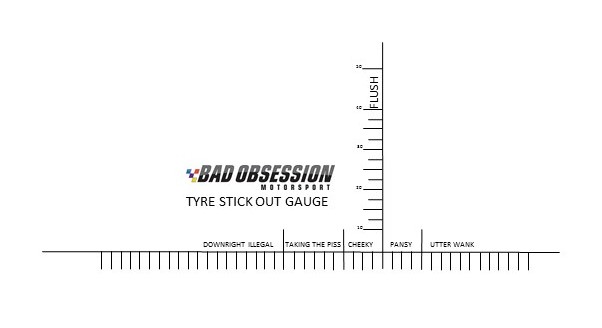

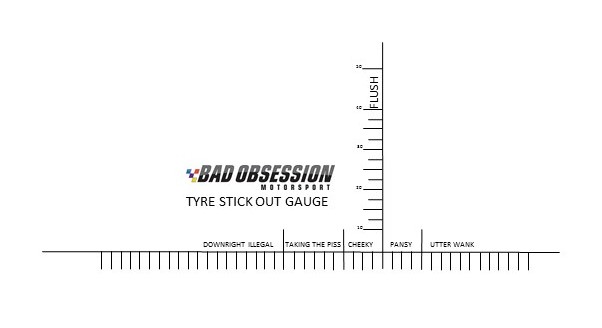

Jumper K Balls said:Fitment is on the cheeky side but with the right tires it could work. Besides minis look great with a bit of tire poking out.

Jumper K Balls said:Fitment is on the cheeky side but with the right tires it could work. Besides minis look great with a bit of tire poking out.

Nice find on the banded Cooper S wheels!

What is your plan for the car again? Is there much rust to fix?

In reply to Chappers :

Plan is to rebuild the 1098, drop it in and drive it. There are two minor rust issues. One in the trunk floor and one in the drivers side rocker. Those will be patched and sealed up eventually but they are quite minor and might just get a slathering of rust bullet for now.

In reply to Jumper K Balls :

Nice plan! Sounds like a lot of fun.

Do you want to run the turbo kit on the 1100?

I’ve previously run a turbo on a 998, used a 1275 head and machined pockets in the block for valve clearance.

To lower compression I machined a shallow dish in the 998 pistons as the crowns are quite thick.

Managed 82hp at 7psi.

Like you say the A series are quite heavy for their size. So I’m not planning on running one in my mk1.

I haven't decided yet. It would be pretty cool to push a bit of boost through it. I guess it kinda depends how long the machine shop takes.

The turbo bits are incomplete and I have yet to see how it all fits together and how things like oil drains and whatnot is routed. I know the intake manifold is so tight that it has to be installed on the head before the head is set on the block.

I also need to read up on the siamese port code for MS2. It appears to be dead, being supplanted by MS3. Perhaps a SPI solution is in order?

I find all of this most fascinating. Apologies for the thread jack, but I couldn't wrap my mind around the DOHC K-100 head on the cam in block BMC engine.

Oh

I do have a question for both Jumper, and Keith : Why are 10" wheels superior?

My hypothesis is that they are first lighter, but also that they are part of the suspension. I know Minis use rubber bump stop like things in place of springs or torsion bars or whatever. I also know these are sometimes filled with fluid, and linked to one another. The point being that Minis are very unconventional, and everything is about finding the sweet spot. I suspect the combination of lighter weight, more supple ride, desired sidewall deflection and whatnot is what makes them the bees knees . None of the race cars from the 60's had 13" wheels.

I'm more curious than anything.

I think it’s weight and overall OD - the 12” wheels do run a larger diameter tire.

My car came with 12” wheels and I wanted 10” primarily for the looks. I was not expecting how it woke up the car. It just felt...right. Nimble, responsive and better riding. You have to remember that rotating and unsprung mass is best expressed as a percentage of total vehicle weight, which is why light cars are so sensitive to it. You may be right about the sidewall stiffness as well.

My car is on a fairly standard “dry” suspension, just aftermarket shocks and adjustable control arms.

Interestingly, a set of 15” wheels transformed both the ride and handling of my CRX, which came with 13s. I think the reason there was tire quality.

I personally like the look of all sizes of wheels on minis. I even love the 13" sportpack cars.

My reasons for changing them up are thus

More tires are availiable in 165/70R10 than 165/60R12

Depersonalizing and repersonalizing. I freaking LOVE minilite style wheels, but I don't want the car to always be known as the previous owners car. I have to make it my own.

I adore the look of wide steelies with caps

Sigh...

And I see the steelies as a step toward my other favorite wheels. 4 spoke Revolutions

As for progress on the car. Some of the parts have started trickling in. Any loose parts have been prepped and painted or powdercoated. The block and crank are still sitting exactly where I dropped them off at the machine shop ![]() again, it is his busy season. To borrow a phrase from my dad "Not angry, just disappointed". I cut out the PO's custom seat mounts and am giving the floors a coat of zero rust to seal them up. Picking up a set of front seats and a chrome Mk3 grill some evening this week.

again, it is his busy season. To borrow a phrase from my dad "Not angry, just disappointed". I cut out the PO's custom seat mounts and am giving the floors a coat of zero rust to seal them up. Picking up a set of front seats and a chrome Mk3 grill some evening this week.

I'm with you on the wide steelies. They just look fun.

FYI: a good UK-priced source for parts in the US is gbcarparts.com.

Thanks for the responses, guys. The steelies are in fact awesome, as are minilites, and those revolutions as well.

Everyone does, in fact love a mini.

In reply to Keith Tanner :

I get a fantastic shop rate from bpnorthwest.com and they are just down I5 from us so parts are here overnight for the price of ground shipping, First order from Seven Enterprises will be here tomorrow. Minispares doesn't like my credit cards for some reason so that hasn't happened yet. In talks with Optimise Automotive to see if they will ship larger pieces to the US.

For a complete car I am sure buying a lot of crap for it....

Every weekend has been spent helping my folks either renovate or move into their new house. I get a whopping 20 minutes at the end of the day Monday thru Friday to work on the Mini.

So I busy myself with small tasks like resealing the gearbox

and cleaning and installing new boots on the drive shafts

And removing the tint from the glass

I don't know what it is. I used to LOVE window tint but now I absolutely dislike it on vintage cars. Plus as a part time motorcyclist and as an enthusiast of cars that might as well be motorcycles I don't like it on other cars because I cannot see the drivers eyes so I don't know if they see me. This was actually nice quality film but the car looks so much brighter and more cheerful without it.

The PO stopped by with a few more bits he found for the car and included was this set of rockers he had made for it and ran for a while. I gotta admit the CNC billet steel looks significantly more durable than the folded sheet metal variety. The PO is a really nice guy.

Off to drive another 200 miles today moving sofas and freezers and the like. Perhaps some progress next week.

Took out the back glass to remove the tint and used the opportunity to pull the last bit of stinky carpet out to be greeted with a bit of a mess on the package tray.

That is a lot of hole!

I think I would like some speakers back there but they will need to be protected since I can guarantee that area will be the spot our Chihuahua "Clementine" will hang out. It also will need to be lightweight since mini so a slab of mdf is probably out. Also wrapped in something other than carpet because dog fur.

Jumper K Balls said:Took out the back glass to remove the tint and used the opportunity to pull the last bit of stinky carpet out to be greeted with a bit of a mess on the package tray.

That is a lot of hole!

I think I would like some speakers back there but they will need to be protected since I can guarantee that area will be the spot our Chihuahua "Clementine" will hang out. It also will need to be lightweight since mini so a slab of mdf is probably out. Also wrapped in something other than carpet because dog fur.

Not sure what your mounting options are there, but I’d consider a sheet of aluminum, mark and cut speaker holes, and then cover it in your favorite flavor of vinyl.

Those rocker arms are stock items from an A+ series engine introduced in 1980 onwards (standard lift is 1.3:1). I'm not sure they were produced by anything fancy like a CNC, probably sintered metal like the stock con rods.

I think the PO is either misremembering or not telling the truth.

You can however buy CNC machined rocker assemblies with roller tips https://usa.minisport.com/1-5-1-mini-roller-rockers.html#product_tabs_description

I had a set of those higher lift 1.5:1 on an A+ engine I built.

Well look at that. They sure are.

I just assumed he had made them based on the hard edges and the fact that he had made so many other bits.

^ That about sums up my attitude right now ^

Waiting on the machine shop, waiting on parts. waiting on more "fun money" to spend more on it.

Whilst waiting for the carpet to arrive and wiping things down I noticed the heat control slider was seized. So out it came

It was blown apart

The metal bits were run through the parts washer and sandblaster. The shells powdercoated wrinkle black

And reassembled with new foam seals

I'm probably going to wipe down the inside firewall and apply a few insulation/ sound deadening sheets next.

I have 5 10x6 revolution wheels. I use 1 as my spare and the other 4 have Hoosier slicks on them from about 10 years ago when I last autoxed it. My set is not real pretty.

In reply to Jumper K Balls :

For the stamped rockers, I seem to recall seeing a weld bead run along the seam of the rocker on race prepped 1098s. For added strength of course.

I never ordered anything from them, but Mini Mania offers some pretty neat stuff for purchase.

I just heard from the machine shop!!!!! 0.10" over on the mains and rods and 0.05" over on the thrust bearing. The bores were indeed pretty scored so instead of going through the extra labor of creeping up on the minimum bore size, we just decided to go all the way to 60 over bringing this baby up to a whopping 1150cc. All parts ordered from British parts northwest and should be here tomorrow!

I also finally got a ship notification from minisport!

Progress is good! I mean, I doubt I will make it to mini meet west on the 25th but it is a reasonable goal!

Picked up another batch of goodness. A geniune 1275 Cooper S 11 stud head that has had some mild porting done. It is ready to install.

Valves are much larger than the head I got with the car.

It came with a set of 1.5 ratio roller rockers as well.

In other news after ordering bearings and pistons and delivering them to the machine shop I got a call saying it wouldn't work. The stroke was too short at 3". So despite the sellers insistence that it was a 1098cc it is actually a 998cc engine. No big deal. They are smoother and the cranks aren't as prone to failure. I returned the piston set and got the correct ones. Still going 60 over so it will be a 1050cc mill.

I also had my first ever ring gear installation failure. The old one came off the flywheel easily enough and I heated the replacement to 250 for 20 minutes as usual but it didn't fit. let it cool, measured and saw it was 28 thousands under. I didn't pull out the machinery handbook to check for a heat shrink clearance, called the vendor and they said "I'm sure its right, try more heat" so I tried it again at 325, then 375. At 375 it slipped over. Just needed a little tap to drive it home as it was sitting at a jaunty angle so I turned and walked 10 feet to grab a hammer and I heard a "pang" noise. Returned to find the ring gear D shaped and the flywheel broken! CRAP!

So next thing you know this guy was winging its way over the atlantic

It is the heaviest of the lightened flywheels I could source. Shockingly inexpensive as a used stock unit was $150 and this was $125

I also misordered a CV joint

Oops.

And got the bonnet trim lip piece from minimania to mount the shiny grill

I have got to get this thing rolling soon!

Sincere thanks for sharing the failings in the process too - building old cars and ordering parts is often very frustrating. Those frustrations have caused me lots of delays and hurt my motivation in the past, so it's a good reminder that they happen to everyone. Keep up the good work!

I remember having significant trouble getting my Mini flywheel off when I did the trans a couple of years ago.

Minis are tough to order parts for because they were made for so long and in so many variations, but the variations are all subtle. Then add in a half century of people swapping parts and VINs and it becomes a real exercise in forensics. I'm lucky with mine in that I have all the paperwork from the fellow who did the initial modification so I know exactly what's inside that Rob Walker engine. A random basket case? Adventure!

You'll need to log in to post.