In reply to moparman76_69:

Excellent. I should be able to track that down in the harness. Nice to know what that pin is for. I'll see if I can find some info on shifter adjustment. Thank you all for this info.

You flip that funky pin upside down to lock the transaxle in neutral so you can adjust the linkage from underneath the car so that the shifter sits in the proper location.

Ah, speaking of the shifter... I swear, if I make it to the Challenge at this point it will be a miracle. Got the shift linkage in last night which went really well thanks to Turboswede's awesome heim setup. Only minor adjustment was needed and I was missing an E clip on the lower pin. No problem, I'll pick one up today, which I did.

Didn't attack that first as I had an extra set of hands and we worked to get the K frame installed with the new steering rack on it. Had a little difficulty with the steering shaft but finally got it in. The power steering pump line was a serious PITA 'cause you can't really see what you are doing and have to pretty much go by feel. Finally got it in and realized I needed a longer 3/8" line for the return as the replacement hard line I got from the JY is a little shorter.

Ok, lets look at that pin. Hmm doesn't look like the arm goes down all the way on the pin. Let's cylce through the gears and see what happens. Oh CRAP, I can no longer hit 1st or 3rd. WTF? Bigger OH CRAP, my new steering rack which is different than the original now interferes with the shift linkage. Shimmed one of the heims and we now have clearance but the pin still is an issue. The bracket holding the pin can come off but getting all the bolts out was another PITA and had to remove the rear mount to get to them. At some point the pin was rewelded on to the bracket and the slag was not cleaned up well. Tomorrow I'll touch up the weld and then grind down the excess to allow the bushings to clearance properly. And then get to put the whole assembly back together and recheck the shifter to make sure everything clears.

Tonight I had hoped to get the whole front suspension back together but got a little sidetracked. Hopefully I can knock it out tomorrow night after work and then install the new struts after they show up Thursday. Gotta keep pushing...

Yeah, I don't miss working on L-body's.... I do miss driving them though. How bloody are your hands and arms? I swear working anywhere near that damned firewall would leave me bloody and covered in power steering fluid, CV Joint grease and/or Engine oil.

One thing I've found is that if you drop the front mount bracket and the transaxle mount, you can usually rotate the drivetrain forward to access things in the back a bit more easily.

Of course if you'd caught the stupid shifter issue before you got the K-member in and the rack hooked up, you'd not be cursing the car and others right now. Sigh, I hate that crap when working on cars, especially one that has been modified by someone else (its bad enough when I do it to myself!). Just keep plugging away and you'll make it.

FYI, the factory actually used a hammered over steel rivet solution for that pivot pin (similar to what was done on the Titanic), at some point they figured out that it would work loose and they began welding them as well. So the field fix is to weld them too, but the stock pivot bushings and brackets end up with enough tolerance to allow for those kind of welding mistakes to be ignored. The bronze bushings I used tightens up those tolerances. So, I guess sorry about that.

In reply to turboswede:

Not too bloody but some of the grime still won't come out of my knuckles. One good cut on the joint where my left thumb meets my arm. I blame the power steering pump. ![]()

I refuse to curse others on this thing. It was my choice to pay $500 for a worn out car that I didn't know enough about to thoroughly inspect. Truth be told he should have paid ME to take it and bring it back but like THAT was going to happen. When dealing with cars like this it is a labor of love/passion for the challenge more than anything (especially the money)...

Thanks for letting me know the tolerances are a little tighter on the bronze bushings. I wish the linkage bracket wasn't in the car but I should still be able to get the pin bracket into it to see where I am. Worst case scenario I'll be able to chuck the bottom bushing up in the lathe and clearance it a little.

The pin was much shorter after it had been welded on. Touched up the weld and ground on it but no way to get the bushings on without machining. I took roughly 1/16" off one and 1/8" off the other and it went together fine. The shift linkage still slightly interferes with the rack piping but it is very minor. I'm sure over time this will be an issue so I'll have to readdress this long term.

Thursday my $3.96 struts arrived and I got the spring perches ground off and coilover sleeves test fit. Rear shocks and control arms got installed and attached to spindles. Last night I got the struts assembled and installed and the front sway bar in. That's where the progress ended and the problems started ![]()

The new rack has longer tie rod shafts than the original (rack was for a Daytona, not a Charger) so I can't get enough turns to get the wheels straight. That means today I get to cut so shafts, clean some threads and chop off a little from the tie rods so I have some adjustment. The fun never stops!

The big job today will be to get the injectors/rail reinstalled, straighten up some wiring, clean up some grounds and, cross fingers, start the car. Really, really hoping the new LM and rebuilt injector harness does the trick. Injectors all fired out of the block so she should run. If all goes well I should be able to drive it tomorrow.

I did tell you that the racks were the same width and the changes for track width between the body styles came from the inner tie rods. If your old ones are not junk you can swap them over. But old ones are usually junk on these cars.

Pretty close to driving it, eh.. sweet.![]()

She runs and she is on the ground.

As I only had 10" springs to choose from I stated with those but they interfered with my front tires. The plan was to run 400/350 but that is out the window at this point. I had to punt and install the 8" springs that came with my $30 CL coilover setup on the front. This is about as low as she will go with a 225 tire and not rub at full + camber.

I still have the 350lb 10" springs in the rear as I've really got nothing else to put in there now. She has a little forward rake to her so I'm hoping that helps loosen the rear up a little. ![]()

After getting the fuel, wiring and vacuum all hooked up she started but sounded like crap. Then she wouldn't refire. Changed out HES with no change. Re-looked at timing marks and they looked just enough off to re-evaluate the whole setup. Checked the timing, no mark. Hmmm. Decided to move the cam a tooth and then checked the timing. No mark in sight. Still won't run. Loosened the distributor and gave it a good swing and she fired right up. No clue how she got so off as I haven't touched any of the timing. After assuring she would run, start stop and restart I took all the belts off, triple checked the marks and replaced all the belts including the timing belt. It was spent and the car came with a new one when I bought it 3 years ago so no hit to the budget!

Still have to set the alignment, get new boost gauge installed, clean up wiring, etc. under the hood and get seat/belts installed and hopefully have time to give this thing a bath...

Sweet! Glad to hear the front end is functional and it runs! Hopefully you are actually over the hump now! Gonna drive it today i guess?

At work today. ![]() so no driving until tonight so I'm glad the lights work! I have tomorrow off but have an 8:15 AM meeting and then tickets to see Book of Mormon tomorrow night so my shop time will be cut short. If I don't go to BoM with SWMBO I may be sleeping with the cats on the couch.

so no driving until tonight so I'm glad the lights work! I have tomorrow off but have an 8:15 AM meeting and then tickets to see Book of Mormon tomorrow night so my shop time will be cut short. If I don't go to BoM with SWMBO I may be sleeping with the cats on the couch.

Eh, it should be a good time anyway. I'm going to sit on my brother's couch and play 4-player diablo3 tomorrow evening IN SPITE of all the stuff i should be doing on the car. ![]()

Got the alignment done which required a little more trimming to the inner and outer tie rods. Finally set it at 3/16" overall toe out. Checked the rear just for S&G and it is 1/16" in overall. Took it for a spin around the block and the steering and suspension feel good and stiff. The tune is not quite right so I am going to have to work on that at the track. At least it tacks up now that I turned the Grainger valve around. Doah!

Without interior lights it is impossible to really know what is going on. I was working on wiring up the lights for my gauge panel and my soldering iron crapped out. I have to work tomorrow but have all day Thursday to get thing straightened out with the wiring.

Does the front have those 200lb/in springs in it now? Good enough? Did you push it hard enough to tell if it was still going to understeer?

No, I chose to use the unknown rate springs that came with my $30 coilover kit, you know, just because. I did not push it hard on the test drive as I was in my neighborhood, at 10:30 PM with an unmuffled car that was backfiring flames. It will have to do for now unless I can get bar stock tomorrow to add to the rear axle.

This is when I would just love to have one team mate that I could say "Can you please do X" and know that it would be done. My list for tomorrow, though not difficult, is long.

Well, Challenge weekend has come and gone and although she still had issues I am psyched to say the Charger ran all events, didn't get spit on by Tim in the concours and drove out of the trailer when I got home. First and foremost I want to send a HUGE Thank You to everyone who offered a hand or word of encouragement this weekend. I love this event because the knowledge base and passion among the participants and attendees is encouraging to those of us that seem like we often wrench alone. Les, Joe, Johnny, Bruce, George, Justin, Kurt, Bryce, Phil and (blanking on name) guy who gave me the bin of Turbo Dodge stuff, THANK YOU again for helping me make it through the weekend in one piece. Steve, Paul, John, Josh and everyone else, it was great to catch up and I look forward to doing it again in 7 months in WV.

Onto the car:

Although the rain didn't help, I fought electrical and fuel issues all weekend. Notice the rainbow under the car? Yeah, the hose clamps on the high pressure side of the lines from the tank to the filter and then to the line all had to be swapped at some point. In the shop, under no load, they were fine but once some higher pressures were added they all started leaking...one at a time. Pulling the system apart a few times plus a SERIOUSLY rich condition caused me to run through 7 gallons of fuel in roughly 20 miles. I didn't think there was any way my fuel usage was this high until I ran out of gas on the drag strip ![]() . 5 more gallons and she was good to go. Note to self: Fix fuel gauge.

. 5 more gallons and she was good to go. Note to self: Fix fuel gauge.

Electrical: Here's the real issue. There is an intermittent short in the engine wiring harness that causes the car to go into limp mode. It can be cleared while the car is running by shaking the portion of the harness. This allows the car to tack up normally until a certain point where it then falls on it's face again. George thankfully brought his OBD1 scanner which allowed me to pull codes for the first time. Lots of codes PLUS the scanner showed that the car thought it was turning 5000 rpms while it was actually idling (~800 rpm). This could be why the higher rev dropout is occurring (car thinks it is over-revving and retards timing). Either way the engine harness needs to come out of the car from the firewall forward, get dissected/repaired and see if that fixes the issue. At some point we swapped my "bad" LM in for the new one and had exactly the same symptoms so now I guess I have 2 good computers. If the electrical system continues to be an issue I am not opposed to ripping the whole system out of the car and replacing with a MS.

Finally, I'd like to give a big shout out to Scott Lear for having the balls to get in this thing with a questionable running condition, stiff suspension and 9 yr old tires and getting a 54 second run on Friday. The car would drop power at THE most opportune moments causing Scott to fight over or under steer within seconds of each other. He never spun and actually seemed to enjoy the challenge with every run. To bad we didn't have the GoPro on during the best slide example as it was glorious to watch from the pits.

Forgot to note that the paint is SO bad, it was THAT wet and the the car was SO fast that my drivers side # sticker blew off when I took the car out for a test run Friday morning. Multiple people helped look for it with no avail.

AND, if the weather/timing had been a little better, Joe (Les' brother) and I were THIS close to repainting the entire car on Saturday before I took it through the concourse. This seriously almost happened and would have been epic. We will do this at a future challenge Joe but first you have to show up with that Bad Ass Ranchero.

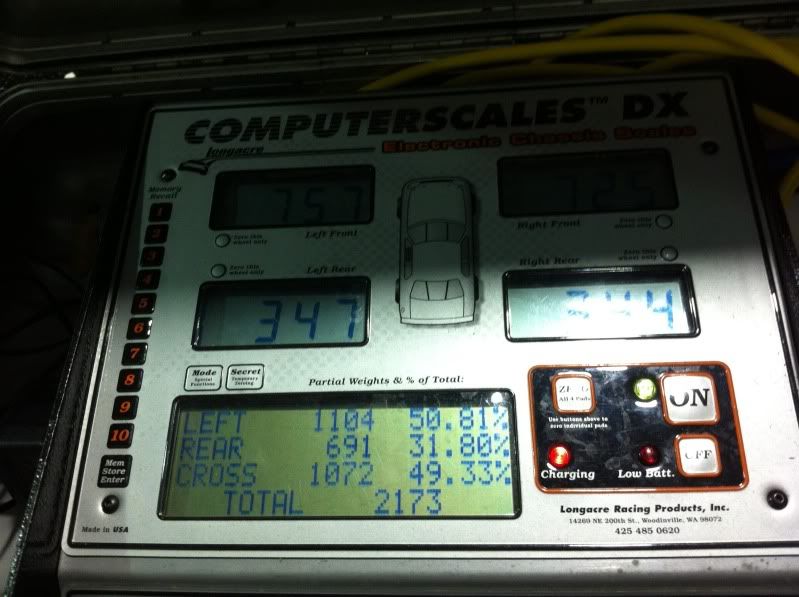

Oh yeah, and with only rough spring perch measurements we got pretty good readings on the scales (for a drag setup).

Hard to tell in this pict but front was 757/725. Rear 347/344.

Taking the whole harness out and going through it is such a good idea i dont even want to help you narrow it down and tempt you to fix it in the car. ![]()

I was still dubious about your 7 gallon consumption until i knew you had leaks as well! Figures, though.. those stupid hoses back there seem to bite everyone on these things sooner or later.

Do you have any comment on the handling balance with the springs you put in?

I fixed one connection then another started, and then another. Good times, especially when you take a face full of high pressure fuel. Learned my lesson there...

No comment on handling as the course was a lake, tires were crap and the cutting out issue didn't allow for really tossing it. The fact that Scott didn't spin it makes me think that at least it may give some decent feedback. ![]()

It would be cool if the harness repair fixes both issues. Not holding my breath on that on though. I do plan on putting the harness back to "stock" and fixing all the hacks the PO did.

And here is where we rejoin the tale. I dragged the Charger back into the shop this weekend, literally, as the RR brake drum was locked solid. Took the drum off and removed the shoes so it would roll. Adjuster is locked up tight and some spring hardware has disappeared but that should be an easy fix. I had a nagging thought that the harness issue was the TPS so I swapped that out to no avail. Oh well, I guess I'm not going to get away from rebuilding this engine harness. Nice to have her back in the shop, cleaned up and ready for more wrench time.

You'll need to log in to post.