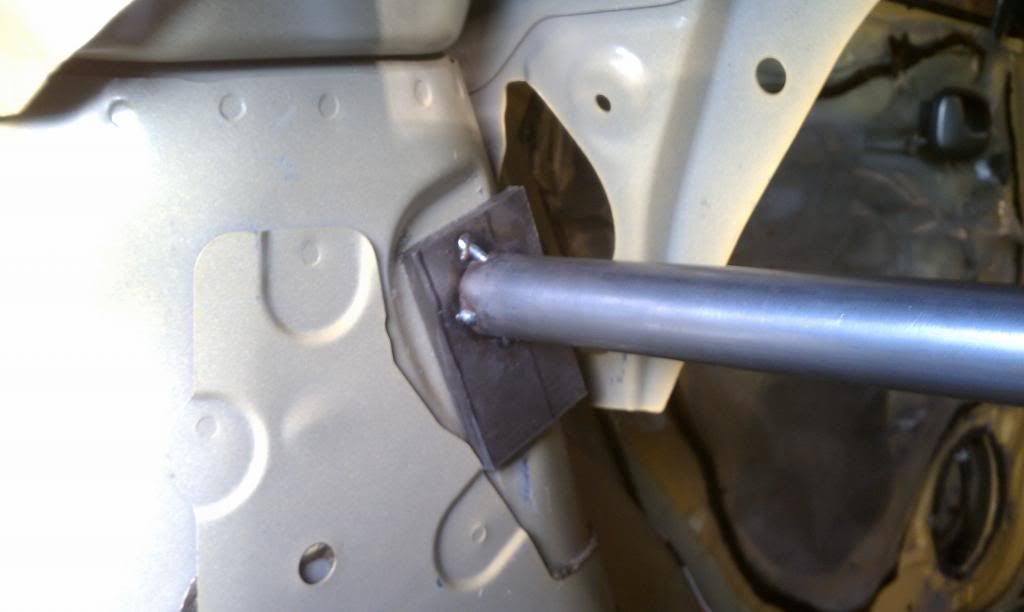

Cut up some old parts and made cluster mounts out of them. New northern tool 140 mig welder works great. Good heat and so far good quality, lots of control for heat and speed and even a spot weld dial ![]() Need to finish up my seat bracket and weld it in then figure out the harness mounting points on it.

Need to finish up my seat bracket and weld it in then figure out the harness mounting points on it.

Well I'm jumping in on a group buy for a gearbox fix solution. Nicely engineered and thoroughly tested. Requires milling and drilling and tapping. I don't plan on putting down as much hp as it's rated to but it's still nice to have that peace of mind. less flexing is always good. Probably won't go in the car until after this season though.

Welded in the seat bracket among other things. Waiting for a few more parts to show up and motivation to spend money on the rest of the parts I need to get it finished up for april 27th (first autox).

Very very tidy under the valve cover. Appears to have been very well maintained. :)

Did some cutting and welding tonight. Brace for the rear strut towers and cut the spare tire bubble out to make room to access the bolts underneath via a flat trunk floor.

golfduke wrote: My first "real car" was an 03.5 msp. God, the hilarity that ensued on mazdaforums then...

I'm not sure where to go with that comment.

Pay day is friday and I'll be ordering up a Tial QR for the MSP. Just a "short list" of things to do until I can start it up for the first time in about 6 months. Doubtful that I'll be ready for the first event on april 27th. ![]() On the plus side though I picked up a set of continental racing tires thanks to one of the mazda peeps on the forum. Slightly used but should be quite nice to burn up for a couple events or so.

On the plus side though I picked up a set of continental racing tires thanks to one of the mazda peeps on the forum. Slightly used but should be quite nice to burn up for a couple events or so. ![]()

So I filled my gas bottle and immediately felt like a winner. Finished up welding the rear brace and mocked up my seat for fitment check.

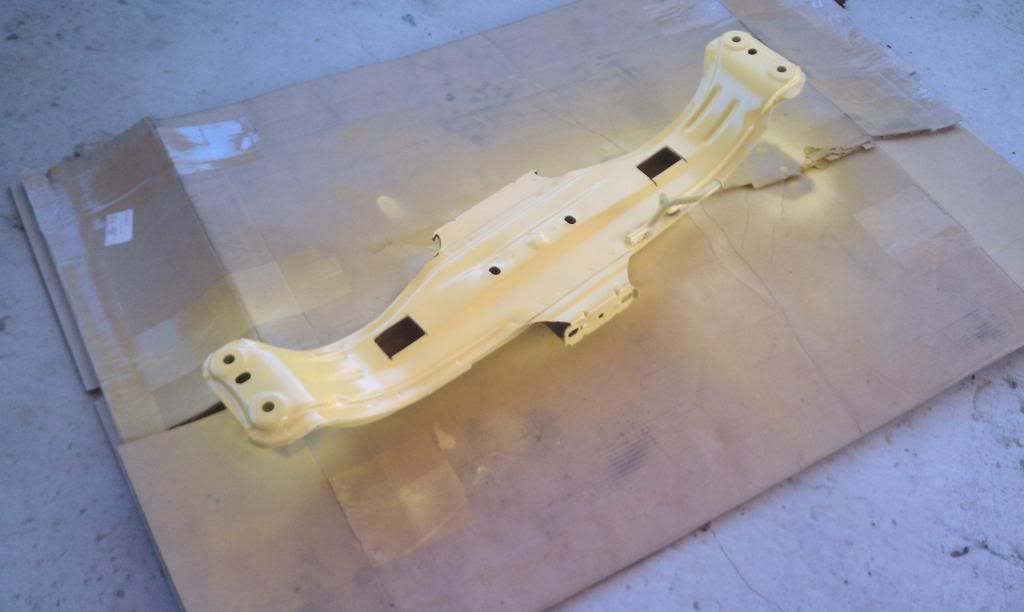

Spent the most of the weekend away. The little time I had I welded up a chromoly harness bar and re-powder coated my ignition coil bracket and bolted together a few parts. I also painted my rear sub-frame to prevent rusting since paint is the best rust protection.

Received my Tial Sport recirculating blow-off valve and aluminum sheet. So I traced my trunk floor hole and added 2 inches or so to each side then cut it out. After that, I laid some wood underneath of it with a small gap, grabbed a scrap piece of tube and put a "bead roll" on it the old fashion way. I did this to stiffen it since the sheet is .032 thick aka paper ![]() Shed about 5 pounds or so by using the aluminum. Will get riveted down to secure it. Now I have to figure how I want to remount the vapor cleaner. Since I'm not doing a stand alone ecu yet deleting it would be negative since the obd2 "learning" ecu will trigger the CEL if it's deleted. Makes me want to just go ahead and do the stand alone route now.

Shed about 5 pounds or so by using the aluminum. Will get riveted down to secure it. Now I have to figure how I want to remount the vapor cleaner. Since I'm not doing a stand alone ecu yet deleting it would be negative since the obd2 "learning" ecu will trigger the CEL if it's deleted. Makes me want to just go ahead and do the stand alone route now.

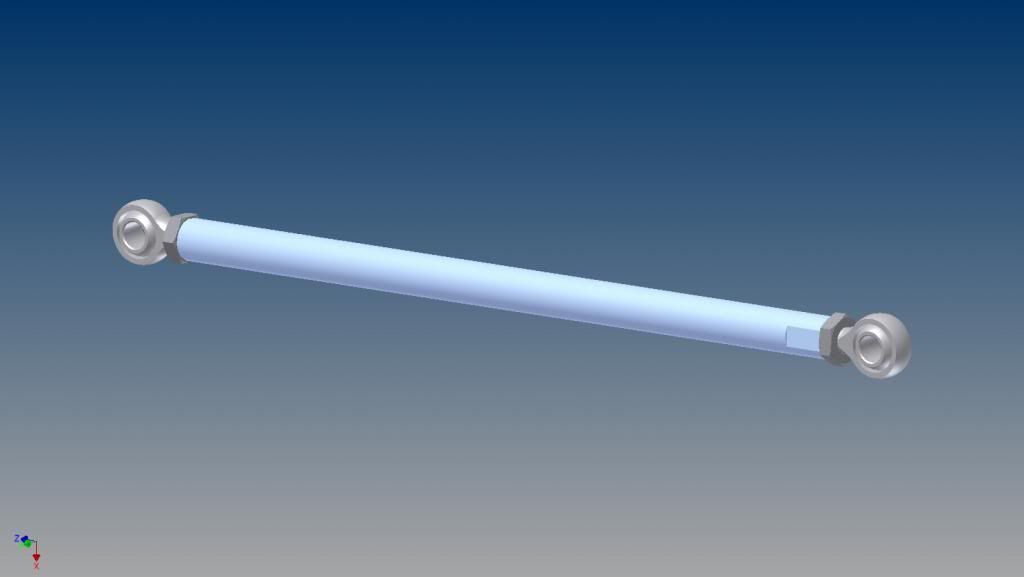

Put some time into 3D models for the lateral linkages. This is the shorter of the two. Have to order the hardware now and powder them accordingly.

Continuing to make small progressions. Only about a week left till the first autocross. Hopefully I can get her back together in time.

So with the winter taking a major toll on my Protege5 I need to replace the lower control arm bushings among quite a few other things and was wondering have you ventured in to making/replacing those yet?

JtspellS wrote: So with the winter taking a major toll on my Protege5 I need to replace the lower control arm bushings among quite a few other things and was wondering have you ventured in to making/replacing those yet?

Yes, not too difficult. Definitely need the right tools such as a press or maybe a vice. I put whiteline bushings in and replaced the ball joints while they were out. Many speculate that the ball joints aren't serviceable but they are. The easiest thing to do though if your control arms are going bad is just to buy replacements since they have the ball joint and bushings in them already. You can get them from rockauto for pretty cheap.

Been a while since my last update so here goes. I cut out the trunk floor and replaced it with a thin sheet of aluminum. Also, fully mounted the seat and harness and stuck in the dash again. Last night I methodically cut the door skins out after pulling the windows, motors and tracks. Last thing was the AN fuel lines. Very close to start up. Need to plumb the catch system and finish some piping among other things.

Over the weekend I took some time to trace out the old windows and cut out 1/16" thick polycarb windows. The fit nicely inside the door window grooves but I haven't secured them on the bottom yet. I'm still debating on how to fasten them.

Took 4 hours with guitar string to cut the front windshield out. Made a polycarbonate replacement to remove a lot of weight. Also, drove 3 hours one way to pick up an 80mm exhaust for her :)

You'll need to log in to post.