Figure it's about time for a project update. Among other things, the issue of noise needed to be addressed ... ummm, yeah this thing barks out a penetrating drone that is apparently irritating. I have asked around the neighborhood and although the dyno can be heard, no one seems bothered by the noise. It's hard to gauge if folks are being polite or they really don't care. I have been mindful and shut down the dyno no latter than 8 pm and I generally wait until after 11am on weekends to start all the ruckus. Anyway I got word through the grape line that someone was not happy with the noise .... so I finally had to make things right.

The result of my efforts is a remarkable reduction in noise, therefore I can probably run the dyno a lot latter in the evening. The exhaust is now pointing into a mini forest and hopefully I'll be irritating the squirrels and whatnot as apposed to any neighbors. We'll see.

Some pictures to look at while you wind away your Sunday afternoon.

The exhaust system had to come off the dyno in order to fit a proper muffler. A Thrush Turbo muffler was sourced locally for $29.00 a few odds and ends brought the bill up into the $40.00 mark.

The exhaust system had to come off the dyno in order to fit a proper muffler. A Thrush Turbo muffler was sourced locally for $29.00 a few odds and ends brought the bill up into the $40.00 mark.

While the exhaust was off, I took the opportunity to relocate the wide band sensor. The exhaust manifold appeared to be getting really hot during tests and relocating the sensor probably was a wise move. The unused bung on the manifold was temporally capped. eventually a thermal couple probe will be installed.

While the exhaust was off, I took the opportunity to relocate the wide band sensor. The exhaust manifold appeared to be getting really hot during tests and relocating the sensor probably was a wise move. The unused bung on the manifold was temporally capped. eventually a thermal couple probe will be installed.

Bzzzzzzt!

Bzzzzzzt!

The muffler is a game changer.... Now I can run the lab 24/7.

The muffler is a game changer.... Now I can run the lab 24/7.

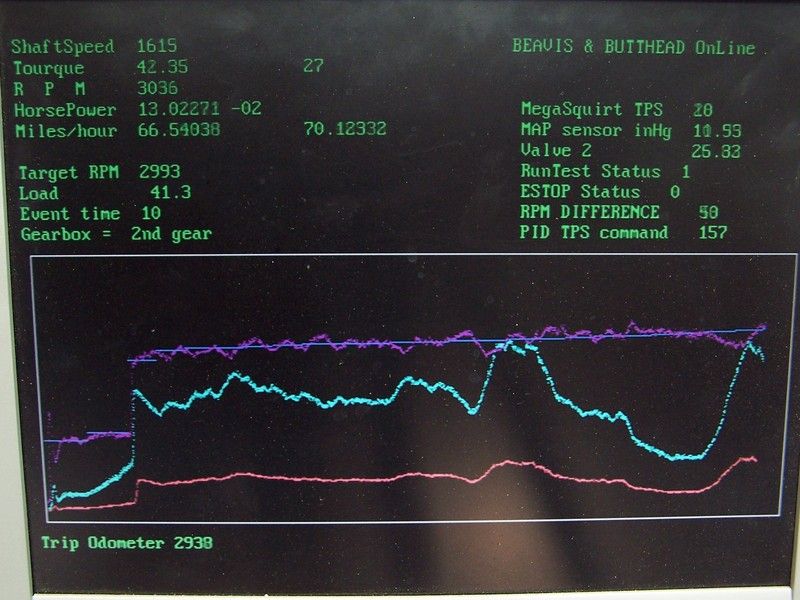

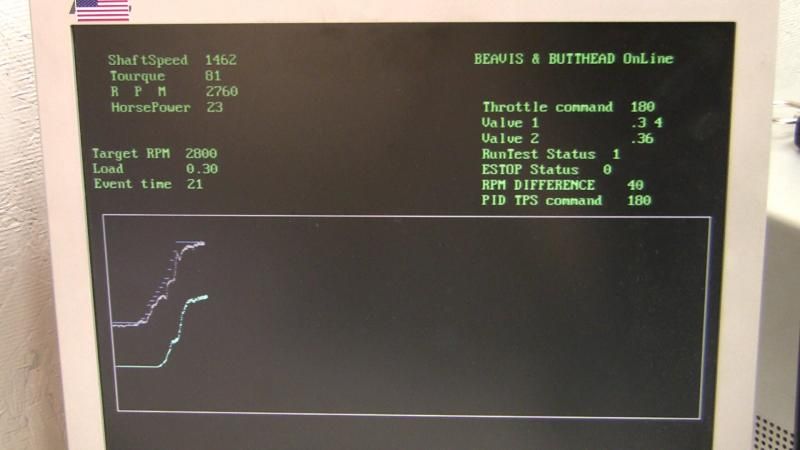

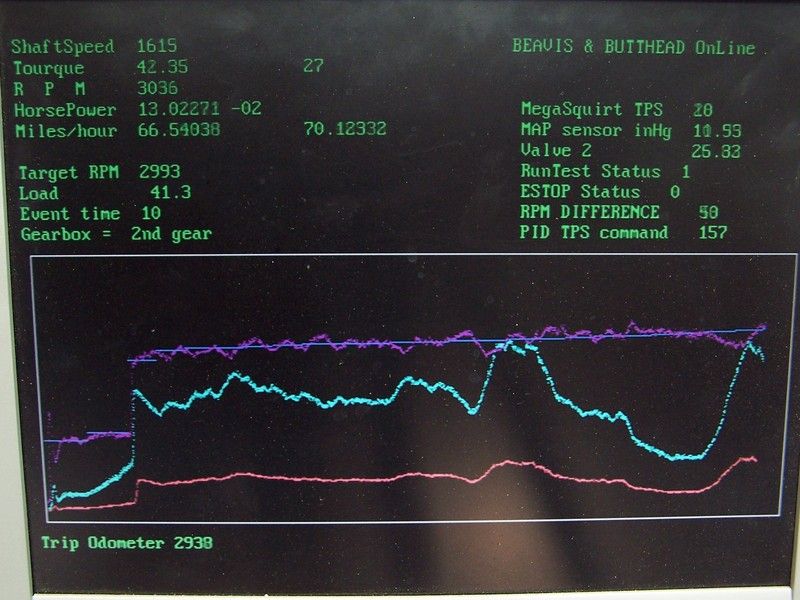

Either torque is still spelled wrong ...or it's the correct European spelling. Needless to say, after a major software revision, some things didn't get fixed.

Either torque is still spelled wrong ...or it's the correct European spelling. Needless to say, after a major software revision, some things didn't get fixed.

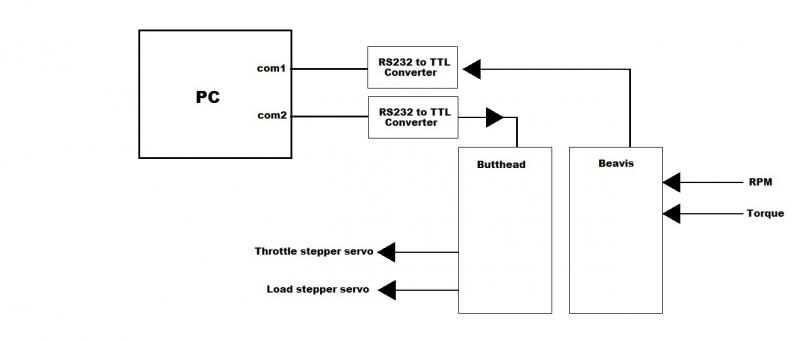

This is actually a screen shot of a test in progress. The dyno is running a simulated 15.7 mile road test. The engine sees loads that are identical the loads recorded on the B3 Miata. It's fascinating to watch the dyno in playback mode.

The tests are repeatable and fuel usage varies + - 2 grams. Whoo hoo!

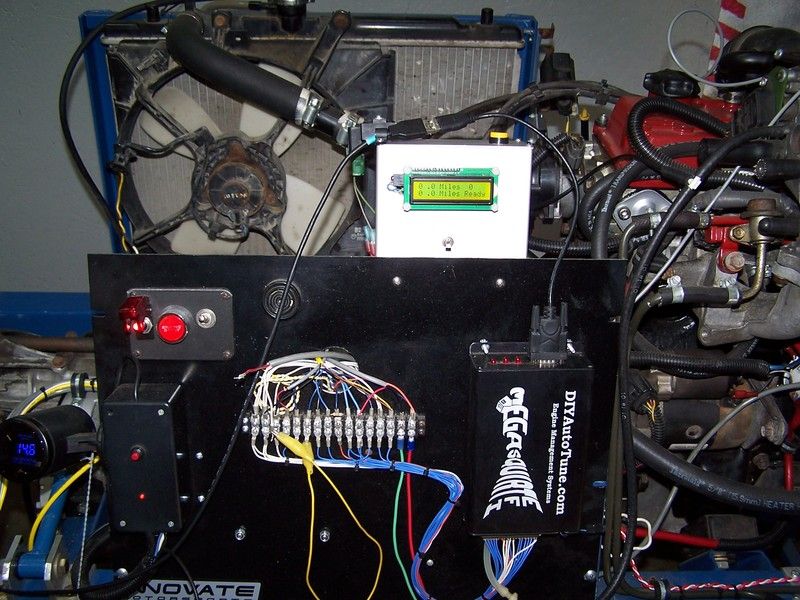

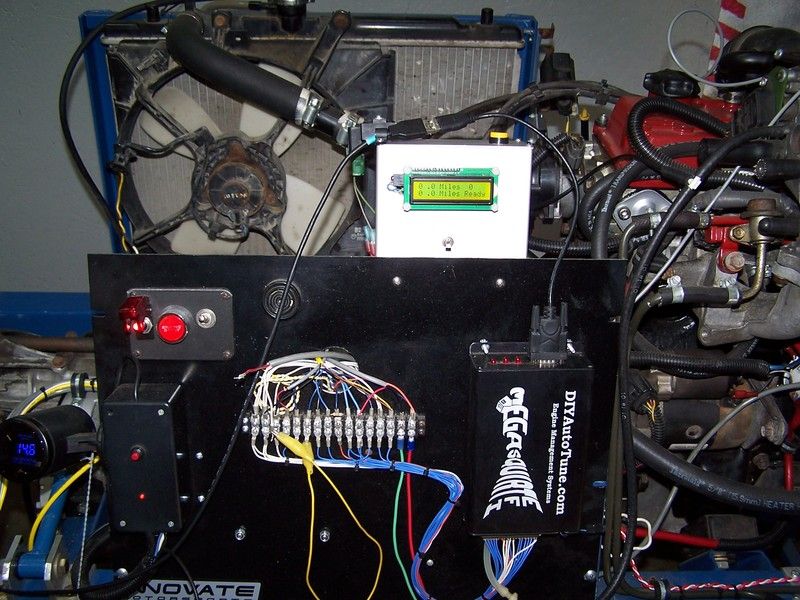

Yet another berkeleying computer....

Yet another berkeleying computer....

Ok, so this computer is the multifunction Odometer. It keeps track of miles and triggers the device formally known as Mr Fusion. It's all good.

Anyway, the miles are recorded for both a simulated 4.10 and a 3.90 axle ratio. When I do a MPG calculation, I can plug in mileage from either axle ratio. The tests are based on the 4.10 axle. Plugging in 3.90 numbers ain't exactly kosher but it gives a close estimate of what the MPG difference would be.

The dyno gets 53 MPG on a simulated 15.7 mile jaunt. Obviously that number doesn't jive with the B3 Miata, however the Miata MPG's are real world and include idling while the barista @ Tim Horton's prepare my morning coffee.

What appears to be a Meth lab is actually my science rig. Fuel consumption data is calculated using cutting edge technology. At some point I'll release the video on how it all works.

What appears to be a Meth lab is actually my science rig. Fuel consumption data is calculated using cutting edge technology. At some point I'll release the video on how it all works.

Stay tuned!

The exhaust system had to come off the dyno in order to fit a proper muffler. A Thrush Turbo muffler was sourced locally for $29.00 a few odds and ends brought the bill up into the $40.00 mark.

The exhaust system had to come off the dyno in order to fit a proper muffler. A Thrush Turbo muffler was sourced locally for $29.00 a few odds and ends brought the bill up into the $40.00 mark.  While the exhaust was off, I took the opportunity to relocate the wide band sensor. The exhaust manifold appeared to be getting really hot during tests and relocating the sensor probably was a wise move. The unused bung on the manifold was temporally capped. eventually a thermal couple probe will be installed.

While the exhaust was off, I took the opportunity to relocate the wide band sensor. The exhaust manifold appeared to be getting really hot during tests and relocating the sensor probably was a wise move. The unused bung on the manifold was temporally capped. eventually a thermal couple probe will be installed.  Bzzzzzzt!

Bzzzzzzt!  The muffler is a game changer.... Now I can run the lab 24/7.

The muffler is a game changer.... Now I can run the lab 24/7. Either torque is still spelled wrong ...or it's the correct European spelling. Needless to say, after a major software revision, some things didn't get fixed.

Either torque is still spelled wrong ...or it's the correct European spelling. Needless to say, after a major software revision, some things didn't get fixed.  Yet another berkeleying computer....

Yet another berkeleying computer....  What appears to be a Meth lab is actually my science rig. Fuel consumption data is calculated using cutting edge technology. At some point I'll release the video on how it all works.

What appears to be a Meth lab is actually my science rig. Fuel consumption data is calculated using cutting edge technology. At some point I'll release the video on how it all works.