I won a single front shock on ebay as well. Now I have three rears and two fronts. I will be selling one of the rears to recoupe some money.

http://www.ebay.com/itm/120917186515?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1497.l2649

I won a single front shock on ebay as well. Now I have three rears and two fronts. I will be selling one of the rears to recoupe some money.

http://www.ebay.com/itm/120917186515?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1497.l2649

I got a decent amount of work accomplished this off cycle.

First of all I attempted to diagnose the bogging under load issue. I fiddled with the sensors and determined that the check engine light is working. If I unhook something, the MAP sensor for instance, the light comes on. With everything hooked up the car runs smooth as can be at idle and revs perfectly when it is not in gear, with no CEL. ![]()

That got me thinking could it be low compression. I always wanted an excuse to buy a compression gauge, and now I have a totally legit reason to purchase one. I went to the local autopart warehouse and bought a new one for $32.00. I pulled out the spark plugs (Bosch Platinum's = worst plug ever) and checked the compression. They were all within two pounds (150-148) across the board. That seems a little low to me, according to everything I read online they should be closer to 180. But hey at least they are consistant. I will retest again in the future in case I was doing something incorrectly.

My next thought was bad gas. Before I bought the car it had been sitting for an unknown length of time. Could bad gas cause it to bog under load? I guess the easiest way to test would be to drain the gas in the tank and put in new gas and a new fuel filter. I haven't tested this theory yet because I put the car on jack stands in order to do the brakes and suspension. I took 20 pictures as I dissasembled and cleaned everything but I somehow erased them.![]()

Here is the old shocks by the new (used) ones after painting for comparison. The rear will have the blue springs (450 6 inch) and the front will have the red springs which are 8 inch 432 llbs. I would prefer a 400 but my other option is a 350 lb 6 inch or the 8 inch 432 lbs. I will see how the autocross on the 27th goes and will make some adjustments accordingly.

The progress on this build has been fun to watch. I'm sure you'll have it running correctly again soon.

Here is a picture of the drivers side suspension to show a "before" since I accidentally erased the real "Before" pictures.

Here is the rear all cleaned up...

Man, I'm impressed. I'm sure you'll get it figured out. I might have gotten that thing running with a few months of work and a load of help from people like you on a forum like this. But just cleaning up the wiring and knowing exactly how to get it to run? No way. That's a great effort and clearly you know what you're doing.

Thanks for the positive coments everyone![]() .

.

I have been happy with the progress up to this point but honestly this thing is easy compared to some of the insane builds my competitors are putting together. The escort with the twin engines for example is way out of my league....

This may be "easy" for you but I'd never be able to figure out that wiring mess.

Personally, I'd rather read about this realistic build on the forum that us normal guys at home can accomplish. Some of the more insane builds just don't seem as interesting for me.

Can I borrow you next time I need to do some wiring? If I do it alone the end result is usually electrocution or a fire. ![]()

DaewooOfDeath wrote: Can I borrow you next time I need to do some wiring? If I do it alone the end result is usually electrocution or a fire.

I am not done yet. There is still plenty of time for electrocution and fire. I haven't had a good fire since the undercoating on my SE-R ignited when I was welding in its cage...

I decided to start this off cycle by draining the gas. I was able to pull about 5 gallons out of the car which I then poured straight into my wife's Sequioa. If it was bad I couldn't tell after mixing it in with 20 gallons of good gas.

My initial plan was to drop the tank and see if the fuel filter sock was clogged. After researching what was involved I decided to kill two birds with one stone and install a walboro 255 Fuel pump. I called up my buddies at Stage6 Motorsports and ordered up an EF pump for $80.00. I will need it to run the 440 injectors when I install the turbo. I was going to wait till later but this way I can mark a bad / under powered pump off my list and prepare for the turbo install later.

To finish off the fuel system for now I also purchased a new fuel filter.

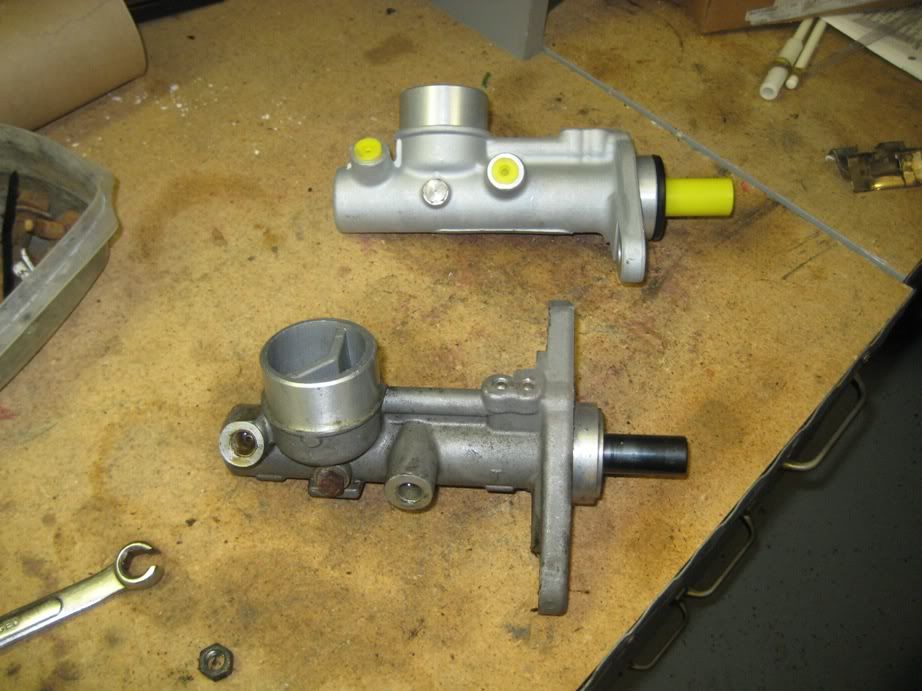

I next tackled the brakes. On my initial test drive I noticed that the brakes required an extreme amount of pedal travel to actuate. This is caused by an undersized master cylinder. After some research I realized that I could use a 15/16th 1991 Civic EX master with my stock booster. The stock Integra master is a 15/16th as well. I scored a new one at Oreily's for $44.00.

A neat trick I have used in the past if you don't have a turkey baster handy to remove the fluid is to use a paper towel. I think it took three pieces ripped in half to absorb all of the old fluid. I didn't think to take any pictures until I had already removed the old fluid.

On to the front suspension...

When I initially tore down the front suspension I noticed that the ball joints on the outer tie rod ends were busted. The local Advance had them in stock for $12.00 apiece.

Here is the old passenger side by its replecement.

Here is the old passenger side by its replecement.

While I was working on the tierods I let the paint dry on the front suspension forks...

While I was working on the tierods I let the paint dry on the front suspension forks...

Here is the front caliper, cleaned and assembled

Here is the front strut after removal. Notice the sweet collar and the unmarked unknown spring rate spring.

Here are the springs I am using on the car. The rear blue spring is 6 inches long and has a 450lb rate, the front red springs are off of the shocks I bought on ebay and are 432lb 8 inchers.

Here is the old stock shock next to the Tockico Illumina that is replacing it.

I am pretty sure this is how everyone installs threaded collars on their shocks. Forget the little rubber rings they give you. Wrap duct tape around the shock until you get a tight fit. I have done this countless times with great results.

Here is everything installed on the car. Much better.

A couple of random shots. Here is the car as it sits now...

Notice my OCD bolt box on the work bench... yes those are labels on each drawer ![]()

Here are the NGK plugs for the car. Did I mention that I am not a Bosch Platinum fan. I think all four set me back like $6.00. Also this will eliminate the plugs as the cause of my misfire.

I tackled the fuel pump today before work. I have been dreading it for awhile because I read online that dropping the tank is kind of pain. Well start to finish it only took me 45 minutes ![]() , I guess that goes to show you can't always believe everything you read online.

, I guess that goes to show you can't always believe everything you read online.

The old pump was not original but as usual with this car was not wired in very well. Everything is as it should be now. The new pump fit no problem and was actually smaller then the old pump.

I took several pictures of everything as I worked on it and will post them tommorow.

Here are the fuel pump pictures I mentioned last week.

The tank after dropping it down.

Top of the tank before I removed the pump.

Old pump after pulling it out...

Pumps side by side. Notice the Walboro 255 is smaller despite the greater flow, interesting.

New pump ready to go in...

Here is the Civic backed into garage so I can get to the timing belt.

After replacing the fuel pump didn't fix my problem, I got to thinking that the timing could be off. I at first discounted this because the car ran so well, idled perfect etc. Since I had run out of ideas I decided to look into the cars timing. The main problem that I ran into was that the previous owner had removed the lower timing belt cover. I assume this was for weight reduction ![]() Regardless of his misguided reasoning, without the lower cover you have no reference for the timing mark on the crank pulley. I was able to use a mark on the oilpump as reference and discovered.... That the timing is off at least two teeth

Regardless of his misguided reasoning, without the lower cover you have no reference for the timing mark on the crank pulley. I was able to use a mark on the oilpump as reference and discovered.... That the timing is off at least two teeth![]()

I didn't have anyone to help me so I had to improvise. In order to get the crank pulley bolt off you have to put the car in gear and hold down the brake. I used this extending paint pole to fill in for a helper.

Here is the bolt off, finally!

All finished up.... I realigned everything correctly and put it back together. I installed a timing belt cover that I bought off of craigslist for $10.00 (It was off of a DA B18a engine but it lined up perfect). Now it is time for a test drive...

I took the car out after buttoning it up, and it runs perfect ![]() . It pulls strongly and the hesitation is gone.

. It pulls strongly and the hesitation is gone.

I am stoked that I was able to figure it out. I would guess based on the way the car pulls that it runs a low 15 to a mid 14 in the quarter. I will drive it a little to make sure there are no glaring issues before I install the turbo.

hell yeah...nice work. I love simple, no nonsene, logical, systematic builds like this one. Thanks for posting all this. Im sure your hard work will pay off.

You'll need to log in to post.