Wednesday nights are generally the evening when I have the most amount of uninterrupted time I can work out in the garage due to SWMBO's work schedule (she doesn't get home until fairly late), so I took the time to tackle things on the rear of the car as I had planned.

At the end of the evening, the remaining original Rampage exhaust is off the car as well as the spare tire (which may be original to the car- it looks OLD). The only real casualty of the evening was the forward spare tire hanger, (looooong threaded piece) which snapped in half as I tried to loosen the nut to lower the tire down. No real loss- I can probably actually still use it as is or make a new one (or for the drive to the Challenge, just keep the spare in the bed).

I also got the gas tank out and cracked open (not literally- by removing the sending unit like you're supposed to) to inspect it and try and figure out how to handle the high-pressure fuel pump the engine needs. The good news is that the inside of the tank looks GREAT- it looks brand new inside, even if the gas that was still in it smelled pretty horrible. I was able to get the majority of the old, bad gas out and into a gas can (hello, lawnmower fuel...) and what little remains should be diluted to harmlessness when I fill it back up with new gas.

The problem I'm left with now is- still- how to handle the fuel pump. It should be possible to fabricate a way to use the original sending unit (which I should test to see if the fuel level sender is actually working or not first...), but it's not going to be particularly simple. Here's what the Rampage in-tank sending unit looks like:

Ideally, the thing to do would be to cut the pickup line inside the tank and attach the high-pressure pump to that. The problem with that is that 1. there isn't anything to secure the pump to if that line is cut, so it would largely just flop around and 2. the sender itself is mounted to that line. It's obviously far from impossible to get around this- I'd need to attach another brace that would hold the current pickup tube out near the sending unit, but out a section of it in the middle where the pump would be mounted, and secure the pump to the new brace. Not difficult to do I imagine- but at the same time, I don't have the tools necessary to do it here at the moment. It may be possible to simply cut the section out and put the pump in place and find a way to secure it without having to weld- I guess I'll have to see.

I can understand though why it was recommended to get an Omni sending unit- it's clearly far easier to handle since I could just pull the TBI pump and replace it with the high-pressure pump:

The problem with that, obviously, is that it would cost $100 to do so unless I can come up with a used one (as well as needing the connector for it, which I imagine would only be available used...).

Is there a sump around the pickup?

Dusterbd13 said:

Is there a sump around the pickup?

I assume you mean an additional line into the tank, like the one with the blue hose on it in the picture of the Omni's unit? Unfortunately no- there isn't one on the Rampage.

Nope. Im thinking alsong the lines of a sheetmetal breadpan welded into the tank at the point the sending unit picks up fuel. If there is, you ca use a rail mounted pump like an e2000 without concern of starvation.

Stefan

MegaDork

9/28/17 11:21 a.m.

I was thinking you could trim the pickup of the original sender and mount the inline pump next to the return line with some zip ties.

The stock pump setup on the later cars mostly uses the hose to hold the pump with a zip tie.

For the bulkhead wiring, you just need two sealed and isolated through bolts with ring connectors. I think I posted a link on the previous page.

Unfortunately, I won't have time to look for a MAP sensor before I go on vacation (traveling with a toddler is way more work than one ever imagines), but I'll try to dig one up when I get back in a week.

So, somewhat frustratingly it's going to be until early next week it looks like before many of the parts I need to really move forward will get here (the internal pump, for example, is supposed to show up Monday...), which means that there's a limited amount that I can actually do with the engine until then.

Since the hoses are in there, I can't really put the cooling system together and do anything with it. I can (and probably will) fill the rad with vinegar to try and clean the inside of it up a bit. I can also change the oil at least.

One thing that I am considering in the 'down time' (besides trying to get the Jeep's transmission sorted out so I can use it, though unfortunately a part I'm likely to need for that is also in one of the shipments arriving early next week...) is trying to do something about some of the rusted-through sections of the underside of the bed. I don't see any places that I think will be a real problem structurally, but if I can reinforce a few areas it will likely help. The downside is that I don't currently have a welder- but am thinking that for this particular application I may be able to get by with snagging a cheap HF flux-core welder and using that.

I also want to see how well it looks like a racing seat will work in the cabin- the stock seats are actually not bad IMO and would probably work (and likely be far more comfortable for the drive down and back...), but I want to see how well the race seat will work in case I can bring it and quickly swap it in at the race.

Still on the fence regarding how much if anything from the cabin that I want to remove. Honestly I doubt that the carpet and door panels weigh much of anything, so I may just plan on leaving those in place. Either the speakers don't work, the wiring is shot/hooked up wrong, or the old (but not likely original to the car) tape-deck head unit is on the fritz- but I'm debating whether to put I the cheap no-mech unit I have for the drive down or if I want to just use the independent speaker box and rig up a way to have the no-mech unit hooked up to it and plugged in.

Stefan said:

I was thinking you could trim the pickup of the original sender and mount the inline pump next to the return line with some zip ties.

The stock pump setup on the later cars mostly uses the hose to hold the pump with a zip tie.

For the bulkhead wiring, you just need two sealed and isolated through bolts with ring connectors. I think I posted a link on the previous page.

Unfortunately, I won't have time to look for a MAP sensor before I go on vacation (traveling with a toddler is way more work than one ever imagines), but I'll try to dig one up when I get back in a week.

Unfortunately the return line is mostly flexible hose vs. solid line. I may be able to figure something out- but won't really be able to until I get the pump in early next week. Of course, I could always jury-rig up the external in-line pump to pull from a gas can- but until I get a MAP sensor (I have one on order as well in case you don't have one and/or I can't find one used- would obviously prefer a used one since the new ones cost $50...) there's no point in doing that.

Don't worry about it- the MAP sensor (and the combo electrical/mechanical speed sensor if you have one) can wait a bit.

I'm not seeing a link to the sealed isolated bolts for the connectors, I'd definitely be interested in that since I've not been having any real luck in finding something that I think would be safe/work. Thanks!

One option, external pump.

Can still use a return line. Use a T fitting, right at the tank connection. Mount the pump as low as practical, under the car. Run the line from the T fitting to the pump. This is similar to how my Maserati is set-up, only the fitting to the tank is under the tank.

If you want a used pump and T fitting, let me know. Not sure of the pressure rating of this pump, but it might work. There are fuel injection cars that used external pumps, although most do use a in tank pump.

The heavy part of the door is the crash bar, the rest typically doesn't weigh much.

In reply to TED_fiestaHP :

I have an external pump as well, but as I said in earlier posts, there are issues with it as well- there's not a really good, safe place to mount it under the car and where I can probably mount it will require running a good bit of new line- line which would likely need to be stainless-shrouded to be safe exposed under the car, so it would add more to the budget (in addition to the external pump costing around twice what the internal one cost). Both are still options though- but the internal would be best if I can make it work.

Since I'm not planning on putting a cage into the truck, I'm not planning on removing any primary structure like the crash bars. Hell, given I've got to drive it 10 hours each way to and from the Challenge, I've pondered how difficult it would be to install the column from the LeBaron that came with it and getting the airbag functional!

For budget, the used pump I have would be free. You could claim a used pump has very little value. Some Volvo's used a external pump as well, I think the 700 series. If I recall properly my 760 turbo wagon had a external pump.

In reply to TED_fiestaHP :

I'll keep that in mind- I may have a source for a used Omni sender with a high-pressure pump & the harness connection that would make all of this a whole lot easier...

WOW, how the hell did I miss those pictures on the first page?!

I recently had to deal with a real PITA regarding Dodges and wiring harness connectors. After a great deal of research and ultimately doing Google image searches out of desperation I found out 2004-2005 Dodge Ram's use the same 4-pin connector on their wiper motors that GM used to retrofit fuel pump connectors through the late 90's. Dodge however doesn't seem to even acknowledge this 04-05 design ever even existed. (They don't even sell the correct wiper motor anymore) It was just dumb luck I remembered the connector looked similar to my brothers Seville that I just happened to recently replace.

Point being, you may be able to find that connector somewhere else should your lead wash out.

Well BERK. >:(

Just got a note from Amazon, "Hey, that fuel pump you ordered 2 days ago? We just realized it's out of stock. Sorry!"

Hopefully the guy who has the Omni senders is right and he has one that already has a 255 pump installed...

Gah... I hate decisions like this.

So I can get an Omni sender with a Walpro 255 pump, the wiring connector/pigtail necessary to wire it up, and a few water fittings I need from a guy from the TD forums for $100 shipped. It will basically be a plug-and-play solution except for having to wire up the fuel pump power relay (since mine had a mechanical fuel pump originally) which I already have most of figured out.

Alternatively, I could take TED up on his external pump (assuming it puts out enough pressure) for relatively little budget hit but need to work out where to put it as well as hose/piping for it (figure $20-30 for hose and fittings, most likely)... but will definitely take more time to implement.

Honestly, despite the considerable (1/20th of my budget...) hit, it's very tempting to just go with the Omni setup...

Hit the easy button. Youre out of time. Worry about budget cutting next year.

Dusterbd13 said:

Hit the easy button. Youre out of time. Worry about budget cutting next year.

THats what I’m going to do- the guy also has a whole lot of turbododge parts in general so will be a good resource for any other parts I find I need.

I definitely lucked out in finding the seller that I did- am getting the TBI sender with a Walpro 255 and the wiring pigtail, an MAP & barometric solenoid setup, and a fitting for the water system for $100- that should be everything I need to get the engine running now.

So, looking ahead a bit to potential engine improvements down the line- one of the first things that comes to mind with this engine which doesn’t from the factory have an intercooler is, of course, adding one.

But- what I’m curious about is whether without getting the computer re-flashed, is that actually going to do any real good? In stock form (note: I’ll likely have a MBC/Graingrt valve as well) can the computer take advantage of having the intercooler?

Somehow the injection should read the air flow coming into the engine. Colder air should be seen as more air.

But regardless of the injection system, a intercooler will be a good idea, and if you turn up the boost it will help keep things from going bad.

I have a pair of intercoolers I have been attempting to give away, since they didn't fit what I had planned to use them for. You can find the same thing on Ebay fairly cheap, so not a big budget hit for fair market value.

TED_fiestaHP said:

Somehow the injection should read the air flow coming into the engine. Colder air should be seen as more air.

But regardless of the injection system, a intercooler will be a good idea, and if you turn up the boost it will help keep things from going bad.

I have a pair of intercoolers I have been attempting to give away, since they didn't fit what I had planned to use them for. You can find the same thing on Ebay fairly cheap, so not a big budget hit for fair market value.

Yeah, I figured that having the cooler air charger would help even if the computer weren't trying to compensate for it.

I'd be interested in hearing the details about the intercoolers you've got if you want to PM me about them. Thanks!

Stefan

MegaDork

10/2/17 9:01 a.m.

The computer is a bit limited by the sensors it has. The Speed Density system is a bit limited in this way, it has to calculate the amount of fuel and spark based on the engine speed, map values and oxygen sensor content.

that said, the engine responds quite nicely to a positive change in the ambient air temp and pressure.

all you need to do is drive a turbocharged car on a cool, crisp fall day. It's nature's intercooler.

so an intercooler will help. Reprogramming the ECU is the preferred method of increasing the boost and it can be DIY'd on these cars with a PROM burner and some soldering skills. A granger valve is nearly as effective, but you have to pay attention to it and make the occasional adjustment.

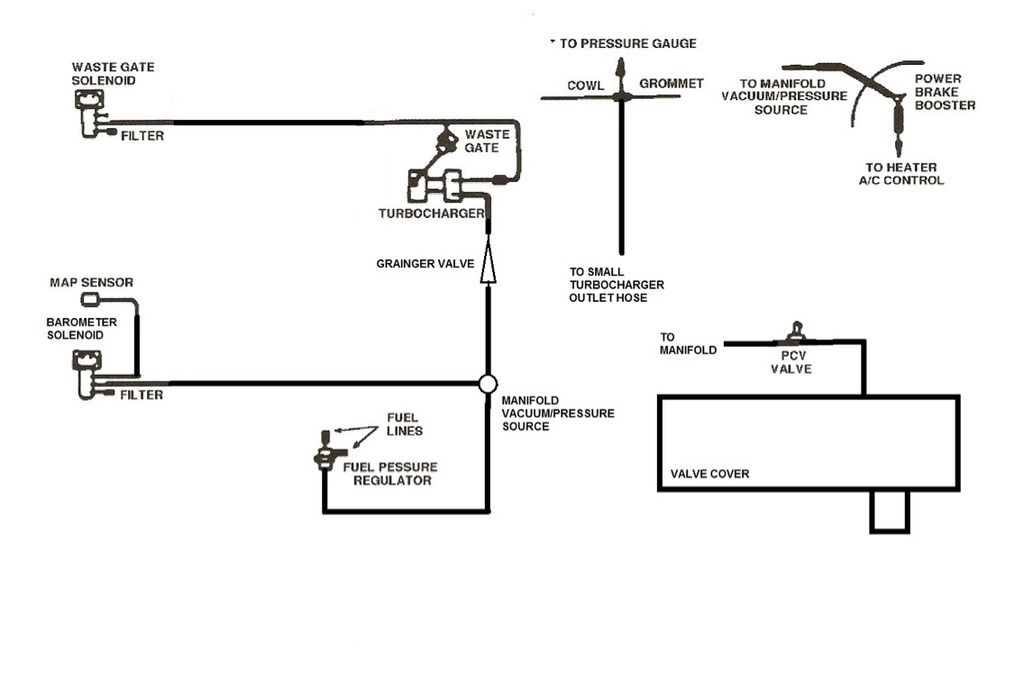

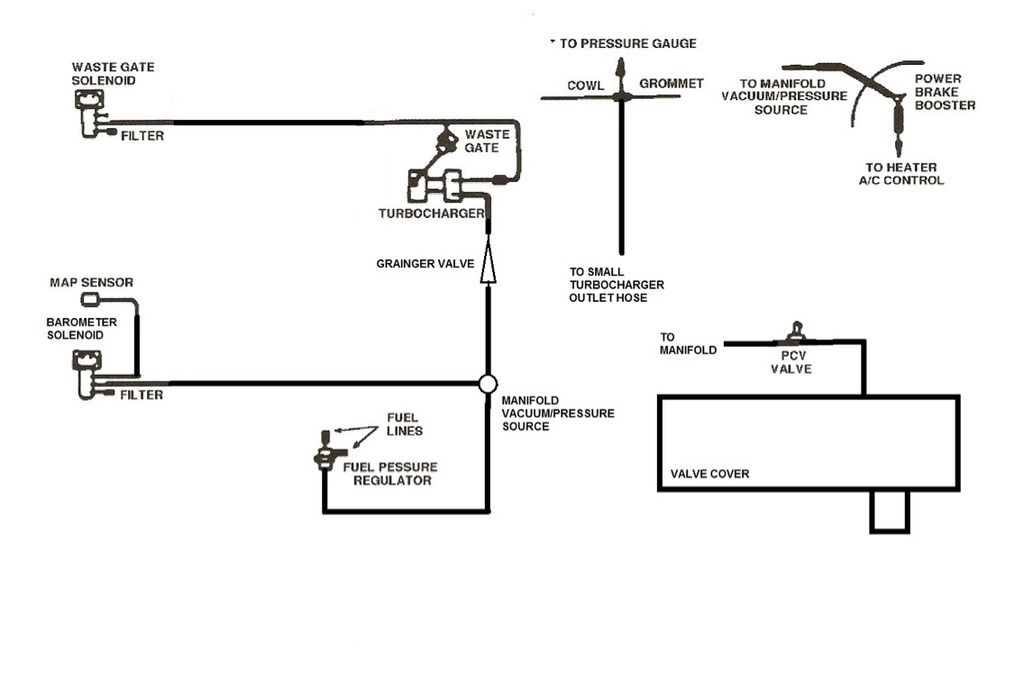

So, the Grainger valve arrived today along with a few parts from RockAuto, and I was doing some looking at the vacuum system to try and work out exactly what needed to be done... and even with the diagram (or perhaps because it's a bit confusing). Here's what I've found for the vacuum diagram for the LeBaron:

So, I'm (unsurprisingly) losing the vapor canister/purge system. If I'm understanding things correctly, if I'm putting in an intercooler and cone filter intake I can essentially lose everything but:

- The wastegate solenoid

- The MAP/barometric solenoid

- Line to fuel pressure regulator

- Brake booster (pretty much its own connection anyway, and the climate control line tees off from it)

Does that mean that I don't need any of the lines coming off the throttle body?

How exactly does the Grainger valve hook in to the system? It looks like the line to the wastegate solenoid is not at all hooked up to vacuum/boost but just to the solenoid (which vents to open air?)- does the line coming down from the turbo in the diagram above go to the manifold vac source, and if so is that where the Grainger valve goes?

If I lose the stock intake and the compressor bypass system, do I need to put in a blow-off valve, or does the stock wastegate handle that task?

So, I mocked this up pretty quickly at work- is this about right for what’ve I’ll need/want for vac hookups?

Also... getting ready for the hoses and such hopefully arriving today I was taking a closer look at the Rampage's stock rad- and I'm definitely concerned about whether it's going to be usable. That upper hose connection is really not remotely circular (and I don't know how to get it back to be such) so I'm not sure I'm going to be able to get a solid seal around it. I may have to revisit using the LeBaron's rad- it's going to take some work to get it to fit properly though (probably involving some welding to move a support tab over a bit.

The advantage to that is that I will get a larger rad out of the deal and better cooling if I can make it work (all at zero budget hit since the LeB rad came with the car).

Pat

HalfDork

10/3/17 5:34 p.m.

The vacuum harness can be extremely simple, especially if you are using a manual boost controller.

From a manifold feed source off the plenum, feed brake booster with a 3/8" line. Tee that line to source the grainger valve boost source. You don't need the boost control solenoid at all for boost control, so no vacuum hoses needed (but you'll want the solenoid plugged into the harness so you don't set off the CEL)

From another plenum source, feed the fuel pressure reg and the baro/map/boost gauge (if running one).

That is all you'll need.