Not quite from scratch - the jaws aren't big enough for a piece of stock that's 5" around, and that's what you'd need if you wanted one out of one-piece billet. We could build one out of a plate welded to a tube, then face it and drill it.

But if there's a piece of German mass production that I can grab off some random junkyard car, that's far easier and more likely to be accurate.

When I turned the stock front discs on the Camaro into hubs for the Willwoods I knocked the bearing races out and grabbed it from the inside with the lathe chuck. I stuck a bearing race driver in the opposite side and slid a live center in the tailstock up against just to keep things from getting to exciting. One could also turn it between centers with a lathe dog.

APEowner said:When I turned the stock front discs on the Camaro into hubs for the Willwoods I knocked the bearing races out and grabbed it from the inside with the lathe chuck. I stuck a bearing race driver in the opposite side and slid a live center in the tailstock up against just to keep things from getting to exciting. One could also turn it between centers with a lathe dog.

This gentleman here knows what he is talking about.

You can also buy an expanding collet of the appropriate size and grab it from the bearing race. About $50-100.

I will not be telling my machinist how to use his tools :) I figure I'll see if there's a bolt-on adapter I can produce out of a Mercedes stub and see if that solves his problem. If not, I'll go looking elsewhere to get the work done.

Looked again at the VW part and we can't bolt it to the Mercedes stub - the hub on the VW protrudes. My coworker Brandon (he of the tiny lathe) has an idea for a different kind of adapter, I've asked him to talk to the machinist and see if they can speak lathe to each other.

Looking at the drawing of the VW part, the outer bearing race is only about 1/2" deep. The inner one is recessed and, depending on the geometry of the lathe, may cause rotor/lathe interference. It's a weird piece - see the first post in the thread for a drawing.

In reply to Keith Tanner :

Keith, and expandable collet would work well on the inner bearing. They allow you to chuck it leaving ample space for clearance.

This is roughly what I am referring to:

You use the one closest to the part and machine its OD .020" smaller that the actual ID on the part; then as you tighten it, it spreads and grabs the part you want to machine. They look like this:

Please do not take this as me trying to tell your machinist how to do his job, not my intention. Just trying to help as I work with CNC mills and lathes daily and there are many ways to skin a cat.

Again, if you want me to take a shot at it I am glad to help.

He didn't say he couldn't do it. He said that by the time he was finished making what he needed to make (and I didn't press for details because I don't speak the language), it wouldn't be cost effective. His opinion was that a CNC mill was preferable. I am leaning towards the lathe-type solution because we cannot have any runout, and I am leery about accurate positioning on the mill. Possibly due to ignorance, as again I have no experience with the tool.

Slippery, I may take you up on this.

In reply to Keith Tanner :

Properly operated the CNC mill will give you accuracy equal to or better than what you can obtain using a car stub axle for a lathe fixture.

My only experience with a mill is with a manual one, an inexperienced machinist and a piece of cast iron that was apparently very difficult to jig up. It did not fill me with confidence that locating a round thing perfectly would work. But I think the inexperienced machinist (a fellow who specializes in getting things wrong five times before getting it right once) was probably a factor :)

A GRM member sent me a link to what looks like the easy button - the hub used on South African Vanagons. For those who are not part of our little community, the Vanagon stayed in production in South Africa and got a bunch of extra development. Including big brakes. And the hub looks like a totally normal hub, consisting of bearing races and a wheel mounting flange. Nothing else.

Two problems - those hubs don't fit the early spindles on my van, and the other South African parts have availability problems. For example, the calipers are NLA. The rotors are available...for now. I'm looking to build this with generic parts that have a high potential for future availability. So I think I'll continue to forge on.

Hey, remember this project? Stuff is happening!

Nearly a year ago, it stalled out because I couldn't find anyone local to machine some stock rotor/hubs down for me. The project got set aside as I did other stuff like finish the transmission swap. But Slippery had offered to help out, so I dropped him a line to see if he was still interested. Turns out he was, so we've been working together on this for the past month or two.

To refresh everyone's memory, the plan is to turn a stock VW one piece rotor/hub assembly into a mounting hat for a generic and common circle track rotor. This makes the consumables very inexpensive and widely available and gives me a vented rotor to replace the solid one used by VW.

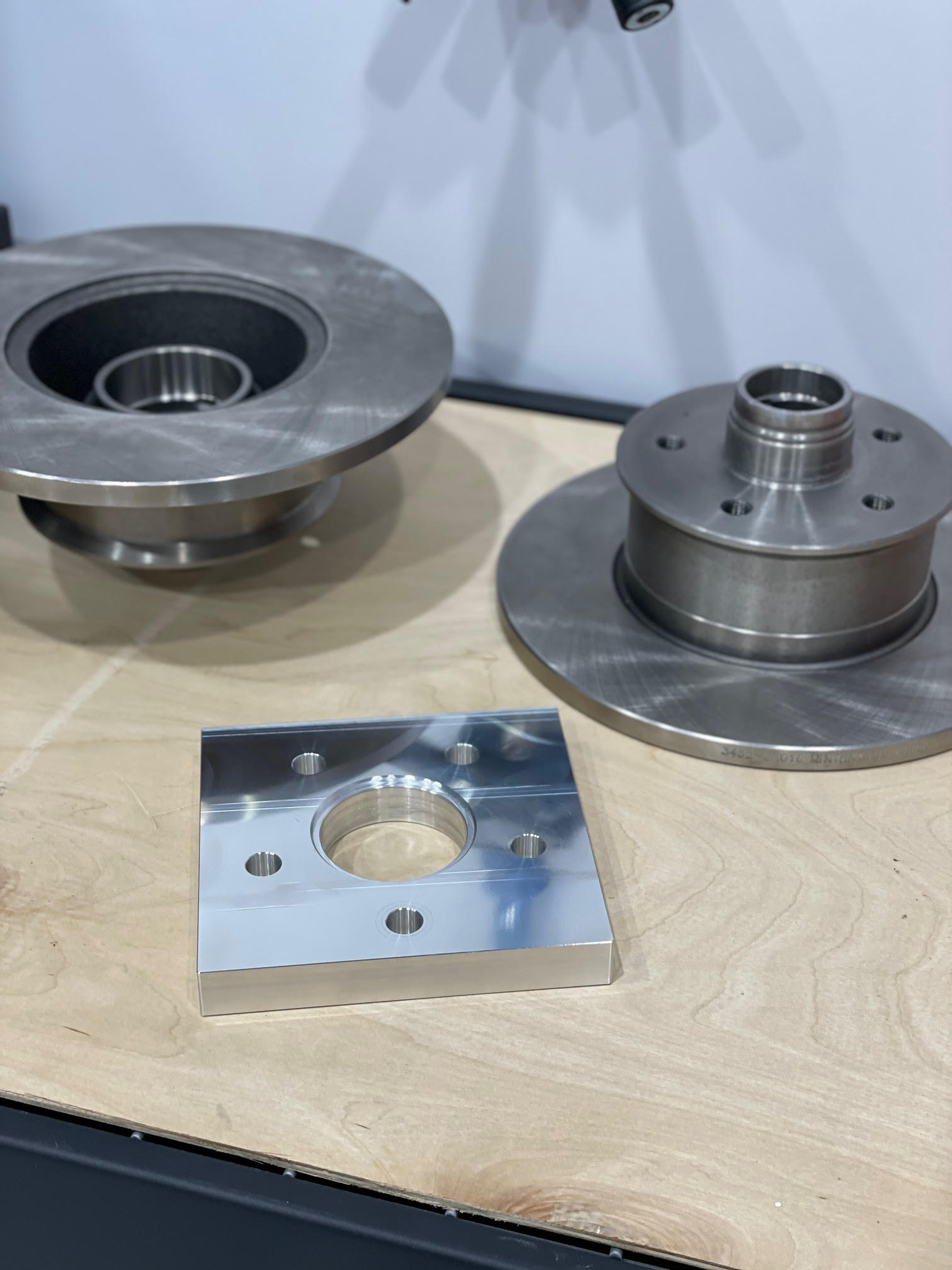

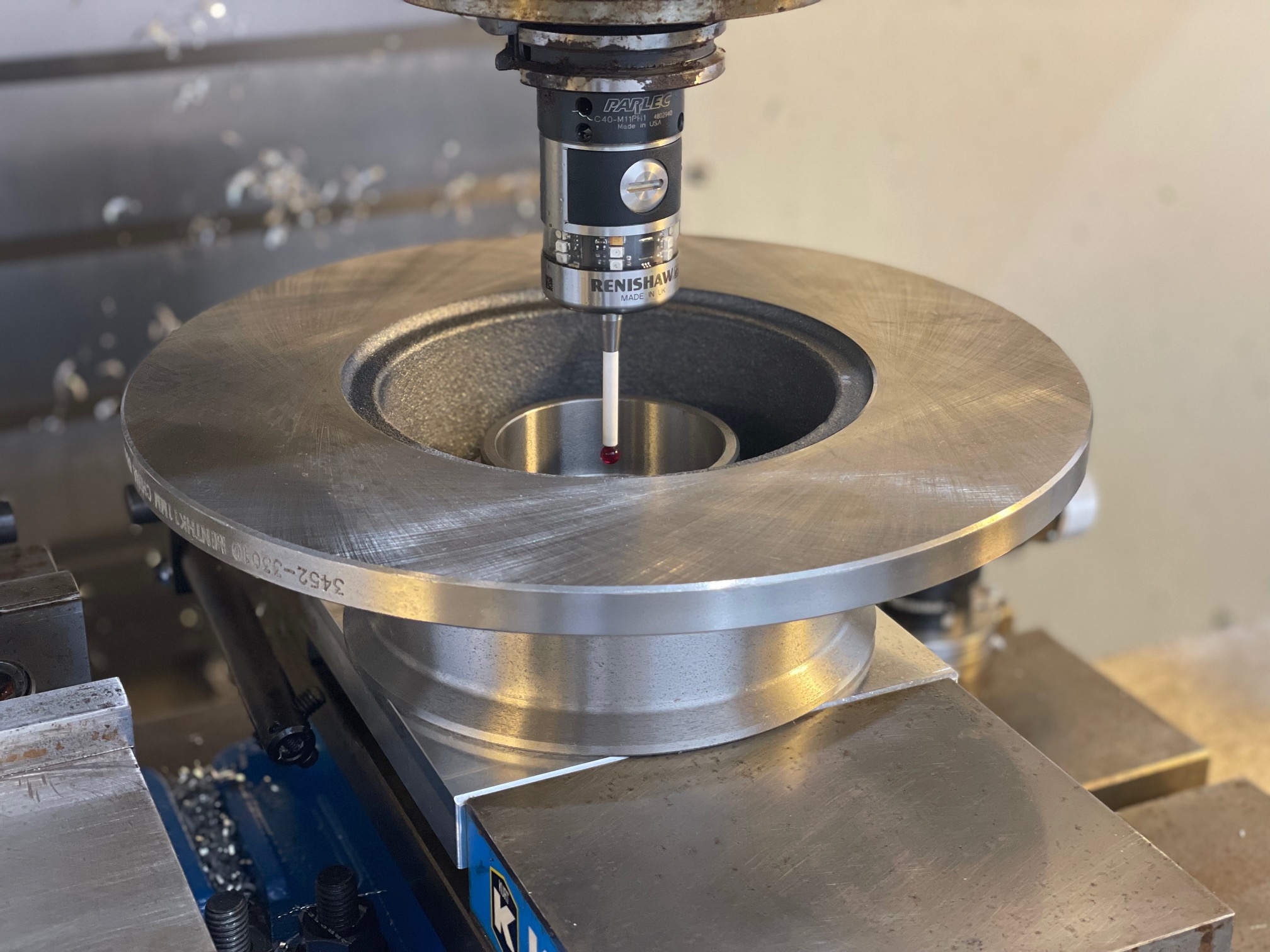

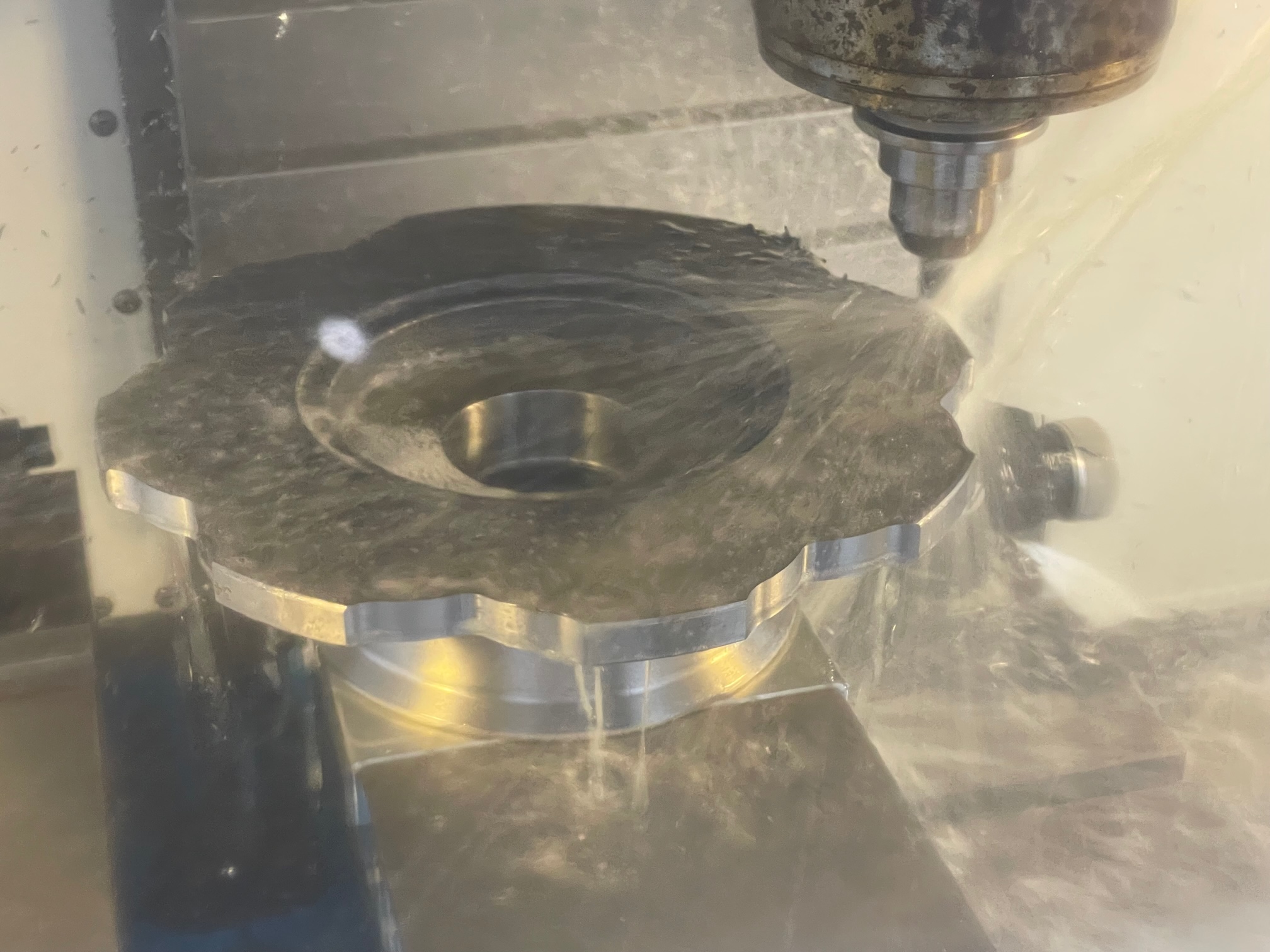

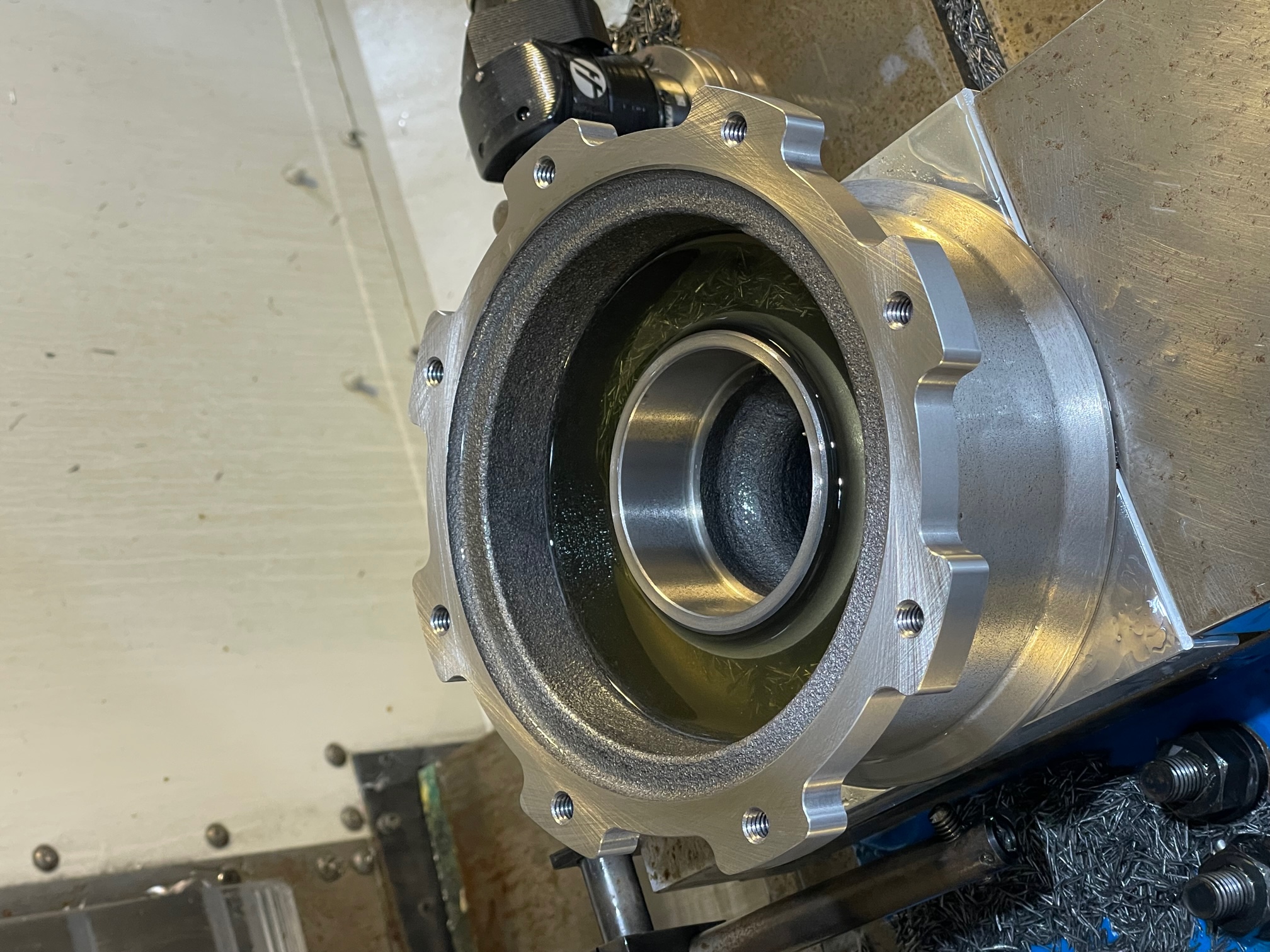

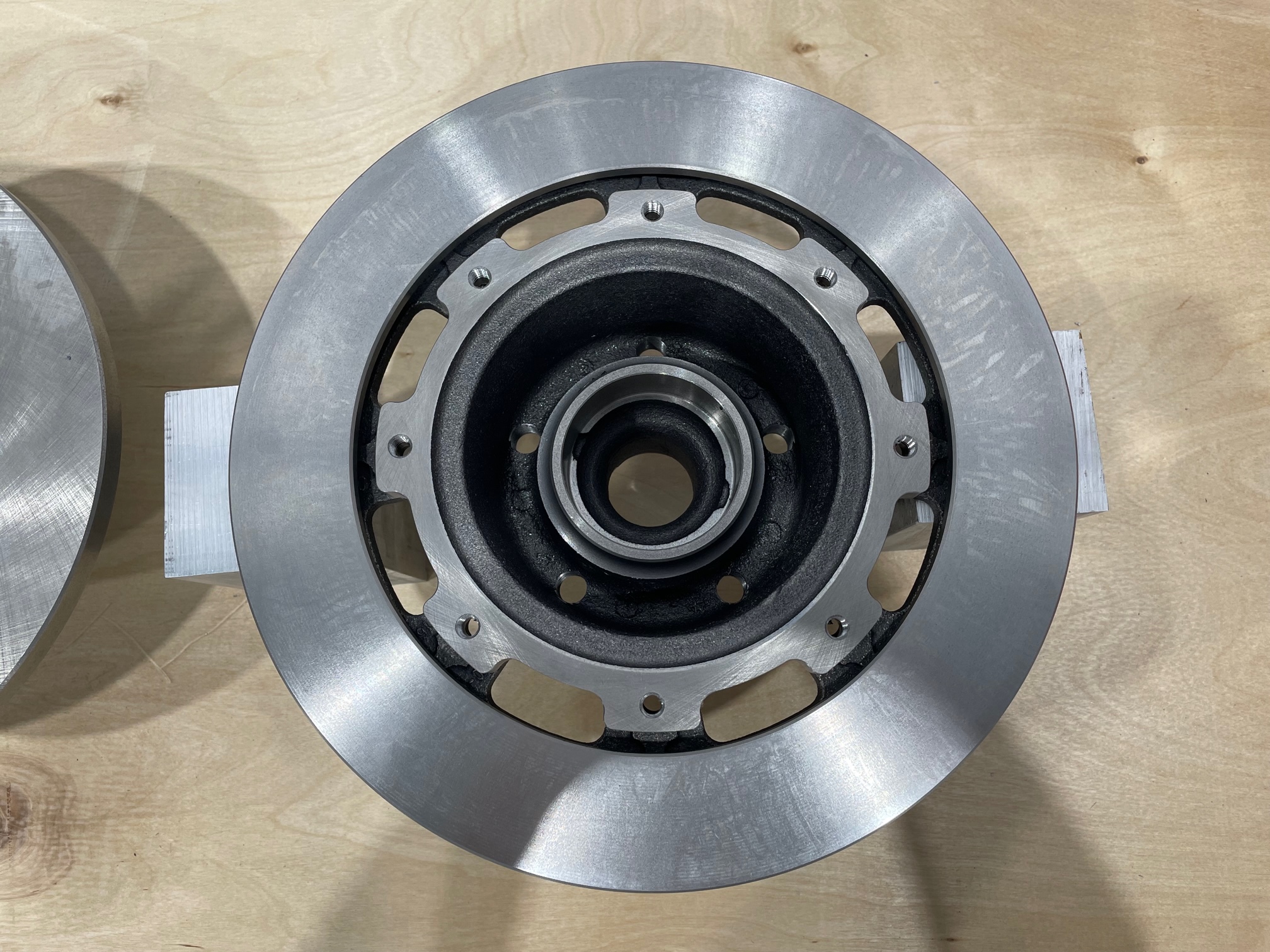

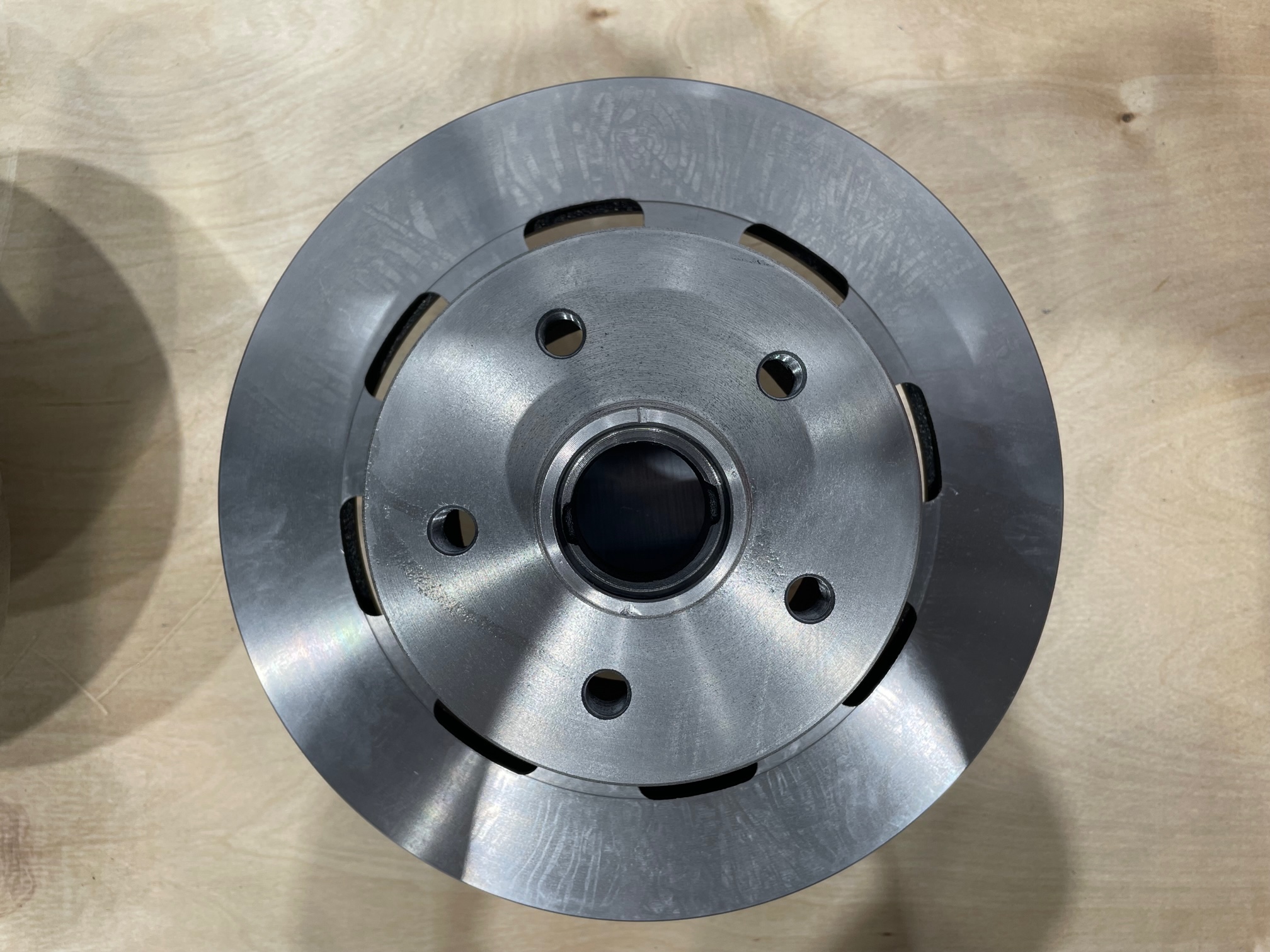

We traded drawings back and forth and he came up with a suggestion of scalloping (if that's the right word) the mounting tabs on the hat to provide better airflow through the rotor. I sent him a circle track rotor and a couple of new VW parts and the chips started flying. We shall now pause for machining porn, because who doesn't love machining porn?

And the result!

Check out that vented rotor, baby!

Slippery has made a couple of things of beauty, so it's up to me to maintain this standard. Next step is to buy some calipers. I did manage to acquire the CAD model for the caliper I'm planning to use (it's useful being a Wilwood dealer with an NDA in place) so I think I'll do a 3D print of one just to make sure I don't run into any expensive surprises when I go to mount this puppy up. Then I'll design the bracket, print it for confirmation, and have them machined. I'd already figured out the plumbing.

Is this project really necessary? Maybe not. But the van is considerably more powerful than stock, a bit heavier due to the new drivetrain and lives in a mountainous area so it's certainly not going to hurt to have a little more heat capacity available. I like the future availability of these rotors and pads as well.

More to come!

Everything arrived today. They're even prettier in person. Check out this finish.

Now I need to stop procrastinating on that printed caliper.

Printed caliper aborted. Partly because the Wilwood models are hollow and fixing that is beyond my mediocre 3D skills, but also because I know the caliper will fit thanks to my previous setup. Check this out, the inner face of the new rotor is in almost exactly the same plane as the original. I'm not bothering to get a perfect measurement, but it's definitely between 0.5 and 1.0 mm.

I have enough inner clearance already, and if I wanted to move the rotor outboard I could just flip it over. I have comical amounts of clearance for my wheels on the outboard side - roughly 1.25". The new rotors are about 3/4" larger in diameter than the current ones but again, I've got a lot of clearance. So I'm just going to order the new calipers. They should come awfully close to bolting up with my existing brackets using a 3/8" spacer to move them out radially, which gives me a nice head start on the bracket design.

I've asked my contact at Wilwood what the lead time is on these calipers. They've been struggling of late. I'm going to do as much work as possible before the van goes on to the lift to minimize downtime. Hopefully Wilwood has stock :)

Awesome. I heart machine porn and 'unnecessary' badassery, hence the little big brake kit on my 62 Midget swap.

It's a ridiculous project, really. But I think the result will be better than all the obsolete junkyard BBKs out there as there are far more options for parts. I'm pretty sure I could also use a 1" thick rotor just by specifying the matching caliper. Depends on the offset of the mounting lugs on that rotor.

Oh man, that Slippery guy is awesome! ![]()

Parts are probably soaked in coolant as I did not want to wash and have them rust. I also lightly coated them in WD-40.

Looking forward to see how this all plays out. Let me know if you need help with the brackets once you have all the measurements.

You know, I didn't really want to ask :) But if you're willing to mill the brackets once the design is confirmed, I'll be in touch!

Ordered new front wheel bearings yesterday, as I don't see the value in reinstalling ones of unknown history. Might make it easier to swap back and forth during testing.

In reply to Keith Tanner :

Yep, no problem. Same deal applies ... you might need to wait a couple of weeks, but it will get done.

More pretty parts are here. I really need to get to work on that bracket design. I came up with a good approach plan today, so it's pixel pushin' time.

This is a fairly new design of caliper and includes excellent dust dealing.

The wheel bearings and seals also arrived, but they're not sexy so no pictures.

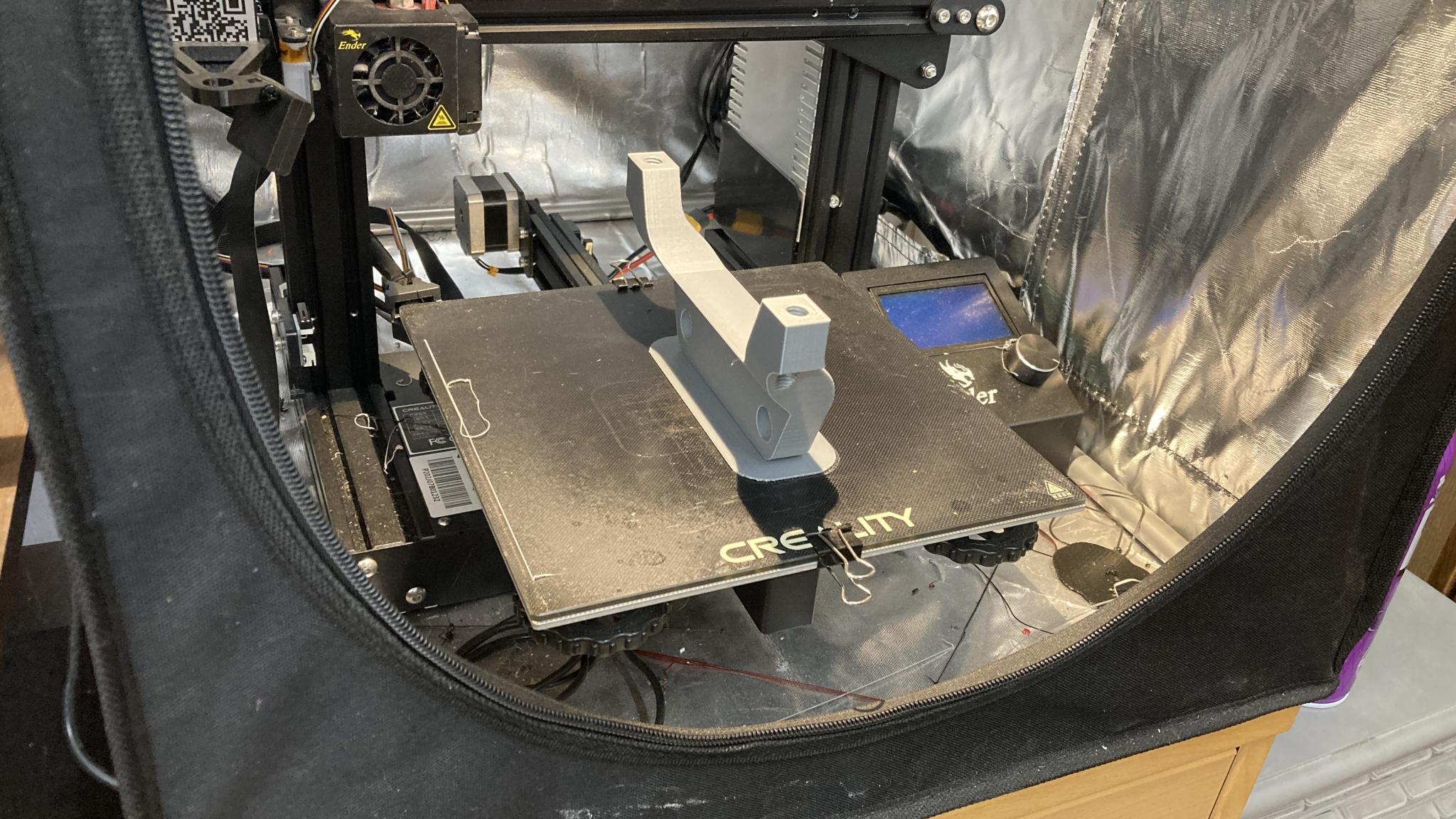

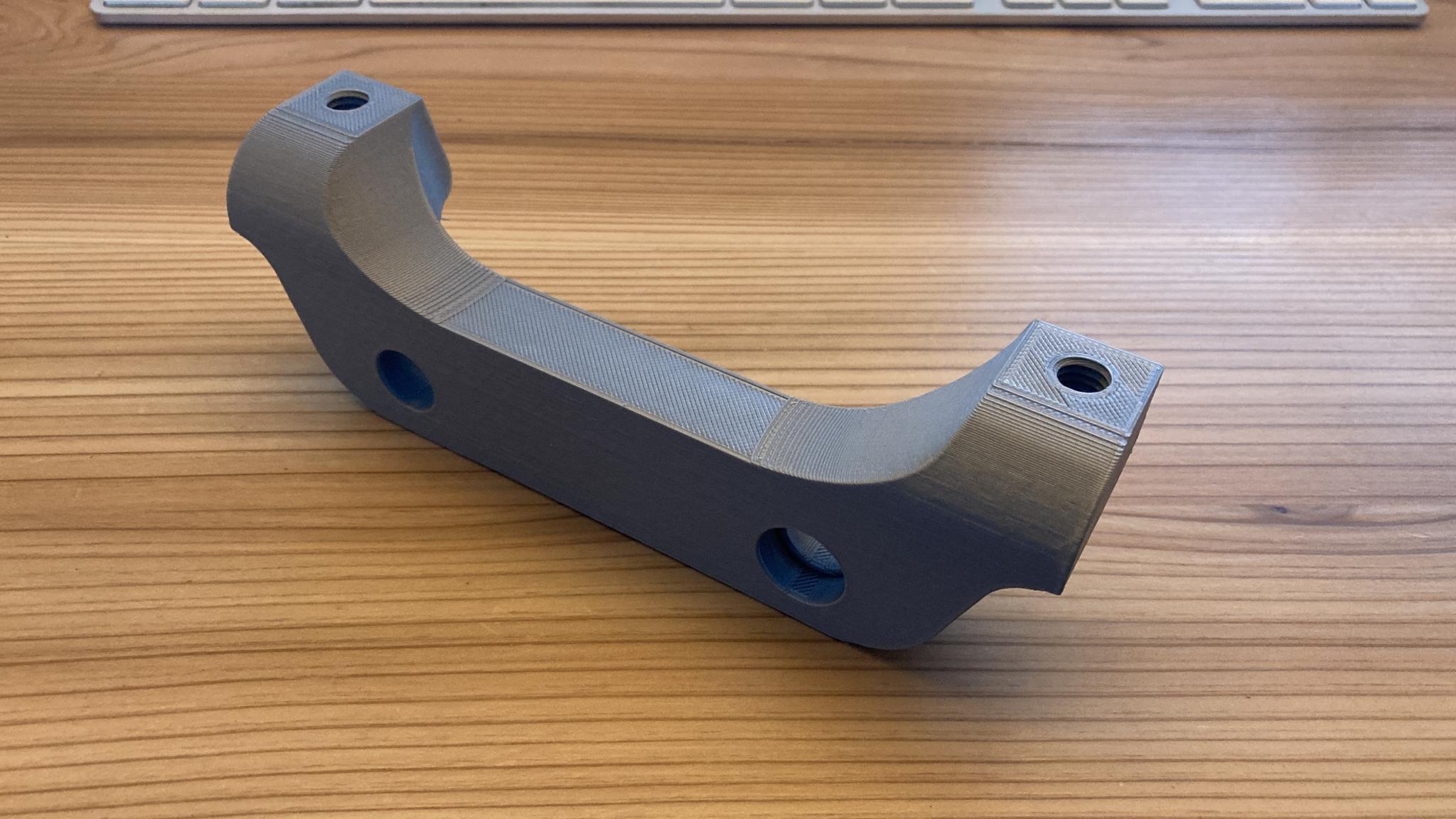

Did a first pass of a bracket design last night and found this waiting for me on the printer this morning.

I'll use this to make sure I'm in the right general ballpark, that I didn't attach the caliper to the wrong side of the upright or something. The problem I have is that I don't have a spare upright, so I can only test on the van. Since I just got it up and running after the whole transmission swap project, I am loathe to put it out of commission again. I have some ideas, though. Might take a few days.

First check and I discovered I'd placed the caliper way too far out - the new rotor is .75" larger in diameter than the original, so those big mounting holes should be 0.375" off the stock caliper. They very visibly are not, and a measurement indicates I placed them incorrectly in my initial sketch. Everything else looks to be in the ballpark. This is where 3D printers are so handy, I spent about $1.50 on that prototype.

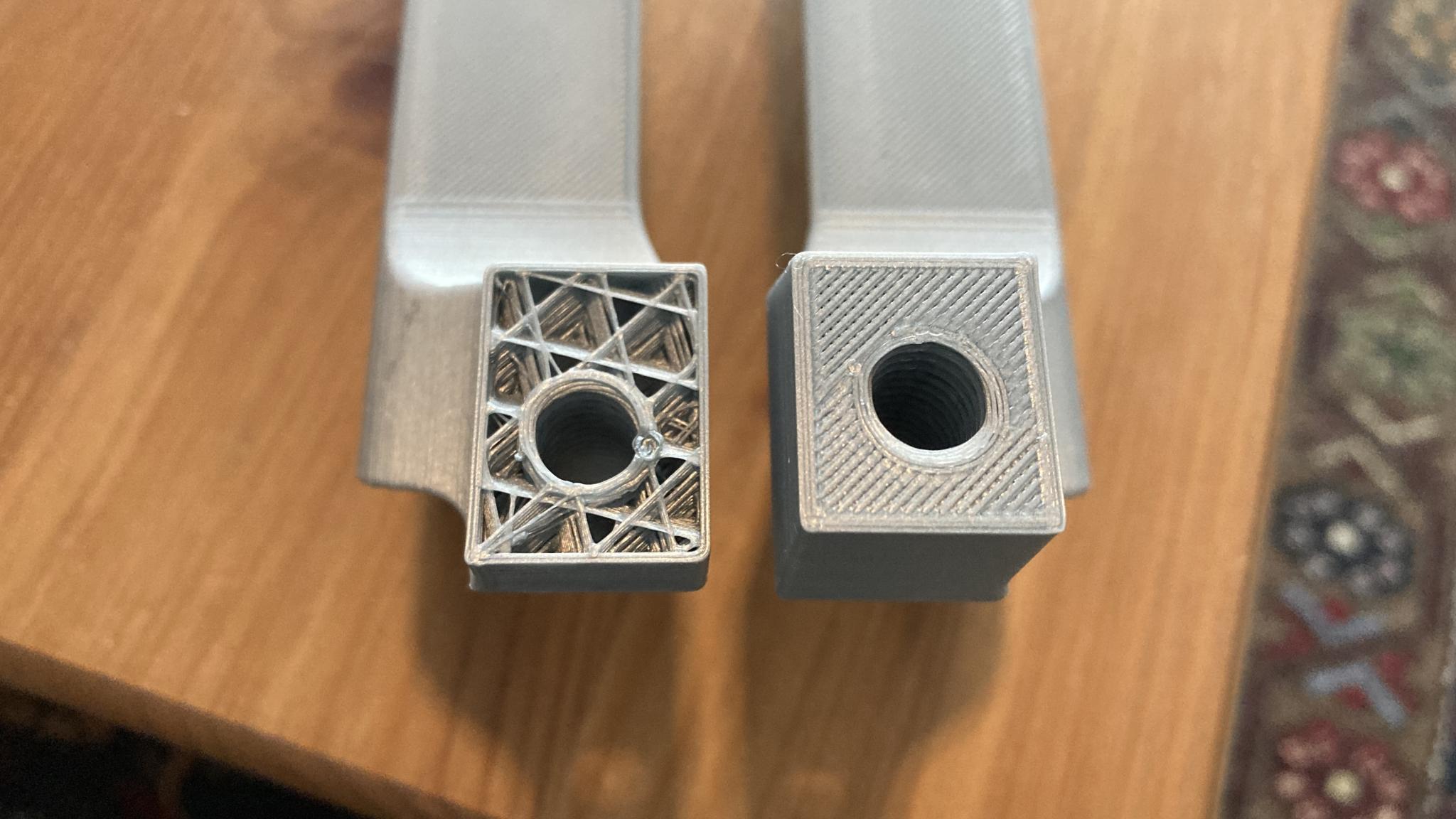

For those who don't do 3D printing, here's a peek into what the models look like inside. I accidentally turned off the printer mid-print (that's not the light switch, doofus) so we get this nice interrupted cross section. They're not solid because that would take much, much longer to print and would require a lot more material. You can dial the amount of "infill" up and down depending on your strength needs.

Moved the stock mounting locations up by 29mm and this was on the print bed this morning.

As for test fitting, I'm hunting for a spare early Vanagon front upright. Turns out a friend tossed a set in the garbage two weeks ago, and all the ones on eBay are $225. Still looking...

i like what you did with the rotors, in theory.

in practice, i'd really have to trust the person who did the math that says those 8 single-shear screws are strong enough to react the torque that they're going to see in their lifetime, or that they're as strong as the cast iron that used to be there. i'm not saying they aren't, because i haven't done that math. i'm just saying that i'd really have to trust the person who did.

You'll need to log in to post.