I've made a few specific question posts and have been threatening to start a build thread. I suppose it's time to do that though...

My backstory - I've been autocrossing for 25 years give or take (holy crap I'm old) and done a bit of crapcan racing, time trialing, etc. along the way. My last "all-in" build was an 89 Civic that was affectionately known as the Snot Rocket. What started as my college daily driver ended up a high compression turbocharged E85 injected fire breather that took me to a couple of Nationals trophies in SMF before I was done with it. A decade or so ago I answered the call of RWD and bought an S197 Mustang to build for CP. And then I bought another to daily drive. And then I had a kid. And I quickly decided that I could either build a good racecar or I could raise a good person, but I didn't have the bandwidth to do both. The CP build got sold off along the way, though I did hang on to the suspension goodies that I had put together for it and they made their way onto the daily driver. And so for several years the daily was a stock powered S197 commuting on a race suspension. Been to Nats a couple of times with it, and have flirted with the trophies, but never gotten there. And given the amount of time I've had to dedicate to the sport, that's no surprise. The years I was in the trophies I was dedicating 20+ weekends a year to autox, and the last three times I went to Nats I did enough events to count on one hand. That had met a table saw. I've also time trialed it a couple of times and that was a good time as well. I finally retired it from commuting duty a couple of years ago when it's old-car-itis became too much.

When I was building the CP car I was locked into using a Ford engine, but in the years since, with CAM becoming a thing and a popular one at that, that opened up cross-make swaps. I've been threatening for years to LS swap it, and that interest did not lessen with it no longer responsible for getting me to work. The final impetus was earlier this year when at a local event, I broke the stock 4.6. It still runs, poorly, but it's not happy. I suspect the timing guides finally gave up the ghost and it maybe skipped timing. If I loved the stock engine, I'm sure it's a few hundred bucks and a weekend's worth of cussing from being fine. But this became the final catalyst to go all-in. And within a week, as if by fate, one of my buddies started bitching about how his wife's Yukon Denali had just lost the transmission. A plan was hatched.

So, the car doesn’t suck as it sits. Rolls on either 18x11’s or 19x11’s square. Rear end is full spherical, T2R, watts link, and has weight jackers replacing the stock perches. Front end has Delrin bushings, but otherwise stock parts and pieces. Running JRZ triples and 2.25” springs. Strano front bar, custom rear bar. The L92 from the Yukon engine is high mileage, but seems healthy-ish. I've got Blackstone analyzing the oil that came out. Before I tore it apart I did a compression test and all cylinders hit between 220 and 230psi.

For the time being I'm planning on keeping the engine as stock as possible, and getting all of the ancillaries nailed down. And those ancillaries are borrowing heavily from the world of stock cars. I'm backing the engine with a 7.25" clutch and reverse mounted starter bellhousing kit from Quartermaster, and then a Hightower / Jerico dog box behind that. Driveshaft details are TBD but will likely utilize a stock car unit shortened to suit and updating the stock 8.8 to accept a 1350 U-joint. Also from the world of stock cars, I'm using a fair number of parts from the ARCA 396 LS-based spec engines. The dry sump system is from one of those, and uses a really nice Ilmor cast aluminum pan coupled with a Dailey 4 stage pump. I'm updating the car to run the later-S197 EPAS to eliminate the hydraulic power steering needs from the engine, and I'll either need to figure out how to get AC and dry sump to play nice with each other on the same engine, or (more likely) convert to a 12V AC compressor. Because what dry sumped dog box racecar DOESN'T need AC? :)

So, with that, our patient....

berkeley yeah! in for updates.

I spent the better part of the last 6 months in planning and parts collecting mode. I want to keep the car as a rolling / driving piece as long as possible, so actually turning a wrench on the car itself will be pretty downstream in the process. On the parts collecting front, here's the trans I picked up along the way from a dude in Indy -

It's unique in the world of NASCAR dog boxes in that it's Jerico based, but the modifications Hightower performs removes the side linkage all together. That was a good thing, as it would mean less / no tunnel modifications to fit the trans. Not that that's a HUGE deal, as the firewall / tunnel will still likely get massaged before all is said and done, but since massaging in this area means less room for driver, I was happy to find a trans that minimizes that possibility.

Other items picked up from stock car world were the dry sump system from an ARCA car from a dude up in Charlotte -

As well as this oil filter mount / bypass that I picked up from a local guy who dabbles in the used stock car parts market -

Using these stock car parts wherever possible is gonna be a big part of doing this for less-insane money. I'm still spending more freely than I am accustomed in builds (I work hard and I wanna dammit!), but the value you get from used stock car world is just nuts. That dry sump pump, pan, hoses, etc. I picked up for $1500 versus it being 3x that new. The oil filter mount was $85 with the hoses. For something that was custom machined in low quantity on a 5 axis mill. I couldn't buy the raw material for that! Hell - I couldn't buy the hose fittings for that!

Finally, the biggest part of parts collecting was getting the engine donor from my buddy. This necessitated a "Yo Dawg, we heard you like Denalis" pic -

I didn't want that thing taking up space at the house for long, so we hopped right on getting the engine pulled and the rest flipped. My kid is super into helping on the project at this point, and he's legit helpful which is a nice bonus. Figured we better document his first engine pull.

Finished up getting the engine pulled and any supporting hardware, and got the Yukon moved on within the week.

Next up was giving the engine a bath. It's got 280k on it and it was pretty damned grimy. And I hate working on grimy E36 M3. Hot water spigot to the pressure washer came in clutch and after a day of pressure washing I introduced the engine and the chassis to each other to let them begin to get acquainted. Sidebar - everyone reading this should go ahead and put a hot and cold suppy spigot next to their shop. Game changer...

Now that it's claen, lets start mocking stuff up. Here is MAYBE where stuff ends up. Engine is a fair bit lower and further back than Ford intended. There will likely be some firewall violation in play. In this mockup I had the dry sump pump and the alternator pretty low, but both interfered with the subframe rails, so work to do. This pic also shows the pickup points for the rear mount of the front lower control arms, being all giant and in the way. They are that way because the factory bushing is a giant fluid filled one. I have a similarly giant poly bushing in the car now, but I may cut these ears off and figure out a smaller spherical / or delrin bushing just to gain the space. I haven't seen anything done like this in S197 land, but it should be simple enough. Right now I'm mocking it up around the head-mounted billet motor plates that the ARCA cars use, but that is still TBD if that is the answer.

Speaking of dry sump pump mounting, I'm doing a fair bit of the work on this project in SolidWorks. Being able to download a pretty respectable solid model of my engine is a bonus to going LS. Here's a few iterations of that pump mounting. It's the pump and pan from the ARCA 396 motors, but they run the pump off of a forward mounted cog. I wanted to stay further back than that, so I'm using an ATI damper with the cog behind the serpentine. Typically folks are running the crank side cog un-guided and putting belt guides on the pump cog (if anywhere). I like the idea of belt guides, but I also like being able to slide the belt off of the pump for pre-oiling, so in the side view you can see where I drew up a belt guide that will press on to the back side of the ATI to provide a rear belt guide.

With the digital space mockup looking good and the 3D printed version seeming reasonable, I finally cut some chips to make things a bit more permanent.

Got to play with a new machining technique on this one for the first time. I only have 3-axis, so getting that angled cut would mean another setup, which I didn't want to do, or a scallopped surface with a ball endmill. That's what I went with. But then I didn't love it once it was done. A few minutes with a file though got rid of the scallops and a few more with scotchbrite made me look better than I should. It was a nice reminder that even with the robots making my parts for me, a bit of human finesse every once in a while is the right answer.

I mentioned the dry sump's primary focus being the ability to lower the engine. And while that gets rid of the lowest hanging fruit, the next lowest piece is the flywheel. On that front, I'm going with a nice bit of kit from Quartermaster (shout out to those dudes and their tech support help helping me to figure out the right answer). I've seen far too many youtube vids of dudes figuring out shim stacks and other random bullE36 M3 with race clutches and race boxes and stuff that is mixed and matched, so when the Quartermaster dudes told me that they had everything I need in a single part number that is guaranteed to just work, that made it an easy call. It's a big spend, so I'm not pulling the trigger until I actually need it, but this is what I'm getting -

Again SolidWorks to the rescue as you can see here the OEM flywheel, and the smaller Quartermaster flywheel that will will hang no lower than the dry sump pan.

Finally, as mentioned in another thread, I was hoping to run GM stuff as a standalone. But after hitting walls at every turn I ended up pulling the trigger on a Haltech R3. It will likely not be in until after the first of the year. I was planning to make this thing a runner on the stand prior to going inside it, but given that timeframe, I might change plans. Go ahead and go inside it, make sure the bottom end looks healthy, make the internal updates that need to be made to support dry sump (eliminate internal oil pump, block off unused galleries, etc) and reseal everything, with the plan to run it on the stand in the new year with the dry sump in place. Only real downside there is that I was hoping to hold off on buying a tank until the engine was in the car. But used stuff is cheap and doesn't really lose value, so not a huge loss to buy something that might not work.

That brings us to current. I'm making decent progress on it and am putting several hours a week into it, so in theory there should be periodic updates....

Why are you doing a dry sump?

Cool project

amg_rx7 (Forum Supporter) said:

Why are you doing a dry sump?

Cool project

Thanks.

Two reasons - Primary is to lower the drivetrain. I'm aiming at moving the engine down ~6" and back ~12" from where it was from the factory. Secondary is that LS's can oil starve at high G's. There are workarounds, but since I wanted to be able to get the drivetrain low anyway, fixing that at the same time is a nice bonus.

Found a set of the Holley dry sump valve covers on ebay for a good price and pulled the trigger. I was tempted to keep them raw, but there were some burrs from the die casting that I wanted to get rid of, and once that was done they looked like hell. So because I'm a ricer, I powdercoated them wrinkle red.

Also the first time I've looked inside. I was pleased with what I found -

Cool project! I like cross pollination, but I am really interested in the used circle track parts aspect too. Keep up the progress.

Looks like you're off to a great start! Looking forward to your progress and welcome to CAM!

Following for dry sump LS goodness

So, getting the engine LOW means that no conventional header will work. And I very well may end up building custom headers for this before all is said and done. But I wanted to run an idea past the giggle gallery.

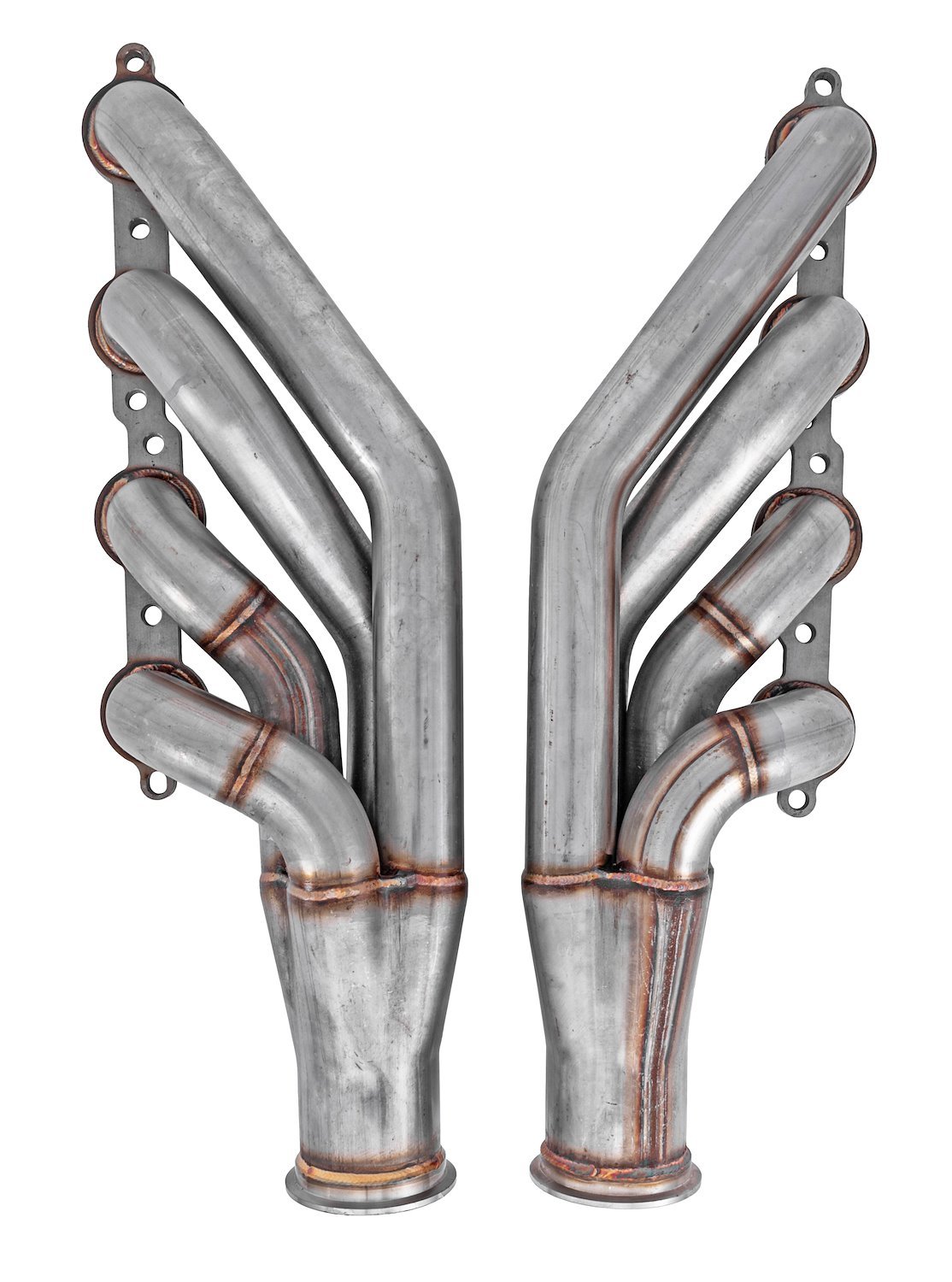

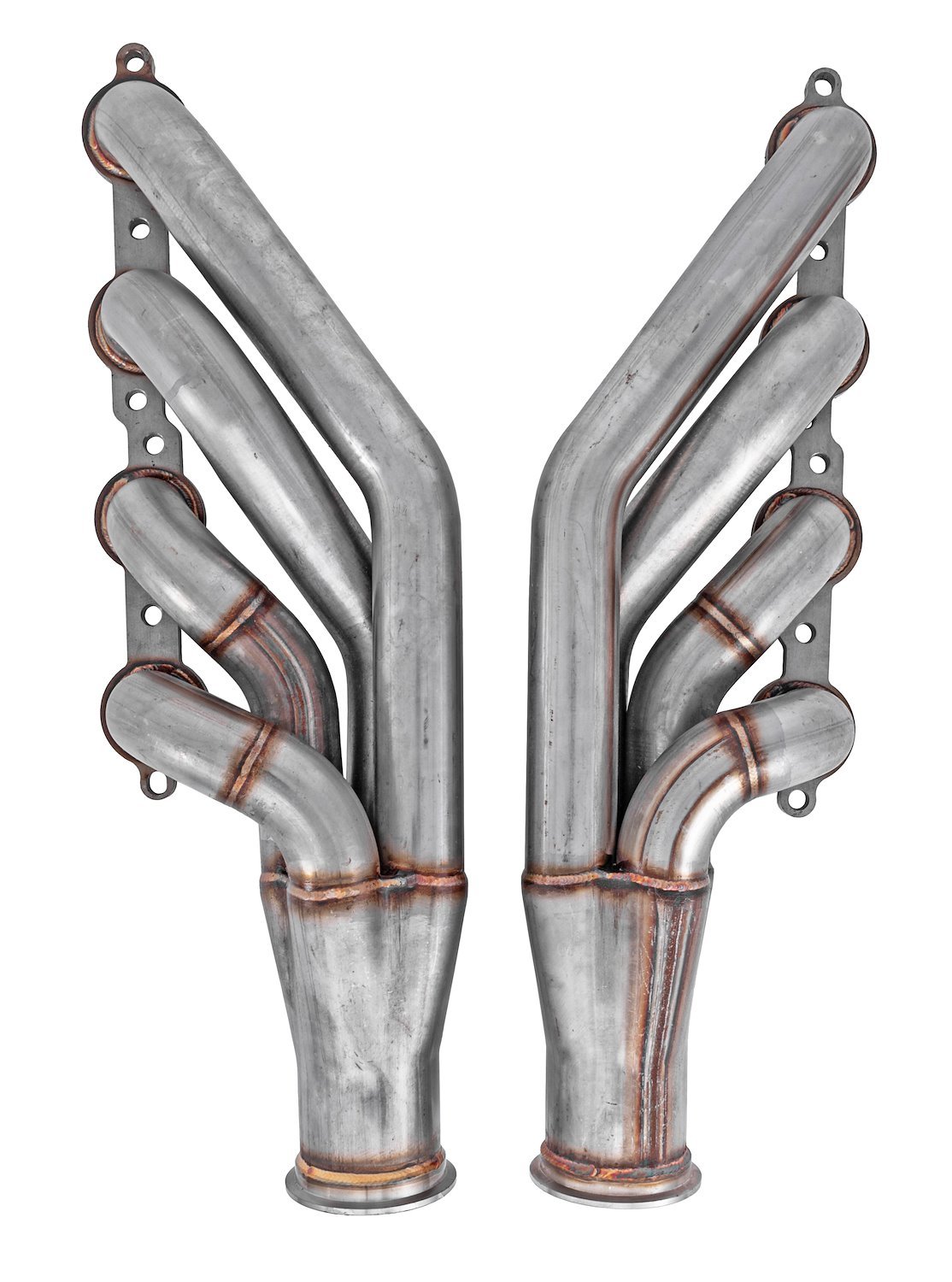

So LS's have a symmetrical exhaust port layout. And this meant that at some point it became a thing to flip manifolds side to side and forward vs back to do turbo things. And of course the aftermarket can't have people just doing with truck manifolds what COULD be done with fancy aftermarket stuff, so the up and forward header was born. And then you flip them side to side and they are a down and forward header, like so -

Now, I PROBABLY don't want to go forward, but, these seem like they might be a decent a answer to a cheap off the shelf header that fits my lowered engine and still has a pretty good ground clearance if I then flip and reverse them and send them down and back like God intended. Maybe. At $225 for a stainless 1-7/8" header with a 3" v-band outlet, it's pretty compelling to see if it will work.

Anyone played with these things and have an opinion on if that's a viable idea?

as long as you can deal with the higher underhood temps, and you have room to package the exit piping, i see no other reasons to not pursue this.

gsettle

New Reader

12/1/23 12:37 p.m.

This is awesome (except for the Ford part)!

gsettle said:

This is awesome (except for the Ford part)!

If Chevy made a Camaro that you could see out of, I wouldn't have to do this. :)

In reply to DILYSI Dave :

AngryCorvair has a set of those I was mocking up on my truck a few years ago, the engine in my Ram50 is mounted very low as well. I ended up with some eBay 5th gen Camaro headers and a whole lot of cutting and welding to make something that fit. C6 Z06 stock manifolds are interesting they kinda come straight down from the heads in a center dump that's an issue for a lot of engine mounts. I have a set taking up space if that would be a possible solution for you.

gsettle

New Reader

12/1/23 1:53 p.m.

DILYSI Dave said:

gsettle said:

This is awesome (except for the Ford part)!

If Chevy made a Camaro that you could see out of, I wouldn't have to do this. :)

I agree! My oldest son has one... I could never own one.

Stoked on this project!

I did the forward exit and send it back on the 302 in my pinto (due to firewall clearance). I've changed it since then, but it worked fine and was a fun conversation piece.

Edit: Oops your talking about running them out the back. Carry on.

RacetruckRon said:

In reply to DILYSI Dave :

AngryCorvair *had* a set of those.

Quasi has them now. i don't want to speak for him, but they could probably be on your doorstep for less than the price you stated above.

Be careful of header heat close to the dry-sump pump. Many times we put the tank on the passenger floorboard. Tech safety rules will have you box it in. Also good to have a tank heater on it to prewarm the oil on certain days.

Yeah, I imagine I will probably end up heat shielding the pump before all is said and done.

On the tank heater, I think I'm at a point where if the oil needs to be pre-warmed, I'm not at that event. :)

I did watch a vid on the startup proceedure of a Cup car. it was pretty amazing the process they go through to have the engine at operating temp before it is fired.

AngryCorvair (Forum Supporter) said:

RacetruckRon said:

In reply to DILYSI Dave :

AngryCorvair *had* a set of those.

Quasi has them now. i don't want to speak for him, but they could probably be on your doorstep for less than the price you stated above.

This place rules. Quasi said he'd send them this way on Monday. Thanks dudes.