Print upgrades for the printer, of course! Then print an entirely new printer! Now you have two printers and can print enough parts for four printers!

Seriously, upgrades are a big thing when I have downtime for actual projects, but I generally use mine to prototype stuff.

I printed adapters to go from a single 1bbl to twin Weber two barrels on my '67 Mustang. I'll be casting these later using the lost wax method.

https://i.imgur.com/W03QKPC.jpg

As well as a throttle linkage for the same

https://i.imgur.com/HLvVXlg.gif

I used CAD to design a replacement for an obsolete outboard part, then I cast it in bronze

https://imgur.com/a/kJjBZ

I printed gauge adapters for the same Mustang I mentioned above

https://i.imgur.com/TiEIbsx.jpg

https://i.imgur.com/nXrifGj.jpg

I printed a hose-to-outboard attachment so I could flush out an old outboard.

https://i.imgur.com/cvY716m.jpg

I needed more light in the garage, so I printed adapters for some cheap LED lights off Amazon

https://i.imgur.com/9HJBDFN.jpg

https://i.imgur.com/h4H7Nd4.jpg

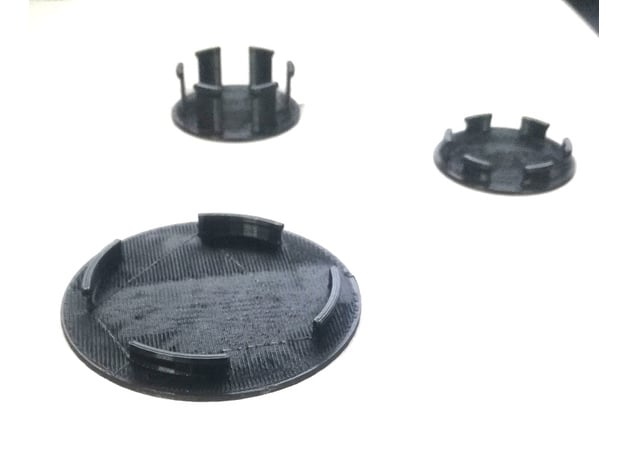

When I rebuilt my engine, I sandblasted my intake manifold for paint. Didn't want anything getting in the injector bungs when I painted, sooooo I printed plugs

https://i.imgur.com/h1WltZN.jpg

https://i.imgur.com/uyIzxq8.jpg

And these were all just a few of the things I've done with my home printer. I also have done at least twice that much with the free ones at college when I was doing my engineering program.

Learn some form of CAD or Blender or some other modelling software and make your own stuff.