So, I've for some time been thinking of LS swapping my Mustang, and I think I'm ready to start pulling some triggers. I have a buddy who has an '07 Yukon with the L92 (LS3's first cousin) that just shat it's transmission. I can have the whole truck for $3k, which seems reasonable enough for an aluminum 6.2 donor. It has 300k on the clock, but other than leaking from all the places, it seems to be healthy.

My plan is to freshen it, but ideally not send it to a machine shop. Pull it down, swap to the hollow LS3 valves and some springs that will get me good revs. Probably a healthy cam, but not sure which one. Undecided on VVT or no. Not sure if stock PCM with HP Tuners or a standalone is the answer. Apparently there is something with trunnions that needs to be done, but not sure.

But this leads to the question - there are a million and one writeups on LS builds, but I've yet to find the one that says "For 500 WHP, order these parts...." It seems like there should be some pretty standard recipes, but I'm not seeing them. Are there, and I'm just having trouble finding the diamonds in the rough?

I don't know if he has any specific to your engine, but maybe look on Richard Holdener's youtube channel. He does have multiple "recipe" videos.

What is the use case, goals and budget for this engine swap? That will help you with a lot of decisions regarding engine management, cam and valvetrain upgrades.

I will say hollow LS3 valves and trunnions 99% of the time are just an excuse to spend money unnecessarily.

In reply to DILYSI Dave :

Turbo's are the easy, cheap way to make 500 hp. There are plenty of How to's on U Tube.

With 300,000 miles the rings will have worn enough so you won't need to open the engine up. If the oil pressure is OK now your bearings should be good to go. If just a little low. You probably can get by with just going to a thicker 20w50 oil.

I'd be extremely reluctant to pull a good running engine apart. Just rebuilding it properly will cost you a serious chunk of money.

Use - Going into an S197 Mustang that is 80% a dedicated autox car but will be caged for the occasional TT or hillclimb. It will be tagged, but very seldom street driven. Running CAM-C (200TW tires), so I don't need infinity horsepower. 400 WHP probably gets me everything I need, but I kinda like the ring of 500 WHP better. :) If there is a reasonable way to get more revs out of it, I think that would be worthwhile, just from a flexibility in gearing perspective. The engine probably will see less than 10 hours of use a year, but they will be 10 hours of flogging. As I have aged I have decided that wrenching at the track sucks, so I'm more interested in a "set it and forget it" build than living on the ragged edge.

Budget - TBD? I'm more concerned with spending wisely than any specific number. One version of this swap involves a T56Magnum and a relatively normal position in the car and off the shelf mounts and headers and such. The other version involves a dry sump and dog box for low and rearward positioning and more radness and fab work. Part of the "Well, what does the engine need?" question is in helping to figure out those budgeting decisions. For instance, if I'm happy with the OE pistons, then that's more money for dry sump, etc.

Power adders - no interest. I love me a turbo, but this is an N/A build.

In reply to DILYSI Dave :

just remember all the good cams are at the bottom of the page and you'll be fine.

I am pretty prejudiced against hollow valves in any engine that gets leaned on. They can lose their heads when everything is hot, especially during valve float when things get cattywhumpus when the valve contacts the seat.

Chevy probably is too, if they didn't use them in truck engines.

Pete. (l33t FS) said:

I am pretty prejudiced against hollow valves in any engine that gets leaned on. They can lose their heads when everything is hot, especially during valve float when things get cattywhumpus when the valve contacts the seat.

Chevy probably is too, if they didn't use them in truck engines.

But they did in the performance variant....

In reply to DILYSI Dave :

The performance variant isn't expected to be able to tow an overloaded trailer up the side of a mountain in August the way a truck engine is.

Duty cycles, duty cycles.

I'd find a reputable local tuner and see what they prefer for engine management. Stock ECU is absolutely capable of handling this task. The Holley systems are very popular right now but have been very hard to get the last couple years and keep going up in price.

Valve springs, cam and potentially a timing gear set would be needed (VVT delete). 500whp isn't too far out of the question with E85 and the right cam on a 6.2L. Your cam and valvesprings will basically set your rev limiter but 72-7500rpm isn't crazy on a cammed LS.

Just wanted to add that it’s nice seeing Dave here. :)

David S. Wallens said:

Just wanted to add that it’s nice seeing Dave here. :)

i was gonna say the same thing but didn't want to seem all man-crushy.

eastsideTim said:

I don't know if he has any specific to your engine, but maybe look on Richard Holdener's youtube channel. He does have multiple "recipe" videos.

Good suggestion. Thanks.

Some reading and YouTube University sounds like a not-too-crazy cam, some springs, decent header, decent tuning, and dry sump should get me a pretty reliable 500 give or take.

I still need to figure out if VVT is worth retaining (most don't) as that will steer the engine management decisions.

Good to see you guys again / good to be back. If this project gets beyond the spreadsheet phase, I'll start a build thread.

If you want hammer reliability and are not needing unlimited horsepower, I'd stick as close as possible to GM parts because they have the R&D budget. Don't sacrifice reliability to get a magic dyno number, I've seen that end in tears far too many times - and I've also seen "recipes" that claim power numbers that are difficult to duplicate.

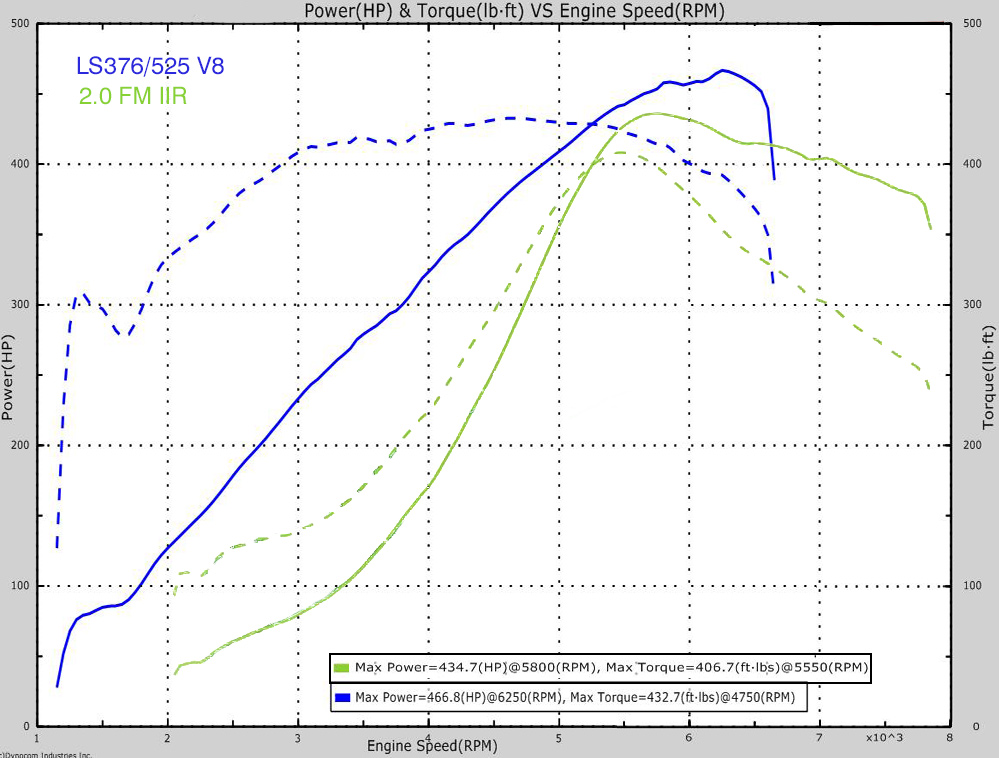

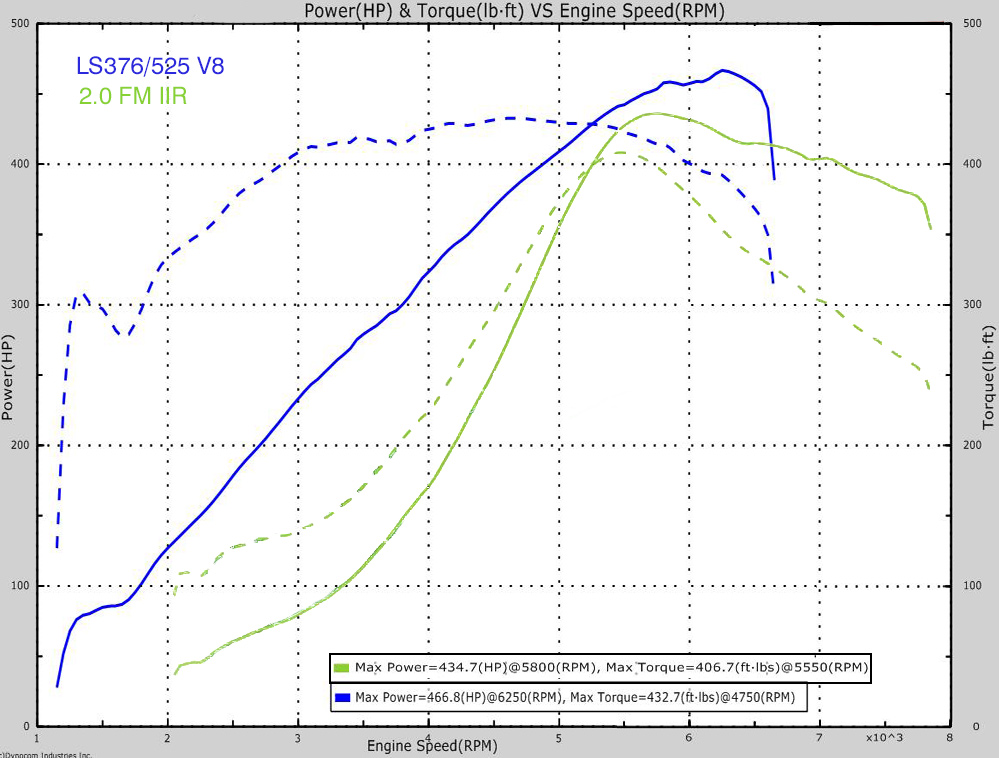

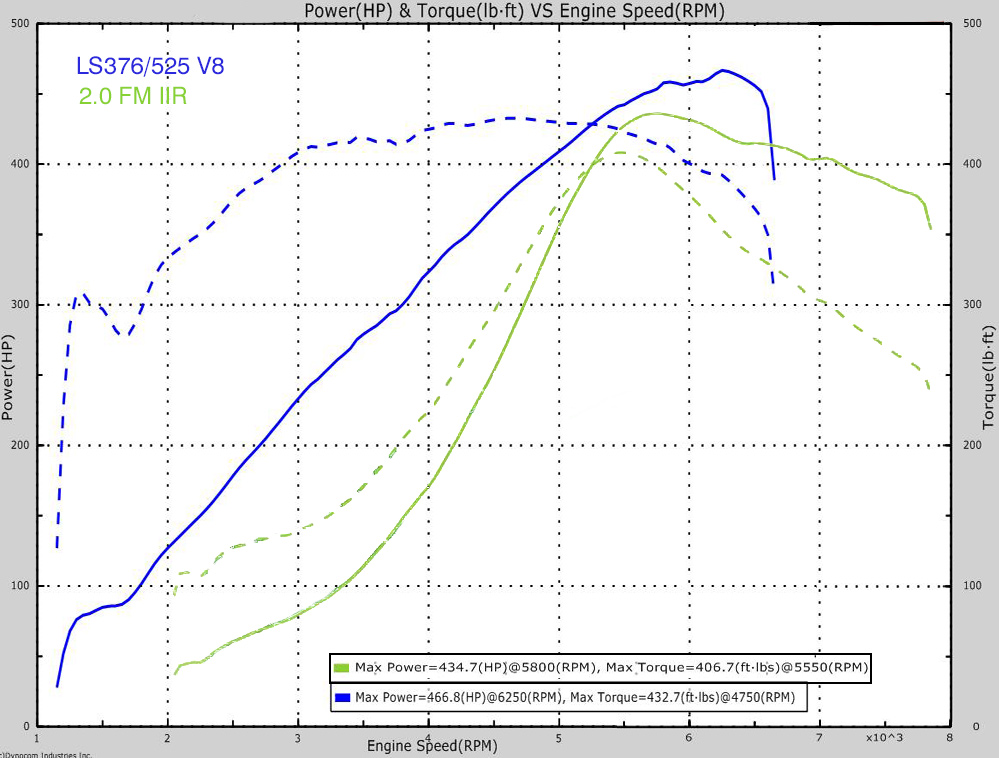

My choice is the GM ASA cam, which has a long history of being easy on valvetrain stuff and can be used with stock LS3 valvetrain bits. Get your power from a good header. Cold intake temps are going to be important in autox, because these engines pull timing like crazy with high intake temps and autox goes from long periods of idling to full power demands instantly. On our dyno, I'm at 466 rwhp with a stock LS3 with the ASA cam and not very good headers.

Dry sump may not be necessary if you have a good pan - IIRC, the oiling problems mostly show up when you have sustained cornering loads over 1.3g or so, which seems unlikely in my autox experience. We use a baffled pan with trap doors on our builds and there's a car that's been endurance racing on fat hoosiers with aero for years and years without an engine problem.

I'm with you on using GM parts where possible. I'm not too obsessed with any specific number, other than conventional wisdom is that anything north of 500 is pretty useless on street tires. Good data point on the ASA cam, thanks. I'll read up on it. How fast are you turning that combination?

Dry sump thought is half driven by oiling concerns, and half by packaging. It's not exclusively an AutoX build. Primarily, but I have also come to enjoy time trial. The packaging part of the equation is the thought that with a dry sump and a small dog box transmission I can move the lump quite a bit down and back.

Opti

SuperDork

4/6/23 8:08 p.m.

I never worried about trunions and Ive seen a couple spit their bearings, but Ive seen way more that didnt. I also dont like replacing them so that does steer my position.

Im not up on VVT on the Gen 4, besides that everyone deletes is. On the Gen Vs most people delete the VVT but the people I know that havent with mid sized cams says its is a huge benefit to keep it. Have to find someone who knows how to and is willing to tune with the VVT though. I would probably want to keep it if possible with a mid sized cam, if you immediately scroll to the bottom of the page and get something in the 240 duration range im not sure that you can keep it.

From someone who loves big cams, Id be leary about putting a huge cam in this even though it will make good power. Something in the 230 duration range or slightly less can be very strong but still have good bottom end. Im not a great driver and prefer a flexible powerband for an autox car. You may not care about this though.

The hot ticket on the LS2 GTOs for a while was L92 heads and an aftermarket cam (LS2 had similar displacement), you could probably check out some of the Goat forums and find some good but slightly out of date information for ideas on a setup.

Buddy did PRC 5.3 heads and a mild cam in a LS2 GTO years ago. It was a great setup. Could lug it at 1400 rpm and would rev to 6800. Made power EVERYWHERE.

If all you care about is a screamer, scroll to the bottom of the page and get some good lifters. Hopedully you are a better driver than me and can always keep it above 3800 rpm

In reply to DILYSI Dave :

I'm spinning mine to 6600. It's the recipe for the LS376/525 crate and that's the rev limit that GM chose. As far as I know, that's what the enduro car is running as well. As noted, my headers are a little restrictive so I'll bet a set of bigger primaries would wake this up a bit. On 200TW tires at my local permanent autox track, I have wheelspin on demand pretty much everywhere but it's very easy to dial the amount. At a track like Laguna Seca, I can hook up well off the corners and it hustles down the straight fairly well.

Here's the pan I'm using, same one as that enduro Miata: https://www.moroso.com/oil-pan-gm-ls-swap-miata-c6-corvette-road-race-baffle/. Depending on where your rack is, it might get you the down and back you're looking for.

Philosophically, I like the idea of retaining and tuning VVT. But it seems that most abandon it. I'm not sure if that's for good reason or because newfangled technology is communist!!!! :)

I'm going to ask the tuner I like / trust for his input. His guidance will be well founded.

Keith Tanner said:

In reply to DILYSI Dave :

I'm spinning mine to 6600. It's the recipe for the LS376/525 crate and that's the rev limit that GM chose. As far as I know, that's what the enduro car is running as well. As noted, my headers are a little restrictive so I'll bet a set of bigger primaries would wake this up a bit. On 200TW tires at my local permanent autox track, I have wheelspin on demand pretty much everywhere but it's very easy to dial the amount. At a track like Laguna Seca, I can hook up well off the corners and it hustles down the straight fairly well.

Here's the pan I'm using, same one as that enduro Miata: https://www.moroso.com/oil-pan-gm-ls-swap-miata-c6-corvette-road-race-baffle/. Depending on where your rack is, it might get you the down and back you're looking for.

Good stuff. Really appreciate it.

Opti

SuperDork

4/6/23 9:11 p.m.

For reference the LS376/525 uses a 226/236

I like the TSP VVT cams. Here is their dyno of a stock headed L99 with the stage 1 L99 VVT cam, its a 223/233

They also have the stage 2 which Im a big fan of . Its a 227/239, they say it does 561/505 at 6600/5200

DILYSI Dave said:

Philosophically, I like the idea of retaining and tuning VVT. But it seems that most abandon it. I'm not sure if that's for good reason or because newfangled technology is communist!!!! :)

I'm going to ask the tuner I like / trust for his input. His guidance will be well founded.

With the VVT engine, you have to watch the piston to valve clearance, which is rather tight on engines like the L99. So you either limit the VVT range or make sure to use VVT specific cam like Opti listed. Personally the LS3 pulled great stock in the 2012 Camaro I had, so I would just delete any VVT and run it straight up.

Opti

SuperDork

4/7/23 7:01 p.m.

In reply to 81cpcamaro :

On the Gen 3s we just flycut the pistons, don't know if people are still doing it, but it was pretty common back in the day when you scrolled to the bottom of the page for that chop chop

Holdener made 475 HP from a 5.3 with a cam and a mild porting job. A 6.2 should easily hit 500,,,,,,

This Cam Swap For 5.3L Engine Adds 100hp (motortrend.com)

Update - I haven't turned any wrenches yet, but the parts collecting effort has been productive.

I picked up a Hightower Jerico trans a few months ago. Ultimately it will get regeared. But it's fine for now. I also picked up an EPAS rack and subframe that I'll be building around. I also recently picked up an Ilmor / Dailey dry sump setup from an ARCA / Truck Series engine, along with the remote oil filter setup from one of the Cup teams. I have not bought, but I have figured out the clutch and bellhousing setup - A reverse mount starter, small diameter flywheel, and 7.25" clutch setup from Quarter Master. It's $2k for the full setup, but it's also every component between the engine and trans in a single part number that has proven to work together. And the small flywheel coupled with the dry sump is how I intend to get this engine LOW in the chassis.

I finally drug home the donor vehicle this week. Next up is pulling the L92 and pulling it down to assess how much attention it wants. Hoping to sell the rest of the vehicle (2007 Yukon Denali) as a complete truck versus parting it out. Then start building the engine and figuring out mounting to the Mustang subframe. Most swaps position the engine roughly where the original was, but my goal is the balancer sitting behind and at the same elevation as the rack. We'll see....