Challenge Budget: Car/parts $200

Donor Lincoln town car: 410

Engine crossmember: 120

Sold transmission crossmember from Lincoln: 10

Sold rear axle from lincoln: -50 Scrapped what

was left of lincoln: -89

Sold AOD from lincoln (300, but can only recoup 261)

Engine swap: 5.0 plus 300 boot

Sold kelstar wheels-200 (cant recoup more than we spent)

2x2 angle iron, tractor supply 12.05

Brand new Watkins glen nascar slicks and wheels, which were bought for $50, and promptly sold to Dallas dad for $50 and some weld wheels with really old drag slicks. So, slicks were $0, but $50 taken out of the recoup limit.

4 5/8 heim and jamb nuts: $37.50

Pair of aluminum seats, $40

Sheet of flame retardant high density foam $10

Fire suppression system parts (not included in challenge budget. But ive had 2nd degree burns on the boys before, so were getting safety gear come hell or high water)

1/4 plate, scrap metal yard: 7.50

Mustang convertible mounts 22

Bending plate cost 25

Swedged tubing, ebay: 31.90

Threaded adjusters and 650lb springs, SRI performance: 65

2 used billstein shocks, pull-a-part: 14

Cage materials: 271.40

1/2 Spool welding wire: 16.50

Leaf spring sliders: 40

Clamps for spring adjusters: 23.59

Adjustable brake bias valve 18 (amazon)

2 cans of flat black spray paint (lowes project source) .97 ea

Half melted, used 21 circuit ez wiring harness cut from my duster after the mice chewed it up and it had a meltdown. $5 is what I was quoted as FMV due to the fact that copper prices are down.

Accessories and flexplate: see link in update

Battery cables and relays, pull-a-part: 12.75

Steering box, pull-a-part: 27.50

25feet 3/8 steel fuel line, ebay: 25.75

Bypass fuel pressure regulator, ebay: 29.23

Used, noisy, and mostly dead fuel pump: 6.50

Used mix and match nitrous kit: 32

Two half cans of ford engine blue $7

3/8 plastic line clamps, lowes: 1.78

1/2 metal line clamps, lowes: 3.48

Throttle return springs and brackets: 5

3/8 2x compression fittings, 3x npt-compression, 1x t fitting from plumbing supply house: 6

battery hold down, oriellys 5.99

2x 36 inch 1x1 holey tube: 2

Driveshaft safety loop (dad bought it at an auction last week) 5

Tractor supply run for bolts and angle iron: 18.08

Wheels for monster slicks: 50 from facebook marketplace

Lower radiator hose: 14.82

Oil filter: 4.17

Bucket of hose clamps (pull-a-part doesn't charge for these, so I added the admission charge to the yard): 1

Scrap chunk of 16gauge sheetmetal: .25

Suspension, driveshaft, and 3.73 posi 8.8, offerup: 100

Traded ultralights and sun tach for pro-tach, mechanical 2 5/8 gauges and chunk of diamond plate from a 4x4 buggy guy down the street

Rear brake hose: Challenge budget exempt

Spark plug boot insulators, ebay, 11

Spring perches, amazon 17.49

Pipe standoffs (5) and 3/8 allthread, rhulens supply 8.22

Chunk of diamond plate dad scrounged it somewhere, and said he got got for free.

Misc crap (zipties, sheet metal screws, wiring terminals, used toggles, nuts and bolts, etc. Pretty much the little oddball crap that goes into every build that I had laying around from over the years) 50

Starter solenoid: 7.90

2 inch glasspacks, chunks of 2 inch exhaust tubing, and a little bit of stainless 2 inch: steves buddy: 15

Tow hook: 3

Steering wheel from swap meet 5

Quick release, ebay: 19.99

Manual trans: 50

Flywheel: 45

2 dog leases 1.98

2 u joint straps 5.99

Clutch kit, clutch master, clutch slave: 107.13 shipped

Power steering hose: 15.99

3/8 coupler: 2.50

Welding: 5

Alternator plugs: 2

Starter: 34.39

ARP pressure plate bolts: 12:50 bradley auto parts

Shocks from scrap metal pile: 5

Hood pins: 7.50. Ebay

Hoosier f40 scrubs (budget exempt, byt I bought 16 with a max of 13 laps for 15 each!!!)

Hydraulic clutch line: 25 from the local tow company

3 inch blocks: 25.89

Trans seal: 4.50

Secret weapon: 100

T-shirt material. Bought 5 yards, but the number will change when I see how much I have leftover: 5.98 a yard for a total of 30.90

3/4 gallon of bondo brand fiberglass resin my sister in law was donated at the school and couldn't use. Very old, and possibly expired. $free

New challenge budget total: 1891.05

You'll notice some budget changes. I've been going through with a fine tooth comb, and re-buying some parts cheaper to make room in the budget for paint and body. It seems insane to me to spend real money to save challenge money, but at this stage, its what has to happen. We may have a top 10 car after all. Doubt it, but im being optimistic.

Also, the secret weapon will not be discussed. Also, the final car form wont be shared until the challenge is over. Wed like to have the GRM mag have first crack at seeing what we built for their event, and also don't want to spoil the surprise. After all, other competitors are watching us very closely. Id love to believe that its because they have something to fear, but its more likely that they want to see what kind of lunatic fringe crap we can pull off. We just don't want to give up any potential marginal advantage we may have.

Anyway, we got the car to my shop this past week, and worked on it over the weekend. A bunch.

Started with a good cleanup, and looking over the list of fix-it stuff. I decided that I was going to start on undercar issues. Clutch, safety loop interference, and leaks.

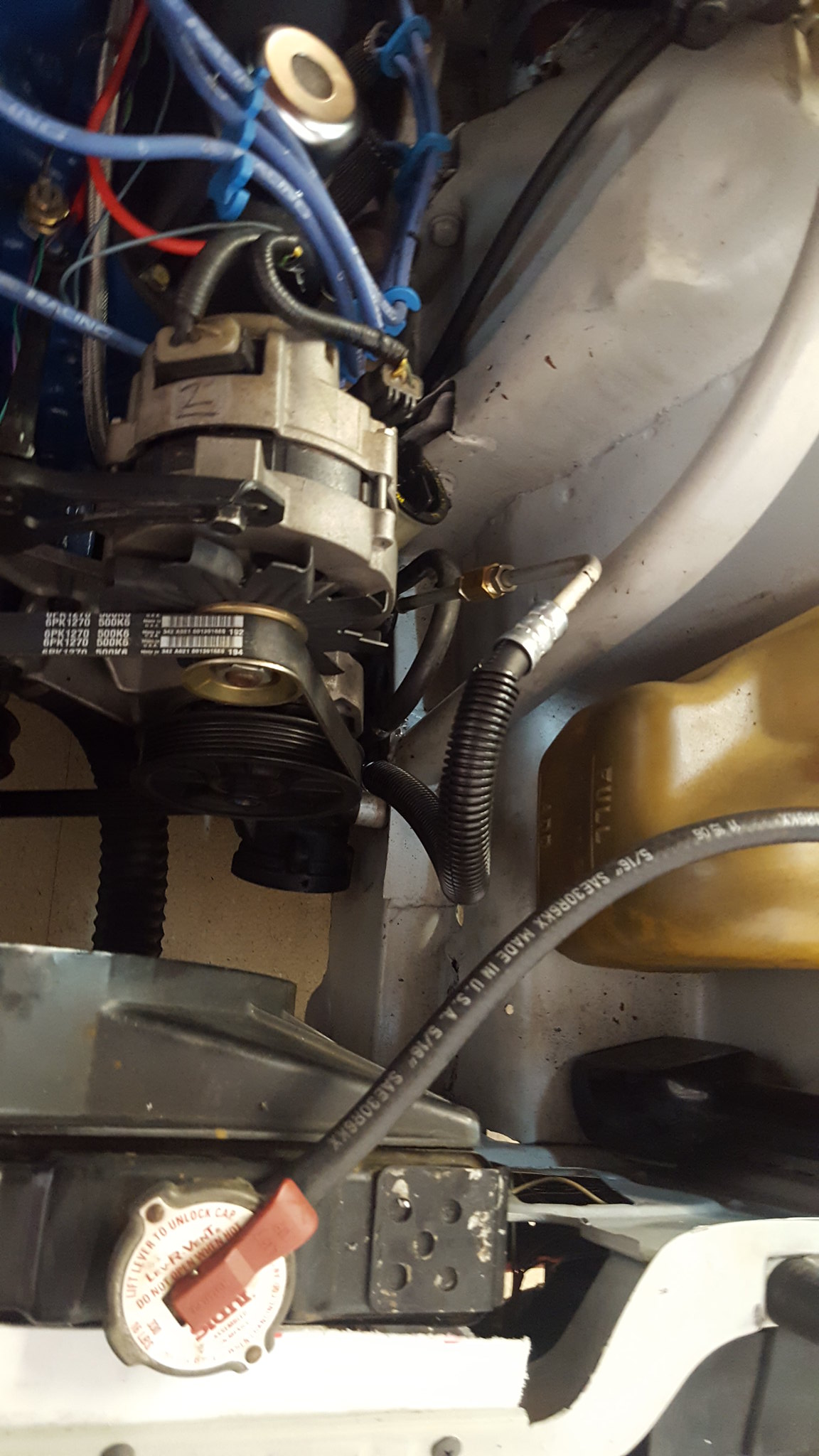

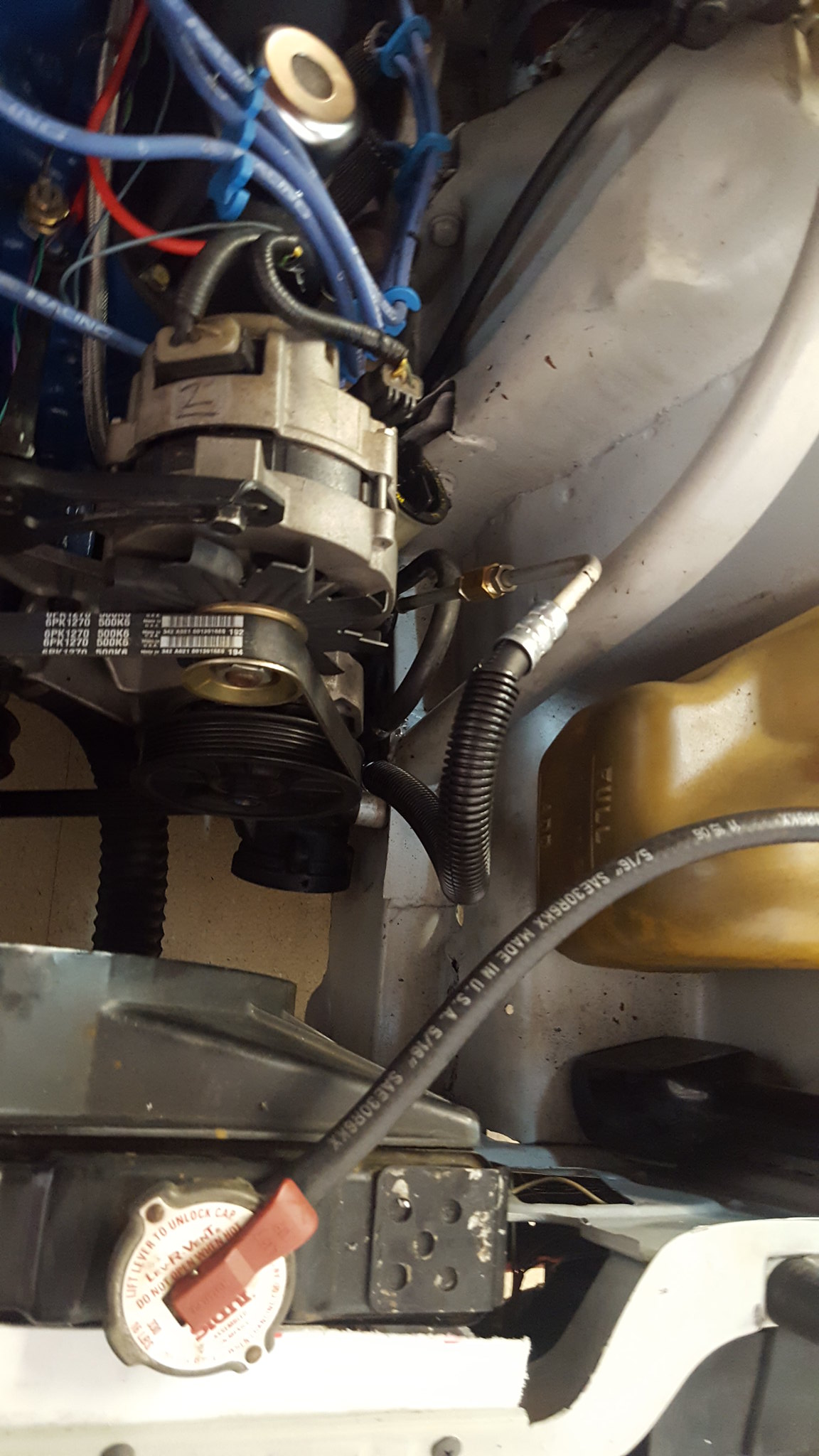

20170811_193315 by Michael Crawford, on Flickr

The rear seal I picked up from oriellys, top plate was leaking and was fixed with some leftover rtv. There’s no pictures of the trans on the bench because I was alone and in the groove. Saturday, Dallas, Steve and I got to cracking, so there's more pictures. We cut the welds on the driveshaft safety look and moved it over by about an inch. One spot, on one driveshaft weld, was hitting one bolt. Now it wont. We also swapped the angle iron clutch slave bracket for one that was made from the square tubing that was welded to the floor of the car when I bought it. Really made the clutch feel better, and it doesn't flex. While I was under there, I also flushed out the power steering system and removed the cooler. We think that the fluid was draining back into the resivoir, overfilling, and puking on startup. That’s why it got noisy at the ends of a run, as it was hot from being low. We also filled the trans with 20/50 engine oil in the hopes of improved shifting. And made the block plate not rub the flywheel anymore. So, hopefully that's all the undercar issues.

20170811_193315 by Michael Crawford, on Flickr

The rear seal I picked up from oriellys, top plate was leaking and was fixed with some leftover rtv. There’s no pictures of the trans on the bench because I was alone and in the groove. Saturday, Dallas, Steve and I got to cracking, so there's more pictures. We cut the welds on the driveshaft safety look and moved it over by about an inch. One spot, on one driveshaft weld, was hitting one bolt. Now it wont. We also swapped the angle iron clutch slave bracket for one that was made from the square tubing that was welded to the floor of the car when I bought it. Really made the clutch feel better, and it doesn't flex. While I was under there, I also flushed out the power steering system and removed the cooler. We think that the fluid was draining back into the resivoir, overfilling, and puking on startup. That’s why it got noisy at the ends of a run, as it was hot from being low. We also filled the trans with 20/50 engine oil in the hopes of improved shifting. And made the block plate not rub the flywheel anymore. So, hopefully that's all the undercar issues.

20170812_122422 by Michael Crawford, on Flickr

20170812_122422 by Michael Crawford, on Flickr

20170812_215034 by Michael Crawford, on Flickr

Before I set it back on the ground, I made some leaf spring clamps up with spare bedframe steel I picked up on trashday a few years ago. This should reduce wheelhop. We also swapped the advance blocks for the EXACT SAME blocks that I got 10 bucks cheaper from amazon.

20170812_215034 by Michael Crawford, on Flickr

Before I set it back on the ground, I made some leaf spring clamps up with spare bedframe steel I picked up on trashday a few years ago. This should reduce wheelhop. We also swapped the advance blocks for the EXACT SAME blocks that I got 10 bucks cheaper from amazon.  20170812_214959 by Michael Crawford, on Flickr

I moved onto building some ducting for the radiator while Steve made seat back braces, services and repaired out fire suppression, and worked on planning our secret weapon. Dallas fixed the leaking gauge, found TDC and gave us a timing mark, and started cleaning up the interior, underside, etc. No real pictures of Dallas stuff, as it doesn't really look any different.

Seat back braces:

20170812_214959 by Michael Crawford, on Flickr

I moved onto building some ducting for the radiator while Steve made seat back braces, services and repaired out fire suppression, and worked on planning our secret weapon. Dallas fixed the leaking gauge, found TDC and gave us a timing mark, and started cleaning up the interior, underside, etc. No real pictures of Dallas stuff, as it doesn't really look any different.

Seat back braces:

20170812_215006 by Michael Crawford, on Flickr

The radiator ducting was made from a box lid. Dallas found a gray plastic one, I found a white one on trash day last week. We decided to use the white. Few new holes, couple of screws, and done.

20170812_215006 by Michael Crawford, on Flickr

The radiator ducting was made from a box lid. Dallas found a gray plastic one, I found a white one on trash day last week. We decided to use the white. Few new holes, couple of screws, and done.

20170812_215102 by Michael Crawford, on Flickr

20170812_215102 by Michael Crawford, on Flickr

20170812_215110 by Michael Crawford, on Flickr

We then spent a while on figuring out fender flares. We need them. We need the car to look finished. Its really too awesome to let the dirt track hack stay. Lets the whole car down, as we've really tried to stay true to what a privateer would have done for IMSA in the late 70’s/early 80’s. That wouldn't have flown back then, so we cant let it fly now.

We started with tape mock-ups of the cut out flares.

20170812_215110 by Michael Crawford, on Flickr

We then spent a while on figuring out fender flares. We need them. We need the car to look finished. Its really too awesome to let the dirt track hack stay. Lets the whole car down, as we've really tried to stay true to what a privateer would have done for IMSA in the late 70’s/early 80’s. That wouldn't have flown back then, so we cant let it fly now.

We started with tape mock-ups of the cut out flares.

20170809_171531 by Michael Crawford, on Flickr

I then took some scraps of metal, and beat/bent/screwed until I was happy with the fender lip to tire look.

20170809_171531 by Michael Crawford, on Flickr

I then took some scraps of metal, and beat/bent/screwed until I was happy with the fender lip to tire look.

20170813_145919 by Michael Crawford, on Flickr

After that, I coated the fenders with a heavy coat of wax, followed by blue tape. See, were making overfenders. Bolt on style. So I need to be able to pop them off. In addition, fiberglass to steel typically doesn't survive well in the long run from what ive heard. So, bolt on seems to limit all the problems. Now remember: I have no idea what im doing here. Making it up entirely as I go. Ive built two fiberglass subwoofer boxes, and that's the extent of my experience working with glass. So, its probably best not to follow these as directions....

20170813_145919 by Michael Crawford, on Flickr

After that, I coated the fenders with a heavy coat of wax, followed by blue tape. See, were making overfenders. Bolt on style. So I need to be able to pop them off. In addition, fiberglass to steel typically doesn't survive well in the long run from what ive heard. So, bolt on seems to limit all the problems. Now remember: I have no idea what im doing here. Making it up entirely as I go. Ive built two fiberglass subwoofer boxes, and that's the extent of my experience working with glass. So, its probably best not to follow these as directions....

20170813_151720 by Michael Crawford, on Flickr

20170813_151720 by Michael Crawford, on Flickr

20170813_153759 by Michael Crawford, on Flickr

Went to Walmart to get super stretchy polyester cloth. Came home with it.

20170813_153759 by Michael Crawford, on Flickr

Went to Walmart to get super stretchy polyester cloth. Came home with it.

20170813_165012 by Michael Crawford, on Flickr

20170813_165012 by Michael Crawford, on Flickr

20170813_165009 by Michael Crawford, on Flickr

Drew the outer edges with sharpie, grabbes some spray glue, and started stretching out a shape.

20170813_165009 by Michael Crawford, on Flickr

Drew the outer edges with sharpie, grabbes some spray glue, and started stretching out a shape.

20170813_170712 by Michael Crawford, on Flickr

20170813_170712 by Michael Crawford, on Flickr

20170813_173036 by Michael Crawford, on Flickr

20170813_173036 by Michael Crawford, on Flickr

20170813_173057 by Michael Crawford, on Flickr

20170813_173057 by Michael Crawford, on Flickr

Sorry no wide angle. Duster is in the shop as it was raining today, and just not enough room. I did start to get resin on it, out of an old partially used gallon that the school was getting rid of. It still hasn't hardened, and im starting to get nervous. Well see what it does in the morning. May wind up buying some...