We have radiator. I feel pretty good about my urethane mounts(skateboard bushings). I've pushed the cooling system back and it's a little closer to the engine than I expected. Gotta kill that thermal clutch I guess.

We have radiator. I feel pretty good about my urethane mounts(skateboard bushings). I've pushed the cooling system back and it's a little closer to the engine than I expected. Gotta kill that thermal clutch I guess.

This is so good. Cannot wait to see it on a track.

That radiator looks a bit skimpy, hope it has enough capacity for this much power.

I hope so too. Guys use these with 200whp+ turbo Civics and I'm asking it for 170bhp so I feel confident. It's a thick 3 row rad. If not, I will add supplementary cooling.

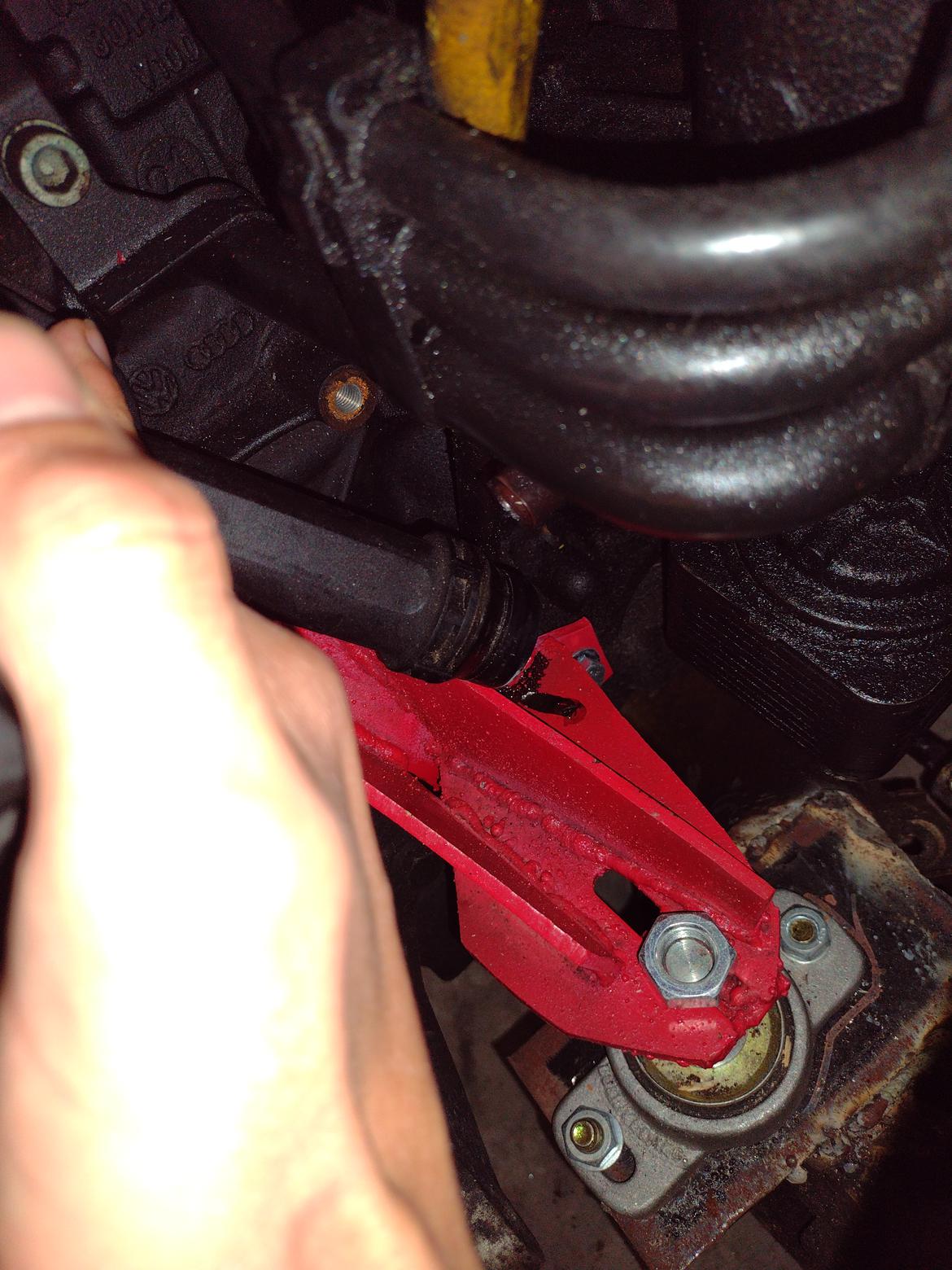

Speaking of cooling, the BHW and BRM TDIs use "quick" connect couplings on the coolant hoses. This is the thermostat outlet. I don't have quick connect anymore and it points straigt at my engine mount.

So I bought a BEW(same era but 1.9L TDI) thermostat housing that I was told would fit. If course it runs straight into a metal thermostat bypass pipe

Time to dig through the VW catalog looking for a different shape. I really like the ALH piece but it runs into the alternator

After weeks I finally have the power steering pump and box and cooler and reservoir all connected up. That was painstaking

Long time no see. I started working on a topper for my Jeep, then started preparing my BMW for sale. Then July/August happened which are my busiest months at work.

I had napa build me a conversion brake line from the M12 master to the M10 slave. That was surprisingly hard, finding a M12 double flare but. But it's here.

I also finally bought an impact and I'm in heaven. Just zipping wheels off a car that's in the air is so nice. This Onyx compact impact is supposed to be pretty powerful and small enough to get in to little suspension sized areas. I think I'm doing front axle u-joints on my XJ soon, so I'll be happy to have this. After doing one wheel I heard my compressor seize...

I threw away pretty much all of my air tools once I discovered batteries. My M18 impact has taken off bolts that even the stoutest pneumatic gun in my box wouldn't touch. And no hoses to lug around. The only thing my air compressor does these days is blow up tires, blow out stuff with the air gun, and run my tire changer. I do still have a pneumatic die grinder and a little angle abrasive disc dealie that get used infrequently, too, that I haven't quite found a cordless counterpart for.

In reply to buzzboy :

i like batteries but hate milwaukee battery prices. About have to sell my soul for a 6ah

Thought I had replied to this thread, but apparently I have not yet done so.

I approve of these Shenanigans wholeheartedly!!!

Glad I saw this thread!

I've done some very very questionable things with an BEW TDi.....re: thremostat housing, I am 97% sure someone used to make one that would allow you to thread in a fitting of your choice, not sure if they are still available, but there are aluminium, albeit cast, housing that you could do some "customing" to make work

In for this for sure!

Between attending my friends' wedding and then my own honeymoon, Planet Express is being shelved for 5 months, a month earlier than I'd like. I really really wanted to have it running this year. But other projects took priority. I spent most of my project time fixing my bmw up for sale, fixing my old jeep for daily use, and building a topper for my new jeep.

At least in the end I used PE as an escape when I got frustrated at other projects. At the end I ran the clutch line. The NAPA guys and I had a long search for the right combination of fittings and adapters to go from the Mercedes master to the Nissan slave. Goodnight sweet prince, I'll wake you after a long winter's nap.

She looking dirty....

In reply to buzzboy :

You spectating, or racing with another car/ team? Looking forward to seeing you again, it will be quite like old times. We'll be in garage spot 15, and we've rented an RV. Most of us will be there Thursday night, I believe.

I needed to move the car back a few feet. It takes two rounds of removing cribbing to put the car down. So why not just put it on 8x8s and roll it?

I started measuring for a driveshaft and realized that my original(and it turns out unneeded) idea to offset the engine to the passenger side is going to cause the driveshaft and about 3 feet of floorpan to collide. So the engine comes out to recenter it in the bay/tunnel.

Nut blocks bolt blocks nut.

VW packaged this engine tight but lots of small fiddley interference. I figured while the engine was out this time, for adjusted engine mounts, I would take the intake off to clean it finally.

I started on page one today, somehow I missed this thread. Really great read, looking forward to updates.

Engine mounts version 2! Engine now centered in the bay and sitting 3° nose up to match the diff angle. Everything appears to clear with "just" enough room. It's definitely sitting a little lower than I had it before. Only about ⅜" clearance between oil pan and engine crossmember. I bought another of these adjustable marine mounts to be the trans mount. It looks like it should be much simpler than my old mount reusing the Nissan part.

You'll need to log in to post.