IMO all FCs should be white. Japan's racing color is/was white, 10th Anniversaries were whited-out, and then there is

Not sure what is up with 74/174 on RX-7s though. Yours, Kevin's, moxnix's, and my '81...

IMO all FCs should be white. Japan's racing color is/was white, 10th Anniversaries were whited-out, and then there is

Not sure what is up with 74/174 on RX-7s though. Yours, Kevin's, moxnix's, and my '81...

In reply to Pete. (l33t FS) :

It was easy to do with tape for Rallycross and #11 was always taken.

I give people a long winded BS story about how 4 is unlucky In eastern cultures and 7 is lucky in western Cultures.. yin yang and all that balance stuff but its just for a rouse.

I had to add the 1 for stage rally because 74 was taken although i think that person hasn't Ran an event in over 10 years.

I think the 74/174 is a bizzare coincidence

I am Aiming for 250whp. If i wanna do a semi PP in the Future with this setup using fresh housing maybe 275whp+ is possible.

If you hit 250whp, I want to run my car on that dyno ![]() Not that it isn't doable, but it won't happen by accident. Will be interesting to see what the RX-8 rotors do for you, I have heard that they boost midrange while hurting top end power and I have heard that they help everywhere. But still, midrange is more important (is why I went bridge) and nothing bad has ever happened from lightening the rotating assembly.

Not that it isn't doable, but it won't happen by accident. Will be interesting to see what the RX-8 rotors do for you, I have heard that they boost midrange while hurting top end power and I have heard that they help everywhere. But still, midrange is more important (is why I went bridge) and nothing bad has ever happened from lightening the rotating assembly.

Speaking of lightening, you should have seen the lightened 9.7 rotors I saw while buying my 12A rotors. (He had a J ported FD engine he was selling, as the restrictor he needed in whatever class did not work well with high overlap engines) They had been severely drilled out widthwise, the area where the rotor bearing presses in was turned into a lattice. That wasn't the only place metal was removed but it certainly was the most visually striking.

In reply to Pete. (l33t FS) :

I think the intake manifold will Bring more benefits than the rotors. Anything north of 210whp would be great. Hell even 225whp would be nice.

If i can do ~195whp w a stock s5 na intake this should be the hot ticket to get me over the 200 mark no problem.

infernosg said:In reply to fidelity101 (Forum Supporter) :

I should clarify by "concerned" I mean "not ideal." You may end up giving up a few hp but in the grand scheme of things it probably won't be noticeable. The convenient of being able to use circular tube for the intake manifold probably makes up for any small losses. As for ideal, you want the intake runners to transition as smoothly and gradually as possible from the round shape of the IDA-style throttle bodies to the oval ports at the engine. Ideally, you also want the intake area to gradually get smaller as you near the engine with the port area be final size. The only real way to do this feasibly is with a cast manifold. I spoke to EFI Hardware about having a one-off cast manifold made to my specifications (equal length runners, 50 mm inlet diameters to match the TB, outlet ports to match my engine, etc). They quoted me something like $1500 AUD, which honestly seems low for a one-off cast part. Speaking of EFI, I can't tell from your picture but did you opt for the tapered bore TB?

Honestly for 1500 AUD they are probably doing a prototype casting method, you 3D print the part you want and it dissolves with the molten metal to get the shape you need in the sand.

I was thinking with a semi PP that this throttle body would be too small and I would want to go for a 55mm or even use one meant for a 20b.

50mm is the hole diameter at the flange for the throttle body assembly, each rotor has 2 ports, one is 2" schedule 10 and the other is 1.5" so if I add a 3rd port to the rotor thats a 1" and a 1.5" and 2" collecting to a 2" opening (50mm) which may not breathe as much. The other wild idea would be keep this the way it is and then when/if I go semi PP that it goes to its own throttlebody assembly controlled electronically but that would require a different ecu as mine is only setup to do cable throttle being an elite 1000.

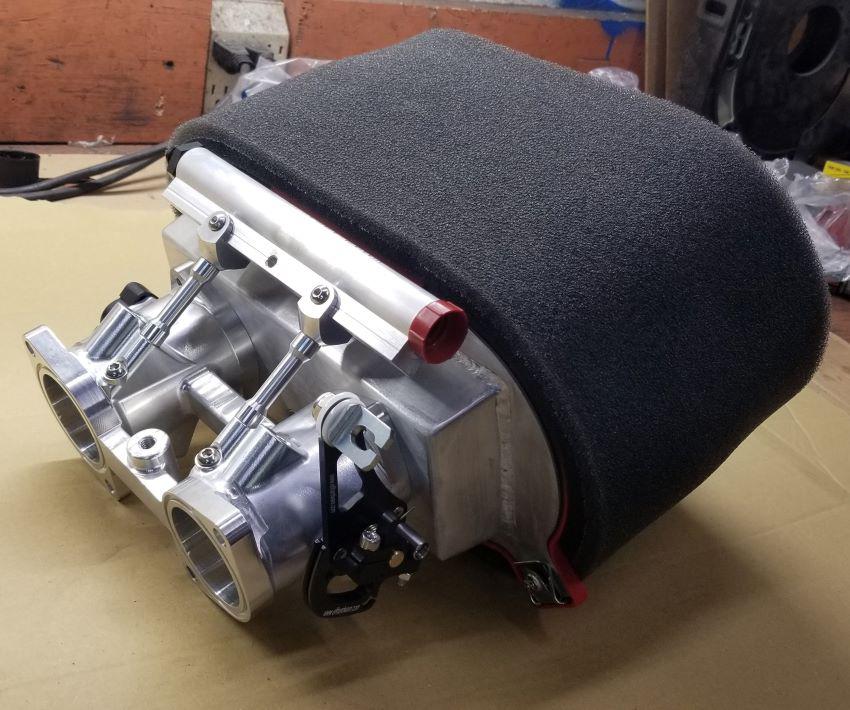

Yeah I went with the tapered bore pro race billet option using the high flow ram tubes (90mm) which caused me to go a custom intake filter route via ITG but it its only a custom baseplate as it still utilizes their off the shelf filter for an IDA type carb or efi setup.

here is some more rotary porn:

front and rear housings have been ported and have been sent out to be resurfaced, working on the center iron now. the key idea is to not have to open up my current engine at all. But that motor will likely get opened up and slapped together to make the rx8 mobile again one day but keeping the rally car going is pretty time consuming so we shall see on that project...

here it is with the extra overfilter for enhanced dust protection

here is some last minute LSPR footage too!

Where'd you get the ITG assembly? Custom or something EFI Hardware now offers? It looks a lot better than the K&N setup you usually see. The biggest issue with a setup like that is keeping IATs under control.

I also have the 55-52-50 tapered bore throttle body with the high flow ram tubes. Mine are the shorter version though and even then I cut off about 5 mm so they'd fit the air box with sufficient over head. Since your configuration isn't far off mine I'd say 250 whp should be doable. Especially since you have the RX8 rotors. Depending on which dyno you look at and believe I'm somewhere in the 240-260 whp range. I will say that I still end up pulling some vacuum at higher RPM. Something like the -0.5 psi at the limit. It's always been there too despite completely changing the exhaust, going to a much shorter intake manifold and going from a 55 mm straight bore to the 55-52-50 tapered bore throttle body. I'm not sure if 55 mm just isn't big enough or something else is going on. People used to run peripheral ports on modified 51 IDA carbs so I'd think 55 mm wouldn't be too big.

In reply to infernosg :

I emailed them, they are super responsive and gave me the CAD model and print with this tray too (so I can print on in Nylon Carbon Fiber in the future) we did some back and forth but you can probably get this replicated if I give you the order number. the ITG assembly from EFI hardware only works with the small horns, I wasn't interested in that. It took some time and we went back and forth a bit. It was a little pricy but without having to do the custom filter part made it cheaper.

I don't monitor vacuum or backpressure but I think I should for tuning, I don't know enough of this subject on how it can affect tuning and why/etc. I have been thinking of just doing a ratio, I want the intake primaries to be half the length of the ehxuast or 1/3. I will be measuring intake primiary length from the tip of the air horn to the earliest entry on the intake port as it enters the combustion area. Piston engines do tip of air horn to back of the valve. Same deal on the exhaust - I will re-measure the exhaust then do from the outlet of the exhaust opening to the collector.

I bought "the book" https://www.amazon.com/Street-Rotary-HP1549-Horsepower-Reliability/dp/1557885494

in efforts to help understand how to design an intake manifold for my application but its pretty vague , alot of witchcraft with diameter and length and how that relates to your port timing and desired power curve so I may just wing (hence ratio idea) it since I don't have the time or funds to try a variety of intake/exhaust primary lengths. Pete tried to explain to me how to measure what my port timing is and I still don't quite get it but that would be good to know when making an intake manifold however my exhaust is already done so it is what it is I guess...

In reply to fidelity101 (Forum Supporter) :

Yeah, trial and error is more or less what I've done. My first exhaust was crap design-wise but at least it was quiet. My current exhaust has much longer primaries but I never dyno'd with it, specifically, so I don't know what it did other than make the car louder. The difference was too small to register with the butt dyno. Intake runner length had a massive impact. My old setup was super long. Longer than the DCOE carb setups. I could feel the power drop after 7000 RPM. The shorter IDA-style manifold bumped that up to around 8000 RPM. Although not a back-to-back comparison (both Dynojets but different dynos) my previous setup made 185 hp @ 7100 RPM and 145 ft-lb @ 6500 RPM and the current setup is 240 hp @8100 RPM and 160 ft-lb at 7600 RPM. Looking at the curves the old and new setups are almost identical up to 5000 RPM but now both power and torque continue to climb (and at a higher rate) above that.

I'm sure my setup could be more optimized. I have a spot between 3600 and 5100 RPM where the rate of increase in hp and torque slows then speeds up again. Overall I'm happy with nearly 250 hp out of a street ported N/A 13B, though. Like you're doing there are some other things I'd like to try (RX8 rotors, lightening, scallops, custom intake manifold, etc.) but I'm not going to pull this motor apart for no reason.

In reply to infernosg :

good point, in reality this would be the basis for a semi PP build, once I tackle this and get it running I can then spring for ceramic apex seals and new rotor housings with proper semi PP treatment. to add 2 runners to this setup would be easy i am even going to pre drill my flange because it will be easier now than later once the manifold is assembled.

I was thinking a longer intake than a DCOE style but still shorter than the OEM S5 intake.

In reply to infernosg :

What is interesting is that switching from a Turbo II intake manifold to a Series 4 N/A intake (MUCH longer runners) on a half bridge T2 based engine did a good job of extending the powerband. Power fell off a cliff over 8000 with the T2 unit, extended well past 9k with the other manifold. Quarter mile times also improved drastically. On GSL-SE injectors I was showing 126% duty cycle ![]() I ran that engine lean a lot...

I ran that engine lean a lot...

*shrug* Maybe the always-open nature of the bridge port meant that a longer runner had more mass in the runner to resist reversion? Or just kept the ol' intake flow freight train moving in a positive direction? The port turn radii were much nicer in the N/A manifold, which was the main reason I tried it.

Also why I have a TWM manifold for the four port full bridge. No turns = no problem ![]() Can't decide if I want to go with 45 or 50mm throttle bodies.

Can't decide if I want to go with 45 or 50mm throttle bodies.

In reply to Pete. (l33t FS) :

I wonder if the S4 N/A intake was so long it was achieving a higher order resonance that benefited the port configuration. Did the S4 N/A intakes have any of the variable length/resonance chamber technology that the S5's had? S5s with the aux ports and everything else wired open tend to make peak power over 9000 RPM despite the massive manifold length. I mean, Mazda knew what they were doing when they designed these things. I won't pretend I'm an expert with this stuff. I just know how my particular engine responded through some trial and error. I'm sure I'm giving up mid-range power/torque but unless you get into variable-length runners, staged throttle bodies, etc. there really isn't any way to have it all. I still fantasize about having a true ITB system. One TB for each port, sized appropriately, on its own variable-length runner and with staged throttle opening via DBW. For now that remains a pipe dream. My next step is going back to a functioning staged injector setup.

In reply to infernosg :

No, the S4 had no VDI stuff, just what j9fd3s calls a "ping pong" intake plenum, where the secondary inlets are aimed sort of at each other for dynamic whatever.

I had been told that the S5 stuff made less power because of pumping losses from all the surface area inside. I have two S5 manifolds but never used them.

With my VDI wired open (no AUX ports with 4 port) and port matched intake manifold I wasn't able to get peak power past about 7800-8200 RPM. I was hoping to dyno this motor on the new intake and do an A-B comparison/extra data point but if it wont start it wont run.

My lower intake manifold is modified to adopt either S5 or S4 upper intake system. It would be neat but a few hundred dollars better spent elsewhere but I could test this theory of which one is better one day.

engine update:

irons are out for resurfacing and im getting WPC treatment on the side seals because they are a known issue of the renesis (but mostly because of the exhaust port configuration) but they are thinner than the prior Rx7 seals so this is more of a F-it approach.

the center iron is a large pineapple racing streetport mixed with a mazdatrix renesis streetport: the renesis doesn't open any lower which is why you only see 1 scribe line at the bottom of the port and given that the engine is originally 0 overlap by design it makes sense. so I'm using the best of both worlds here and lets see what happens!

oh yes things are happening, quick holiday break then its fun time!

printed collectors! (AlSi10Mg)

rotor housings are all set!

Printed inconel exhaust inserts, titanium hardware cleaned and OMP ports plugged, the opposite side now has a mount for a knock sensor too just need to re-wire the connector then.

I may even begin side seal clearancing and rotor assembly.

meanwhile I wait for the side housings to come back from the refinisher I can get this intake wrapped up and possibly do the engine rebuild in the same week. Apex seals and gasket kit just arrived so we are in the home stretch! car should be raceable for ice racing season, hopefully.

So I have to ask, since you were going to print the collectors why not just use a stock intake flange to avoid the short transition from round to oval?

I can't remember are you printing these at your place of employment or somewhere else? A new intake manifold is somewhere on my list of things to do so I may bother you about this in the future.

I didn't think of that to be honest but a fresh flange/gasket surface was key in my mind. the stock one doesn't transition well in the middle and needs JB weld to fill in the gap, which i found upon disassembly that one of them was coming loose. the exhaust was printed at work, i changed jobs so this one was done at a 3rd party. I have ported the flange a bit to ease the transition, not so easy on the axis but easy with a die grinder.

fidelity101 (Forum Supporter) said:oh yes things are happening, quick holiday break then its fun time!

printed collectors! (AlSi10Mg)

rotor housings are all set!

Printed inconel exhaust inserts, titanium hardware cleaned and OMP ports plugged, the opposite side now has a mount for a knock sensor too just need to re-wire the connector then.

I may even begin side seal clearancing and rotor assembly.

meanwhile I wait for the side housings to come back from the refinisher I can get this intake wrapped up and possibly do the engine rebuild in the same week. Apex seals and gasket kit just arrived so we are in the home stretch! car should be raceable for ice racing season, hopefully.

those fancy bolts just increased your value statement for the SuperChampio.........

In reply to irish44j (Forum Supporter) :

oh yeah rotary is generally expensive and sometimes you gotta go full retard

You don't have to give specifics but just out of curiosity, ballpark what did the 3d printed runners cost?

Sean

That new intake and exhaust setup is looking amazing. I have been out of the rotary world for a decade but back then, NA builds didn't get a ton of attention and now they are really doing great things with them. It's interesting to see how much you can squeeze out without boost.

In reply to smokeysevin :

I think john q public could buy them for about 1000 each via a service bureau, realistically they should cost around 350-500 each.

I love NAs because its so simple and with rally 2wd you don't need over 250hp really, and since its endurance racing reliability and simplicity is more critical - NA does tend to cost more for less power but it works really well on these motors. However these engines spool turbos really well and turbo tech/standalones have come along way since I started in the rotang klan world.

10 years or so ago you'd have gotten laughed at if you said you wanted more than 200 hp to the wheel N/A without a bridgeport or larger. Back then a N/A "build" consisted largely of bolting on a Racing Beat exhaust and deleting all the emissions components. Knowing IT cars make about 200 whp max, mostly due to class rules, no one wanted to invest the time and money when more power could be made with a turbo. Now we've (re)discovered the capability of 4 port N/A motors, started custom-making full intakes and exhausts and are applying modern fuel injection and ignition with aftermarket ECUs. All things that were historically reserved for turbo builds. Sure turbo builds will always make more power but with rising part costs how much does one want to pay? I can certainly say 250 hp to the wheels is a blast in a car that weighs 2500 lb with me in it.

What I'm interested in is how much porting comes into play now. Historically you'd need a bridgeport or more to get near 250 whp. We're doing that now with large streetports. If I decided I wanted to live with bridgeport driveability what kind of gains would I be looking at? 25 hp? 50 hp? There's a guy out there just now getting a semi-peripheral port, 6 port ITB build running and I'm really curious to see what kind of power he makes. He briefly had the car running with a stock REW intake and made significantly less power than my streetported, 4 port ITB engine.

Obviously I'm closely following this build since there're some interesting ideas at play: custom, 3D-printed intake manifold (with round-to-oval flange), lightened, scalloped RX8 rotors and hybrid 13B/Renesis porting.

In reply to infernosg :

I find that the IT cars around 200hp on a 6 port motor is easy when you have a 4.778 or 4.875 or 5.12 rear end but I will say they certainly put their time into squeezing every ounce out of it. Definitely the stock intake is a restriction too but the ceiling is well established. yes many of the competitive cars still had 4.10s/4.30s but you'd be surprised how many of them out there like that. I talked to a guy running a GT3 FD with a streetport and claimed to be making 300whp at road america but barely anything is OEM at that point so who knows what really was going on there.

What I find interesting is that even some renesis stuff is better off with the 4 port irons and mixing in rx7 housings, pretty interesting state of things for NA power, remember we aren't adding any displacement either. I have been following James Wood's ITB setup as well like you mention and i chat with him time to time. I knew that REW intake was a bad idea for what he planned but once I wrap up this motor and get it dyno'd, between the 3 cars we have a lot of data, plus this current streetport motor putting out nearly 200whp with below 80psi compression lol. I remember about 10 years ago with defined autoworks getting 220whp with RE irons and the largest streetport possible but there was no scalloping or fancy rotors then either but Logan is no slouch either, building or tuning. We have similar builds but opposite, he has 4 air horns, i have 2, he has a short runner system, i have long. he is using new housings with ceramic apex seals i'm using old housings and some aviation apex seals.

The goal for this current motor is break it in and have fun but if i need more power, I can print a new collector and add semi-peripherial ported housings, replace the apex seals (ceramic) and slap it together with a new o-ring kit. the motor will be cooled/oiled appropriately so its an easy upgrade down the road, I hope to get 5-7 years out of this motor too because its alot of fun racing when you don't blow up a motor after every season.

His street port is remarkably small. Most of his gains were incremental, developing header lengths and collector angles. IIRC he went from 180ish whp (still very very good) to 206 just with a different header. Refinement of the header and intake manifold got him to 230whp.

Mind you that import drag racers have been getting 400-450hp from naturally aspirated 13Bs for a decade, decade and a half.. Judge Ito let on that an 8.5:1 engine made 326whp all motor before he started feeding in nitrous.

You'll need to log in to post.