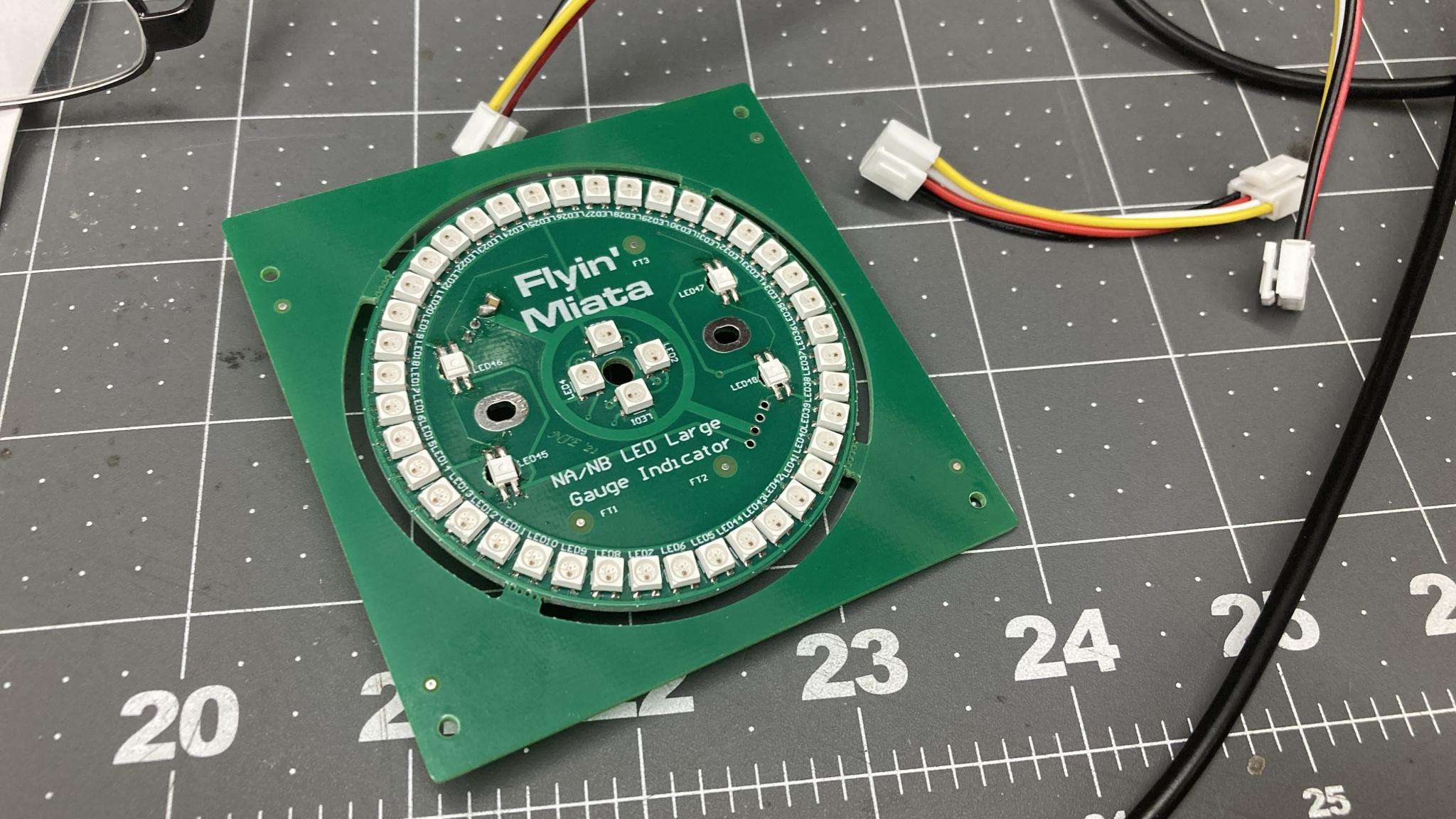

Remember this? There has been thinking, planning and implementing under way! We now have two modes.

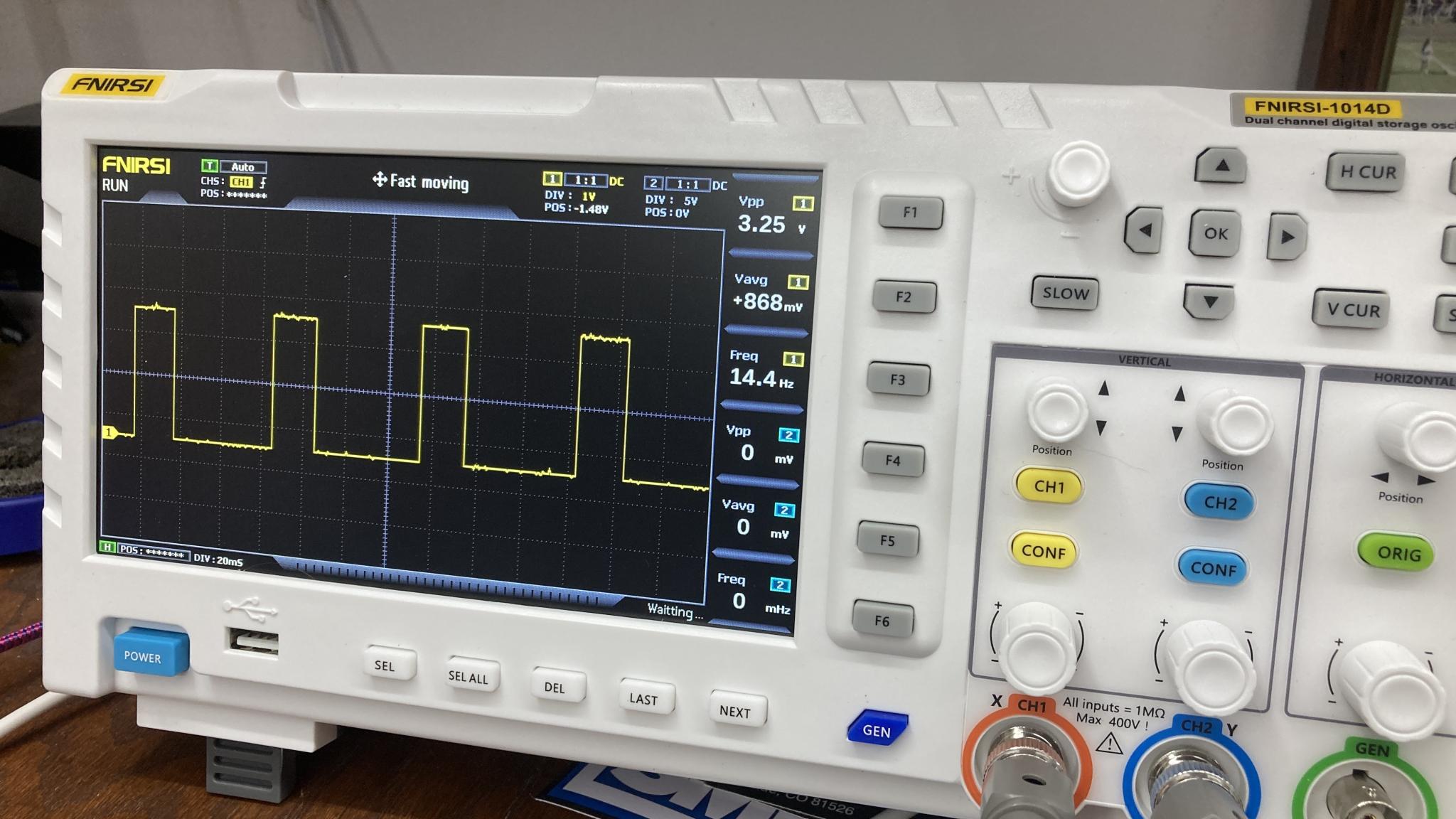

Stradale (street in Italian to celebrate the fact that the only Italian part of this car is the livery)

- tach shows "trails"

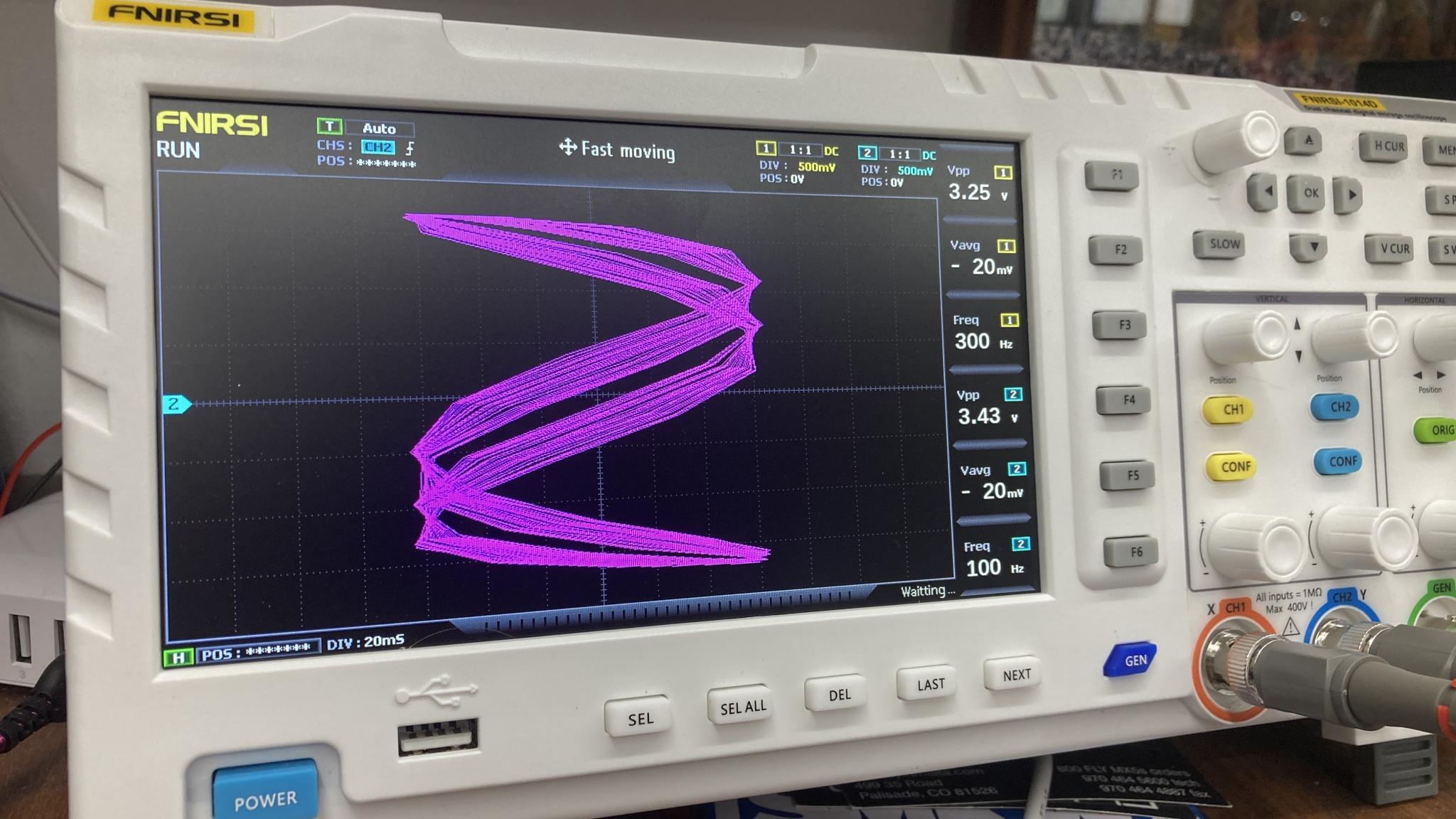

- speedo shows friction circle indicator

Corsa (race!)

- tach is solid sequential LEDs

- speedo is split into four quadrants. Coolant temp on left, lateral G on top, longitudinal G on right. Bottom is currently unused. I wanted to be able to monitor coolant temp behavior so I can be aware of how much maximum attack I have available to me. I have considered adding fuel flow indication to the display just because I can :) Probably more useful than the g meter, honestly.

In both modes, there is now a "warm redline" that starts adding orange segments as the car gets over a certain temp, to encourage the driver to shift a little sooner. There is still the freakout mode when the coolant temp gets too high and a flash of the tach at the shift point. So we have a cold redline that shows blue LEDs below a certain temp, a happy zone where there are no special redline indications, and a warm redline that shows orange up to freakout. I like it, that's useful.

To change modes, I wanted it to be automagic. I was going to use a subtle switch on the column but didn't manage to come up with anything I liked. So I decided to make it wheel-aware. I have two steering wheels for the car, one for street use and one for race use. The dash changes mode depending on which wheel is installed. For example, here it is booting up in the default Stradale mode (blue flash) and I attach the quick release for the race wheel (red flash indicates race mode). I'm still waiting for my second quick release to arrive so I can't show the actual wheel swap yet.

I also decided that it would be fun to add a switch to one of the wheels so I can switch modes...just because I can. Here's the bracket I drew up. S for Stradale, C for Corse. Or Sport and Competition if you want, I won't judge.

Mounted. I'm pretty happy with that. I may change the switch style, I have a few other options on the way.

And here it is in operation. In race mode, the two white dots at 12 and 3 o'clock indicate 0 for the g meters. The white dot at 9 o'clock is the warning threshold for coolant temp - above that, it starts to add the warm redline to indicate that we're higher than desired. The coolant LEDs go from blue to red as temps rise. The car is almost at normal operating temp here. You can see the flashes as it changes modes as well as the tach change.

And yes, you can see g meter showing the car rock on its springs when I blip the throttle :)

Not big changes, but now if I come up with more ideas I can have more distinct behavior between the two modes.