In reply to bbbbRASS :

Got it yeah, I did try using 2nd gear starts just to challenge myself for one drive but gave up on it haha. I wasn't giving it any throttle most of the time which gave me slow starts. I started using more throttle (no more than 1500) and it's gotten much easier.

So apologies for disappearing for a bit, life took over. Went on vacation using a friend's dad's old car which turned out to not have tight lug nuts and almost killed us (I thank my mechanical sympathy for telling me to pull off and check what the vibration was), then got a nail in the tire on the way back and I discovered a rear lower wishbone/trailing arm (subaru outback multilink rear I believe) bushing that was completely shot.

Recently I've done some more work. I replaced the odometer

Wheel off:

Empty cluster hole:

Wiring mess under the steering wheel (the panel is missing):

Cluster out with one broken mounting tab (not my fault haha):

Taken apart:

Old gears:

Functional Odo with mileage added that I've been tracking:

I also had the opportunity to go to a ford driving skills for life event. The various safety activities were cool such as impaired driving and emergency lane change and braking, but the best part was driving the mustangs with the casters. I went back again for a second day and the instructor let me move on to doing figure 8's. The most fun i've ever had in a car and I can't wait for more motorsports. I learned a hell of a lot and feel much more comfortable with less grip and making the car move around. I also met mike snyder who campaigned this CRX in SCCA autocross:

As well as a gentleman named nico who campaigns an f22 240i in nurburgring 24 hrs and another gentlemen named clint boisdeau who's raced in many series. I can't wait to do a real high performance driving event.

On the drive back i heard a metallic ping and felt something in my pedal box. I looked down to find a sheared off bolt with a nut and washed and a smooth part. My clutch still operated fine and felt weird but I tried to limp it home. On one of the side streets suddenly my accelerator locked up. I came to a stop and a spring fell out of my accelerator pedal assembly.

Turns out the clutch helper spring assembly had sheared off at the bolt and deleted itself.

After seeing the price tag for a new assembly at over $100, I decided that I could live with a deleted helper spring. I've actually turned out to enjoy it more without that weird effort hump/detent in the pedal travel where the spring switches from pushing against you to helping you.

However, i am worried because there is some of free play/travel at the top of the pedal travel. I'm worried that this is putting some depression on the clutch cylinder and wearing the throwout bearing and clutch. I am also worried that when i rest my foot on the pedal I might also be depressing it slightly and causing wear. What do you guys think?

Lastly, I had the misfortune of experiencing a hit and run. Went to a doctor's appointment and parked in the garage and someone broke my left rear bumper trim while I was gone.

I've done a crazy amount of googling and it seems like, while the right side is plentiful in supply, and I can find plenty of left side ones without marker lights slots, the left side with marker light slots is completely unavailable anywhere. I've messaged some people on facebook marketplace advertising "e30 parts" but if anybody would happen to know where to get a new trim piece I'd be very grateful. Or if anyone has one to sell.

1. Do not rest your foot on the clutch pedal. Seriously. Get out of that habit now.

2. The pedal does not weigh enough to cause any wear of anything in the clutch system.

3. good to see you back!

In reply to AngryCorvair (Forum Supporter) :

Thanks it's good to be back. And that's for the pedal info!

Do I hover my foot over or rest it on the dead pedal?

Leave it on the dead pedal. Better yet, use the dead pedal to brace yourself when you toss the car around! That's what it is for.

Hi everyone, I am back!

Been away at college (RPI if anyone knows it) so I didn't have much time to work on the car. Over thanksgiving break I got home to the car not starting - that was a wonderful surprise.

Turns out I guess my mom hadn't been starting it enough because the charge had dropped horrendously. I ended up having to jump it a bunch of times before getting it tested at autozone. They said the battery was fine but the charge was low. After driving it daily it stopped having issues starting.

I also got home to the cold and realized my heat wasn't working. It didn't work unless I was idling, basically anything over 5-10 mph and it started blowing cold. After a bunch of googling I realized that my heater matrix hoses might be swapped. Sure enough, I checked and that was the issue. Not sure what moron put it together before me but I did fix my heat!

One of my best friends also purchased his first car. A few days before i came home he contacted me asking me to help him find a "good, reliable, fwd car" that would be good in the chicago winters and for him to get to his internship. I sent him a few cars, mostly civics, before he said he changed his mind and his dad would be giving him his old car.

I then found a cheap as E36 M3 E36 M3/4/5. I sent it to him just for fun - it didn't come anywhere close to meeting the requirements but I thought he would like to see it.

He ended up buying it - it's an ex track car owned by a gridlife instructor with no e-brake (if anyone had advice for how to fix an e-brake that's been deleted at the hub let me know), a carbon sunroof delete, m50 intake manifold, recaro bucket, no stereo or door panels or speaker, borla exhaust, vice grips as a hood release lever, and driveshaft and shifter issues. He also had to machine a bracket/anchor for the seatbelt latch because it didn't have one. But it sounds AWESOME and we've had a ball with it.

Here's our cars together:

and his car

Additionally I'm part of a formula SAE team. Disappointingly we are EV team :(.

i haven't been as involved as I'd like due to academics and time management, and I've mostly been doing menial shop work instead of fun design. And I've already managed to piss someone off. BUT I have gotta the chance to do a lot of (admittedly simply) CNC machining. I'm having a ball, but also realizing it's a lot harder than I thought it was. We don't have electronic edge finders/ probes, or automatic tool changers, or any good/repeatable workholding, so i spend 45 minutes zeroing and tool changing for 15 mins of machining. We also don't really have too many collets so we have to switch around tools a lot so we haven't been able to set tool heights either - we use an edge finder, zero x and y, and then put the tool in and zero z off of the tool - not as precise as we'd hope and it's causing issues with some of our smaller, detailed parts.

I am pretty proud of me and my buddy's solution for cutting an angled hole yesterday. We 3d printed angled shims out of 100% infill nylon and put the in the vice jaws on top of our parallels and then used them to hold the piece at an angle. It works very well considering the circumstances and was hopefully within tolerance (we haven't checked yet).

Any tips would be greatly appreciated! Also anyone with experience in FSAE in general advice would be greatly appreciate and advice on becoming a useful/valuable member of the team

I also had my winter break. I got home and once again had issues starting that resolved themselves after enough driving.

I then got a wonderful new surprise - I put down my other rear window and was greeted by it not going up. This was late at night in the cold. I checked the switches and they were all fine. The rear switch didn't even light up which tells me it wasn't getting power. This has led me to deduce that one of the wires into the door has frayed. I have no clue how to track down or fix this issues (if anyone knows i'd love advice). Ended up pulling the door panel, disconnecting it from the regulator, and propping it up with a length of bamboo. now I have 2 non-functional rear windows

I also ordered a bunch of parts for the car, and got almost none of them installed due to the cold.

A few days later I went to visit with my friend and cruise together without cars. He did not enjoy driving his lowered, oversprung/underdamped car on chicago roads, but it was awesome. I drove the car ridiculously hard, and on the way back - like 5 blocks from home, I smelled something burning. I assumed it was environmental but then saw steam/white smoke coming out of my hood. I nursed the car home, barely taking my eyes off the temp gauge which stayed steady at the 12 o'clock position. When I popped the hood and traced the leak, I found a whole lot of coolant had leaked out from around the coolant level sensor. I knew the sensor was bad electronically, but I didn't know that it wasn't sealing right. I hope it was just a leak from normal coolant system pressurizing, but I did get worried at the fact that coolant got pushed out of the expansion tank. I started to wonder if my cooling system was overpressurized, potentially by exhaust gases. I ordered a new coolant level sensor in the hopes that the seal had simply gone bad.

The next night, after dealing with the window, I noticed white smoke pouring from the tailpipe. This seemed to confirm my fears and scared the ever loving E36 M3 out of my that my head gasket was blown. I started looking at gasket kits and machine shops in the area. The next day I got an exhaust gas leak tester and fluid, and a compression tester. The leak tester showed perfect blue fluid - not a hint of color change to indicated exhaust gasses in the coolant. Not satisfied, I decided to do a compression check.

I was actually astonished by my compression numbers - a perfect 150 psi on all cylinders. I think that is remarkable for a 218,600 mile engine,and it put my head gasket fears to bed. I also drove it some more and noticed that there was no more white smoke. Still can't, for the life of me, figure out what caused the smoke but I'm not worried with those compression numbers.

Due to the cold, i couldnt get much done. I tried to replace my glove box latch handle twice but got screwed over on the parts both times.

I did however manage to do my valve adjustment and replace my valve cover gasket and do an oil change to a 0w-40. This is where the problems started.

I looked in the engine bay and found the source of my power steering troubles. When I had done my timing belt in august, I had no teeth on the power steering tensioner and had to try to hand tighten it. It worked briefly, squealed a bunch, and then stopped working. I assumed it hadn't been tensioned sufficiently and didn't have time to figure it out due to going off to college. In the engine bay I saw that the belt was not there - I suppose it had been thrown at some point. However, underneath I noticed two long bolts that looked like they held the power steering pump together were missing nuts and rattling around - I assume the nuts vibrated off somehow.

It got worse - I opened my PS fluid reservoir and it was bone dry. Not even a film or residue in there - just straight up plastic. It's possible it leaked out but I can't understand why the power steering used to work, then it stopped working and now there's no fluid but I never saw a puddle under the car and I assume a leak wouldn't make it that clean and dry inside.

Anyway I moved on to the valve adjustment. Got the rear end up so I could turn the wheels to turn the engine over and what did I discover? I'd been scammed. The seller told me, on three separate occasions in writing, that the car had an LSD. It does not have an LSD - it has an open diff. That pissed me over something fierce, but I moved on.

I got the valve adjustment done - I had a hard time with the feeler gauge determining what was "slight drag" but I thought I got it. I also found the cylinder 5 exhaust valve rocker arm was loose along the shaft - sliding back and forth. I got the car back together and took it for a drive and was greeting by a horrific ticking sound - worse than a damn sewing machine. At this point I was fed up, discouraged, and announced to my family that I was giving up and towing it to a shop.

The next day I found a writeup that discussed using a go-no go system of three sizes of feeler gauges to make sure of the tolerance. I was pretty afraid to muck it up but I decided to re-adjust the valves and sure enough, every single one was loose. I guess I didn't quite figure out the "slight drag." I also figured out why the rocker arm was so loose - the retaining clamp was no longer springy enough to hold it in place. I ordered a new on through the dealer with a surprisingly cheap price and short lead time.

As I was closing up the valve cover, I noticed two problems. One - the vaccuum hose to the FPR was broken off. Two, and much more severe, the front most driver's side valve cover bolt didn't seem to be getting any tighter. I went as far as I dared out of fear of stripping it, and decided to leave it alone.

A few days later, my clamp arrived and I opened the cover up again to replace it - an easy enough job that took all of 30 minutes. However, when I closed the cover back up, disaster struck. The valve cover stud stripped right out of the head. I barely had to turn the nut and in fact I was able to just lift it out of the hole.

This was 2 days before I had to leave for school and I freaked out.

After a bunch of research I decided I would drill it out, tap it, and insert a helicoil insert. After running around to parts store to get the inserts, drill bit, and drill guide block I got back to realize that the engine hoist bracket wouldn't allow me to get my drill in. I pulled the distributor and rotated the bracket out of the way to realize my drill guide block wouldn't fit with the intake manifold and rocker shaft caps in the way.

I cut down the guide block, chucked up my bit, and drilled as straight a hole as I could. I then tapped it and as I was tapping it realized that I had completely berkeleyed it.

here's the picture, let's see if you can see this issue:

yep, that's right - it's not straight. At this point it was ridiculously late, the damage was done, and I decided ot just put it together to seal the valve cover and call it a night. I inserted the insert and then the tang wouldnt break off. Then the insert tool got stuck and completely mangled in the hole. i eventually got it out however, and the stud went in. Except it didn't really turn to that high torque - it still felt loose.

Not wanting to strip it again I called it a day, and went to put the cover on. Of course the stud was too angled to allow the cover on and I had to force it - completely improper way to do it but I was low on time and knackered. I got it on and torque as tight as I dared (can't really fit a torque wrench in there) and called it a day - dissapointed and pissed off. I also managed to break the oil fill cap when I was smacking the valve cover to get it to go on past the binding stud.

I am honestly at a loss of what to do. this is the most recent work I've done on the car and now I'm back at university but I want to find a solution before spring break so I can fix it. My only solution is to drill it even bigger and the only was I can think of to keep the bit straight is machining my own L-shaped drill guide that clamps onto the other valve cover studs on either side of it. But I still would have to remove the insert, drill an even *bigger* hole with a bigger helicoil, and take all the risk of mucking it up again.

I could really use some advice because I'm competely out of my depth, and almost at the point of taking it to a mechanic.

Lastly, i went to put my front strut bar, and found a random, zip-tied, white wilwood fluid reservoir in the way. My best guess is that it's the clutch reservoir from the manual swap and the person bodging it together, but I can't figure it out and it's in the was of my strut bar. I will have to diagnose that over spring break as well.

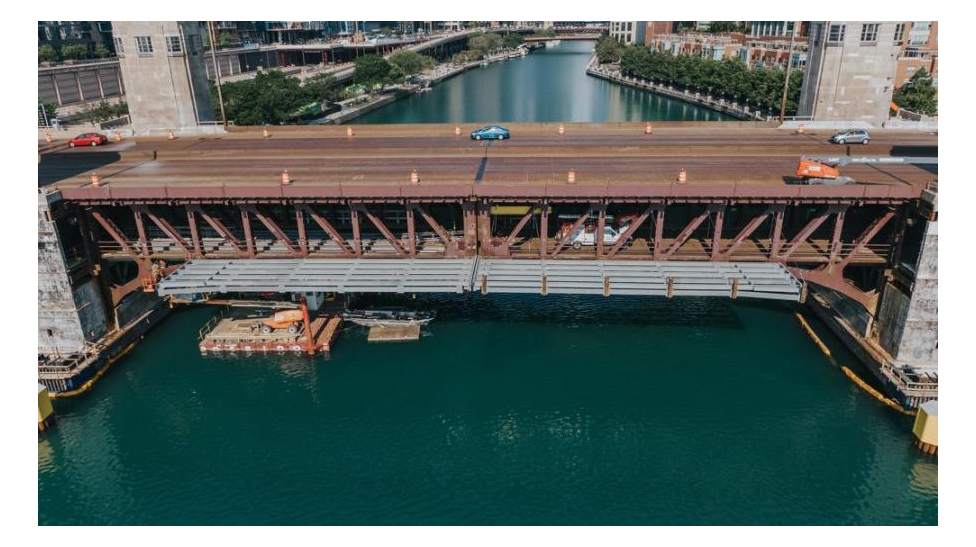

I did have a fun and terrifying experience however. I was driving to a doctors appointment, in the cold, and drove across a nice metal grate bridge - specifically this one:

Well as I drove on the bridge and upshifted, All of a sudden I was facing the water, then back on the other side of the water - fishtailing back and forth. I eventually caught it, and was really glad I had taken the driving class that i took about 6 months ago because I think my car would've been totalled if I hadn't managed to catch it. It was absolutely terrifying but also ridiculously fun.

I don't really speak much BMW, but what are the chances that you could go with a larger stud? bolt? in place of the original? Is there enough flange on the valve cover that you could drill that out a bit? My first thought would be to get a block of metal, aluminum I guess, make sure it's flat, clamp it down into a drill press and make your own drill guide of the correct size. That size would be maybe the next size up helicoil. Then use that new guide to attempt to drill a larger hole straight in, tap it, and then put in the insert. I'm not sure if that's a good idea or not, but that's probably what I'd try second. The first thing I'd see is if an application of RTV would seal it up enough. I suspect the "right" answer would be to TIG the hole shut and re-drill it. Maybe an epoxy would be enough to fill it and then make your own drill bock that would fit in the space and drill through the cured epoxy?

The extra block of metal sounds like a good method to guide the drill bit for the new hole. I would go with a helicoil too.

You know that BMW stands for "buy more wrenches", right?

Or is it "broke man walking"...

In reply to wae :

Thanks! I am not sure if I could go larger, my gut instinct is yes. There looks to be a decent amount of meat around it, and it's not taking any side loads or even really very much load from the nuts. However, I have just started my strength of materials class this week so I don't know haha. In terms of the valve cover there is plenty of flange, in fact the hole slightly oversized so i think it would clear a larger stud.

Welding does seem like the most proper way, but my gut instinct is that it would never work. The hole is too small and deep to be able to properly clean and there's no way I would ever get all the oil, debris, and shavings out - which is a big part of a good weld, a clean surface. I suppose if I pulled the head, drilled it out fairly large, and then had it welded it might work but that gets to the point of cost and still may be very difficult with how small the hole is. Plus if I'm pulling the head it will likel warp requiring it to be decked, and then the "while you're in there fairy" might visit me. Pulling the head is not a path I'd love to go down.

I hate the idea of tapping into epoxy and leaving part of my head supporting threads as a piece of epoxy. It just feels wrong even if it might technically be safe. I'd rather drill it larger and helicoil or timesert it if possible. and I think that I can mock up a jig to keep the bit straight (mostly) using the machining resources on campus.

You'll need to log in to post.