This is enough of a setback that I won't even have this car back in time for Ascutney 1. I'll either have to throw the CRX or RX7 together (most likely un-caged, which means I can't break out) or rent a car from another racer. I like to think that at this point, I've proven myself to be just competent enough to not throw cars off into the bushes willy-nilly and someone will be willing to loan/rent a car to me. I have my eyes on one momentum car in particular, which should be reasonably similar to the Miata.

This thread may get a little off-topic for awhile here. My options include:

RX7

Needs some sort of wiring, possibly new injectors. After that, a windshield and new seat mounts and a harness. Not too bad, overall, but I'd have to actually focus on it.

CRX

Needs fuel tank plumbing. The stock fuel pump mount is just silly, and I wish I had just opted for a fuel cell rather than sorting this out. Otherwise, it's ready to tune the suspension then race with the wheezy little DPFI engine.

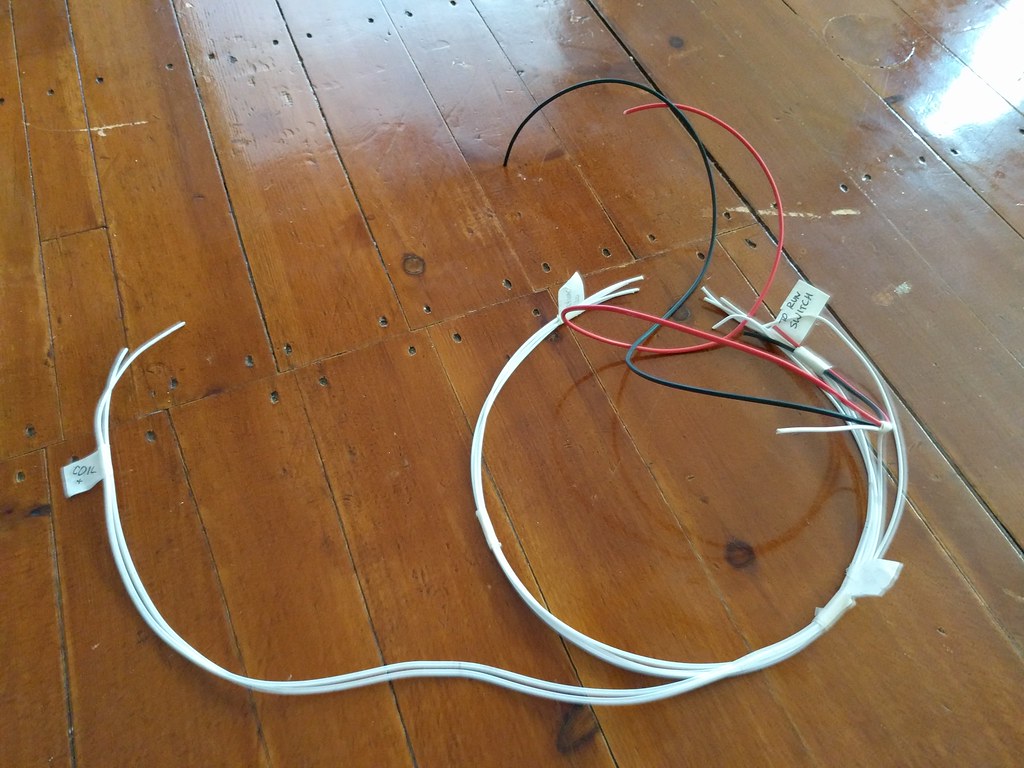

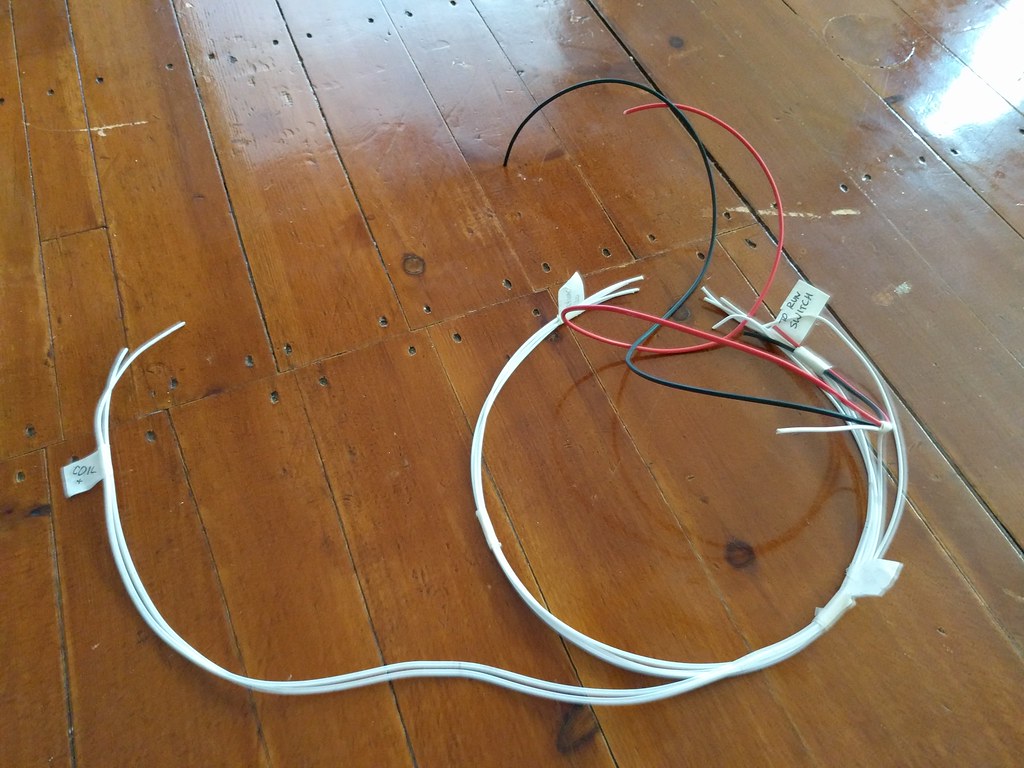

This is the ridiculous pile of awful that Honda said was, "good enough" for the CRX.

Powaaa?

If I want to get ambitious, I could plop the high-compression d16z6 and si transmission that's sitting in the garage into it. I'm told this cranks out around 155whp, which should be pretty good in this car.

That requires a dpfi->mpfi and obd0->obd1 conversion though, and to be honest, I've had my fill of wiring for this lifetime. Trying to complete wiring jobs when you're colorblind is a new flavor of hell. It's almost as repulsive as mayonnaise.

Other News

There've been other things going on as well!

Karting

During the off-season, some of the other hillclimbers and I have been going karting to keep our driving skills from getting too dull. This month was our last race of the season, and I had a pretty spectacular off. I got pushed into the wall ... then onto the wall ... then over the wall and onto the tires beside it. It just proves that practically nothing can ruin a day of karting.

Bikes

While I wait to get the Datsun back, or decide what to do in the meantime, I've been wrapping up my Honda cl360 for the season. It needed new controls, a re-wire, and new tires all last season, and I'm just getting around to it now. I've also been helping a friend out with her cb350, and my girlfriend just got a cb360 for her birthday ... which, as it turns out, has a seized engine.

They're simple enough that anything short of an engine rebuild is only a weekend project. To prove it, here's the "race harness" that I just mocked up, which is enough to run the engine and charging system. I have a separate harness together for the lighting system, but as far as mechanical components are concerned, this is all of the necessities.

This might show why "jack stands on bits of wood" won't work for this build. The jack stands would just fall over; The floor is THAT bad. My chassis table is within 0.05[font=arial, sans-serif]° [/size][/font]on all three planes.

This might show why "jack stands on bits of wood" won't work for this build. The jack stands would just fall over; The floor is THAT bad. My chassis table is within 0.05[font=arial, sans-serif]° [/size][/font]on all three planes. I'm pretty pleased with the results, overall. The plan is to finish welding it by the weekend, then jig up the front suspension.

Steering is going to be a bit of an issue. Rotary engines have a little bit of trouble with rear-steer (when the steering rack is behind the front axle line, rather than in front of it) because they dip down so low. I might have enough space to have the entire engine behind the steering column, otherwise I may have to place it higher in the car than I'd like. I'll deal with that after next weekend though. Right now, I'm relaxing after an oppressively hot, sweaty, humid weekendrolling around on an un-level concrete floor.

I'm pretty pleased with the results, overall. The plan is to finish welding it by the weekend, then jig up the front suspension.

Steering is going to be a bit of an issue. Rotary engines have a little bit of trouble with rear-steer (when the steering rack is behind the front axle line, rather than in front of it) because they dip down so low. I might have enough space to have the entire engine behind the steering column, otherwise I may have to place it higher in the car than I'd like. I'll deal with that after next weekend though. Right now, I'm relaxing after an oppressively hot, sweaty, humid weekendrolling around on an un-level concrete floor.