I have been a huge fan of Datsuns since I was a kid. The first car I ever drove was a 1970’s 210 that my dad used to check oil wells in Kansas. I would shift or hold the wheel for him while riding along. It was one of my earliest memories of me and my dad.

The goal with this car is to accurately catalogue decisions, work, time, and money spent on the car. I am doing this real time with a paper log that I will keep with the car, but in an attempt to share this with others I am also writing it on the PC. I believe this document will capture the lion’s share of the information, but to really understand what was going through my mind, and see small drawn figures the paper log will likely be the definitive version of this document (though no introduction appears there).

The purchase was different than most of my car buying experiences in the past. In the past five years I have looked at no less than six to seven Datsun 510s. I am a frugal person that knows what I want to pay for an item if it isn’t that price I don’t buy it. The exchange usually goes like this:

Me: Hey I am interested in your 510, I see it needs a lot of work. It is missing almost everything

Seller: Yup, $4k is the rock bottom price, these things are skyrocketing in value, and I know what I have

Me: Agreed, but that car still needs everything, I am essentially getting a chassis and title

Seller: I know what I have, I had an offer of asking price +$100 last week

Me: Why didn’t you take it?

Seller: … (They then stop returning my calls)

This one went like this:

Me: Hey will you take half of what you are asking, I am not a flake and I can have the cash in hand

Seller: No man sorry too low of offer

Me: Understood, I could do minimum offer plus $500

Seller: I will let you know I have a potential buyer coming tomorrow.

Me: (Two days later) Hey did it sell

Seller: No the guy said it had too much rust

Me: Can I see pictures of the rust?

Seller: Sure (Author’s note there was/is a TON)

Me: I am still interested, but back at my original half price offer

Seller: I move Friday, if you can get it before then, yes

Me: OK, I will do that.

This was all over the course of a few days; it was the Sunday before the Friday I needed to pick it up when we decided on the price. I drove my 1996 Buick Roadmaster Estate Wagon the 500 miles to pick up the car. The trip from my place the Buick did great, it also turned into an impromptu family get together with five of the six siblings, which was great, and my kids loved seeing their aunts, uncles, and cousins. The car was very near my parents’ house which worked out great.

I knew the car was coming with an engine, some brakes, suspension, and an extra transmission. I was not prepared for what I received. The list of items will be added later that came with the car when I bought it.

The total for that list when I went jumping from website to website finding prices, is not what I paid for the car, it is much more. Needless to say I think I got one of those “Once in a lifetime” type of deals with the purchase of this car. When he said I could have the engine stand and engine hoist I somewhat lost my composure. I am truly blessed to have been given a simple opportunity like this. That is one of the reasons I wanted to make sure I write all this down.

I got it back to my parents’ house and realized, there was no way I was safely towing this car back with my family in the Buick and have an uneventful trip. I am lucky enough to have a father that would let me borrow his truck ad pull the trailer back. Before I arrived at that course of action I tried to get the car running and all of the large parts that I could bolted back on the car.

I first unloaded the truck at my parents’ house, and then unloaded the parts so I could catalogue. The list is above and is mostly complete, though there are some parts that I did not catalogue, as they were miniscule in the sea of other parts received.

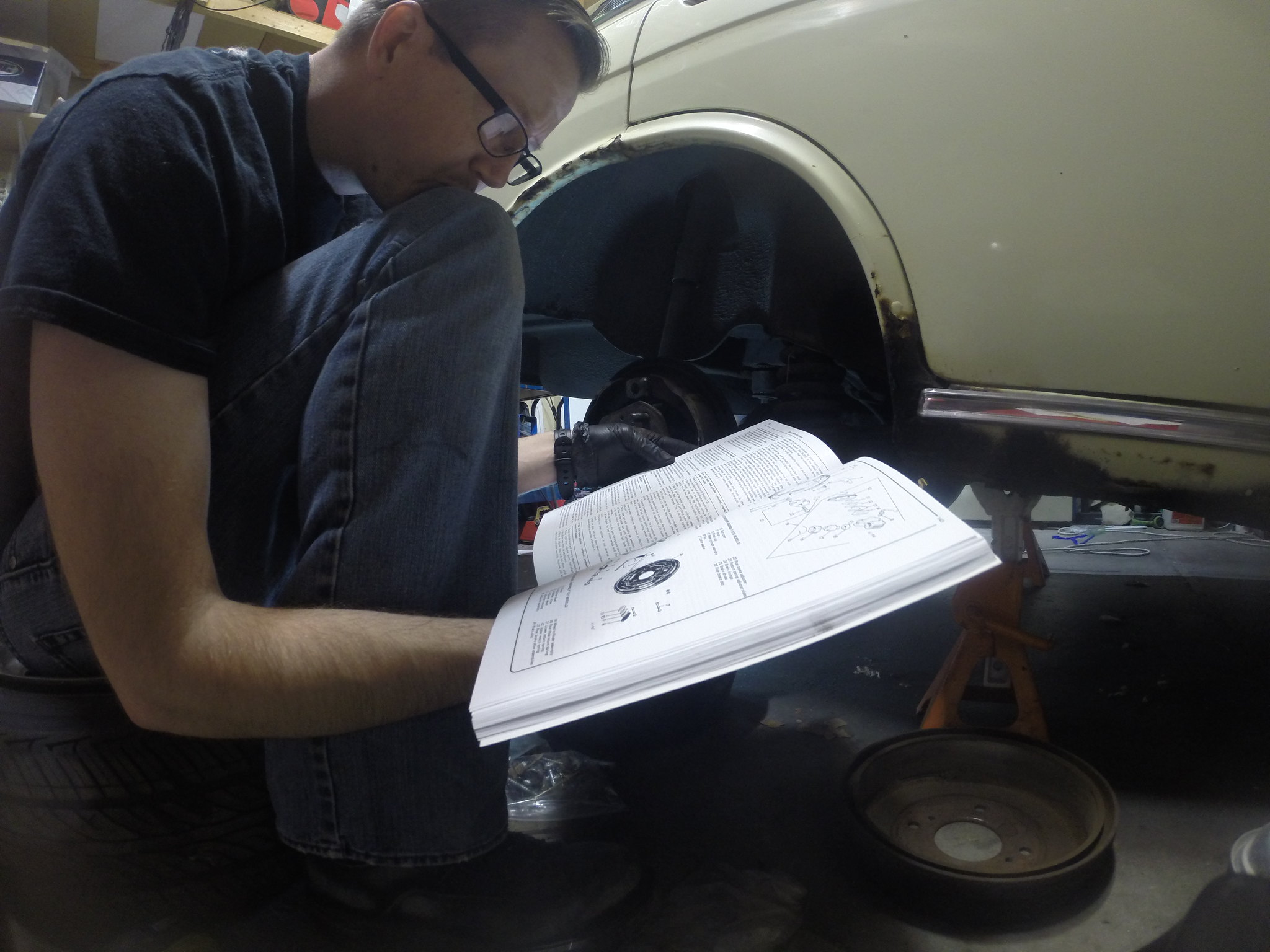

I decided that it would be irresponsible of a gear head to not even try to get the thing started on day one. So I put together a checklist of things that I thought needed to be done to get it ready to go back to my house, and if lucky even drive there (Author’s note: Looking back there was literally almost no way I would have been able to drive that back, ahh the joy of a foolish plan). The original to do list is located below (Author’s Note: I changed the order of the list to allow completed items to be listed first)

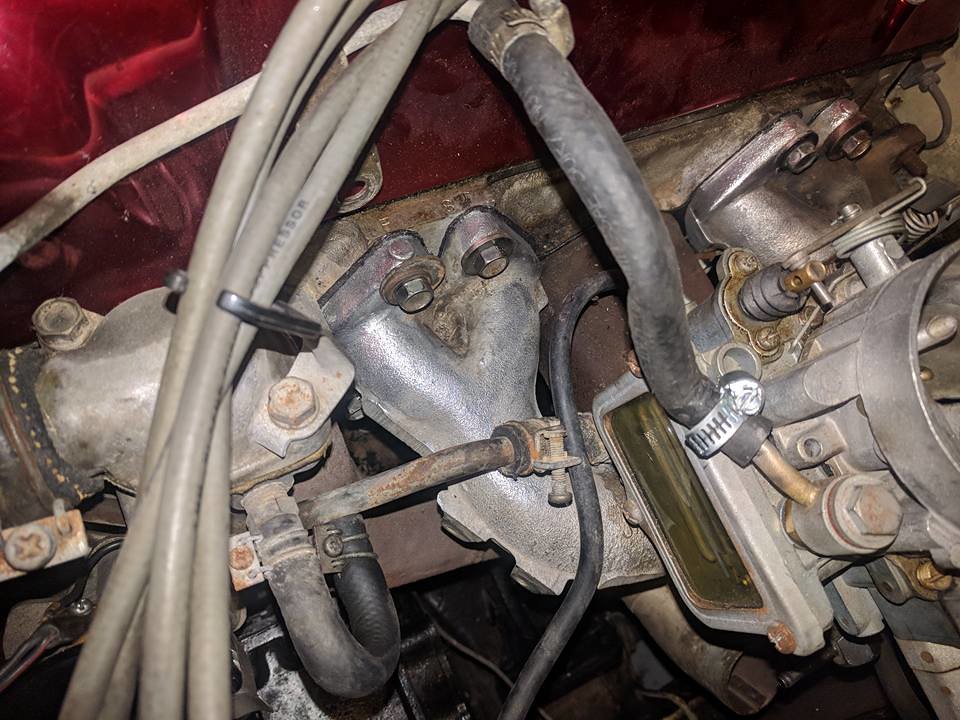

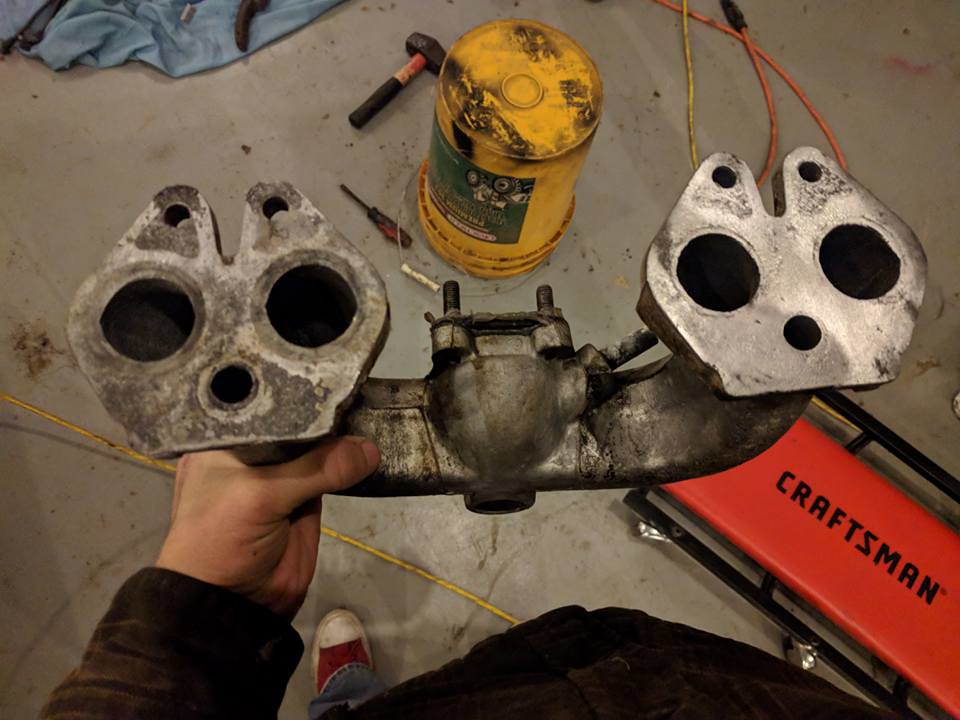

- Mount Exhaust Manifold

- Mount Intake Manifold

- Install Spark Plug Wires

- Check all fluids

- Mount front and rear bumper (space savings)

- Remove beer can coil-cover

- Mount Grill and Headlight surrounds

- (Not Done) Check Brakes

- (Not Done) Figure out what the red toggle does (Figured out XXXX Date)

- (Not Done) Vacuum Car

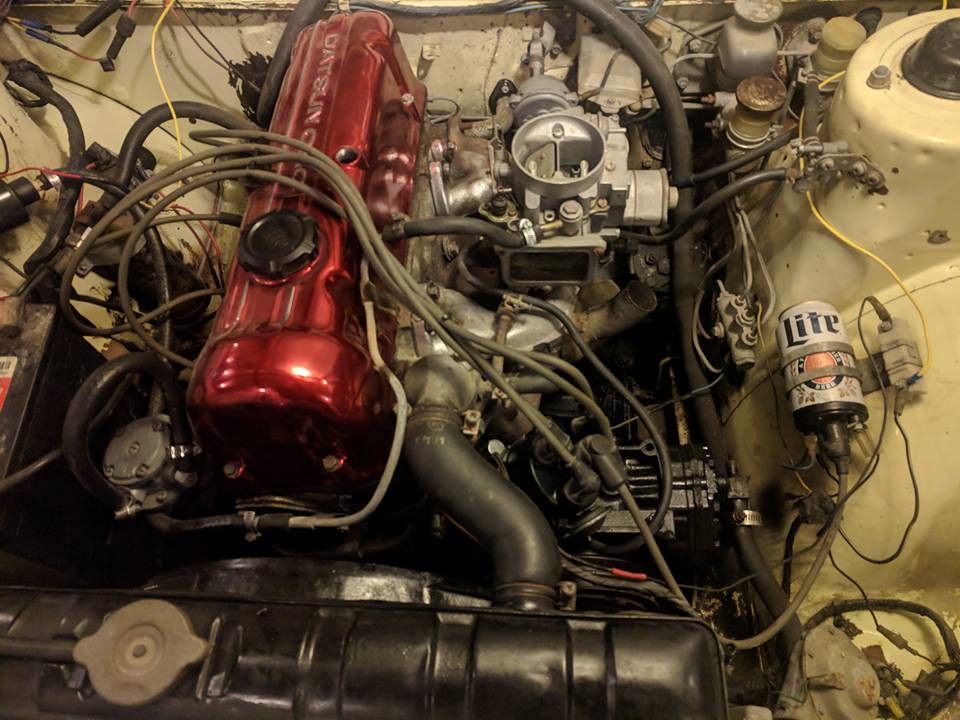

As you can see, I didn’t get the list of things completed. The car idled very rough but started, which I figured out later was something very simple. The exhaust was incomplete and not hooked up, but most importantly I didn’t have a lug adapter for the tuner lugnuts so I was unable to remove the wheels to check the brakes. Only an idiot would buy a non-running 45 year old car and attempt to drive it 500 miles without a thorough inspection of the driveline and brakes, I am stupid, not an idiot.

Some things that I immediately catalogued were:

- Stock carburetor is leaking

- Missing exhaust nuts and bolts for manifolds

- All lights work

- Taillights

- Brake Lights

- Headlights (Dim and Bright)

- Dome Light

- Blinkers (though they did seem sticky)

- All glass is in good condition

- The interior pieces are also in good condition

- The ash tray had at least $15 worth of quarters in it (No lie!)

- The rust is going to be a tough battle on this car

- One blade of the radiator fan is broken off

My love of lists and checklists will become apparent as I move through this project. I start almost every day in the garage with a short checklist of things I want to get accomplished. I usually write these types of things on a white board, but I wanted to ensure that I would be able to pass this document onto any future owners or perhaps my kids if they decide they want the car.

What I did next was the best decision I could have made. I packed everything back in the car, and loaded it on the trailer and spent the rest of the weekend with my family having a great time.

Sunday the 12 November 2017, I borrowed my parents’ truck and packed up my wife, kids, and new toy and drove the 500 miles back to Denver. It was an uneventful drive back which is the best thing I could hope for. The car towed very easily, and I had the car in my garage that night.

Here is where the log starts to get a bit different. I am going to switch from a narrative to more of a “Log Entry” type of log. I expect the template to change overtime as I determine what all information I need to get in this document. Please enjoy some of the pictures from my first couple days with the car.