In reply to mazdeuce :

I would love to, however it said i have to be approved by an admin to send messages. wierd.

In reply to mazdeuce :

I would love to, however it said i have to be approved by an admin to send messages. wierd.

Why not use a flapper wheel for paint and rust removal? I understand the wire wheel is required to get inside corners and such, but I'd think a course grit flapper wheel would make short work of those long flat surfaces.

In reply to csmith1510 :

I have a solution!

If anyone needs to reach me for stickers or anything I now have an email address for you to directly email me. It is: ttwo.elm at gmail dot com. This should get messages to me without risk of massive spam or screwing up my regular email account which I don't really want to post because I'm old and grumpy. I've tested it though, and anyone can email me directly at that address. Stickers for everyone!

In reply to douglawrence42:

Two things, the first is that flap disks are kind of agressive, aren't they? The second is that I always read that flap disks remove material and also kind of smear it over. If you have clean metal this is fine, but on rusty metal you either have to remove a bunch of material or you end up with pockets of rust trapped under fresh metal that has been pushed over it. Maybe I'm being paranoid?

In reply to mazdeuce :

I use flapping for weld prep all the time, so I've not really experienced "trapped" rust or paint as a side effect. It is aggressive, but on metal aggressive means maybe you are taking .003" of material. I used flap wheels to strip an aluminum Jon boat, and I didn't feel like I was taking to much material then. Just a recommendation based on how strenuous running the wire wheel for a long time is, flapper is a lot easier on my arms.

I'll buzz you an email tomorrow afternoon for some stickers MazD. Actually now that I think of it, that'll be the best way of getting ahold of me when the shirts are ready.

mazdeuce said:Some of them are still good and decided to grow through the seams in an old joint. Small things like this make the outside worth it.

There's something ironic about life sprouting from an exhaust pipe.

I mostly dislike exhaust stacks on light duty pickup trucks, but if there was ever a vehicle that stacks would look sweet on, it's this one. (Camper/bed and perceived use/fitment and host of other issues aside.)

In reply to oldopelguy :

It's only a 12 inch cutter. I'm basically a weird middle aged lady who scrapbooks, but with cars.

In reply to Chaw :

I think stacks are still a diesel thing. Not that this will always be a gas truck, so maybe someday. For now I keep thinking "bundle of snakes". If I'm going to learn to build headers I'll never have more room than this.

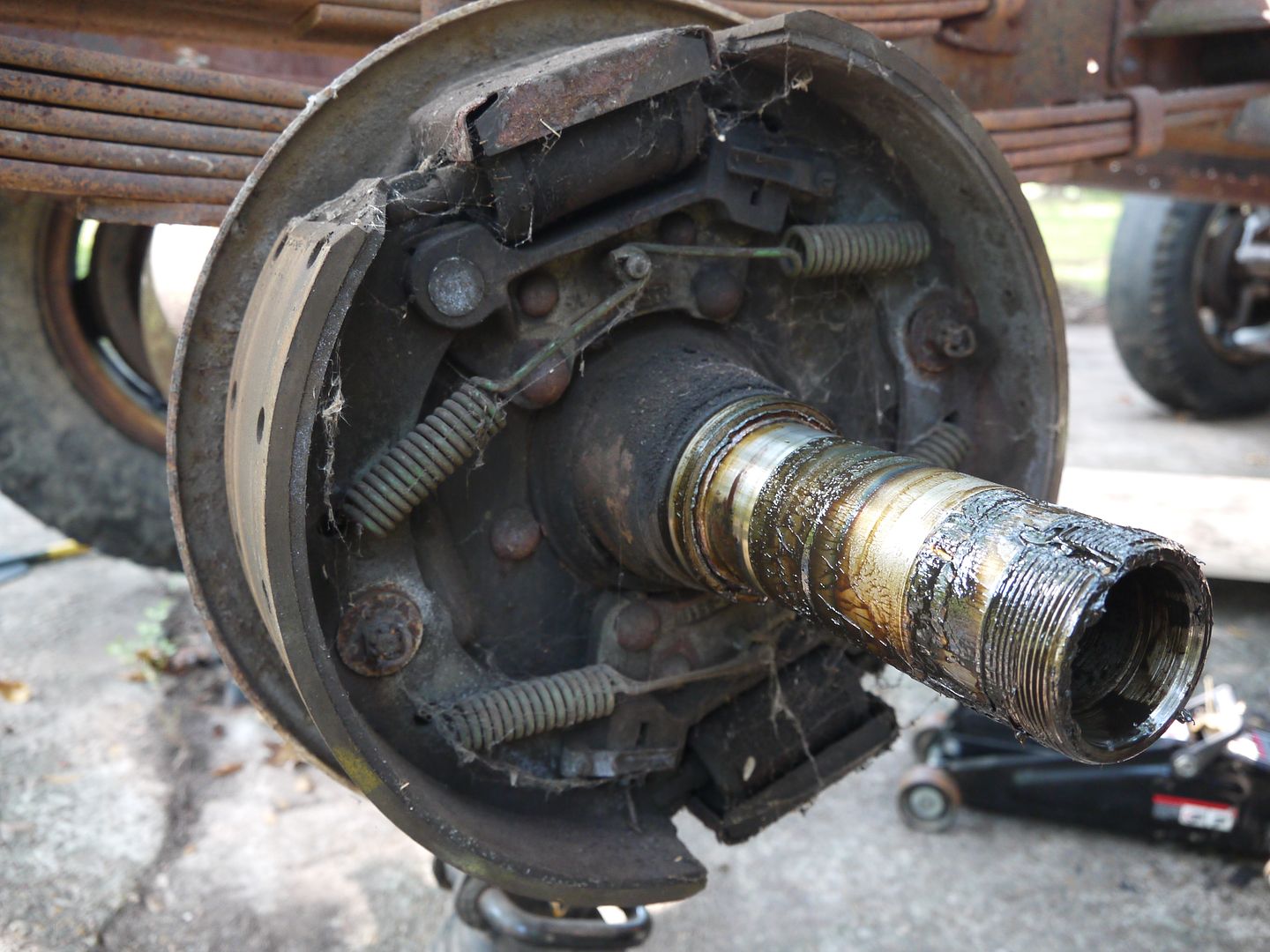

Never one to pass on a perfect setup, Mrs. Deuce spent the morning asking me about my big nuts and whether I was done playing with my rear end. I love that woman. ![]() It turns out there is an outer nut, a big washer with locking tabs, and then an inner nut. Took me a few minutes and some grease scraping to figure all that out.

It turns out there is an outer nut, a big washer with locking tabs, and then an inner nut. Took me a few minutes and some grease scraping to figure all that out.

Then the wheels slid right off with considerable effort and cursing.

I'll still complain about lug bolts, but my days of thinking the R63 wheels are heavy is over. The rear brakes are 15x4. There is a LOT of surface area.

I didn't actually pull these brakes apart. Once the drums were off I could bleed everything, mash the pedal, and the cylinders would move. I did a couple of cycles of expanding and pushing everything back in.

Then more cursing, assembly is the reverse, I did not engage the locking tab because things need to be rebuilt before any actual road driving, but I can spin the wheels up, climb into the cab, mash the brakes, and they stop. An hour and a half on the second wheel and now both rear wheels spin and stop meaning the entire hydraulic brake system works in the technical sense. With the stop part complete, now I need to work on the go.

I would consider new shoes (For Ferdinand's brakes, your Crocs are fine.) before a road test. I'm sure those are petrified and would offer very little stopping power.

So because you have two wheel cylinders per hub, does that mean you never have to adjust the brakes? Or is there adjustment stuff somewhere else in the hydraulic system.

There are adjusters front and rear. The fronts are little snail shell looking cams and the rears are the more usual star wheels that you adjust through a hole in the backing plate. The master only has so much fluid, and there are eight cylinders that need be moved, so I suspect it's pretty important to keep the brakes in adjustment. You want minimal cylinder movement before pad engagement.

If these brakes stay then all of the lines, wheel cylinders, shoes, and master will be replaced or rebuilt. Right now I just want to become familiar with the system and make it work well enough to be able to move around the yard once the motor is back together.

Just going to drop this here..

https://appleton.craigslist.org/cto/d/1988-ford-short-bus/6302966659.html

In reply to RossD :

"There is a queen mattress inside that can either be removed or stay depending on what you want to do."

Does he really expect anyone to NOT want the mattress?

In reply to mazdeuce :

I'd be afraid Dirty Mike and the boys used it for an F-Shack.

I mean, it practically has "Soup Kitchen" written all over it.

Can I get on that extra t-shirt list? I know I'm late but we had a few windy days down here that kept the power out for some reason.

btw: my extended family had a trucking business back in the 80's and 90's- and I'll never forget getting to ride from Chattanooga to Nashville in a big rig. I recall that smokey and the bandit came our sometime around then, which only added to the the cool, sort of odd family business. My grandfather worked at Chattanooga Kenworth for 30+ years and when he passed away last year- my dad ended up with all of those tools. He recently came down and brought my grandpas drag strip toolbox to me, complete with old stickers. It's held a place of honor on a shelf in my garage ever since. I've always figured I got my mechanical knack from him. This project has kicked up my interest in the bigger trucks again. We've got a 50's era medium duty truck for sale near my gym- may have to bring that baby home in grandpas honor.

Keep up the good work MD.

8cyl engine

8 brakes cyl..

Its almost a 888 truck (read AAA)

Make it a tow truck and call it ferdinan the triple 8 truck

Seriously, nice works so far, keep on wrenching :)

Would the harbor freight air powered eductor type vacuum pump draw enough vacuum to allow you to test the brake booster? Maybe park the pickup next to the ih and hook the ih booster to the pickup with a chunk of soft copper or maybe pex? I'm curious about how and if that thing works.

I know we talked about the air over hydraulic brakes as an option, but did you know that there is an electric over hydraulic option as well? I wonder if you could go direct from the master to a distribution block through a check valve for single circuit manual brakes, then add an old school pressure proportional trailer brake controller to electronically trigger a master cylinder that feeds into the hydraulic system downstream of the check valve? Normal operations would have the electronic master doing your braking and seating the check valve, but if that failed you would still have the manual you have now.

With multiple wheel cylinders at all 4 corners I'd be tempted to split the system into two circuits that each feed one cylinder on every wheel. One circuit failure takes out half of the brakes, but half of every wheel instead of half of the wheels.

grover said:My grandfather worked at Chattanooga Kenworth for 30+ years and when he passed away last year- my dad ended up with all of those tools. He recently came down and brought my grandpas drag strip toolbox to me, complete with old stickers. It's held a place of honor on a shelf in my garage ever since. I've always figured I got my mechanical knack from him.

I've recently converted over to tool bags for my track stuff... easier to jam into random corners of trunk space and lighter too. This quote, though, may have me rethinking that eventually... would have to build custom ones though.

mazdeuce said:There is a rhythm to working outside that I enjoy. I like rolling out with my coffee when it's just getting light and the air is heavy with moisture. The birds are singing, it's still cool out, great way to start the day. I think my ultimate garage would include a slab of concrete outdoors.

The other fun things that happened with the recent rain involved the exhaust that I tossed over to the side. If you remember, it was packed with mouse stuff including a ton of seeds.

Some of them are still good and decided to grow through the seams in an old joint. Small things like this make the outside worth it.

The other part of that outside morning rhythm is being able to take advantage of one of the two soft light 'golden hours'

Mrs. Deuce had a meeting this morning but it got done early and she surprised me by coming home and asking me out on a movie date. ![]()

She stopped on the way in the driveway because she was so impressed that I was wearing safety glasses, ear plugs and dust mask while grinding off the old welds.

I'll post more later, I've got a date with a hot chick!

I take back what I said earlier about your Crocs being fine. I forgot they were red.

Mine are camo. Much manlier. ![]()

You'll need to log in to post.