Winter work the final part: some actual upgrades!

I finally decided ~2.5* front camber just isn't cutting it and gave in and ordered some camber plates. The secondary benefit is being able to suck the whole wheel/tire inboard, creating better wheel/tire clearance.

The nice part about these vorshlag plates is that the upper spring seat articulates on the spherical bearing. With the base ohlins setup using the stock upper mounts the only thing that absorbs angular misalignment of the spring is a 2mm thick rubber spring pad and the strut tower, which I never loved. Having properly articulating upper mounts made me feel better about the reduced isolation of damper forces from the strut towers.

The less nice part about the vorshlag plates is that they're designed to reduce caster slightly. I'm not exactly sure I want that, and having the strut offset towards the front of the tower opening makes for some clearance/adjustment issues especially with the tower reinforcement brackets. It also moves the wheel forward in the fender opening which I also don't love aesthetically or for tire clearance at large steering angles. So the first thing I did was disassemble one camber plate and create a CAD model of the baseplate so I can get my own made with whatever caster offset I want in the future if needed. For now they're going in as delivered and we'll see how it goes.

Of course like my modifications to the ohlins, these aren't quite a direct fit with the nonstandard spring setup I'm using. The upper spring seat actually lands within 2mm of the existing setup, so despite needing to modify some shiny new camber plate parts I'll come out not needing to move the other spring perches at all. The primary modification needed is shortening the piece that the strut rod sits on to get the travel correct. I forgot to take a before photo but here's the after; the before was this, but about 18mm taller. Only the slightly larger diameter part press fits into the upper spring seat, so there's no functional impact.

And for better understanding, the spring seat with that piece installed.

The ohlins are an inverted monotube design, the top of the "rod" (which is actually the man damper body) necks down at the top to a normal strut rod shape. The ohlins setup uses a spacer to make the right total length with stock upper mounts, this piece basically replaces that spacer and then seats into the spherical bearing.

As is maybe visible in the spring seat photo, the necked down part of the strut actually nests into the bearing ID a bit. Clearance is tight but it does clear.

And there's (barely) enough room for the dust cover. Fully assembled it looks like it was intended to be this way:

And one final modification: because of the significant shortening of that spacer/adapter piece, the collar nut is a little bit too long and would have bottomed out on the end of the threads before tightening. I solved that by removing a few mm of thread from the end, leaving the collar functionality. Before and after:

After install there's a slightly comical amount of thread sticking out the top, but the total height from the strut tower isn't any more than with stock upper mounts, so no trouble there. I ended up adding the normal nuts on top just to be safe.

And installed to the car:

While I was in there with the suspension mostly apart I figured it was a good time to swap in the matching low mileage right steering knuckle to go with the left side that I replaced a year or two ago. This bearing doesn't feel quite as crispy new as the left side but it's definitely nicer than the one it's replacing. I installed the leftover pair of new caliper studs and cleaned it all up:

And here's the right front corner looking very empty, waiting for parts to be reinstalled:

Also while I had everything apart, that tie rod end was looking particularly crusty and the ball joint feeling a bit soft. I had a lightly used one with a super nice feeling ball joint sitting around so I decided to swap that in. Old versus new(er):

And the final upgrade, hinted at earlier: when I swapped back to the X73 front swaybar I used stock endlinks for simplicity. The stock bars on these cars have odd, basically L shaped ends that drop the lower end of the endlink super low, like below the nottom of the control arm. I learned the hard way that the link/bar end make contact with the inner lip of the autocross wheels at full lock. Not a huge deal but enough of an annoyance to investigate shorter links. The adjustable links from the GT3 bar were too short for comfort even set as long as I felt confident with. So I did some measuring, contacted tarett, and was able to get some longer link bodies for a surprisingly reasonable price. Here's the GT3 bar link, the new body version, and the stock link.

So the new setup is basically splitting the difference between the two other options. With the mid-length links installed, wheel clearance should be a non-issue, and the swaybar arm angle is actually probably a bit closer to horizontal which is a nice bonus.

Put everything back together and did my best at setting camber back to what it was and the tie rod length correctly so that I could drive to do an alignment without dying or wrecking the front tires. Turns out I way missed on total toe and it was something like a quarter inch off, but the steering wheel was straighter than some purposeful alignments I've done. I also loosened the left tie rod end and moved it through a bit of travel to make sure I wouldn't run into any issues during the alignment process so I guess i missed equally on resetting both sides.

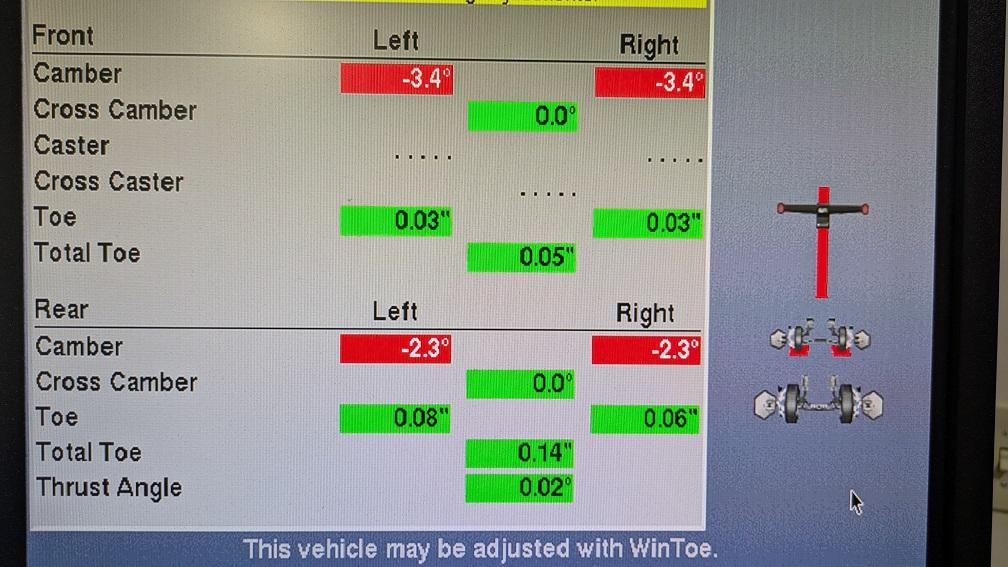

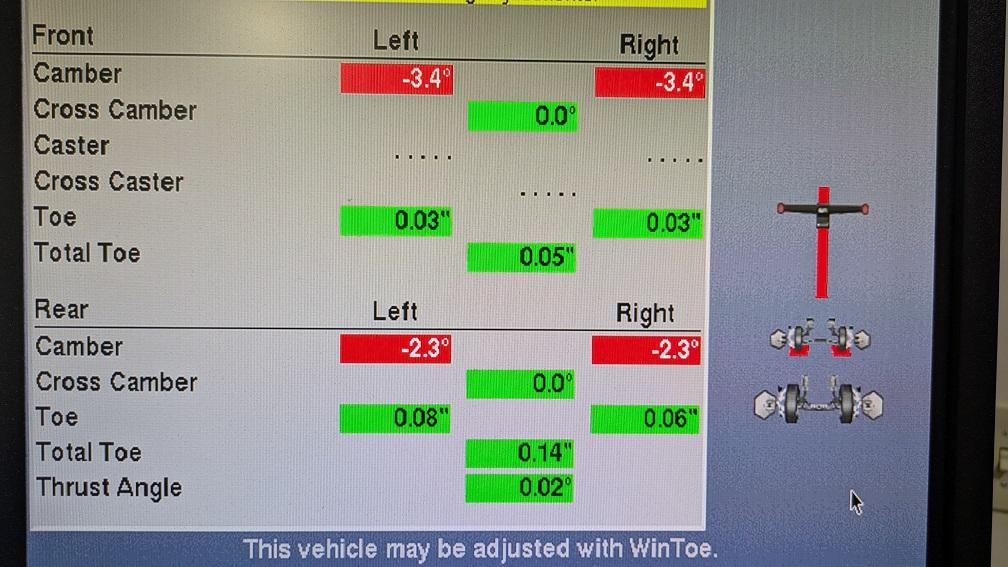

After a bit of effort to get everything even, this is the alignment I ended up with. I also changed from slight toe out to slight toe in in the hopes of not being too hard on the tires with the extra camber.

In the alignment process I also pulled 3mm of spacer out of the control arms, to move the whole wheel/tire assembly inboard. Fitment looks better, the autocross wheels look kind of natural in there and I had to move from 7mm to 10mm spacers on the street wheels to not be too sunk in. So naturally now I'm contemplating moving up to 10" wide autocross wheels. I'm guessing I'll end up making some further adjustments once I get some time on this setup but this seems like a good, if maybe a touch aggressive, starting point.

So the car is back together and driving now, waiting for good weather and/or the first event of the season. Initial assessment is that there's shockingly little NVH impact from the camber plates. I had softened the front struts a click just to be safe, I'll probably undo that now. I finally remembered to take a photo as the car sits now; the low light was nice because it hides that the car is actually fairly filthy