In what can only be described as a totally berked chain of events, I have come to own a new smoker. Isn't she a beaut?

The cooking chamber is a 30 gallon compressor tank from 1967. When I found it ~12 years ago and gave it to my buddy, it had been sitting in the weeds on the side of the road for god knows how many years. Finally, it got a new pinhole, so he pulled the pump and motor, and I got the tank. The propane tank, and the chimney which isn't pictured, came courtesy of the scrap pile at his work.

I took some rough measurements, and realized I had a great place to actually work on it instead of crawlying around on gravel.

As a side benefit, it marks almost a perfect centerline. Actually off the exact amount I want it to be. The top of the stand is where the cooking grate should sit.

As a side benefit, it marks almost a perfect centerline. Actually off the exact amount I want it to be. The top of the stand is where the cooking grate should sit.

There was a plate that held the motor and pump assembly, so after a spray down with simple green and a hose, I ground off the old welds and got to making things a little shinier.

There was a plate that held the motor and pump assembly, so after a spray down with simple green and a hose, I ground off the old welds and got to making things a little shinier.

Because I know there are a lot of fans of CAD here, I've got the door mocked up.

Here's the math

While the propane tank isn't the ideal size for a firebox, it will work. This is going to be a reverse flow smoker, so I still need to source a baffle plate.

I HAVE drawn everything up in autocad and made it work, I just don't feel like taking, editing, and uploading a bunch of screenshots that have bizarre dimensions half there that no one will understand.

I'll be using 2.5" weld on hinges on both doors, I have some angle iron to hold an expanded steel cooking grate, some flat to make the flangers for the doors and cover the gaps. The chimney will be 3.5" steel pipe, 1/4" thick.

I haven't weighed everything yet, but I've found a nice supply of steel pipe that I'll be using for legs. Harbor freight has some VERY cheap wheels and tires available, so I'll probably weld on what's left of my round stock for axles so I can move this pig around.

Once I get this cut open tomorrow and see why it sounds like it's full of gravel, I may ask that this thread be deleted, or I'll continue on with assembly.

RevRico

SuperDork

7/3/17 12:20 a.m.

OK, I managed to get it sorta legible all on one page. For scale, tank is 34" long and 15" diameter. propane is 12x14

The plan was to enlarge the nozzle hole on the propane tank to 3 inches, but now I'm thinking that I should leave the nozzle alone, and put a 2 inch hole on either shoulder with dampers.

Mathamagically, cutting matching holes in the should of the compressor and propane tank will work. We'll see how my lack of welding skills and questionable working methods pan out.

Being that I'm building it with reverse flow, I can fudge the holes a bit, as long as I make it leak proof. There will be some sort of steel plate going across the majority of the bottom of the cooking chamber, with the exhaust pipe beside the fire box. This configuration allows for much more even heating and smoke penetration. I'm going to put a layer of insulating cement on top of the steel to help hold the heat with the door open.

If you have any questions as to why I'm going it like this, or some advice, please, let me know.

Cool!

Can you explain a reverse flow smoker? I mean, I know EXACTLY what that is, but just pretend I don't.

In reply to DrBoost:

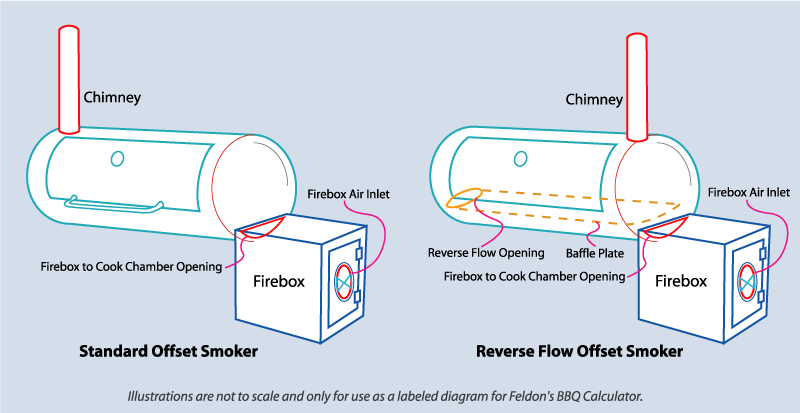

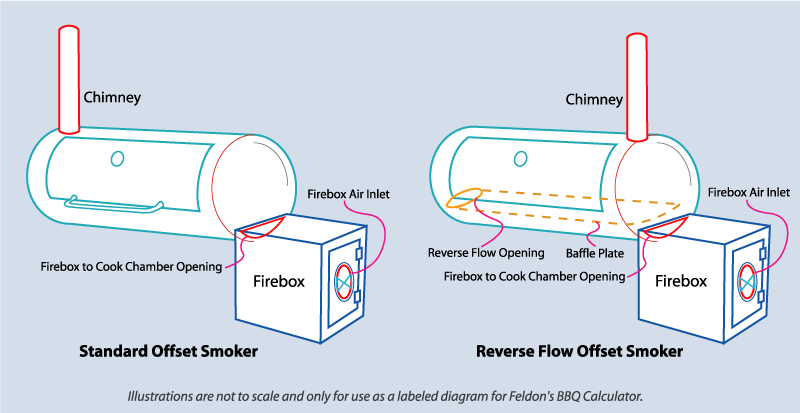

This picture might help more than my words will.

With a "traditional" smoker, the fire box and chimney are on opposite sides, ideally with the chimney resting on the cooking grate. Depending on airflow, this typically results in uneven temperature distribution with hot spots and cold spots, and a sometimes overwhelmingly strong smoke flavour from the airflow.

Meanwhile, a reverse flow smoker has a baffle going over the connection of the cooking chamber to the Firebox, and the chimney winds up on the same side as the firebox. This configuration allows for far more even heating of the cooking area, resulting in more consistent temperatures and an easier to manage, albeit slightly hungrier, fire, but could result in less smoky flavor overall. (Not less, just different, this is something I just don't know the words to describe, you just have to taste it).

My new braunfels I grew up on was a traditional smoker. After 18 years, I added just small a baffle plate over the firebox port, and saw my side to side temperature differences go from 55 degrees to around 6 degrees. Just with an old cookie sheet bent to fit and screwed in. The downside of my just adding a baffle plate was a slight reduction in smoke flavour, as the chimney being on the far side pulls most of the smoke straight through missing the meat.

My hope is that adding insulating cement and maybe some fire bricks top the top of the baffle plate will really even out the temps across the whole cooking chamber, and allow faster temperature recovery after opening the door, letting me experiment more with mop sauces and more varied cuts of meat because I won't take quite the temperature hit opening the door.

There is no right or wrong, and smoking forum debates tend to devolve into Ford vs Chevy or donkey versus elephant style arguments. I will say I see reverse flow used a lot more often in the 200 plus gallon sized smokers where keeping even temperatures is more difficult and important, so some of the thought is if it works for them it should work for me.

RevRico

SuperDork

7/3/17 12:35 p.m.

When I got back from HF, forgetting until I got home to get the tool to remove the nozzle from the propane tank from Mikes house(dammit), I set to work. Drew out the door around my cardboard stencil, and selectively cut it out. I started by cutting 6 inches in from either of the top corners of the door, then tacked down the hinges, and went around the rest of the way leaving some metal in the corners until everything was done.

Yellow is almost visible.

And then I opened it up, and found out why it sounds like gravel.

Just a little bit of rust in there.

Just a little bit of rust in there.

I am surprised at how thick the walls still seem to be. A good 3/16, I still need to do some dialing on the welder, but it'd working out so far.  And this is how she sits right now. I'm debating my next steps. I know what all needs to be done, I'm just not sure the order to do it in. Which means I'll probably bounce back and forth, then set it all in some sort of order with the pictures and the post.

And this is how she sits right now. I'm debating my next steps. I know what all needs to be done, I'm just not sure the order to do it in. Which means I'll probably bounce back and forth, then set it all in some sort of order with the pictures and the post.

I also made an executive decision when I saw pneumatic wheels for $6/each. It's going to stay on this stand. The steel table top happens to fit perfectly inside my new work bench, so I'm going to cut the casters off the stand and weld them to the table top to make it slide, then weld on some 5/8 round stock for axles and put the air filled wheels on the cart so I can move it around freely. Pneumatic casters would have been better, but were also twice the price.

I have a 120 gallon tank. Bought it for a air compressor tank, I dont need that really now. Thought about a large smoker, but have not done that yet either.

There is still more rust in there, and I haven't pulled out a grinder or wire wheel yet.

There is still more rust in there, and I haven't pulled out a grinder or wire wheel yet.  This is roughly what it will look like. Not using that halon tank though.

This is roughly what it will look like. Not using that halon tank though.

I was going to cut the hole to connect the firebox, but decided it would be best to make the firebox and use it as a template to cut the big tank. I have extra propane tanks, I only have one big air tank. Currently, the future firebox is sitting full of water while I debate the best ways t get it set up.

In another thread, someone asked what I use to get the nozzle off the propane tanks. This is it. A solid rod through the collar of the tank, a crowbar through the top hole, and pull them together. Or way easier, have someone else available and push the bars together.

In another thread, someone asked what I use to get the nozzle off the propane tanks. This is it. A solid rod through the collar of the tank, a crowbar through the top hole, and pull them together. Or way easier, have someone else available and push the bars together.

That's all for today. Tomorrow I'm going to make the firebox, try to cleanup my welds, and possibly connect them.

I don't have a picture of it, but I cut my chimney too. 16" tall, 3.5" diameter. It might actually be too tall, but I'll deal with that later.

Bery cool. Thanks for the explanation of reverse flow.

I started today off working on the fire box, and getting a completely dissenting opinion on how I should proceed that would make things easier. I'm probably going to flip a coin to decide in all honesty.

Hinges welded on and the door cut out. Actually made a pretty weld too.

I need to decide whether I'm going to go vertical or offset reverse flow before I do much more to the firebox.

Hinges welded on and the door cut out. Actually made a pretty weld too.

I need to decide whether I'm going to go vertical or offset reverse flow before I do much more to the firebox.

I got about this far today and took lunch.

After lunch, I went down with a plan. Put the sealing strips on the cooking chamber. Should be easy, clamp them on and tack the ends, then weld it up. Well, the lip welded on easily enough to the outside, but I still needed to cover the gap along the top where the hinges are (probably should have just bought a piano hinge like I thought about). THat strip need to be welded to the inside.

And that's where I berked it all up.

It doesn't close at all anymore. I can force it, but it won't just shut.

It doesn't close at all anymore. I can force it, but it won't just shut.

I can't see it catching on anything, and it gets most of the way shut. Should I cut the welds and do it again from the inside instead of the outside? Or should I just get some barrel locks to bolt on and use force to keep it shut?

My personal suspicion is the area under the hinges or right in the middle. I ground the welds in half and trimmed the lid some but it didn't help much.

simon_C

New Reader

7/4/17 4:42 p.m.

Hinges need to be DEAD IN LINE with each other. Any deviation and they will try to warp the panel when opening or closing.

You also may have warped the panel welding those strips on. Did you clamp it all down to the main tank before welding? You also may have been able to get away with a few stitch welds instead of doing a continuous seam.

I say cut your losses, and cut out the old hinges and BOLT in a piano hinge.

In reply to simon_C:

I didn't even think about that, it warping while I was welding. Really though, I was not terribly concerned because there's an almost 1/8" gap the whole way around from cutting it and smoothing up all the sharp edges. I expected some warpage, and it stayed in the gap.

I clamped the strips onto the lid and spotted them every inch while the lid was vertical, then went back and filled the bead in with the lid shut. With the 3 outside strips it shut just fine though, that's what making me think the back strip is the hang up.

simon_C

New Reader

7/4/17 5:33 p.m.

Grab a couple of these latches

I do want those. In also considering a hood pin style holder.

I came out after dinner to beat on it a bit and shave some stuff with the grinder. While I was taking out some frustrations on it with a 5lb hammer, one of the hinges came loose. So I used my weld breaking wedge(hatchet) and a hammer and busted both of the hinges off. Then I strapped it shut with ratchet straps where I needed it to be, and welded the hinges back on.

It works. It's got slightly more gap than I anticipated, but nothing the fireplace gasket I'm going to install can't fill.

Still thinking though. Pins, those jeep clamps, maybe something spring loaded to hold it down.

I'm also now thinking about handles. I've got some 3/4" stainless conduit I might use, or some rebar. If I start spending money on this in going to get those springy metal handles that are on cheap welding hammers and fireplaces and stuff.

One of my customers was telling me he got a smoker for christmas and it has changed his life, lol. He said smoked meatloaf is amazing. I need to get or make me one of these. Keep us the great work

simon_C

New Reader

7/4/17 7:48 p.m.

Those jeep clamps are spring loaded and only a few bucks at a PnP

A reverse flow BBQ sounds like a brilliant idea. We cut down a big pecan tree that made for several years of smoked errything.

I've wanted to build a smoker but now the whole fire building thing seems like too much work. My perspective was a lot different when it served a dual purpose in dead tree disposal. LOL

Before adding a spring loaded latch, consider the latches will end up being hot enough to require using some sort of mitt or other heat insulator. Spring loaded latches sounds like an extra opportunity to get burned on the regular. Not to mention, they could potentially heat cycle enough to ruin the springs. (I see this in spring loaded doors on competition rigs a lot)

I'm thinking something like this. One on either side of the lid.

I'm thinking something like this. One on either side of the lid.

This way I can open it with tongs or something and have some adjustment for clearance.

I did take pictures after I cleaned it up some but really they aren't much different than the ones already posted.

In regards to the "dissenting opinion" I mentioned earlier, this is the style suggestion.

Many years ago, my dad and I were going to build a rotisserie like this. I don't see why it wouldn't work as a smoker other than 90% of the ones built like this use the same size drums.

It would be easier to just drill 4 3 in holes (2 in the cook chamber, 2 in the firebox) than to try to mate the propane tank and air compressor tank curved ends together.

The thing is I've NEVER cooked on one like this, so the learning curve could get very very time consuming, wood consuming, and expensive.

You really shouldn't need a latch at all if the door fits well.

Only thing I know about the vertical types is they can be hard to keep a consistent fire that doesn't get too hot. They have a tendency to cook like a traditional grill.

The side by side ones are better at regulating low temps with a stable fire.

RevRico

SuperDork

7/6/17 10:57 p.m.

So how would you, any of you, join the ends of 2 rounded cylinders?

What worked on 2D paper doesn't translate to 3d life.

Easy button for right now is a piece of 4 inch diameter steel pipe welded in to matching holes in either tank.

Option 2 is find a big piece of plate somewhere to put a square edge on one or both tanks.

Option C is put the firebox under the cook chamber and I don't particularly want to do that.

So thoughts? Experiences?

I'd fish mouth the compressor tank then weld a band of flat bar between the two around the entire junction like a gusset.

You might want to plan a flue between the 2 as well.

If using 4" pipe to connect the tanks Google homemade pipe contour gauges.

Fit and mark one tank at a time. Contour the pipe to each tank after or just let the pipe slip through each tank.

0.02

As a side benefit, it marks almost a perfect centerline. Actually off the exact amount I want it to be. The top of the stand is where the cooking grate should sit.

As a side benefit, it marks almost a perfect centerline. Actually off the exact amount I want it to be. The top of the stand is where the cooking grate should sit.

There was a plate that held the motor and pump assembly, so after a spray down with simple green and a hose, I ground off the old welds and got to making things a little shinier.

There was a plate that held the motor and pump assembly, so after a spray down with simple green and a hose, I ground off the old welds and got to making things a little shinier.

Just a little bit of rust in there.

Just a little bit of rust in there.  And this is how she sits right now. I'm debating my next steps. I know what all needs to be done, I'm just not sure the order to do it in. Which means I'll probably bounce back and forth, then set it all in some sort of order with the pictures and the post.

And this is how she sits right now. I'm debating my next steps. I know what all needs to be done, I'm just not sure the order to do it in. Which means I'll probably bounce back and forth, then set it all in some sort of order with the pictures and the post.

There is still more rust in there, and I haven't pulled out a grinder or wire wheel yet.

There is still more rust in there, and I haven't pulled out a grinder or wire wheel yet.  This is roughly what it will look like. Not using that halon tank though.

This is roughly what it will look like. Not using that halon tank though.  In another thread, someone asked what I use to get the nozzle off the propane tanks. This is it. A solid rod through the collar of the tank, a crowbar through the top hole, and pull them together. Or way easier, have someone else available and push the bars together.

In another thread, someone asked what I use to get the nozzle off the propane tanks. This is it. A solid rod through the collar of the tank, a crowbar through the top hole, and pull them together. Or way easier, have someone else available and push the bars together.

Hinges welded on and the door cut out. Actually made a pretty weld too.

I need to decide whether I'm going to go vertical or offset reverse flow before I do much more to the firebox.

Hinges welded on and the door cut out. Actually made a pretty weld too.

I need to decide whether I'm going to go vertical or offset reverse flow before I do much more to the firebox.

It doesn't close at all anymore. I can force it, but it won't just shut.

It doesn't close at all anymore. I can force it, but it won't just shut.

I'm thinking something like this. One on either side of the lid.

I'm thinking something like this. One on either side of the lid.