I finished up the molds for the doors today (2.5 layers of 10oz chop mat).

While that was curing, I finally trained myself on the vinyl cutter that Roland donated to the Makerspace a couple of months ago. Sometimes I'm surprised by the little changes that really get me excited to make big progress. Making a silly sticker is one of those little inspiring things.

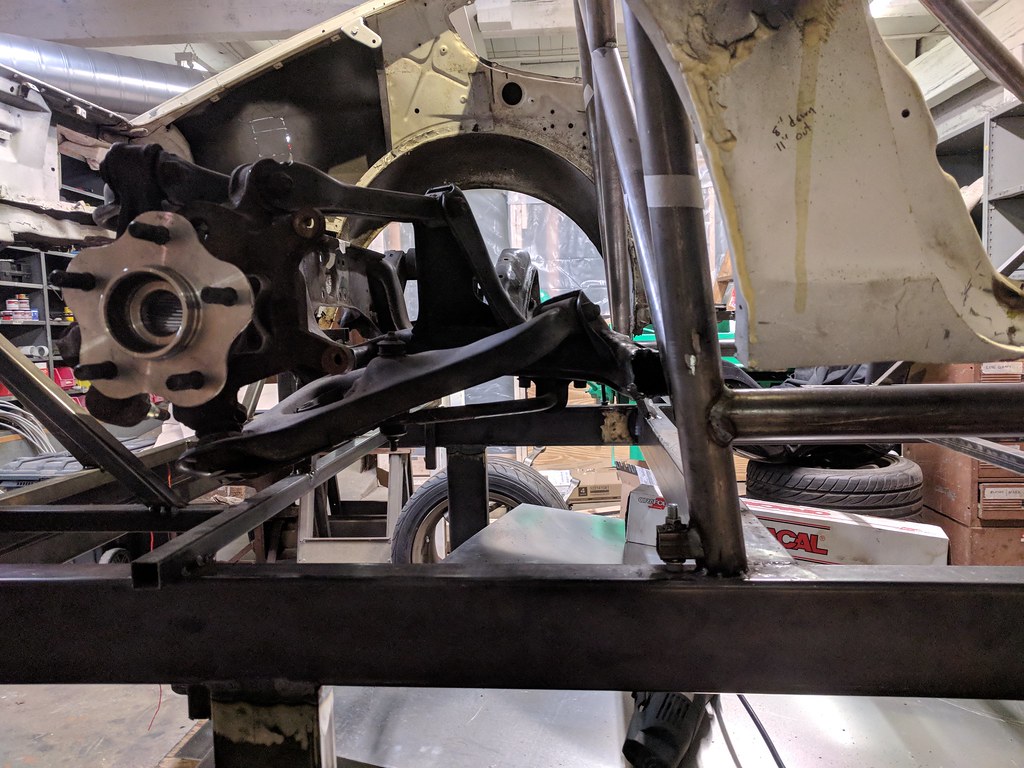

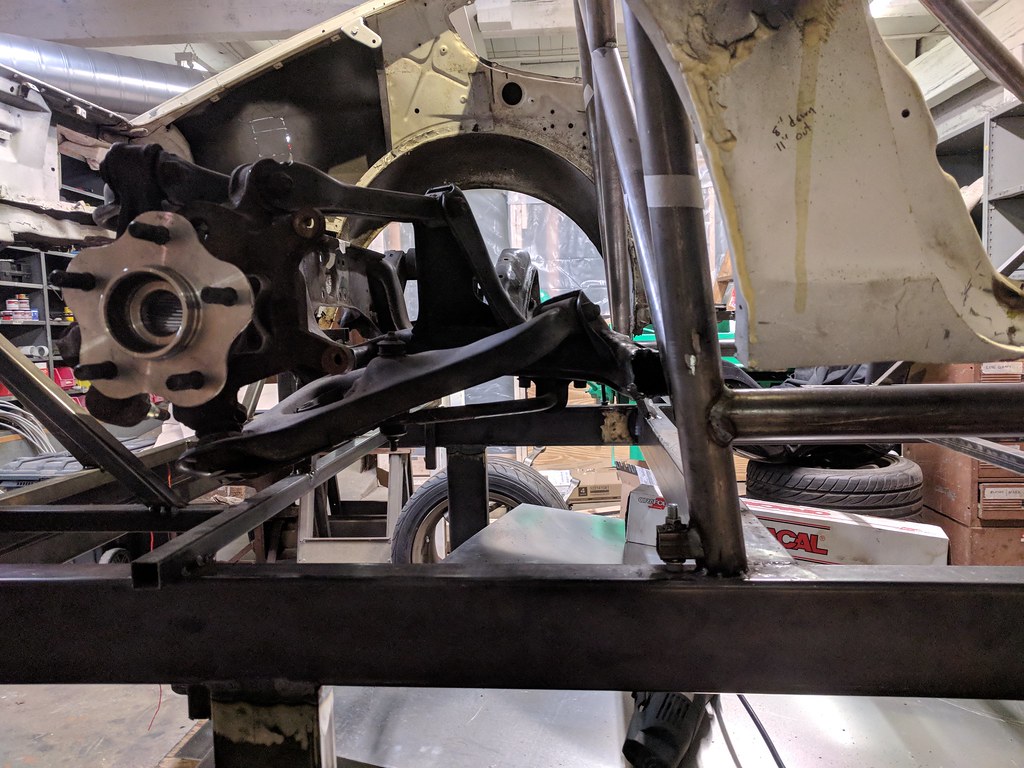

Now comes some more hard math. Finishing the jig for the front suspension was quite an ordeal, if I'm honest. The g35/350z front clip that I had purchased wasn't exactly straight, so I decided to pick a side and build a jig that could be used on both sides of the car. This is the result of around 20 hours of 'braining' and a half hour of cutting, drilling, and welding.

It allows me to place the subframe on the chassis table and establish my suspension pickup points in thin air. Then it's just 'connect the dots' between the pickup points and the roll cage structure I've already built.

In other news, I'm getting closer to finished on the profile for the rear quarters. They're coming along pretty nicely, I'd say.

Just read the whole thread and got here and said "Aw Man!" out loud. I'm really enjoying this build, keep up the good work. Now off to the tube of you and watch your vids!

Glad to hear that you're enjoying it. I really need to make time to get the new video episodes wrapped up and published. SOON.

The first door mold didn't come out perfectly, it was a bit too cold during curing, and we didn't use enough MEKP in a few spots.

However, this weekend was a massive success. We added leveling feet to the base of the chassis, chopped out a bunch of parts, and now suspension is ready to weld in! This is a major milestone, and we could even see this car rolling around next weekend.

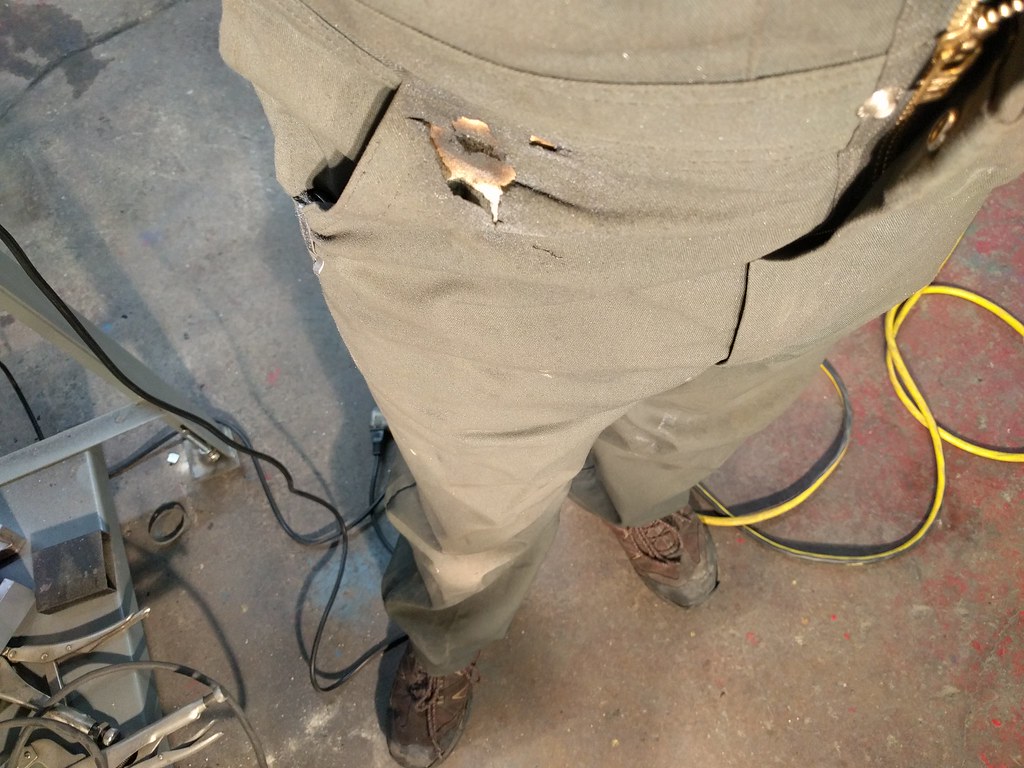

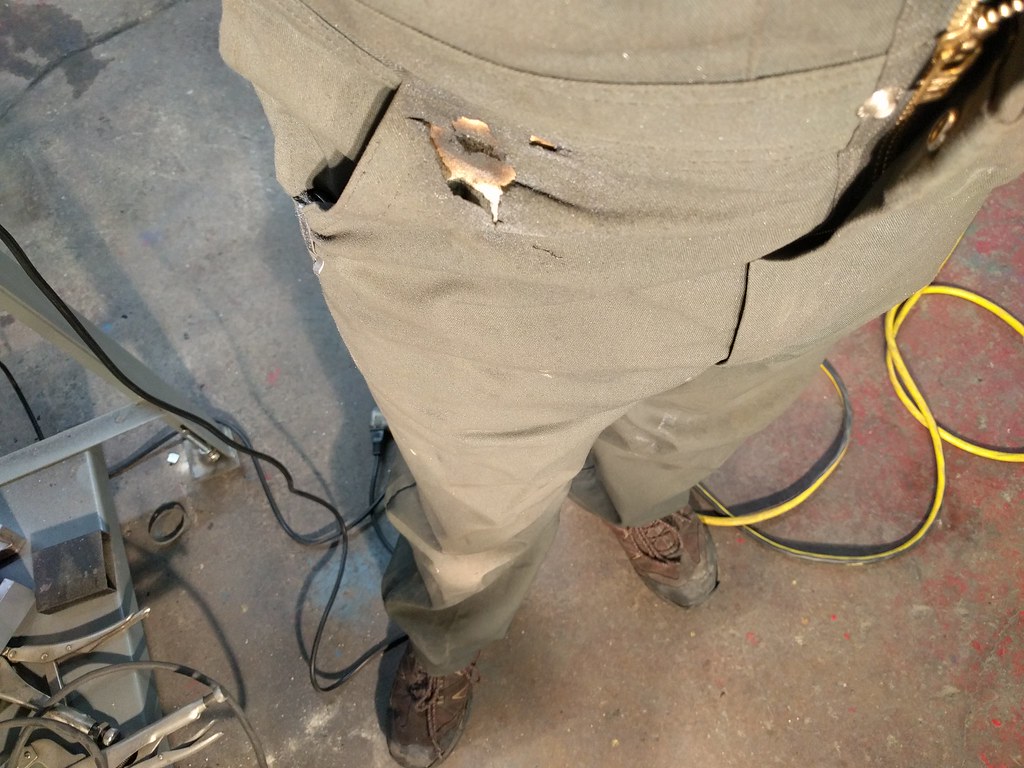

Today, I lit myself on fire.

I was removing the mounting pins (studs? bolts?) from the g35 front suspension so I could align the pickup points in the Datsun, and that meant a [B]lot[/B] of cutting and grinding. I should really have fired up the lathe and just made some from scratch ... but I chose to do it the hard way.

In the end though, I have all 6 pins necessary to locate the front suspension. Hopefully this week I can weld the pickup points in place.

I'd say we're making up for being behind schedule. We're getting there, and things came together really well this weekend.

Mike (my co-builder/crewchief) and I attended the rules/awards banquet. Mt Washington changes everything for the season, and because so many more folks will attend our events to shake down their cars, the season schedule has already been announced. That's great for me, because it lets me solidify our schedule for the season.

Working around the "start in late May" schedule, there are two autocross events I can attend at NHMS. That should be enough shakedown to be able to trust the car, but Ascutney is known for being the car that will shake out whatever your car's weakest link is. Assuming we want to shakedown in late April, that gives us around 7 weekends left to get the car on its own wheels. It's a tall order, but not entirely out of the realm of possibility.

Once we got back from that banquet, we dove back into the front suspension. After lots of measuring, coping, measuring, adjusting, measuring, and confirming ... we finally have suspension pickups welded in place.

I'm super happy with how that upper control arm tube turned out. Now we need one more, then line up the subframe pickups on the bottom. Once that's done, we focus on the (s13 240sx) rear suspension, and the car should be able to roll around on its own after that.

Ryed

New Reader

2/27/17 10:08 a.m.

"I love it when a plan comes together!" Impressive work Jesse. Sorry we didn't get a chance to catch up at the banquet. We left early due to the weather. Only had to drive through one flooded road on the way home!

Ryed wrote:

"I love it when a plan comes together!" Impressive work Jesse. Sorry we didn't get a chance to catch up at the banquet. We left early due to the weather. Only had to drive through one flooded road on the way home!

Yeah, our drive was pretty hairy too; We left right after the awards. I tried to make it over to say hi to everybody, but it seemed like we were circling the room in the same direction.

Hopefully all this rain/melt will make up for how dry last year was.

I spent some time on the crossmember and lower control arm pickup points, but it'll take a little bit more refinement before I call it done.

I got this far before I had another set of hands to see where the hub ends up relative to the fenderwell.

The current wheelbase is 90" ... but I have everything set up for 94" as it turns out. Luckily, now that I've established my design, it should be quick to reproduce.

I really must've gotten a [B]lot[/B] of dust in my eye when I cut all that work out.

... What? No, I wasn't crying. Like I said, dust. Someone must've been sweeping before I got to the shop ... or something. Definitely not crying.

After I pulled myself back together, I got everything aligned on all the planes. Then I got to work on the first (and most important) tube: The subframe mount tube.

Progress has been slow this week, as I'm the only one in the shop and most of the work on the todo list requires two sets of hands. On the bright side, that frees me up to edit more video.

I decided that trying to make the front suspension happen by myself wasn't working, so today I switched to the rear subframe pickups. I'm really glad I did, that little change of focus solved my mental block, and I was glad to be back in the shop.

Continuing on that trend, I started welding in the pickups today.

The front pickups for the rear subframe:

The rear pickup (one of two) for the rear subframe:

Every day, it's a little closer to rolling around on its own wheels.

java230

SuperDork

3/17/17 9:48 p.m.

Roller Soon! Cant wait to see it

Why a s13 and not s14 rear???

jfryjfry wrote:

Why a s13 and not s14 rear???

There are only minor differences between the two, and I found a local complete rear subframe (diff, axles, brakes, etc) s13 rear end for $100 assembled. I couldn't find an s14 rear subframe for less than $500, and it doesn't seem to offer enough benefits to justify the price.

Some more materials arrived today, so I started building my new subframe mounts.

Well, the s30 definitely won't be ready for the first hillclimb event (Ascutney) but we've been making brisk progress on it lately. This weekend we changed gears a little, and put some time into the race hauler instead of the race car.

I had made the mistake of ordering a gasoline filler neck for it a few months ago, which doesn't accept the larger diesel fillers (I didn't know this until I stopped for a fillup). It's still held up by a bungee cord, but at least I don't have to remove the filler from the tube every time I want to fill the tank any more.

Up next: The coolant system had a slow leak for awhile, but it recently became critical (which is why I parked it). We spent some time isolating the source of the leak, finding the right(ish) replacement hose, and breaking our fingers to get them to fit in place.

Then we turned our attention to the interior. Ugh. Just ... It was disgusting. This used to be a roofing truck, so there's tar everywhere on it. Seats, in the box, all over the dash, steering wheel ... everywhere. The floor had some housing carpet pad with vinyl on top, and wasn't sealed. Everything smelled of mildew and sadness, and the whole truck just felt soggy. After tearing out the flooring, we found enough dirt to plant a garden. It may have been growing, for all I know. That channel above the rockers had around 6" of packed-in mud.

After a lot of cleaning, wire wheeling, and some phosphoric acid, we threw a bit of primer & paint at it.

I haven't decided what kind of long-term coating to put on it yet. I have a bunch of POR15 left over, but I don't know how well it'll hold up to this kind of environment. I'm open to any suggestions you folks might have. Everything's reassembled right now, and the next project will be finishing up the box itself (hopefully this week).

We have some catching up to do, but the video series is finally getting edited now!

(The new editor doesn't appear to have any youtube embedding capabilities)

https://www.youtube.com/watch?v=yMzfChavIsg

The rear subframe is crudely jigged together, and should be ready to rock in the morning. Centering it, defining my ride height, and setting the pitch required a lot of braining.

Based on the measurements from a friend, the LCA should be at a ~14 degree layback. I'm at 13.75 degrees on both sides, and have decided to call that good. At some point, I'm going to move the arm pickup points anyway, so this'll have to do to get me started.

Anybody interested in a new video episode?

I'm just going to leave this here.

Tire fitment mockup (27 tire diameter, 13 tire width, 15x15 wheel):