tuna55

MegaDork

5/2/24 3:52 p.m.

It got pretty loud today. Sometime in between creating extra runs and running out of primer ahead of schedule, the compressor started knocking. It sounds like a rod knock if a rod knock sounds like an internal combustion engine. It's a two-cylinder single stage compressor head but the motor is good and the tank is fine. I still have to do body color and clear, and I need the compressor to be good for those obviously, but I don't intend to make this a giant investment of dollars because I don't intend to do this again. I recognize that, like a woman in labor, I'm saying this while everything is terrible and then I'll change my mind eventually and go back wanting to paint another vehicle. Right now, I don't want to invest a lot of money in a brand new compressor that's just going to sit there after I finish this truck.

Are there any hot tickets? Check the pictures.

The hot ticket is to call your local equipment rental place and rent a compressor.

Do you want me to pull the one that I've used to paint quite a few cars in the driveway loaded the back of the truck and run it down to you tonight?

Other option is they sell compressor heads over at Harbor Freight for a belt driven compressor like you have

tuna55

MegaDork

5/2/24 4:37 p.m.

Dusterbd13-michael said:

Do you want me to pull the one that I've used to paint quite a few cars in the driveway loaded the back of the truck and run it down to you tonight?

Dude you're the best, but I can't ask that much and also won't be home tonight anyway

tuna55

MegaDork

5/2/24 4:38 p.m.

Dusterbd13-michael said:

Other option is they sell compressor heads over at Harbor Freight for a belt driven compressor like you have

How "harbor freight" are they? I see them pretty reasonable in terms of cost

In reply to tuna55 :

According to some industrial customers that use them in the maintenance shops they've been working great. Seem to be an actually decent product

NOHOME

MegaDork

5/2/24 5:32 p.m.

I would be worried that if you shrapnel the guts on the one you have you might introduce oil into the air tank before you realize what is going on. Not ideal to mix with paint.

When I ran into the same issue painting the Bugeye, I borrowed a much smaller compressor ( 10 gal?) that I then tied into my large 50 gallon tank. Took a while to pump up, but was not a big deal to keep up with the pace I was painting at. Might have been abusing the poor borrowed compressor cause it ran a lot.

tuna55

MegaDork

5/2/24 9:12 p.m.

NOHOME said:

I would be worried that if you shrapnel the guts on the one you have you might introduce oil into the air tank before you realize what is going on. Not ideal to mix with paint.

When I ran into the same issue painting the Bugeye, I borrowed a much smaller compressor ( 10 gal?) that I then tied into my large 50 gallon tank. Took a while to pump up, but was not a big deal to keep up with the pace I was painting at. Might have been abusing the poor borrowed compressor cause it ran a lot.

Yeah that's possible. I'll drain the tank. I'm obviously using a good filter at the gun too.

I think the best option is the replacement HF pump. I thought of borrowing or renting, but I'm going to need a compressor after I'm done anyway.

tuna55

MegaDork

5/3/24 12:43 p.m.

I have a new HF pump. It ought to out-pump mine anyway.

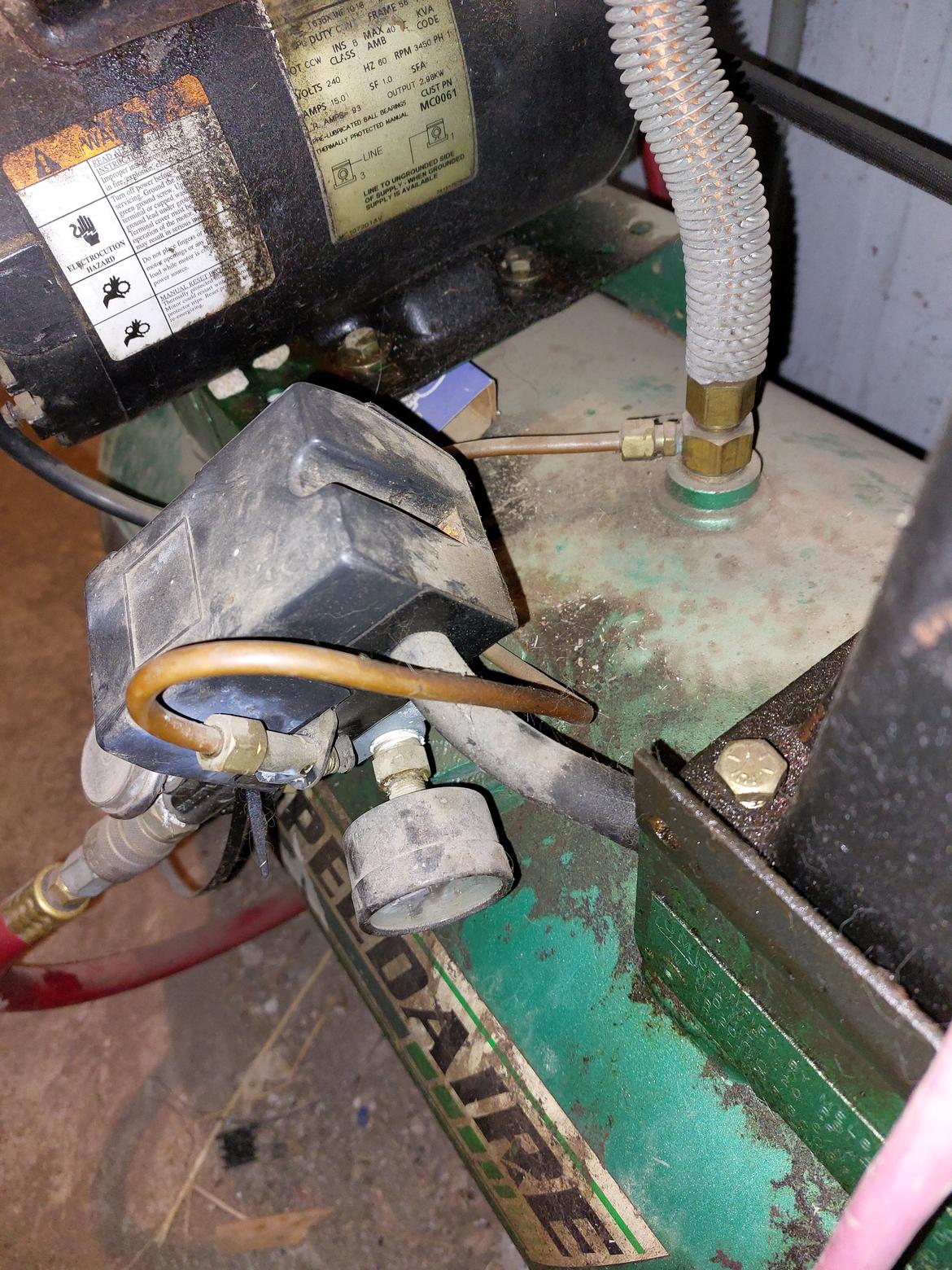

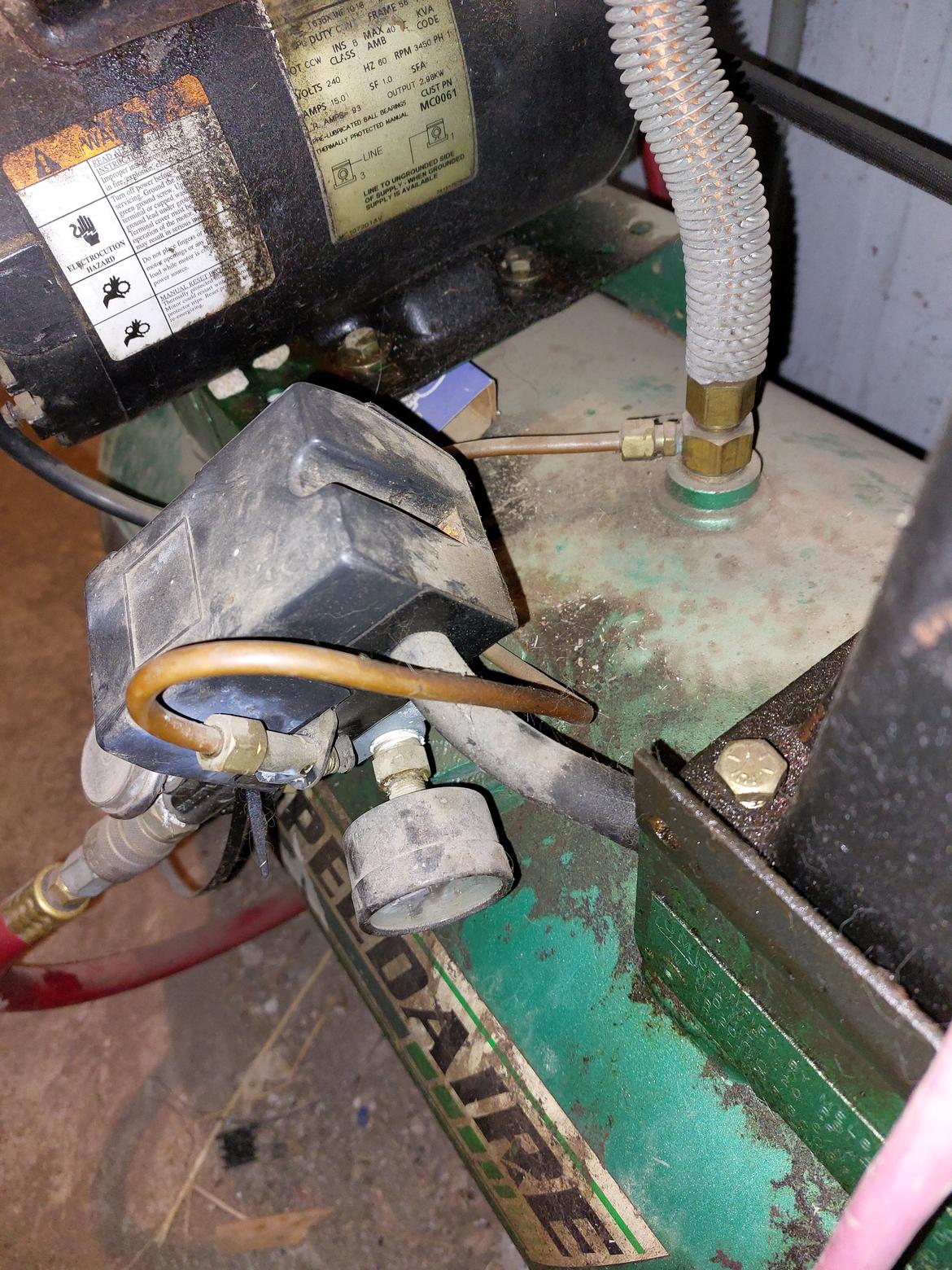

One question, what is this line for? I can't figure out what theya re doing, maybe it's just the way the switch sees the tank pressure? Seems odd.

ShawnG

MegaDork

5/3/24 1:48 p.m.

That's the unloader line. The pressure switch has a little valve that dumps the air pressure in the line between the compressor pump and the check valve in the tank. That way the motor can start without working against tank pressure.

It makes the "Pssht" sound you hear when the unit turns off.

tuna55

MegaDork

5/3/24 1:50 p.m.

ShawnG said:

That's the unloader line. The pressure switch has a little valve that dumps the air pressure in the line between the compressor pump and the check valve in the tank. That way the motor can start without working against tank pressure.

It makes the "Pssht" sound you hear when the unit turns off.

Interesting!

So where do I run that on my new pump?

https://manuals.harborfreight.com/manuals/59000-59999/59672-193175478177.pdf

ShawnG

MegaDork

5/3/24 9:46 p.m.

In reply to tuna55 :

That's an old Speedaire pump on your machine currently. The newer pumps moved the unloader line from the head to the check valve on the tank.

You may need to swap your check valve for one that has an unloader fitting or add a tee to the fitting at the pump.

ShawnG

MegaDork

5/3/24 9:52 p.m.

Also. Don't buy a two stage pump unless you need more than 120psi of air pressure, you're just wasting money and electricity.

Buy a two cylinder pump instead, you'll get more air volume for the same power use.

A two stage compresses the air twice, once in the big cylinder to about 90 psi, then it's compressed up to about 150 in the second cylinder.

A two cylinder, single stage pump only compresses the air once, up to about 125psi but it does it two times per pump rotation.

Two stage = high pressure.

Two cylinder, single stage = high volume.

Two stage compressors are the most over-sold tool in the world.

NOHOME

MegaDork

5/3/24 9:56 p.m.

In reply to ShawnG :

I had not considered that, but you are right.

tuna55

MegaDork

5/3/24 10:49 p.m.

ShawnG said:

Also. Don't buy a two stage pump unless you need more than 120psi of air pressure, you're just wasting money and electricity.

Buy a two cylinder pump instead, you'll get more air volume for the same power use.

A two stage compresses the air twice, once in the big cylinder to about 90 psi, then it's compressed up to about 150 in the second cylinder.

A two cylinder, single stage pump only compresses the air once, up to about 125psi but it does it two times per pump rotation.

Two stage = high pressure.

Two cylinder, single stage = high volume.

Two stage compressors are the most over-sold tool in the world.

I'm this --->][---< close to installation. I don't know where to find a cheap two cylinder single stage pump. That's what I had before. You're right, no doubt, but where can I get something for like $300?

ShawnG

MegaDork

5/3/24 11:04 p.m.

tuna55

MegaDork

5/3/24 11:05 p.m.

ShawnG said:

Also. Don't buy a two stage pump unless you need more than 120psi of air pressure, you're just wasting money and electricity.

Buy a two cylinder pump instead, you'll get more air volume for the same power use.

A two stage compresses the air twice, once in the big cylinder to about 90 psi, then it's compressed up to about 150 in the second cylinder.

A two cylinder, single stage pump only compresses the air once, up to about 125psi but it does it two times per pump rotation.

Two stage = high pressure.

Two cylinder, single stage = high volume.

Two stage compressors are the most over-sold tool in the world.

It seems the smaller compressor at HF is indeed a single stage two cylinder with enough cfm to do the job. I can swap them tomorrow, and save myself $50 too.

I am not sure I understand how to route the unloader. There is a check valve on the head of the pump motor, but I assumed that was just a safety check valve, is that the one you mean? Can you link the animal you think I need just so I am sure?

tuna55

MegaDork

5/3/24 11:11 p.m.

also, what is the hot ticket for connecting the compressor to the tank? My old pump, and what seems right, is a soft copper tube with compression fittings at either end, but golly, I can't find fittings like that locally anywhere.

ShawnG

MegaDork

5/3/24 11:21 p.m.

Here's the check valve I used, standard speedaire check valve. Screws into the tank. Small port in the side connects to the copper line going to the pressure switch. No more line to the head

Hromee Air Compressor Replacement Components Brass 1/2 Inch MNPT Compressor in Tank Check Valve Kit with Three Different Unloader Tube Fittings 20 SCFM 4 Pieces https://a.co/d/dJ6siCZ

The valve on the new pump is probably a safety valve.

The line is probably 1/2" soft copper. Uses a rubber compression sleeve at each end but you can use a standard brass sleeve too.

tuna55

MegaDork

5/3/24 11:28 p.m.

All right thank you so much

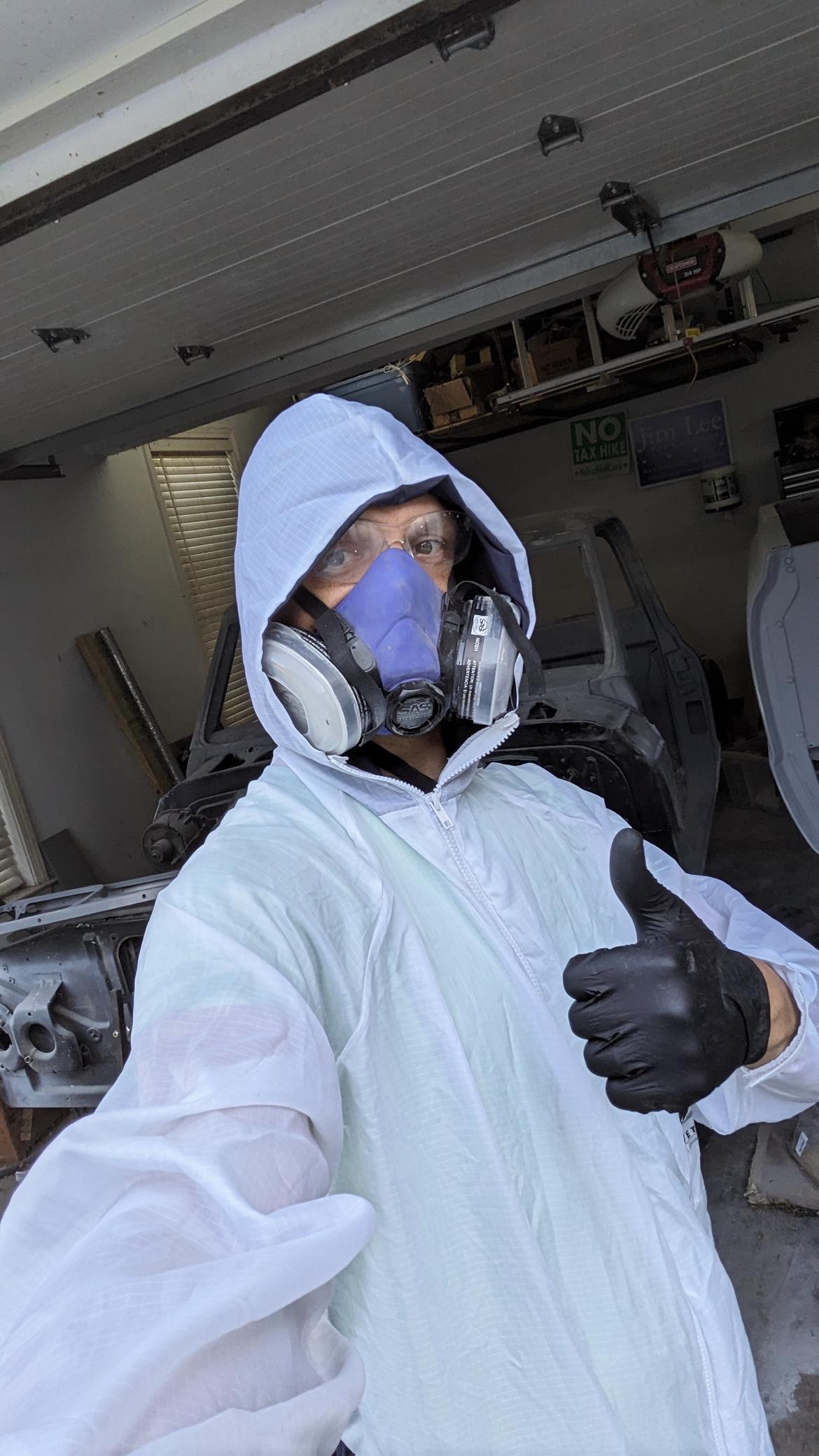

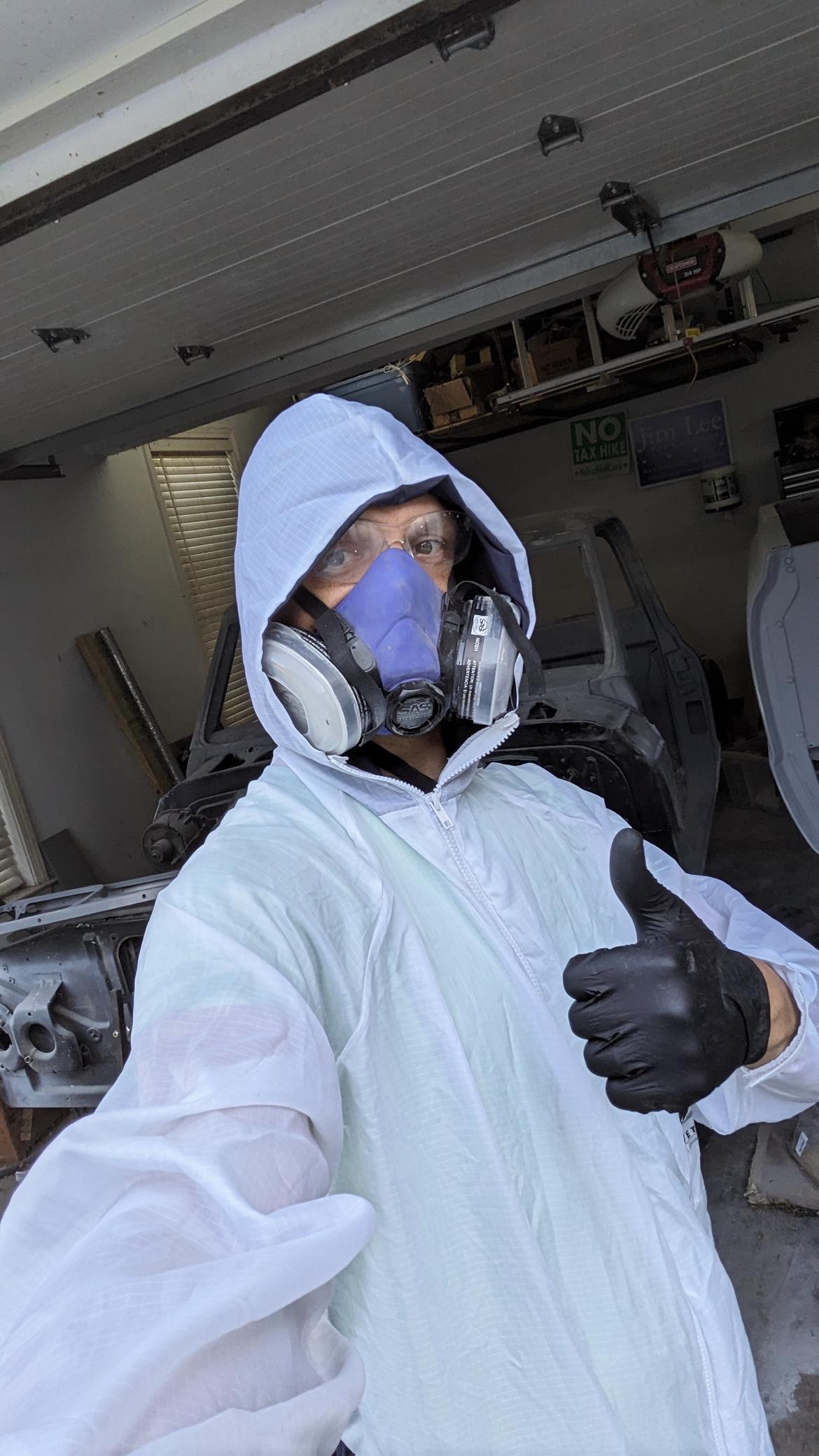

For your reviewing pleasure..

NOHOME

MegaDork

5/4/24 12:24 a.m.

I know that you want a compressor for the long haul, so no rental option, but the reality of then having to sand all those parts before color sucks hard. The sealer you would have shot color on top of, "wet-on wet" with the time window being like 24-72 hours or so depending on your MDS. You might still have that window if you rent a compressor.

The above said, painting under pressure (pardon pun) is not something I would really want to do. It is stressful enough as is.