I didn't know that; thanks! I can still access the inside of the tubes, so I'll add some spacers.

It's also super easy to move a Miata shifter forward on the transmission and no you do not need to open the transmission up to do it. See the 4 bolts that hold the shifter housing on? They are about 4" apart. (Measure yours to be sure.)

Remove the shifter housing, at one point you will come across the piece that goes on the rod which goes into the transmission case. That's held on with a roll pin (possibly with a bolt, roll pin is more common).

Drive the roll pin out. Now mark the shift rod from the roll pin hole forward the same distance that the bolts are apart. Measure the original roll pin hole diameter and drill another one in this new poisition. Cut the same amount off the rod also.

Cut the same amount out of the shift rod tube (that's the tube from the shifter housing to the transmission) and weld it back together. The ends are formed, so you have to cut the extra out of the middle. You'll need a carbide burr to reach down inside the tube hole to grind off the excess weld.

Now cut the shifter housing just ahead of the rear set of bolt holes and reassemble the whole mess with the shifter in your new forward position. I added a brace from the side of the housing down to some tapped holes on my transmission to help make the whole thing rigid. RX7 transmission after the same mod:

Link to RX7Club thread on this: http://www.rx7club.com/1st-generation-specific-1979-1985-18/tii-tranny-fitment-sa-555938/

If the link doesn't work, go to RX7Club.com and search 'TII tranny in SA'.

This means you may yet be able to get your rack exactly where you want it!

Awesome! I'll keep that in mind if I need/want to move the shifter forward in the future. The engine position was finalized yesterday, so the rack will be where it will be.

Winston wrote: Awesome! I'll keep that in mind if I need/want to move the shifter forward in the future. The engine position was finalized yesterday, so the rack will be where it will be.

Finalized until you move it...![]()

Well, it seems that I got lucky (that's what she said). The 5 degrees of "nose up" engine tilt created just enough room underneath the oil pan for me to slide the rack a little further back. Now the inner tie rod ends are positioned where I originally wanted them. Sometimes it's better to be lucky than good.

There's about 1/4" of clearance between that bump on the oil pan and the rack body. I think that should be enough with my urethane motor mounts, but if it looks like it might become an issue I can add some spacers to raise the engine.

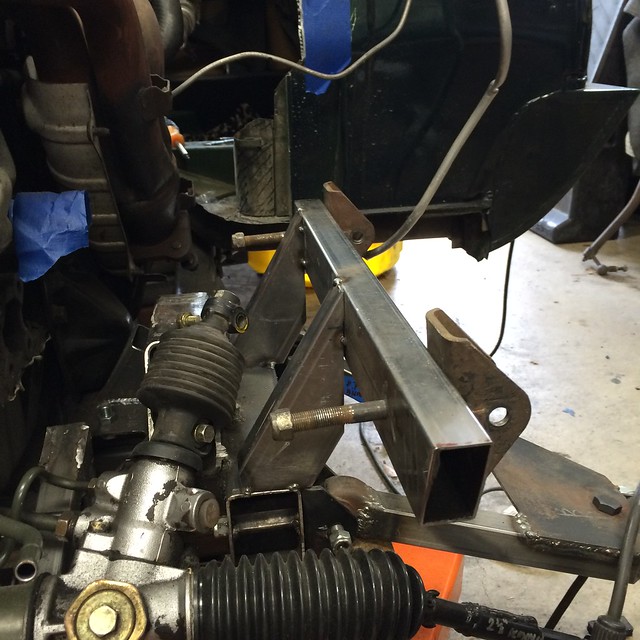

It did require even further trimming of the old chassis rail, so that the pinion has room. This is the third time I've trimmed this part. You can also see one of the spacers that I added at erohslc's prompting.

And a wide-angle view of the current state of things.

Next up:

Between karate tournaments, company outings, and kids' birthday parties, I haven't had much of a chance to melt metal during the past couple of weeks. However, I've been at the drawing boards when I got the chance, and this morning finally got the opportunity to crank out the beginnings of the steering rack crossmember.

First, we'll start with some 1"x2" 16swg tubing. A few slices with the chop saw, and we're underway:

Some passes with the trusty Weld-pak 100, and the pieces are joined.

For those of you scoring at home, this is where this piece goes:

I could just weld the crossmember in place, but I want to be able to drop the oil pan (if needed) without pulling the engine. I'm going to bolt this piece in two planes, parallel to the drivetrain as well as vertically. Those vertical bolts will need these:

And now they're welded in place.

The crossmember is then placed so that I can drill the holes for the other bolts. I'll say it again, cobalt drill bits are so nice compared to the cheap stuff.

Here is the piece removed again, so that you can see the holes.

That's where we'll pause for now. Next up: getting the actual steering rack mounts fabricated and attached to the crossmember.

Are you going to make control arms that are closer to the Miata design? Flat across the front instead of the equilateral triangle design of the Sptifire?

jgrewe wrote: Are you going to make control arms that are closer to the Miata design? Flat across the front instead of the equilateral triangle design of the Sptifire?

Yes -- for the lowers. The front "legs" of the lower A-arms won't be exactly perpendicular to the chassis, but very close.

The upper A-arms will be equilateral triangles.

I'm trying to take this Friday off work so that I can make up for lost progress. Unfortunately, the Baja needs a power steering pump and rear shocks so I'll be doing that as well.

Still, there will be more progress this weekend. Watch this space!

I've been working (here and there) on the steering rack crossmember during the past couple of weeks, and finally finished it yesterday. Started with a pair of these for each side:

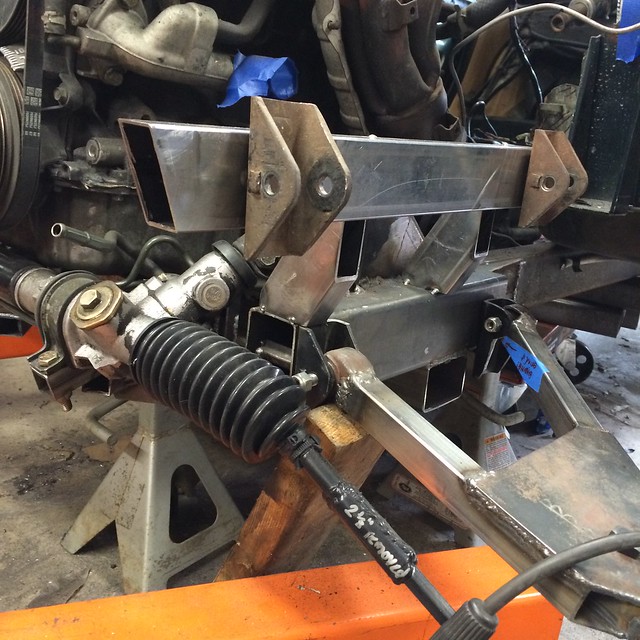

Mocking them up like so:

Then there was a bunch of fiddling around to make sure that the rack positioning was correct. Then welding happened:

Then I bolted the rack in so that I could see just how wide my track was.

Pretty wide. Around 2" on each side, give or take. Damn, I guess I'll have to shorten the tie rods after all. You can see just how far it sticks out past the widest part of the body in this shot:

Pretty wide. Around 2" on each side, give or take. Damn, I guess I'll have to shorten the tie rods after all. You can see just how far it sticks out past the widest part of the body in this shot:

When we last left our hero, the Spitfire's track was about 2" too wide on each side. So, the next order of business was to correct that. I took 2 1/8" out of each tie rod, then beveled the edges for butt welding. I purchased a small length of DOM tubing with ID slightly smaller (0.51") than the OD of the tie rod (0.55"). I then split it lengthwise and pried it open slightly such that it would fit snugly over the tie rod pieces. This would give me more weld area for increased peace of mind.

New tie rod vs. stock length tie rod:

This was then repeated for the other side, and the new tie rods and boots were installed. Time to re-fit the wheel to check my work (crosses fingers).

Looks good!

Looks good!

Now to start on the control arms. First, the driver's LCA. Step one, harvest bushing carriers (FYI, these control arms were a bit twisted, so it's not like I hacked up good parts).

Now to begin making the bracket that holds the Miata lower ball joint. First, I cut a couple 1"x3" tabs out of 11 ga. sheet (first drilling the bolt holes and then reaming them out to 12mm because I didn't have a bit that size):

Tabs drilled and cut:

The tab for the leading side has to be angled in order for the (future) tube to meet up with the bushing carrier:

Here's the beginnings of my mockup. I have the urethane bushings in the carriers with some 3/8" rod threaded through. Next step is to fix the rod and carriers in place so that I can keep them steady enough to cut accurate tubes. Stay tuned!

This is looking fantastic Winston. I'm enjoying following along and I can't wait to see it together.

Thanks, man. Each step forward makes me want to push a little harder to get this thing on the road -- and throwing up some rooster tails on the rallycross course!

I have an open seat auto crossing at the police academy tomorrow. I'm not sure if registration is still open, but if you want to drive just let me know.

Thanks a bunch for the offer, but I think I need to take care of some household chores tomorrow -- and hopefully get more done on this car. I'm really chomping to push my way past this suspension stuff and into the other systems.

Before I packed it in for the evening, I cut the more difficult of the two tubes for the LCA. A hole saw, protractor, chop saw, angle grinder, and bench grinder got together in my brain and produced this:

Like a glove! Before I tack it in place, I'll use it as a template to make its evil twin for the other side of the car. I REALLY hope I don't ever have to remake this thing. Since I plan on rallycrossing this car, I'll probably heavily reinforce the LCAs after the general structure is there.

Like a glove! Before I tack it in place, I'll use it as a template to make its evil twin for the other side of the car. I REALLY hope I don't ever have to remake this thing. Since I plan on rallycrossing this car, I'll probably heavily reinforce the LCAs after the general structure is there.

I was kind of hoping you'd say that. Not because I don't want you in my car, I do, but because I want to see your car get done. It's going to be the prettiest rallycross car in Texas.

![]()

Nice project and very impressive work! I'm following it too.

I guess never related to the idea of stuffing V8s in these little British cars. You are bringing that Spit back to where it should be!

Keep up the good work!

mazdeuce wrote: I was kind of hoping you'd say that. Not because I don't want you in my car, I do, but because I want to see your car get done. It's going to be the prettiest rallycross car in Texas.

Thanks! I do feel that my fabrication skills are getting better as I'm working on this project.

Since I'm using this thread as a secondary repository for my notes on this project, here are some bits of information for me:

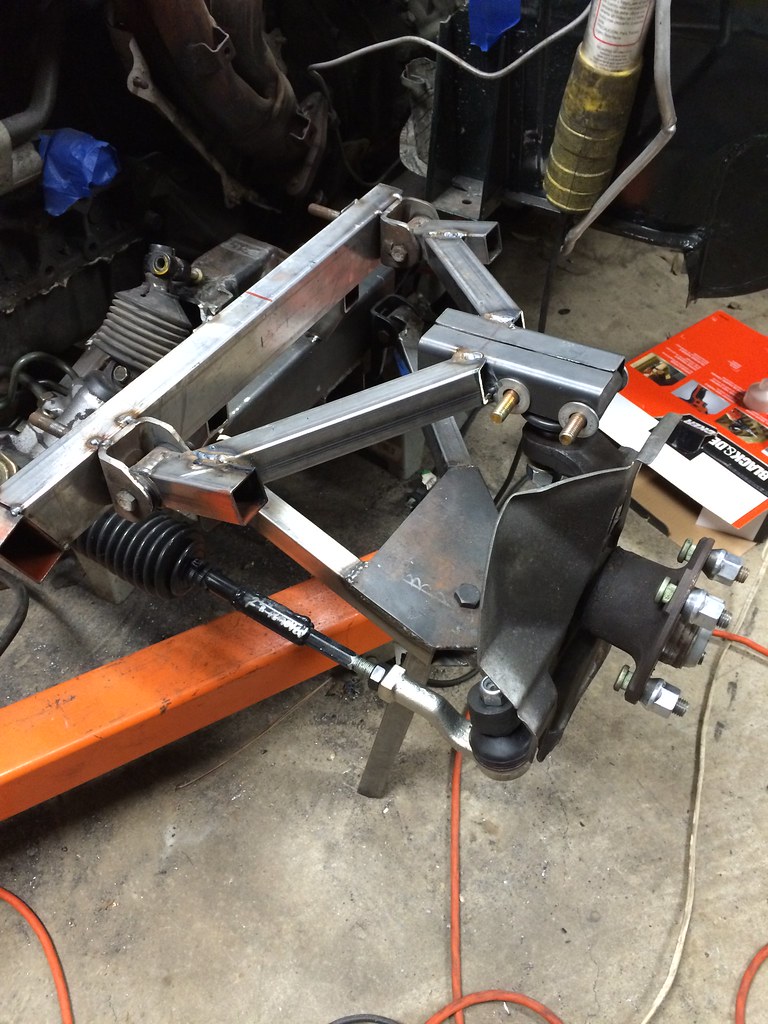

This morning's work:

Aft leg measured, cut, and tacked in.

Shock support tube cut and tacked in. Now to see if this crazy thing even fits the car.

Success! Okay, now I can't help myself.

This feels pretty good. Now for the top plate. Cut from the same 11 ga. sheet, it's pretty beefy.

Underside.

Whew! One side done. That only took... 5 hours?! Well, to be fair I was cutting the mirror image tubes and plate for the other side at the same time. Undoubtedly that one will go much more quickly.

Winston,I'm new to this commenting but just a inquiry.Why did you cut and weld your tierod when you can just grind down the rod ie;round off the hex on the rod ,thread the rod further along and cut off the excess.I have just done this on mineThis would be much safer and stronger.In New Zealand we are not allowed to cut and weld steering parts.

Well, it's been almost a year and half since my last update. What have I been doing this whole time?

Mostly just polishing my knob.

Before: After:

After:

Oh, and the e-brake handle as well:

Into:

Into:

Also received a lovely Nardi (knock-off?) wheel from my lovely bride for our anniversary this past year:

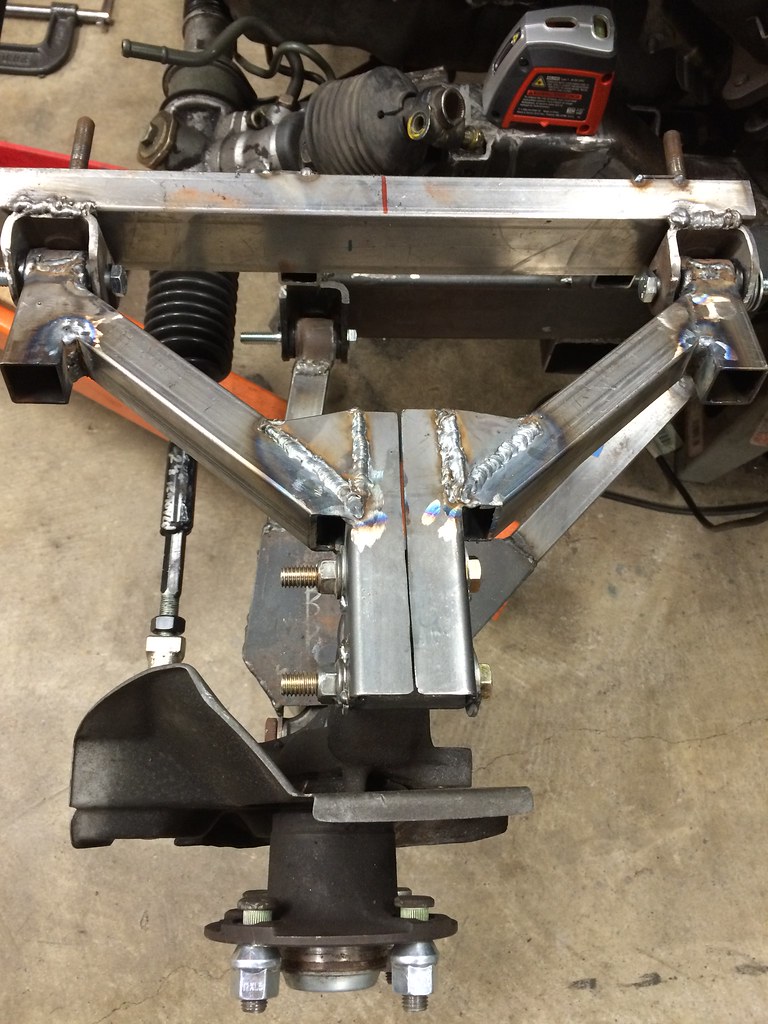

And this weekend I finally knocked out the passenger side lower A-arm:

kiwipete wrote: Winston,I'm new to this commenting but just a inquiry.Why did you cut and weld your tierod when you can just grind down the rod ie;round off the hex on the rod ,thread the rod further along and cut off the excess.I have just done this on mineThis would be much safer and stronger.In New Zealand we are not allowed to cut and weld steering parts.

Pete (if you're still around), that is probably the easiest and smartest way. I don't have the proper set of dies to cut the Miata thread. However, I'm confident in my cut/weld job. When it comes time to replace these tie rods, I'll order the die and shorten them as you describe.

EDIT: Sorry for the giant pics. Flickr has changed their site in the last year and a half, and I wasn't able to find the links to the reduced sizes... I'll work on that.

Time to work on the rest of the suspension.

First, some maths (yes, I know that the two angles are complementary, but calculating both allowed me to check my work)...

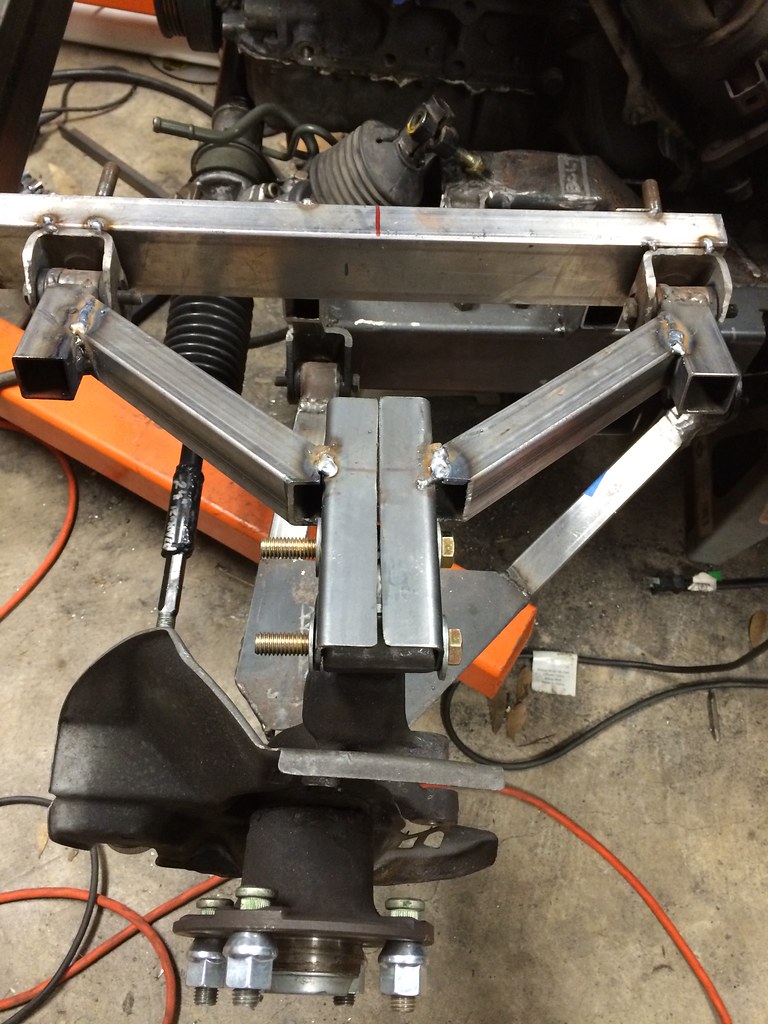

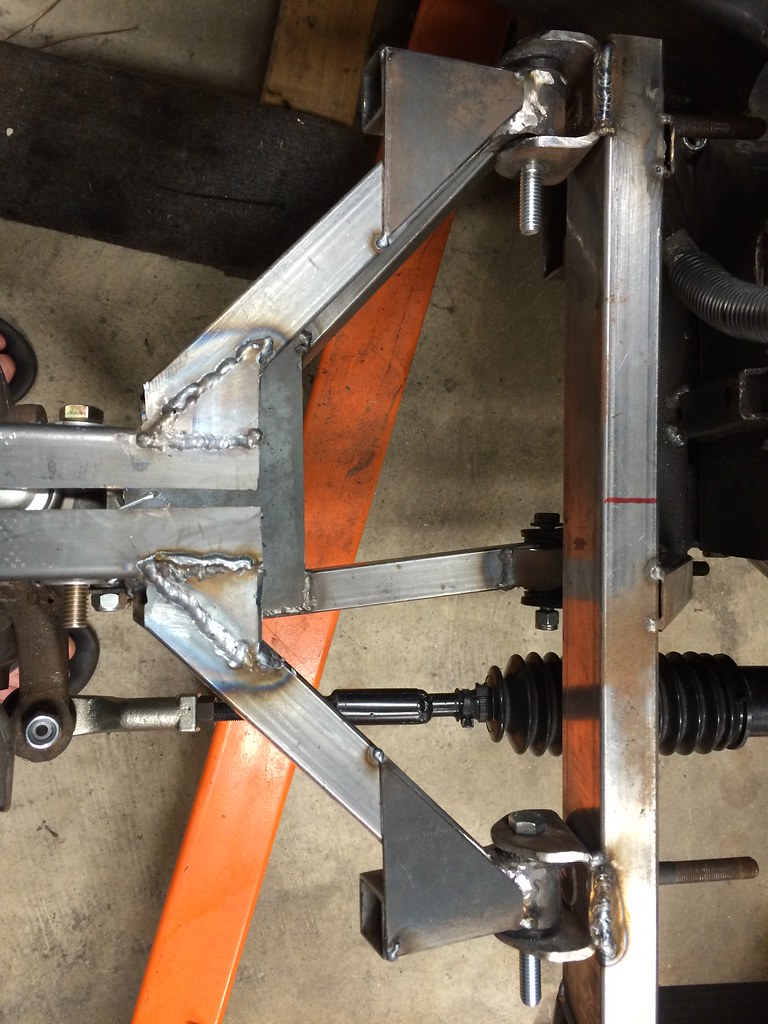

First to cut the vertical pieces for the upper control arm support structure:

Anti-crush inserts/guides for the control arm brackets (using the stock Spitfire brackets since I have them):

Welded in:

Ground down:

Structure tacked in place with brackets:

I actually screwed up a little bit and accidentally made the bracket mounting holes 13" apart instead of the planned 14"; however, since I haven't yet made the upper control arms, it's no big deal. I just need to re-dimension them.

The structure extends forward past the front of the engine, and will allow me to tie the two sides together with a crossbar. The crossbar will also provide a jumping-off point for the bodywork/bumper support structure that will give the bonnet and radiator (and probably an anti-roll bar at some point) a place to sit.

The build continues to plod along slowly. Actually, I usually work on it in bursts, then nothing for a while... as you can probably tell. At any rate, I've been pushing myself to finish up the suspension. I think that if the front end looks more like a car instead of a Cessna with the cowl off, it'll motivate me to keep pushing forward.

I took a big, scary step and drilled my Miata spindles to accept the TR6 upper ball joint. The initial bore-out was done with a 5/8" bit, then finished with a 7 degree taper reamer to match the ball joint. It only took me three spindles to end up with two usable ones! After doing a decent job with the passenger spindle on my first try, I got a little cocky on the first driver's spindle and ended up drilling at an angle. I couldn't save it with the reamer (because I didn't notice quickly enough), and had to order another spindle off of eBay. This time I took a lot of extra time to make sure that I was drilling straight, and it turned out great. Here's the passenger's spindle, along with the implements of destruction, and the first driver's spindle (pre-botch job):

Then I got to work on the upper A-arms. I cut and split some 2x3 steel tube and drilled the requisite holes to make the two sides of the ball joint cradle. I re-used the bushing carriers (as with the lower a-arms) and cut steel tube to mate them all up. I'll be adding a little plate at each joint to increase strength, but you get the idea:

Both sides near complete. Also, you can see the cross-member I added.

I happened to look at the data tag in the Spit's door jamb the other day, and noticed that my car was built in May of 1976. So, in about 42 weeks, my car will turn 40. I think that getting it on the road by then (not "finished", just tagged and inspected) is a reasonably achievable goal. To keep me honest (and provide a little extra motivation), I'm going to provide weekly updates on my progress, typically posted Sunday or Monday. Without further ado:

42 weeks remaining.

I'm continuing to make the push toward sitting the car on four wheels, which involves making sure all of the suspension is strong/fully welded. I reinforced both upper A-arms at the ball joint end.

Fully welded, just missing reinforcing plates at the bushing end and they'll be totally done.

I also picked up some extra 3/8" a-arm-to-chassis bolts from the hardware store, since I only had enough to do one side (I'm using two sets of Spitfire lower a-arm brackets to get all eight brackets). I'm basically ready to order my coilovers, since I'd really like to have them in hand for reference when building the mounts. I'm probably going to order from Viking Performance. Anyone have anything good/bad to say about them?

http://www.vi-king.com/

41 weeks remaining.

I spent most of my garage time this week/weekend in cleaning mode. Though that means that not much got done on the car itself, the upside is that it will make it easier to work on it.

I finished up the upper a-arms with another set of gussets, and that's basically all that got done other than some staring and thinking, measuring and planning.

I also added some small gussets on the lower a-arms.

I'm still undecided about whether or not to further reinforce the rear tube of the lower a-arms. It carries basically all of the loads introduced into the lower arm. I was thinking of "half-sleeving" it by splitting some 16swg square tubing into two L-channels, then welding those onto the existing 16swg tubes. Anybody have any thoughts about this?

There won't be any progress the next two weeks, nor an update on 7/27 since we're flying to London on Friday for vacation. I don't see my housesitters (in-laws) doing any work on the car while we're gone :) Maybe I'll have some pictures from the Lotus factory (doubtful, pictures are forbidden) or classic Team Lotus workshop (likely) for the 8/3 update.

You'll need to log in to post.