And because I won't have time to get anything else done today, here's the steering all assembled. It all went together as one would expect.

And because I won't have time to get anything else done today, here's the steering all assembled. It all went together as one would expect.

There will be some trimming and refining but the major cutting is done.

Will fresh metal be going on by the end of the weekend??

Who needs a brake?

Me. I do. But since I don't have one, I'll just do it the hard way.

The plan is to make this funky section separately and then butt weld it to a single vertical piece that will replace much of what is now missing. I'll then rosette weld a flange to the back side of it which will support the floor. I think it'll accomplish the exact same thing as what the factory did and will drastically reduce overlapping panels. The sill plate and seam sealer will disguise the change in design.

I don't remember the gauge of the metal I'm using but when I started the Healey project I bought two 4x8 pieces of sheet metal - one thicker than the other. I'm making all of this out of the thicker material. It makes the bending a nice little workout and isn't quite as thick as this section of the rocker is but I don't have the ability to fab anything thicker that will even remotely match.

A bunch of goodies have shown up. I bought them from a very well known company and, I have to say, am not at all impressed with the quality. I ordered three lower door repair panels - one for each door (eventually) and one to cut up and use for the fender repairs. Two have a small dent right in the middle and one has a dent out by the end and the cab corner (eventually as well) is super, super thin metal and really isn't formed terribly well in the most visible spot.

Along with the repair panels, what you see are new sill plates, door weather stripping, door glass channels and anti-rattle felt. Elmore is becoming a luxury truck.

Well I forgot about the big section that incorporates the hinge mount when I said the big cutting was done.

First I made a simple jig to ensure I get the spacing right going back together.

Then I held my breath and cut.

Next I spent a lot of time grinding, flap disk-ing and wire brushing. Tomorrow will be template making for the big vertical repair piece.

I cannot weld any where near well enough to do the work your into on this, but I AM a right good fabricator... and my hat is off to you! LOTS of nerve, cutting there!!!

Seeing the rest of your work, I also know you got this! But I can imagine the "deep breath" that took!

Amazing , and thanks for the posts!

In reply to 03Panther :

Thanks!

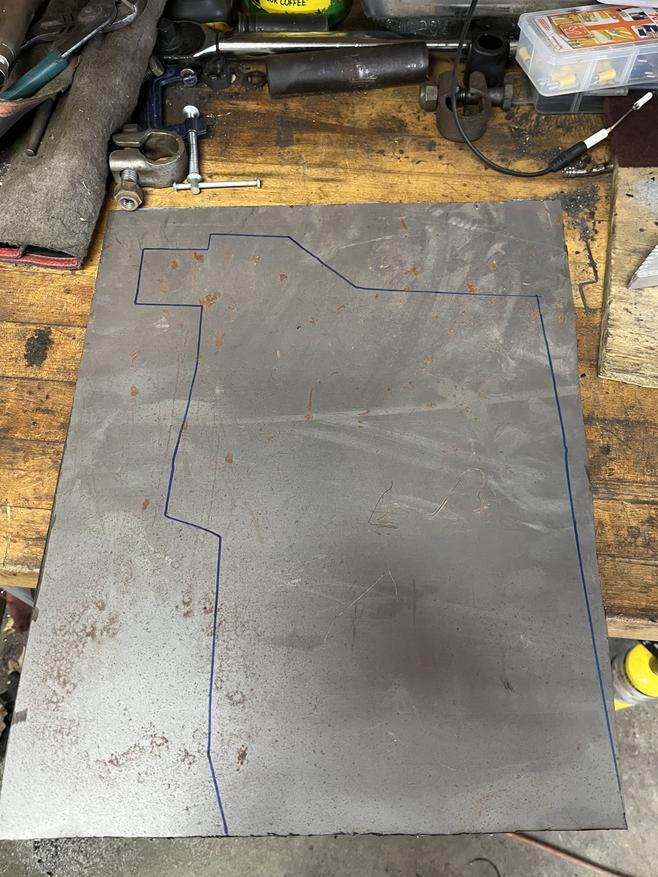

This may be the most complicated flat patch panel I've ever made. Counting the template and all of the cutting and trimming I've done so far, I'm probably 2+ hours into this and about 75% done, I'd say.

It's a funky shape because of all of the rust chasing I had to do while cutting the old stuff out.

Cut, cut, trim. Cut, cut, trim. Etc.

Nailing that section below the heater intake toward the firewall is going to be tough. It will be a careful game of very light flap disc work so as to not take away too much material.

I discovered a bit more rust on the bottom side of what I'll call the intake box for the heater when I vacuumed more E36 M3 out of there. Cutting into and attempting to repair that section will definitely be a massive snowball so I'm likely not going to tackle it now.

I need to remember to spray rust converter everywhere I can before getting this big patch panel in place as well as get some paint on the back side.

You're reminding me that I still need to fix the dogleg rust on my MSM. At least the other car projects have forced me to set up the new garage somewhat better.

In reply to JoeTR6 :

Well, you're welcome, I guess!

Last night I got the piece dialed in.

I'm pleased with the fit but there will be a few areas where blow-throughs may be inevitable.

It was way too cold to do any painting out there last night so I tried out the vice grip flange tool I bought years ago for work on the Healey.

This piece technically should have and flange and although it's a bit of a bear to squeeze this thicker material it should be doable.

It's in the single digits this morning so, again, it'll be too cold to paint but I'm hoping that between meetings/on my lunch break I will have time to get a fresh propane bottle and run the torpedo in there to get it somewhat up to temp. Progress must continue.

In reply to AxeHealey :

If you got your tin from the same well-known company I am thinking of, they are somewhat known for thin sheet metal.

In reply to Recon1342 :

I don't want to give too much away but it rhymes with Shmassic Shmindustries.

Propane and ...enough... temp attained.

I'll have to remove some of this freshly applied paint/converter for install but at least things are protected now. I think the next step is trying to figure out exactly where the flange needs to go and then struggling through that.

OK quick update because I was excited.

Unfortunately it looks like I cut the outside of the hinge panel a bit high but I'll add some material to the top of the repair panel before install after checking and re-checking again.

On another point, the aforementioned well known company whom I bought the repair panels from almost immediately agreed to a full refund for the two damaged panels. Good on them for being easy to work with.

A quick afternoon break and big forward progress. First of all, the flange tool worked great.

It doesn't quite match the factory profile but, like, so what?

I then got the funky repair panel I made welded in place to mock up the final trimming I'll need to do on the big piece.

Cutting the excess off the funky piece will be a little hairy with it in place but it'll be fine.

In reply to AxeHealey :

I think they get their stuff from the same place as the popular truck restoration catalog Ellemmcee truck.

These old trucks, OEM sheetmetal is almost always better than the replacement stuff.

In reply to Recon1342 :

The OEM stuff is beefy, for sure. Even with the rust-made texture on that rocker it's still pretty thick.

I was out of town Wednesday afternoon through last night but was back at it today for a bit. After painting the funky patch piece as well as the back of the pillar repair panel, I first welded up the slit I needed to cut to remove the rusty section of the pillar.

Then it was a simple clamp up.

And melt it all in.

I didn't chamfer the edge where I butt welded at all so it didn't sink in as much as I'd like but clearly there was good heat penetration. Once I knock it down with the flap disc I may need to touch it up a little with the welder, we'll see. I also need to do one little stitch on the inside.

First thing this afternoon I turned on the propane heater, got the metal warmed up and ran seam sealer in the areas about to be covered up. Second was a LOT of patient, slow work to end up here!

Right under the heater inlet just got so thin when I was prepping it that I knew I would be in danger of some blow throughs and blow through it did. Only a little, but it did nonetheless. In the pic from the inside of the cab you can actually see where there's a little crack coming out from the lower-right bolt. I won't be doing anything with that right now.

I will probably drill a hole and put one more rosette weld from the funky patch to the A-pillar but otherwise I'll clean up the welds that will be tough to get to once the floor patch is in and then move on to said floor patch.

To and from Erie this morning for a meeting but I did some flap wheeling and started to work on the floor support flange on a quick break this afternoon. That's the only relief cut I will need for a bend on that axis but I may actually need a couple on the other surface to better follow the patch I just put in.

I also drilled the hole for the final rosette weld which I'll do tonight once my wife's truck isn't in the way.

Flange done. Not the best effort I've made on this project but it's under the truck and will do the job.

There's still a lot of cleanup to do but that's pretty much it.

I should have time tomorrow to at least make a template for the floor patch.

Somewhat annoyingly the welding-in of the patch hasn't gone great. Strange stuff was happening. Turns out I was running out of wire. That on top of the fact that the existing floor is very contaminated means it ain't pretty.

Nothing a flap wheel can't fix, I guess.

I've been leaning toward bed liner for the floor. Tan bed liner, to be specific. It should be much more durable than paint and the tan both matches the bumper/grille and will show less dirt than black, which I think would always look filthy. I don't think carpet is appropriate for Elmore and how he gets used and I usually don't like the look of the factory rubber floor covering.

NOHOME said:That right there, is some top-shelf A-post repair.

Pete

High praise, and well deserved. You do nice work, Axe. Or is it Mr Healey?

You'll need to log in to post.