Just posted Part 9 of the Video Build Series

Progress.

The radiator is back in and connected

Also, the heater hose fittings/hoses/shutoff valves and all of the gauge sending units

Engine is ready for fluids

A little progress is better than no progress. Pulled the distributor and spun the oil pump to prime the engine. Started installing the carb and noticed that the factory supplied air cleaner will not fit. Ordered and spacer to raise up the air cleaner and also a bracket for the throttle cable and one piece fuel line for the holley carb.

It is possible to get the air cleaner base in place, but it is jammed up against the distributor.

Woohoo that's starting to look nice. Was wondering if you are going to make the fold down gates for this that are on the original truck?

brad131a4 wrote: Woohoo that's starting to look nice. Was wondering if you are going to make the fold down gates for this that are on the original truck?

No, just a fairly shallow bed. I may try to wheel the metal to mimic the lines of the bed sides.

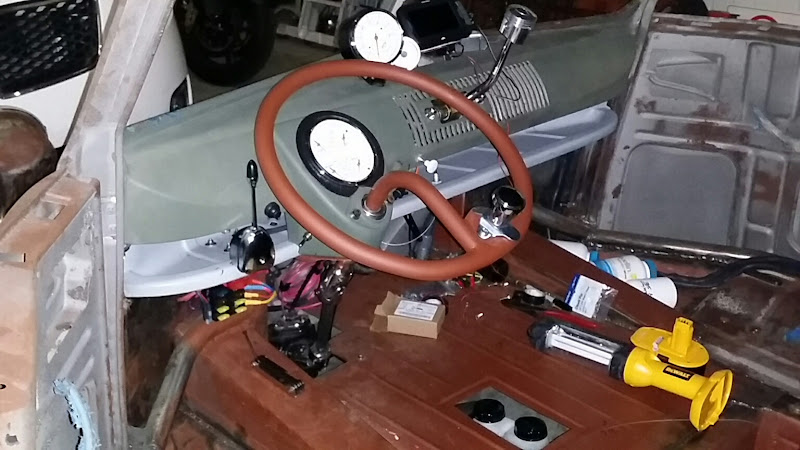

Making good progress on the wiring harness. I started at the rear lights and have made it to the rear wall of the cab.

So far: Tali lights / blinkers/ running lights / reverse lamp / back up camera / tag light / gas tank sending unit / Trailer light plug / radiator and transcoder fans / All gauge leads / Distributer 12v / tach / electric choke Starter / alternator / rear cab wall bulkhead connectors

The diy multi pin plugs make things a lot easier

Got something done on several things today.

Routed the negative cable in conduit under the cab, but ran short on clamps. Most of the wiring is complete at this point!

Stripped the seat frames of the ragged remains of seat covers. Also ran a wire wheel on an angle grinder over everything. Then sprayed them with rusty metal primer.

Rough cut some sheet metal to fill in the rear fender along the frame rails. Need to run them thru the bead roller and weld in. This is the last of the welding before I can put gas in the tank!

Ben_Modified can you shoot me a link the diy multi pin plugs you are using? I have been looking for some kind of multi wire plugs to rewire my motorcycle. I have seen some but nothing worth pulling the trigger on. Maybe I haven't been looking hard enoug.

Whoa . . . just now realized that your build is in raw metal and random primer! Does this mean that you'll have to completely take it apart for paint, or are you gonna leave it nice and raw and let rust and patina take is course?

Wondering. REALLY wondering !

Skervey wrote: Ben_Modified can you shoot me a link the diy multi pin plugs you are using? I have been looking for some kind of multi wire plugs to rewire my motorcycle. I have seen some but nothing worth pulling the trigger on. Maybe I haven't been looking hard enoug.

This first link is a variety pack that I really like. Nice connectors and the pins accept the solder well.

Here is a link to a variety of similar products. I have used the Ron Francis and Painless products as well.

TeamEvil wrote: Whoa . . . just now realized that your build is in raw metal and random primer! Does this mean that you'll have to completely take it apart for paint, or are you gonna leave it nice and raw and let rust and patina take is course? Wondering. REALLY wondering !

The metal is already badly pitted and I am not interested in slathering body filler on it, so I plan to use some bed liner material in some key areas as well as under and inside the cab and a high impact color on parts of the cab and bed. I will need to disassemble to a degree. The cab will come back off so that I can finish welding the underside of the floor. Also need to build a cage for the cab, so paint is still a long way off. I want to get it running first and work out any bugs and enjoy it for a bit before I pull it all apart again. I live in a area with high humidity and lots of salt and sand. If i left it in raw metal it wouldn't last very long!

The wiring harness is done and installed. Hope to test it tomorrow and also fix some imperfections in the steering wheel.

Started shopping around for an upholsterer to wrap the steering wheel in leather. So far an estimate of $120. Reinstalled it for the time being. Also welded a bracket on to mount a spinner.

Tested the wiring harness. Couple of small issues, nothing major.

Ok it looks to me you might have been a electrician in a past life. Noticed the copper busbar laying on the ground plus the use of sealtite for covering the wire just screams inside wireman.

brad131a4 wrote: Ok it looks to me you might have been a electrician in a past life. Noticed the copper busbar laying on the ground plus the use of sealtite for covering the wire just screams inside wireman.

Good guess, but no. I have been using the heatshrink tubing for years...good stuff. The busbar is actually a piece of copper water pipe that I have flattened with a hammer. Somebody showed me this great trick a while back to easily butt weld thin gauge panels together. You place it behind the gap in the panels. The copper will conduct so you can weld directly to it and spread the bead to the steel panels, but the weld will not stick to the copper. Great for filling gaps. The copper gets really hot, so after I flatten it out I put a bend on the end to clamp on a pair of vise grips.

Huh I was talking more about the bar under the seat frames. Funny thing is I do know about that copper trick. I came about it from a old timer welder years ago when I first tried welding. I like heat shrink as well it just finishes up wiring so nicely. I was talking more of the grey conduit. That's used mainly for outside connections in commercial or industrial applications. Still looking good can't wait to see it finished.

brad131a4 wrote: Huh I was talking more about the bar under the seat frames. Funny thing is I do know about that copper trick. I came about it from a old timer welder years ago when I first tried welding. I like heat shrink as well it just finishes up wiring so nicely. I was talking more of the grey conduit. That's used mainly for outside connections in commercial or industrial applications. Still looking good can't wait to see it finished.

Thanks! Should be able to fire it up soon!

You'll need to log in to post.