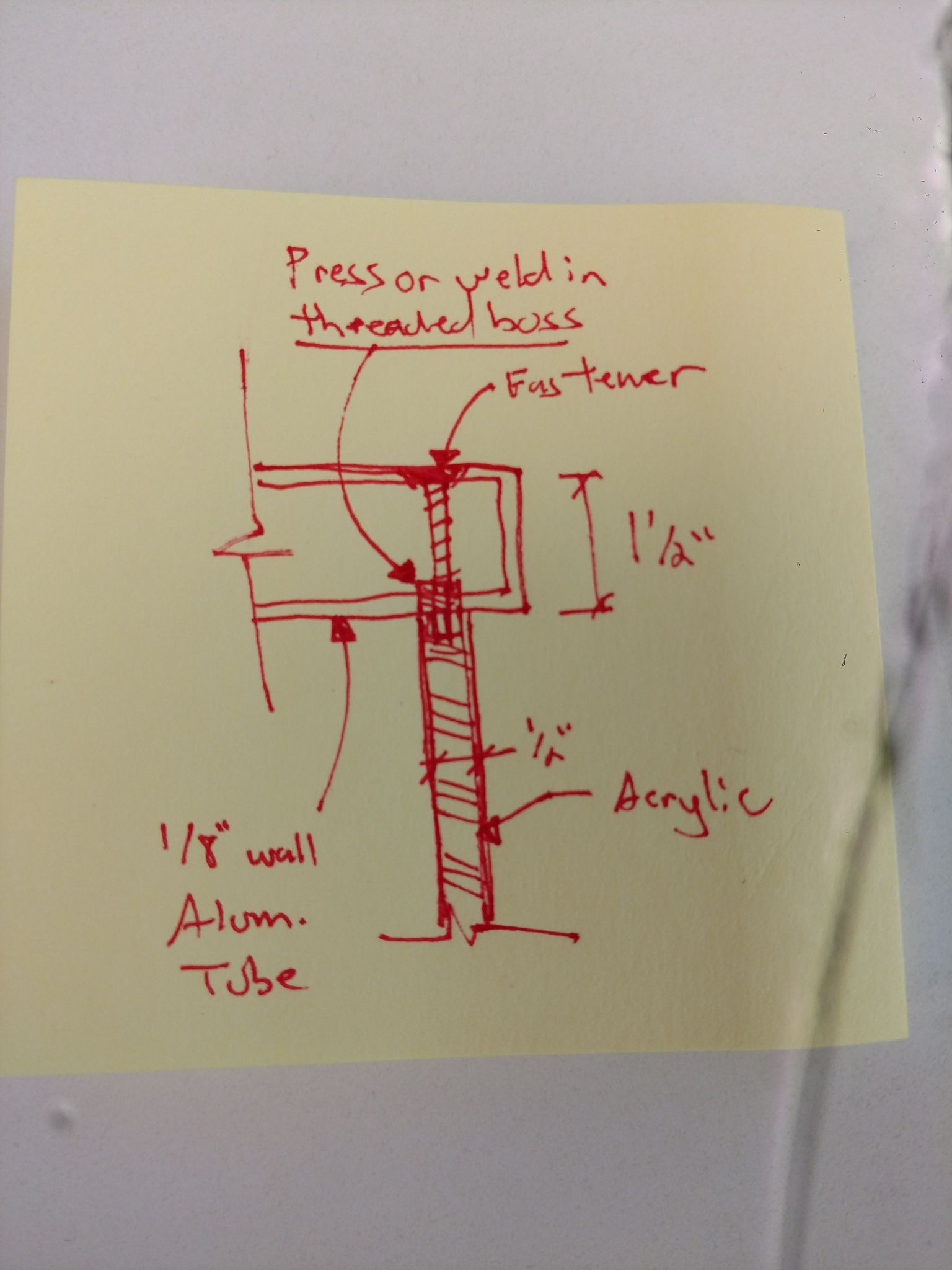

It's a bolt. Here's a sketch of what the need is. There's a frame of aluminum tube and I need to hold the acrylic panels in place w/ minimal visible hardware. The pin portion only needs to be ~ 1/4" long.

I would consider the qty needed a fair amount for the types of things we usually design. Definitely more than 100 but less than 1,000 of these fastening points.

bluej

UltraDork

8/11/17 9:57 a.m.

also, having the fastener head proud of the tube is pretty undesirable, hence the flat-head.

thanks for the thoughts all, helps a lot!

So a dumb question- what's the need for the extension? Is it specifically for shear strength and alignment, or just one of those?

OR is it so that it's easier to install- since the extension can be located in the hole?

If it's the last part- there are bolts that prevent cross threading out there- which also have a similar extension.

edit- I see the clarification

bluej

UltraDork

8/11/17 10:03 a.m.

This might be a winner. The fabricator could weld internally threaded rod into the tube, then thread these all the way through. I think the tip would be just long enough:

Mcmaster is life

Most acrylic I've seen like this (typically signage applications) would be retained by a small C channel that was internally screwed to the square tube above. This also helps account for less than perfect edges on the acrylic if necessary. Would that work? What is it that you're making here?

bluej

UltraDork

8/11/17 11:21 a.m.

ultraclyde wrote:

Most acrylic I've seen like this (typically signage applications) would be retained by a small C channel that was internally screwed to the square tube above. This also helps account for less than perfect edges on the acrylic if necessary. Would that work? What is it that you're making here?

I can share after mid December

For aesthetic reasons, no extra capture channel here.

What you're looking for is DIN 925. See this sheet: http://www.newfastener.com/wp-content/uploads/2013/03/DIN-925.pdf

T.J.

MegaDork

8/11/17 12:27 p.m.

bluej

UltraDork

8/11/17 12:32 p.m.

the_machina wrote:

What you're looking for is DIN 925. See this sheet: http://www.newfastener.com/wp-content/uploads/2013/03/DIN-925.pdf

you sir, get ALL the cookies for today! THANK YOU!!

![]()