So we're caught up to the present, which means it's time to discuss my plans for the Winter. I have three areas I want to address: brakes, aero and cooling.

Let's start with brakes. Rear lock up has been a struggle. It's particularly bad at VIR and Summit Point Main but really it's any time I have to get hard on the brakes. I've never corner-weighed my car but the RX7 is supposed to be 50/50 from the factory though I've removed a lot of weight from the car overall (about 300 lb). I need to do something about the rear brake bias and, to a lessor extent, pedal feel. I've toyed with running different F/R pads but I think I need to just bite the bullet and get an adjustable proportioning valve. Earlier this year I bought a kit from Chase Bays (https://www.chasebays.com/collections/mazda-rx-7-fc-fd/products/chase-bays-brake-line-relocation-mazda-rx-7-fc-for-oemc) thinking I could get it to work with my brake setup (Mazda 929 booster and master cylinder). While possible, I think I'm better off building my own setup and selling the kit vs hacking it apart. So the plan is to buy a generic Wilwood proportioning valve, make up a few lines and call it done.

The next step is to replace/rebuilt the front calipers. They were last rebuilt circa 2015 and the last time I changed pads I noticed a couple of the pistons were pretty hard to move. Fortunately, I've already got a spare set lying around. They just need to be painted and put together. The hardware was a little crusty so I sent it all out to be cleaned and zinc-plated.

Lastly, I'm going to finally swap in the smaller booster I picked up earlier this year. I like the pedal travel associated with the 929 master cylinder but its dual 8/9" booster is just too much for this car. Pedal effort is fairly light and there's a fine margin between smooth braking and lockup. The replacement booster is slightly smaller at 7.5/8.5". I think the end game is probably full manual brakes but I'm not there yet.

Goal #2 is aero. I don't think I'm ready for big downforce but I need something on the front of the car. My current plan is for a very modest splitter, maybe 1-2" extension from the bumper that's flat back to the front subframe. The radiator and oil cooler are already ducted but the rest of the front of the car is open. I think this causes it to feel a little light at higher speeds. Given my brake bias issues I don't want all the front downforce, though. Mazda was nice enough to have these factory brackets, which look perfect to serve as rear anchors for the splitter.

I'm going to try to work with the folks over at Professional Awesome to develop some brackets unique to the second generation RX-7. Now that the season is over I need to get under the car and start taking measurements.

The last item is cooling. I don't know if I'm just pushing the car harder or not but this year I saw oil and water temperatures 10F+ higher than I've ever seen. I've already procured a spare stock oil cooler that's been cleaned and had the factory thermostat removed. The idea is go with a better-flowing aftermarket thermostat and plug the bypass in the stock cooler. I'm also toying with changing the position/orientation of the factory cooler. Right now there's a 2-3 in. gap between the oil cooler and radiator, which is where the factory AC heat exchanger and power steering cooling loop lived. Since I have neither it's just dead space, which is probably building up a pressure head reducing airflow through both the oil cooler and radiator. I made a quick sketch of the system as it sits now:

The orange circle is tubular cross-member to which the oil cooler is mounted. The thin black lines are my ducting. The total inlet area is approximately 1/3 of the total radiator area and the split going to the oil cooler is about 1/3 of the oil cooler area. At first, there was no split ducting behind the oil cooler. I thought that air going around the oil cooler may build up behind it and hurt flow so I continued the split. Now the issue is about 1/3 of the flow through the radiator has to first go through the oil cooler. Since I have no need for the space between, I'm thinking it would be better to push the oil cooler all the way back to the radiator. My first two options are basically the same, with just the oil cooler orientation slightly different:

Option 1 eliminates all area between the coolers but Option 2 presents more of the oil cooler surface area perpendicular to the direction of airflow. Both move the oil cooler slightly lower and significantly free up area to the radiator. What isn't clear to me is whether any ducting split would even be necessary in these configurations since air can't flow around the oil cooler anymore. Both are relatively easy to implement. Another alternative is to move the oil cooler to the top of the radiator:

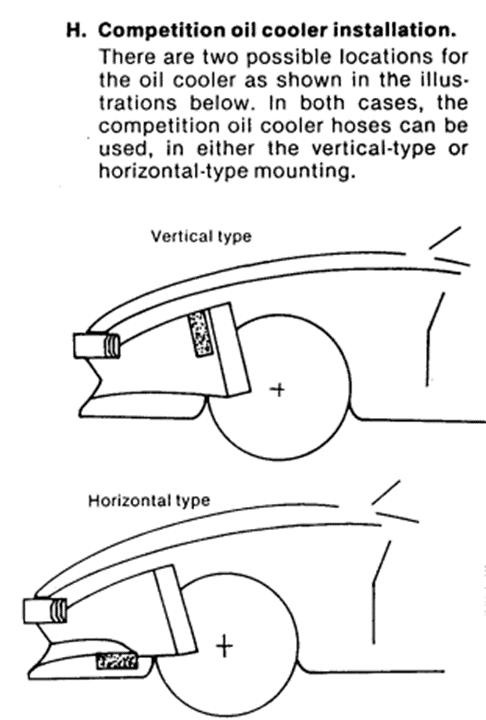

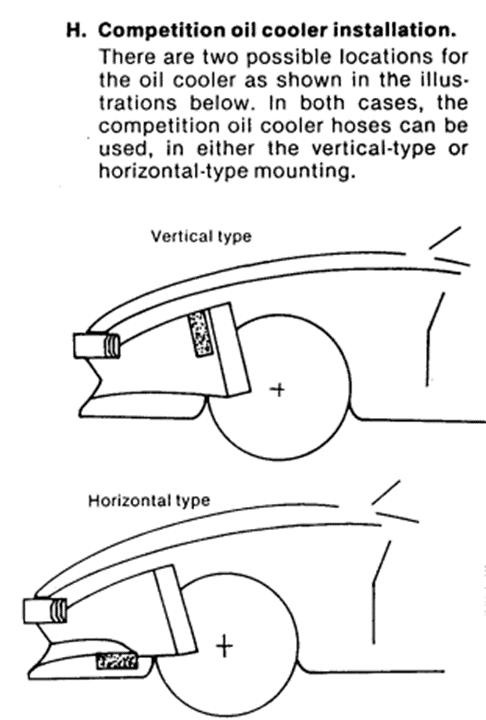

The only reason I even bring this up is because an old Mazda Competition guide for the first generation RX-7 gives this as one of the two mounting options for the oil cooler:

I'm not sure of the benefit of this arrangement other than perhaps the heated air that's gone through the oil cooler is interacting with the hotter part of the radiator (inlet at top). My concern with this setup is oil flowing back into the pan when the engine is off since the cooler would now be above the pump. This configuration also may not be feasible without a lot of cutting.

My last ideas involve ditching the stock oil cooler altogether. It's a 7 row, dual pass design that looks like it has a lot of restriction and pressure drop. It could easily be replaced with something like one of the larger Setrab 1-series oil coolers. I may give up some volume but surface area and flow would be significantly higher. Any of the above arrangements would still work but it also opens up some other opportunities. Something like this, with the oil cooler off to one side with the inlet/outlet at the top:

With a cross-flow style radiator the oil cooler could be on the "hot" side. With something like what's shown above I could even cut out the stock cross bar for more flow to the coolers. I'm thinking for 2024 I should stick with optimizing what I have now (Options 1-3) and if temperatures are still an issue, upgrade for 2025.

The last cooling-related item is slowing down the water pump to avoid cavitation. Reknown rotary tuner Racing Beat says the factory pump and pulley ratios are only good up to 7000 RPM or so. I shift at 8000-8500 RPM. There are several options out there but because of my setup I'm going to look into machining a 3.75 in. 6-rib supercharger pulley to work as a main pulley. This would get my pulley ratio down to 1:1, which should be good for 8500 RPM.