Woody wrote:NGTD wrote: You made the Canadian version of MSN too: R63 RebuildMSNeH?

Close enough ![]()

Woody wrote:NGTD wrote: You made the Canadian version of MSN too: R63 RebuildMSNeH?

Close enough ![]()

mndsm wrote: And this is how grm gets famous-er. Or something.

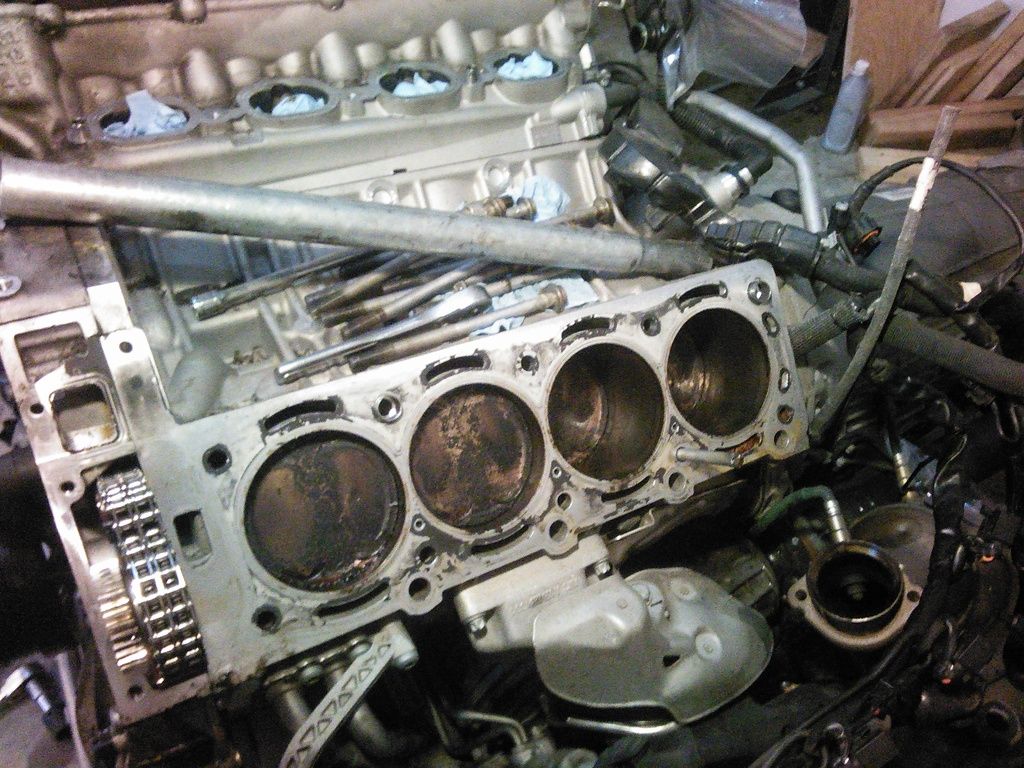

Sitting in my little Grosh looking at a disassembled motor, I can only think that this is interesting to anyone because it's expensive and rare. It's not any more complex than any other DOHC motor. There's more pistons than usual, but the pieces are all the same. The quality of engineering actually makes a lot of the disassembly easier than it is on cars that aren't really meant to be taken apart and serviced.

I really am glad that people are having fun. I like to think that maybe a couple of people had a bright moment this afternoon reading about some idiot and his broken van. Making the world a little more interesting is good. I'm having fun.

So how do we turn this famous-ness into more subscriptions? "I learned everything I needed to know to do this van from reading GRM" ![]()

mazdeuce wrote: You guys have no idea. When I was discussing things with MB USA earlier she said "berk it, call Weistec and have them build you an 800hp motor and we'll roll up to the dealer and do a massive four wheel burnout with our middle fingers out the sunroof!" I managed to talk her down. She's feisty.

Wait...The need to absolutely make this happen just moved the blower from the "scope creep category" to the "must have", user requirements category. Screw Fergus, if you could make this happen it would go viral.![]()

In reply to QuasiMofo:

I want to vote this up but my distaste for those people just won't let me do it.

In the early 80's people didn't love Chrysler because they made K-Cars and Cordobas, they loved them because they used to make Superbirds and Hemi Darts.

Bruce Jenner was indisputably awesome.

My daughter read the R&T article and said "enough people like to read your stuff, you should try and write". And honestly, I think about the the articles Peter Egan wrote about disassembling and reassembling his E-Type in his garage and how I devoured them all. While his hands were getting cold tightening British bolts in Wisconsin, my hands were getting cold keeping my K-Car alive long enough to to get me to school and work. I longed to trade places with him and work on cars that were actually worth it.

I need to go scrape carbon of a couple more pistons.

Pistons are neat. Slight dish. Valve reliefs. QR code laser etched into them.

Another cool thing that I can't remember seeing on other motors is on the balancer/crank pulley. The usual timing marks are there, but there are also marks that indicate TDC for each pair of pistons. Move this mark to the indicator and 3-5 are up all the way. Nifty.

Another cool thing that I can't remember seeing on other motors is on the balancer/crank pulley. The usual timing marks are there, but there are also marks that indicate TDC for each pair of pistons. Move this mark to the indicator and 3-5 are up all the way. Nifty.

Mazdeuce, I found this thread thanks to your new found fame via Oppo and R&T, and myself and some others back on my home site (mbworld.org) are now following along. I am on my third C63 with the M156 motor, two of which were built prior to 2010.5, but successfully dodged the bullet.

First, and most importantly, far be it from me to drag you over from this great site (which I am really enjoying), but I really think you ought to post up over there, or at least visit, cos I think you can find a ton of info and expertise. I know there are very, very, VERY few R63's out there but this motor went in so many more cars (C63, E63, CLS63 and more) and they can all be potentially be affected by this and have info in their individual sub-forums. I think you can learn from us, and we can probably learn a few things from you. We may be able to save you some time, frustration, skinned knuckles, and cash. We DEFINITELY know about parts and parts acquisition over there, and superchargers and long tube headers etc. A lot of guys there have done their headbolts, both as a result of failure and as a preventative measure (which is a lot easier and cheaper, as Im sure you can imagine). There are also a few small items you may want to do at the same time, like the buckets. So come on over and visit. Im in the C63 sub forum, my user name is the same, minus the underscore, and we would love to help.

We do have one application specific question though.......why did you drop the motor right out? I realize you cant crank your hood open at 90 degrees like we can, and you are even more stuffed in, but it does seem like once you removed the cowling you had sufficient space. I know you have thought this through pretty decently so curious the rationale on that.

Anyways, best of luck, you are doing God's work lol. Hope we can help.

mazdeuce wrote: My daughter read the R&T article and said "enough people like to read your stuff, you should try and write". And honestly, I think about the the articles Peter Egan wrote about disassembling and reassembling his E-Type in his garage and how I devoured them all. While his hands were getting cold tightening British bolts in Wisconsin, my hands were getting cold keeping my K-Car alive long enough to to get me to school and work. I longed to trade places with him and work on cars that were actually worth it.

I suspect a bunch of guys like Egan didn't set out to write columns that would gain huge followings. It just sort of happened. They wrote an article or a story and people liked it. So they wrote more. Eventually that morphed into what they are known and celebrated for today.

You have an interesting writing style that makes your adventures fun to follow, regardless of whether you are tearing apart an engine or digging up a sewage pipe next to the Grosh. In today's digital media age of searching for anything that brings eyeballs to websites and thus eyeballs on ads, that has value. Maybe more than you or any of us realize. I'm almost curious to see if the forum readership changes any during the Summer months when you are up in MI.

In reply to 604_C63:

Thanks for reaching out, I'll be over shortly.

I actually spend a fair amount of time over mbworld. Any time I pretend to "know" something about M156 issues, it's because I've googled and the answer is on your forums. You guys are like a chatty service manual. GRM is my home for various reasons. Mostly because I like these guys. I also find it exhausting from both emotional and time standpoints to try and keep up with two different forums. I'm a simple man.

As far as pulling the whole engine. The biggest reason was the confines of this particular engine bay. There just isn't the room to work that the C cars have. The hood does have a service position, but that doesn't give access to the sides of the engine. I had to pull all of the cooling stuff off to get to the front of the engine if I wanted to pull off the timing cover and replace the guides, which I do, and once that's out removing the motor assembly is trivial. It's like 10 bolts and two wires. I did have to install a lift, but who among us isn't looking for an excuse to put in a lift?

One last thing on space. The heads are darn near up against the sides of the engine bay. Normally you just need to pop the heads up a half inch or so to clear the dowels. When a bolt is broken off in the block, like the one below, you need to pick the head waaaaaaay up and over to get it to clear the bolt. I don't think it was possible. Observant readers will note that I didn't actually know the head was broken off until after I pulled the motor, but sometimes we do the right thing even if we don't know why.

mazdeuce wrote: My daughter read the R&T article and said "enough people like to read your stuff, you should try and write".

beyond the obvious "do or do not, there is no try"... I think your daughter is making the common confusion of "you are what you're paid for". I, and I think a lot of the hive, would contend you already are a writer

In reply to mazdeuce:

I knew their would be solid logic behind that decision, I guess I didn't realize quite how truly tight things are for you. And I absolutely understand the desire to avoid a two forum approach, as you could spend all your time just posting. I totally agree with that mentioned the need to keep up your momentum, keep the tear down fresh in your mind for re-assembly time, or risk this motor becoming "that lump in the corner". No M156 deserves that fate. They are just too cool and too fun.

In reply to sleepyhead:

And as you're well aware because of a million transit hours on One Lap, I've carefully crafted my life to NOT get paid for anything. It would be a shame to mess that up. ![]()

Pistons are all clean, time to move onto the heads.

Nurse, hand me my WD-40 and toothbrush! Stat!

In reply to 604_C63:

This picture gives you a pretty good idea how tight things are especially on the driver's side. Honestly, the head might have come off, but the whole process would have involved great suffering.

In reply to mazdeuce:

Yup. You are literally up against it on all sides there for sure. Drivers side is nasty. Didnt quite get a sense of that from earlier pics. The second guessing will now cease. That had to come out, plus you DID get a lift out of it ;)

Mercedes for some time now have been packaging wizards. That's how they cram so much car in to a normal sized body, but it has the side effect of making it impossible to remove the heads with the engine in the car, for example.

Just look at those hoses and valves crammed in next to the oil filter and in front of the intake. Nobody else does that.

Long runner side draft quad-carb is acceptable too.

Maybe after that you can add a twin centrifugal blower set up. I'll help with plenum fabrication. LOL

That thing is plenty heavy for 800+ HP. ![]()

In reply to mck1117:

There is some very clever packaging/engineering going on. If these motors weren't so expensive I think I could really get into them.

Crackers wrote: How much was your run out gauge? I'm gonna need one soon.

It was $30. The alalog version is $20. The magnetic base was another $12 and it's crap.

Working on decrusting the heads. The carbon on the combustion chambers is coming off, but the stuff on the valves is not of this world. Any ideas?

Also the block and heads have this nice thin layer of black stuff that used to be stuck to the head gasket. It'll come off with a fingernail, but is there an easier and better way to clean the surface than spending hours picking at it?

Also the block and heads have this nice thin layer of black stuff that used to be stuck to the head gasket. It'll come off with a fingernail, but is there an easier and better way to clean the surface than spending hours picking at it?

You'll need to log in to post.