Today was a good day. I now have a parking brake.

For as long as I've owned this car, the parking brake has been nothing more than a suggestion. Oh sure, I pulled it up every time I parked the car, but it never did anything. I know that there are people who never use them, but that's not me. It bothered me every time that I drove the car. I need a parking brake.

I made a few attempts at adjusting it, but even after installing new brakes and adjusting the rears with the help of the factory shop manual, I could never strike a balance between brakes that don't drag and a functional parking brake. As it turns out, the situation was the result of a combination of a faulty part and a couple of faulty mechanics, one of whom is currently typing these words.

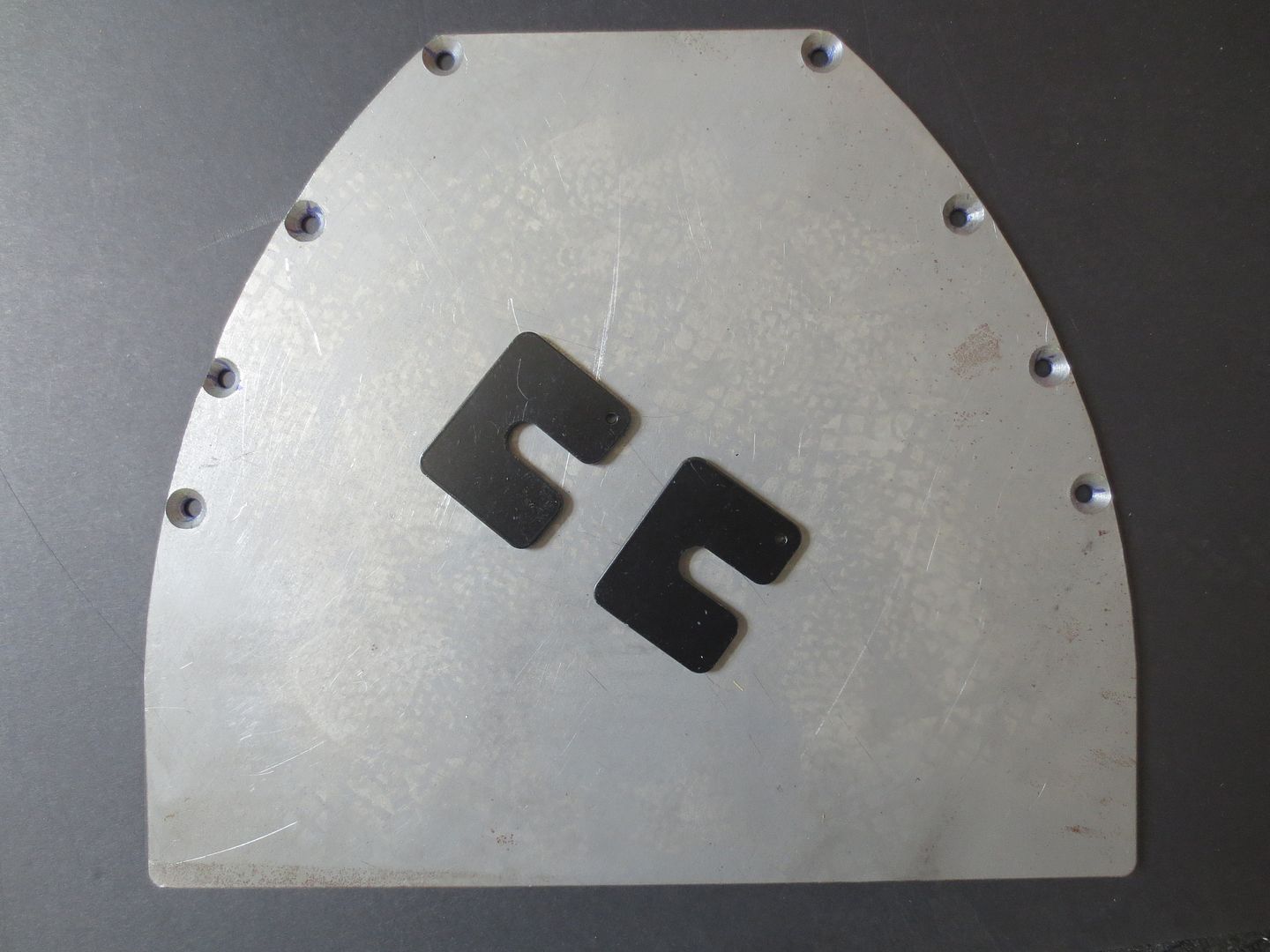

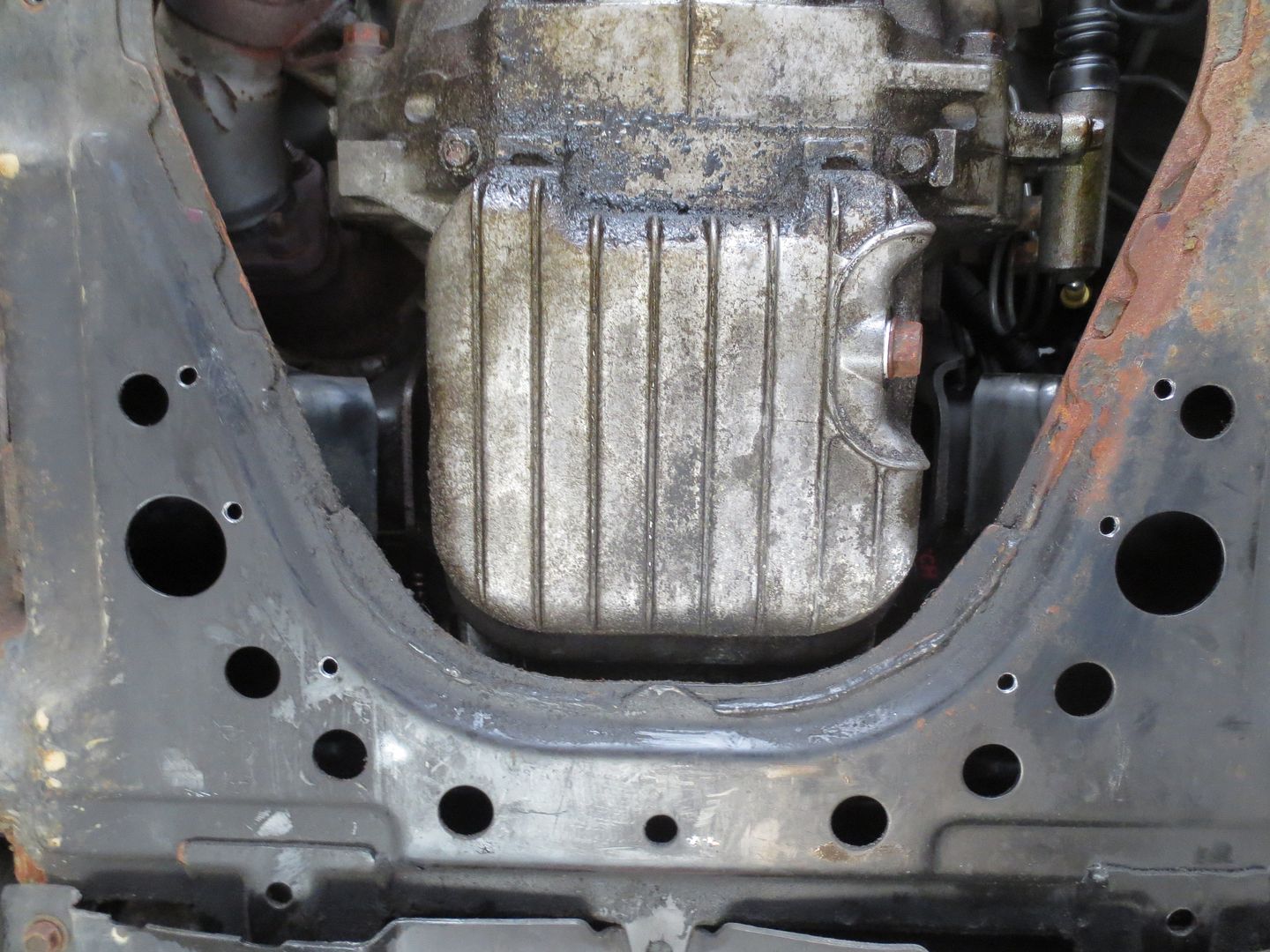

There are three parking brake cables. The first goes from the parking brake handle to a balance adjuster in the transmission tunnel. From there, there are two cables, one going to each rear brake caliper. As I tried to adjust them individually, I wasn't getting the results that I was expecting. The system made more sense after I took a closer look at this diagram:

You can't tell from the illustration, but area where the two rear cables cross isn't visible from under the car. I was adjusting one side based on what I was seeing at the balance bar and things just kept getting worse. As it turns out, I was adjusting the wrong side.

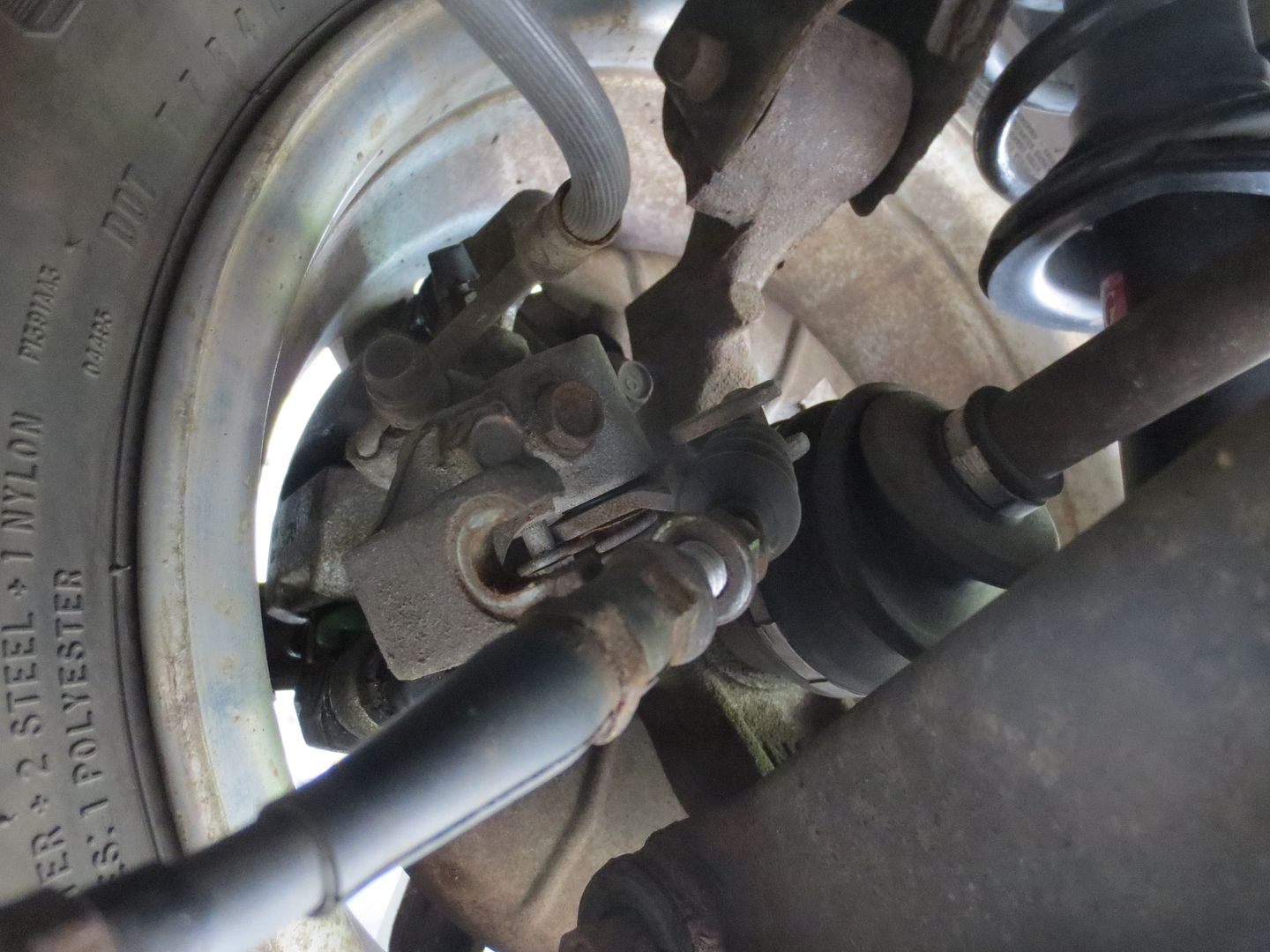

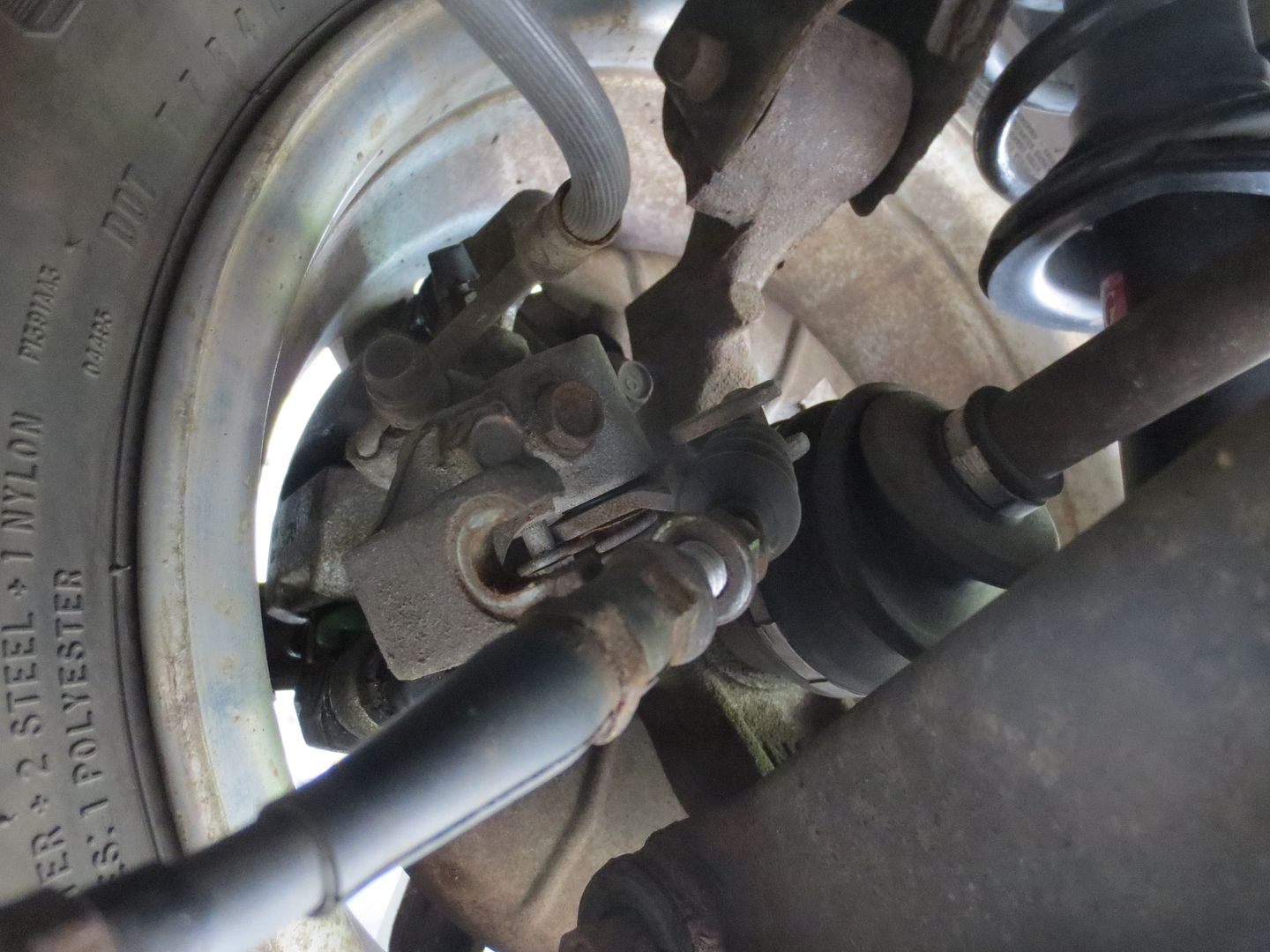

Complicating matters was the fact that the passenger side cable's adjuster was pretty messed up. The car came with a replacement caliper installed on that side and I suspect that whoever installed it also screwed up the cable.

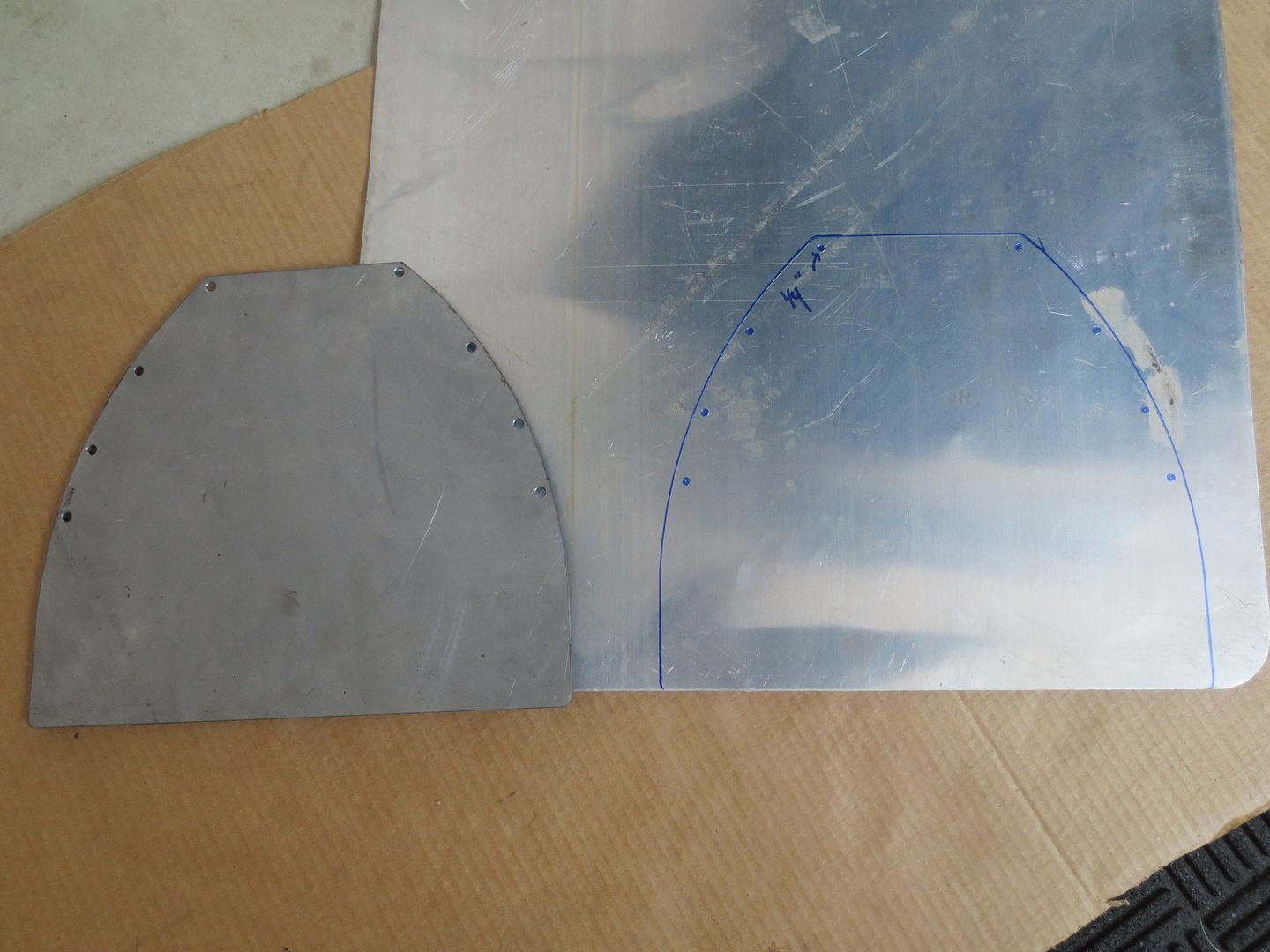

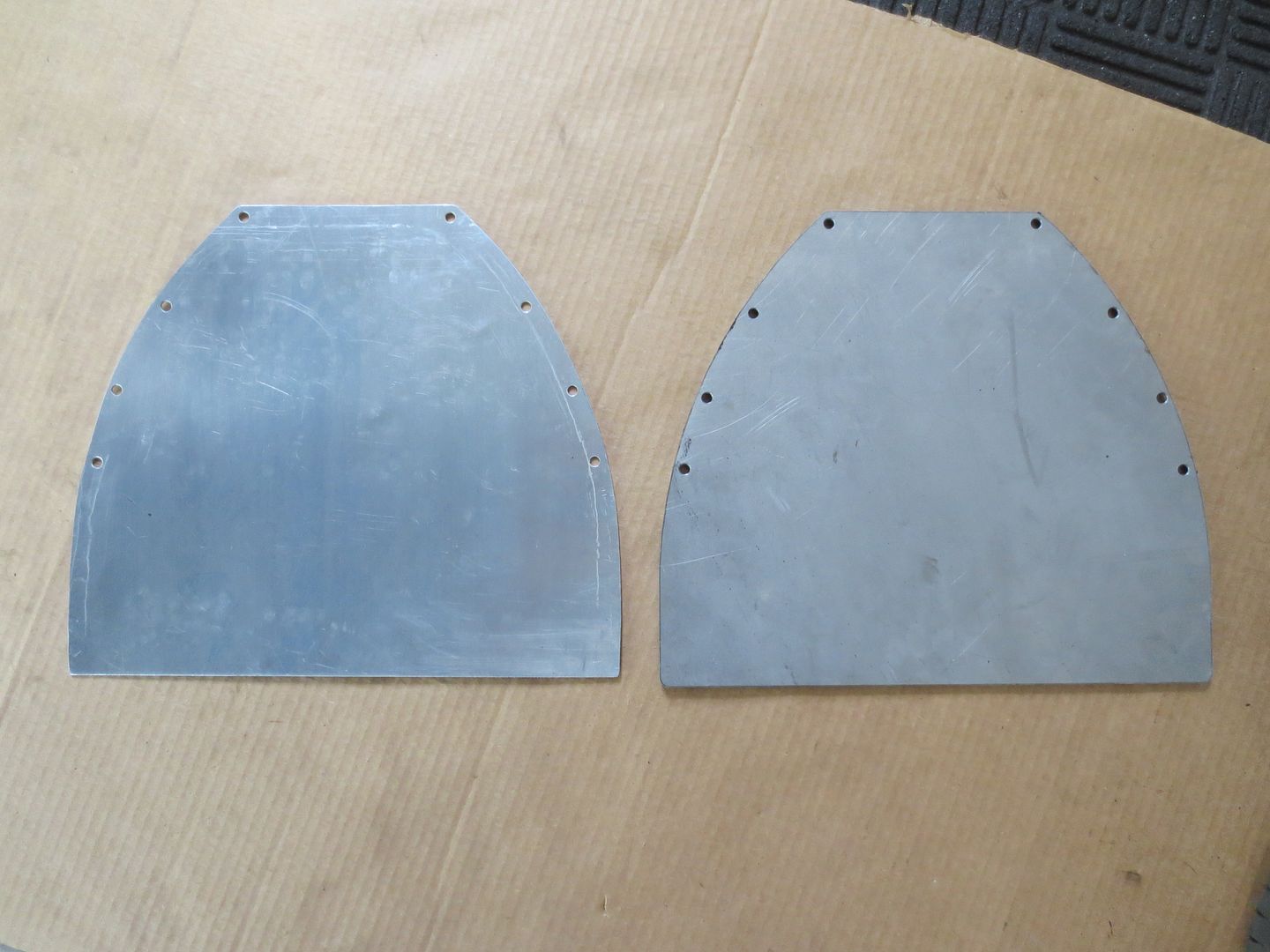

I decided to replace the bad cable. I figured that I should probably replace both at the same time. I couldn't find a part number for genuine Mazda cables on the Mazdaspeed site, and the thought of paying $40 each for aftermarket ones was making me chafe. Fortunately, I found a guy in Texas who was selling a pair of good looking used ones on eBay for $19.99 including shipping. I decided that they were worth a shot.

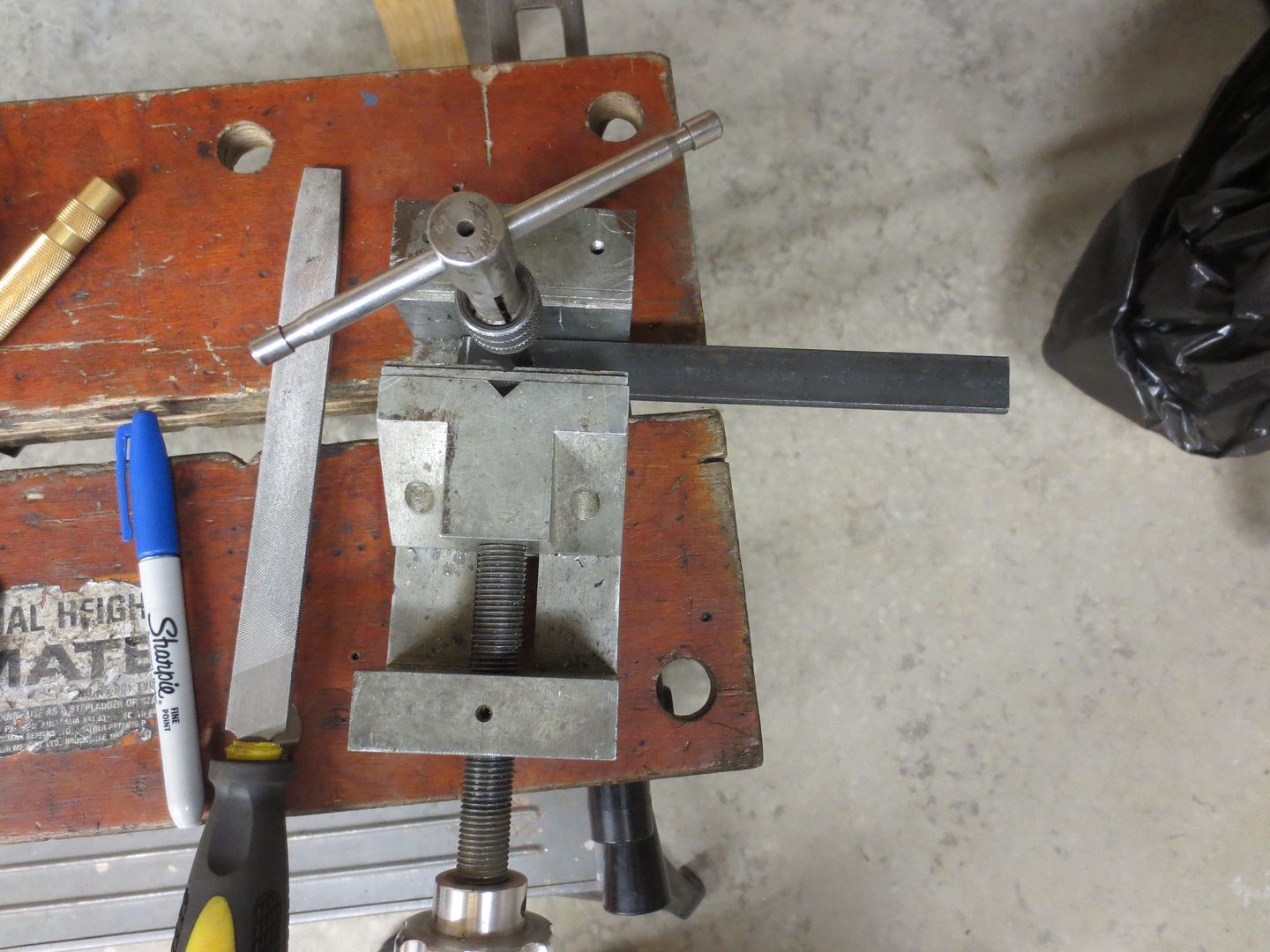

It was fairly easy to disconnect the old ones, but before I pulled them out, I tied a piece of strong string to the front end. This was a good thing, because the cables snake around so many inaccessible and sharp things that I never would have gotten the replacements back in there without it. Even with the string, it was a little tricky.

Getting the cables out of the balance bar was fairly easy. It was much more difficult to get the new ones back in but I finally got them to fall into place with the help of a couple of pairs of long needle nose pliers.

There's one clamp about midway up each cable that bolts up to the frame.

Before connecting the cables up to the calipers, I readjusted the rear brake pads. This step seemed to make all the difference. When I replaced the rear brakes a few months ago, the bad cable was preloading the caliper. The brakes appeared to be adjusted correctly, but the preload was screwing up the parking brake balance.

Then all I had to do was connect the cables to the calipers, tighten them down to the brackets and then adjust the tension using the adjuster at the parking brake handle. I don't have a photo of the actual adjuster, but it's a long 10 mm nut hiding between the lever assembly and the transmission tunnel.

Now the rear brakes are properly adjusted and the parking brake holds the car as securely as it should. This takes care of the last annoying mechanical flaw on the car.