In reply to Johno100 :

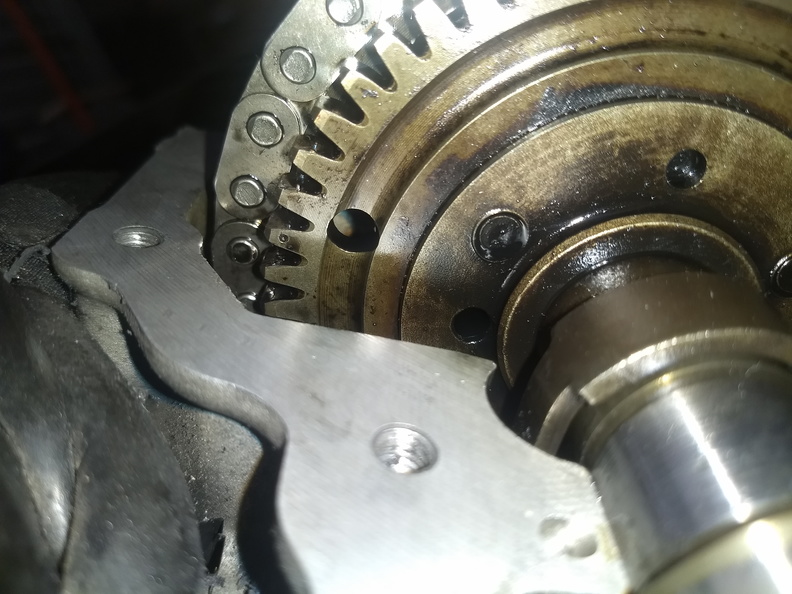

I meant the timing of the high pressure fuel pump. For sure timing of cams is crucial! That is how I got into "heads off" territory in first place lol. Some people say that it doesn't matter how you put it in as long as gears mesh, others say that the pump works in impulses and it's supposed to be timed so that it pushes when an injector fires so as to keep constant pressure (at least that is my understanding of what I read). Wis instructions which I can provide if anyone wants, say to find a tooth at center of counter weigh on the HPFP, then count counterclockwise to find 5th and 6th teeth from it. Those teeth should be vertical (I understood that as pointing up perpendicular to horizon) when the pump in inserted while engine is at TDC.

My intakes were not as bad as wae's but they were gummed up bad as well. If you are up for it, I recommend cleaning them, and you will probably want to clean I take ports in the heads as well. SUPER important to ensure valves are closed as you clean them. I didn't do it, and got enough crap into cylinder to keep engine from turning over. But you probably know this. I am not a mechanic by any means. While I had heads off, I took note of when each cylinder is at TDC in relation to the TDC on the crankshaft flywheel (in degrees). I posted his info on MBWorld. I can provide that tomorrow here as well if you want. That will tell you when valves are closed.

In reply to wae:

Thanks mate! Can you vent it just to atmosphere? I thought that it needed to be "sucked" out. I saw mods where people route it to front of engine with a catch can then back to intake to reduce suction. But it worried me that without enough suction, more unburnt gasses will linger in crankcase leading to sludge. That not how this works? I like the idea otherwise... I think another important bit is keeping air filters clean.

I also got Arnott! Remanufactured, so I can keep the ADS functional. Glad to hear they work for you, promising :)