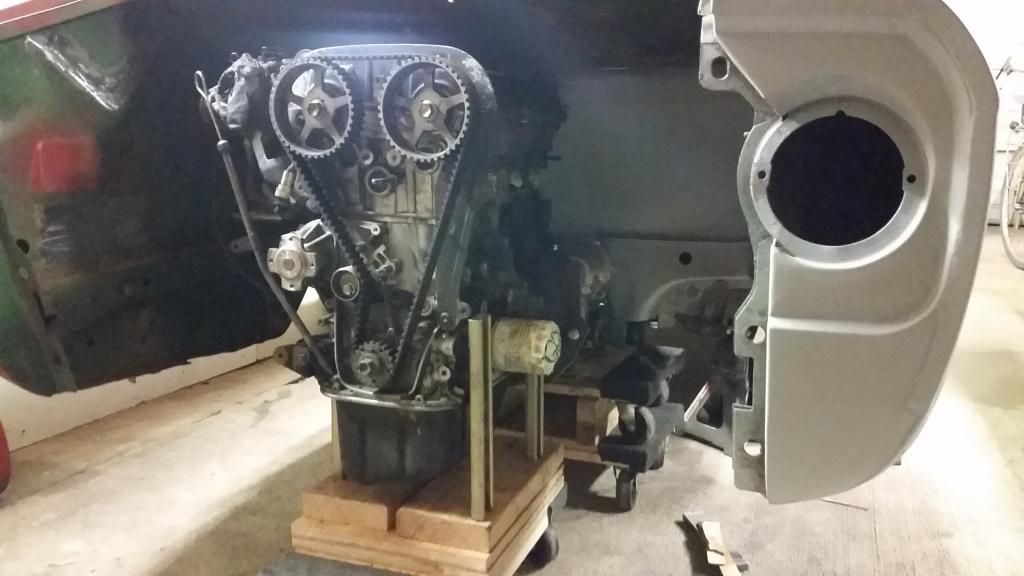

Wow. I can't believe it's been almost a month since I posted an update. I've been setting little arbitrary goals along the way and this month's goal was to have the engine and transmission mounted and leveled and get the car back to being a roller. I've only just made that deadline, too.

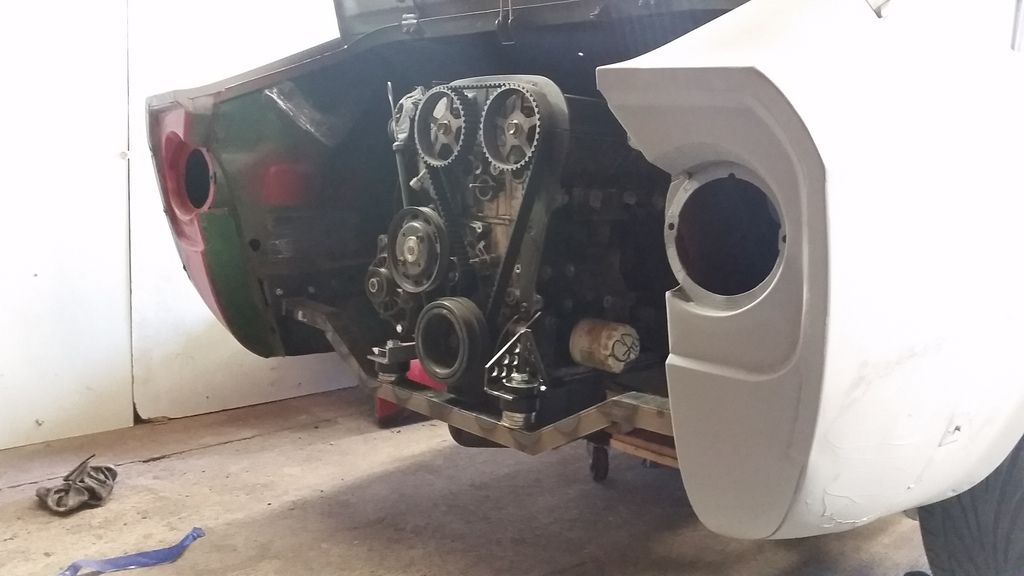

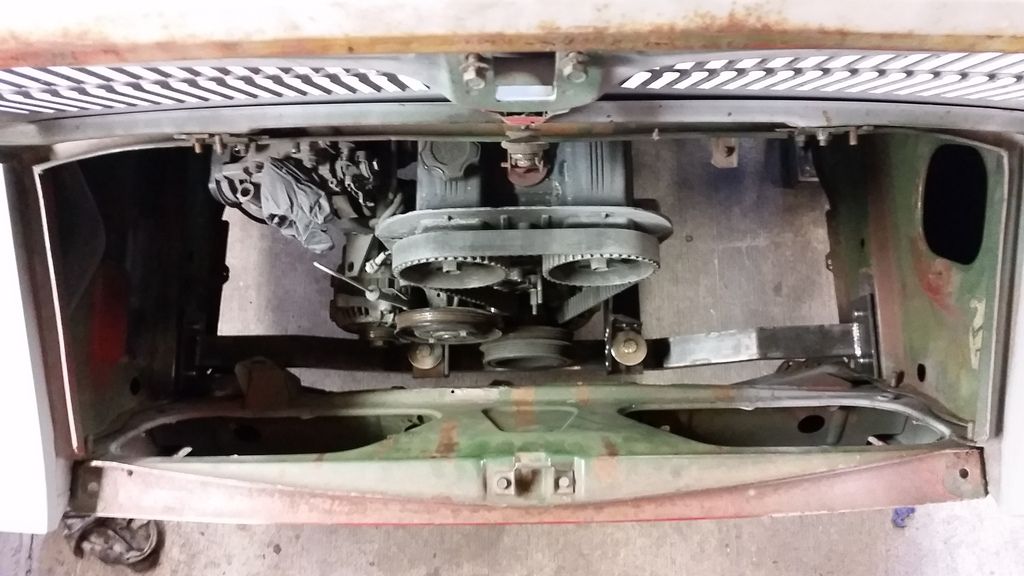

I started off by removing all of the existing motor mounts from the rear valance as they were fouling the waterpump on the new, much larger engine.

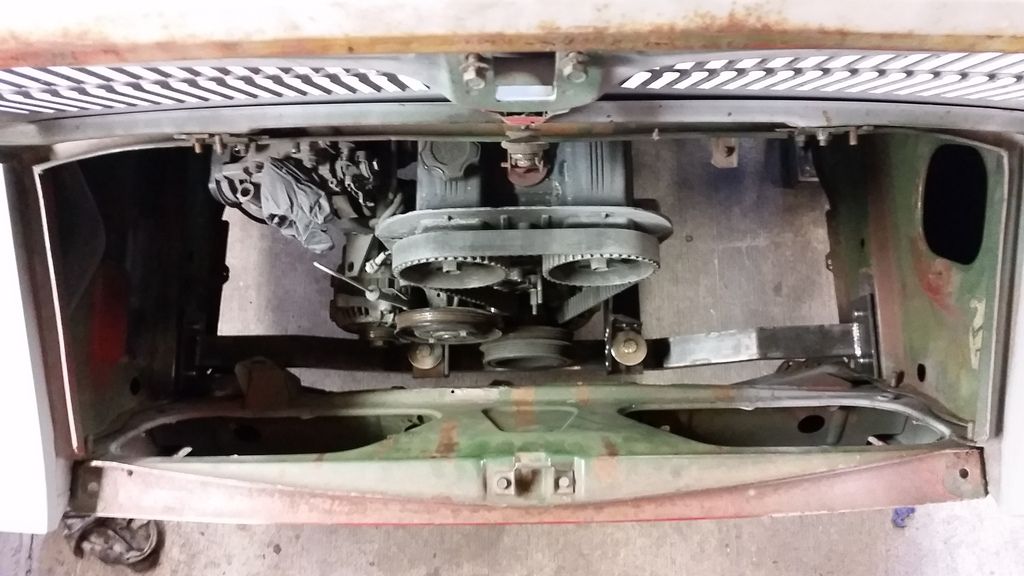

I then set about making a new crossmember that would stretch across the bay, underneath the crank pulley, and attach to the stock bumper mounting location.

Here it is in all it's glory. The top piece is 1.75"x.125 and the sides are 1"x.125. The end caps are .1875, because there was a decent chunk in the scrap bin.

There's still some finish welding to do on it, but for all intents and purposes it's "finished".

There's still some finish welding to do on it, but for all intents and purposes it's "finished".

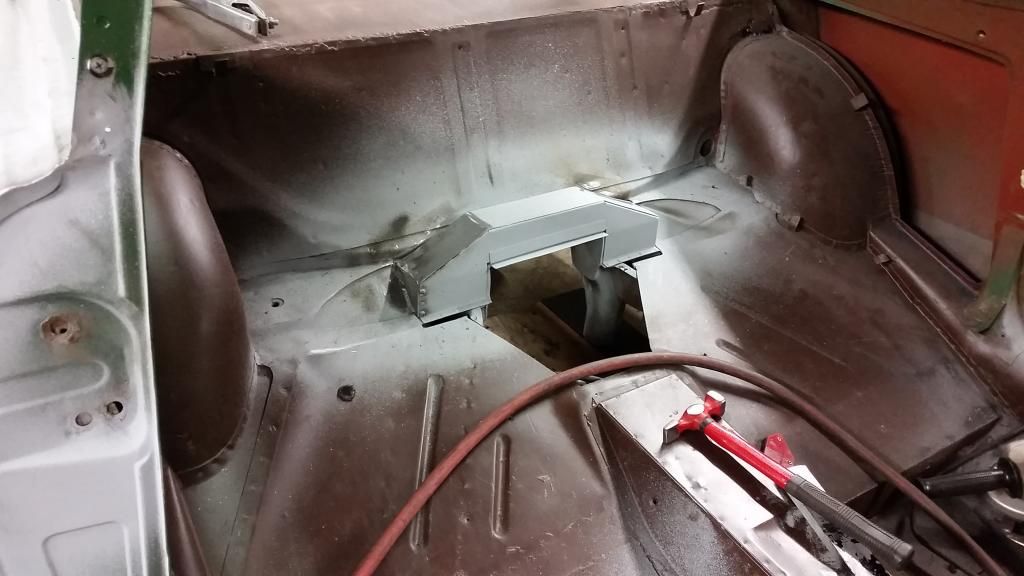

Step two was motor mount #1...

Apparently there's no pictures of motor mount #2. I assure you it exists. Imagine motor mount #1, but slimmer so it clears the serpentine belt... also MM#1 got a slew of speed holes. Because racecar.

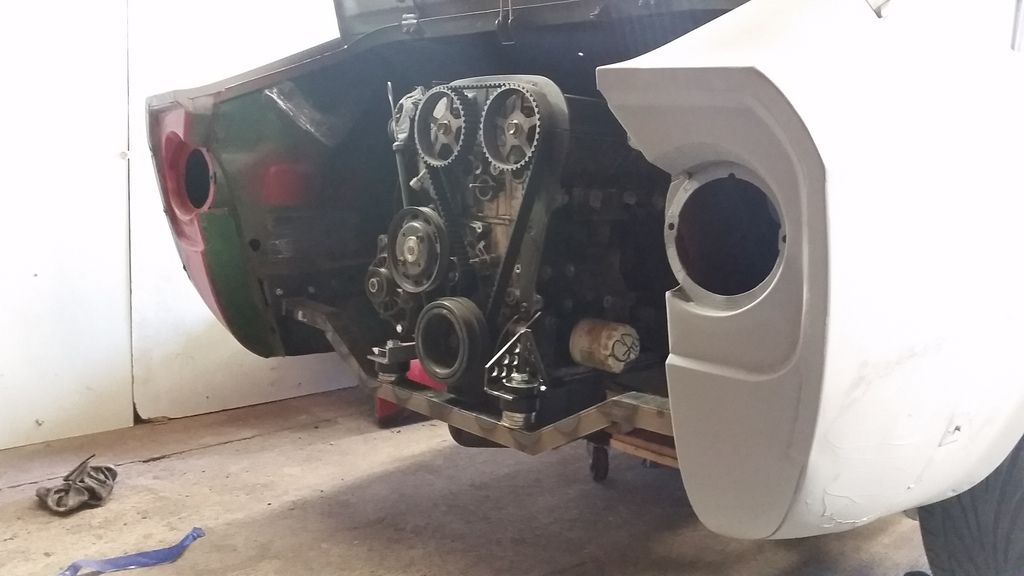

The rear valance still clears nicely and will get tied into the new crossmember to aid in, uhhh, torsional rigidity.

The urethane isolators themselves are a universal Energy Suspension part. I went with the harder of the two available kits, but left enough space to use the slightly taller and softer ones if these are absolutely dreadful.

The urethane isolators themselves are a universal Energy Suspension part. I went with the harder of the two available kits, but left enough space to use the slightly taller and softer ones if these are absolutely dreadful.

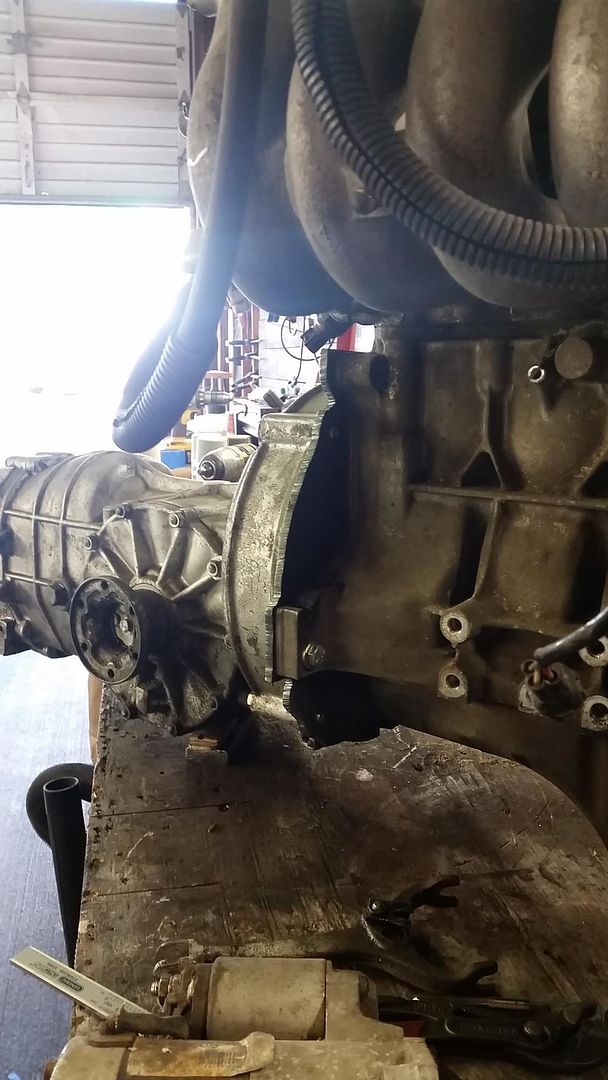

The transmission mounts were a similar affair and use the same urethane isolators.

Again, I failed to get proper pictures of them before mounting them. I was pretty dang excited at the time. All of the motor and transmission mounts are slotted and will give me about an inch of for and aft movement, we are in the furthest back position currently.

Again, I failed to get proper pictures of them before mounting them. I was pretty dang excited at the time. All of the motor and transmission mounts are slotted and will give me about an inch of for and aft movement, we are in the furthest back position currently.

Then, for the first time in the better part of 4 years, I tossed enough suspension under it to mount up the VTO wheels from the Scirocco/Spider and set her down.

Needless to say, I am a bit excited. There are things that need reinforcing and there are things that need finish welding and grinding, but the engine and transmission are bolted together, supported by their mounts alone, and I'm two furniture dollies richer.

As an added bonus/surprise, this will be the last update from South Unit #2. I'm moving down a few bays to Middle Unit #6, which has niceties such as real lighting, a loft that isn't ready to topple, and, best of all, it's own berkeleying breaker panel.

There's still some finish welding to do on it, but for all intents and purposes it's "finished".

There's still some finish welding to do on it, but for all intents and purposes it's "finished".

The urethane isolators themselves are a universal Energy Suspension part. I went with the harder of the two available kits, but left enough space to use the slightly taller and softer ones if these are absolutely dreadful.

The urethane isolators themselves are a universal Energy Suspension part. I went with the harder of the two available kits, but left enough space to use the slightly taller and softer ones if these are absolutely dreadful. Again, I failed to get proper pictures of them before mounting them. I was pretty dang excited at the time. All of the motor and transmission mounts are slotted and will give me about an inch of for and aft movement, we are in the furthest back position currently.

Again, I failed to get proper pictures of them before mounting them. I was pretty dang excited at the time. All of the motor and transmission mounts are slotted and will give me about an inch of for and aft movement, we are in the furthest back position currently.