New job is fairly low-intensity desk work, so I find myself brainstorming my projects in an effort to not buy more garbage.

'60s Morris Mini. 2001 Honda Fireblade engine. Started the install as a FF setup, but I have two concerns. First, the chain-drive differential has to live behind the engine, which puts the drive sprocket and chain awfully close to the drivers right foot. Second, the diff will be far enough back that the CV axle angles will be pretty extreme (30ish degrees?).

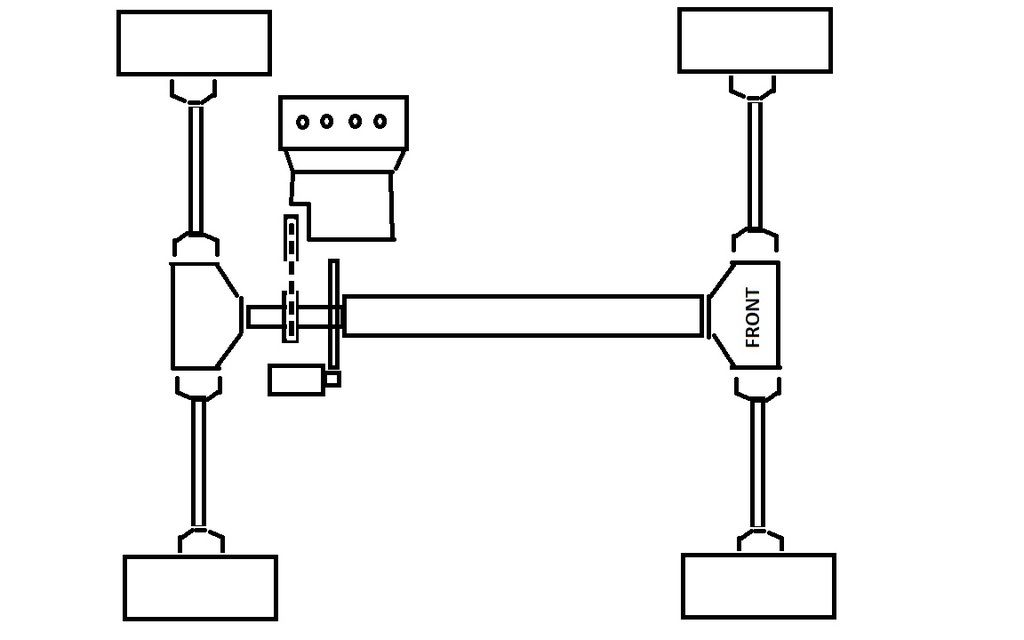

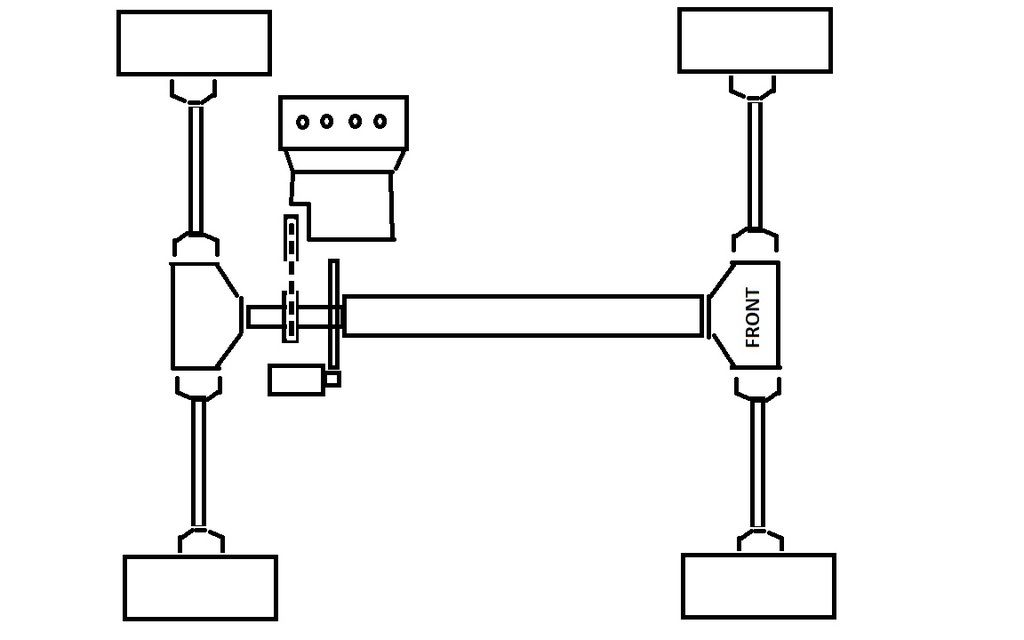

So what if I did something like this instead?

Longitudinal engine mount (probably rear-mounted due to space concerns) with chain-drive jackshaft. Jackshaft runs a flange on either end for sending power to the matching front and rear differentials.

I’m curious as to why no one seems to use a shaft-drive motorcycle engine and keep it more simple.

The Honda VFR1200F is a 1,237cc liquid cooled shaft drive for instance

I've had devious thoughts like this, before. Except mine involved Civic RealTime AWD drivetrain. Subframes already exist, for the D series - Mini swap.....

That looks like a lot of RC on road shaft drive chassis, having played with those the prospect of one large enough to jump in sounds like a great idea.

Adam

Duke

MegaDork

10/26/18 9:14 a.m.

RealMiniNoMore said:

I've had devious thoughts like this, before. Except mine involved Civic RealTime AWD drivetrain. Subframes already exist, for the D series - Mini swap.....

The main problem with the RT-AWD system is that it only sends a maximum of 15% or the torque to the rear wheels, I think.

Ransom

PowerDork

10/26/18 9:26 a.m.

My first two thoughts are:

- Lack of center diff seems like it's going to make things super-weird and bindy

- I think having the entire engine on the left might be even weirder than just hanging it off the back (unless, I suppose, you're going to do RHD and you and the engine can sort of balance each other)

Ransom

PowerDork

10/26/18 9:30 a.m.

In reply to ebonyandivory :

I keep having similar thoughts, though my understanding is that a lot of the really big bikes have engines with significantly lower specific output, and enough heavier than sportbike engines that you lose a lot of the weight advantage.

That said, BMW's 1.6L six seems like it would be pretty rad. Goldwing flat-sixes apparently fall into the heavy and untuneable camp; they just don't want to make much more power than stock. Triumph's 2.3L(!) triple would be neat; I wonder how tall it is?

Bike drive into an E30 325ix transfer case? I wonder what the full list of car-sized, diff-containing transfer cases is...

Robbie

UltimaDork

10/26/18 9:30 a.m.

ebonyandivory said:

I’m curious as to why no one seems to use a shaft-drive motorcycle engine and keep it more simple.

The Honda VFR1200F is a 1,237cc liquid cooled shaft drive for instance

The motorcycle engines that are cheap and make huge power are all chain drive. The big cruiser motors are generally way down on HP compared to the literbikes. Even vfr compared to 'busa of the sameish year the vfr is down 30hp.

This VFR1200 is very interesting though as it makes good power (170hp), BUT the dual clutch transmission option is really interesting to me for bike engine car use. Paddle shifters for the win.

The snag I've run into regarding transfer cases is gearing. In order to keep a reasonable rpm in 6th gear at 70mph, the final drive has to be about 3:1 or less. If the transfer case is geared down and the diffs are geared down, you turn into a rock crawler pretty quickly. Which isn't necessarily a bad thing, if that's what you're going for.

Ransom

PowerDork

10/26/18 9:40 a.m.

In reply to JohnInKansas :

But is the E30 transfer case geared down? A normal E30 would take care of all its gearing needs in the trans and diffs; I would have thought it was strictly a torque-splitting device.

Robbie

UltimaDork

10/26/18 9:55 a.m.

Why do you need a transfer case at all? If you chain drive the center diff the gearing is really flexible.

Ransom

PowerDork

10/26/18 10:00 a.m.

In reply to Robbie :

My impression was that there was no center diff. And you'd probably want one specific to the job. The one in the E30 transfer case has a roughly one-third front, two-thirds rear torque bias.

If you can come up with a suitable diff, I agree entirely, unless it forces a funny engine location.

_

Reader

10/26/18 10:05 a.m.

Duke said:

RealMiniNoMore said:

I've had devious thoughts like this, before. Except mine involved Civic RealTime AWD drivetrain. Subframes already exist, for the D series - Mini swap.....

The main problem with the RT-AWD system is that it only sends a maximum of 15% or the torque to the rear wheels, I think.

30%, but weak nonetheless.

Duke

MegaDork

10/26/18 10:33 a.m.

In reply to _ :

I stand corrected, thanks.

Though, frankly, what if the engine / trans is installed facing the wrong way and in the rear / mid of the car? That gives it 70% rear bias and puts more weight on the rear wheels... Just need to reverse the driveshaft rotation.

_

Reader

10/26/18 10:40 a.m.

That’s not a bad idea. Or! You could mate a K series to the RT4wd system, since it spins the opposite direction.

Dont flame me too hard if I’m missing something obvious...lol.

In reply to Ransom :

Yeah, the way I'm envisioning it, there's no center diff, just a jackshaft that functions as a kind of transfer case/locked center diff with no bias.

I'm not a smart man with regard to AWD design though.

As Adam said, not at all unlike AWD RC setups. Like the Traxxas 4-tec.

Ransom

PowerDork

10/26/18 11:42 a.m.

In reply to JohnInKansas :

A quick google suggests even Traxxas offers an optional center diff, though I'm having trouble with whether for the 4-tec specifically. Either way, I think unless you're looking at sideways-on-the-gas-all-the-time rallycross as the only venue, you'd really miss having a center diff. I think a short-wheelbase car is going to exacerbate that issue because the difference in the paths taken by the front and rear axles can be more pronounced.

I raced a lot of R/C cars, though a long time ago, and I think you have to be pretty careful about applying vehicle dynamics from R/C to full size stuff.

At the very least, I'd hate to build a car around this plan without giving thought to how you might add one if it was a tire-scrubbing, hopping beast. I mean, on the bench, the internet, and in one's head, sure!

I can’t see how a chain-driven, direct drive transfer case (as opposed to clutches or viscous coupling) won’t bind and start destroying itself on pavement almost immediately.

I hadn't considered that the fronts have to go farther than the backs.

So I need the jackshaft in my diagram to be a chain-driven LSD with flanges to send power to matching (to each other) LSDs in the front and rear. Right?

As far as weight distribution, the front and rear diffs wouldnt have to be centered; could offset them to bring the engine closer to centerline and to help offset the engine weight. Would just mean different length CV axles.

Ransom

PowerDork

10/26/18 12:37 p.m.

JohnInKansas said:

As far as weight distribution, the front and rear diffs wouldnt have to be centered; could offset them to bring the engine closer to centerline and to help offset the engine weight. Would just mean different length CV axles.

I think this can increase torque steer, but I'm also sure it can be managed; I think many (most?) FWD cars have different-length CV axles; I want to say they try to match inertial mass so one side isn't easier to accelerate than the other. Probably sooner run into packaging issues on an already-small car like a Mini with the short side axle getting really short and running into angular issues or length-compensation issues.

My Volvo V70 XC had the torque management done in the drive to the rear with a viscous coupling. It was magic, on a front wheel drive car when you goosed it the back end would step out like a RWD. This was in snow or dirt but still it worked very well.

The front bevel gear was sturdy but the splined shaft linking the bevel to the trans was made of butter.

http://www.awdwiki.com/en/volvo/

Can this be used coupling unit be backwards to power the front wheels.

Robbie

UltimaDork

10/26/18 12:54 p.m.

In reply to Ransom :

I think torque steer being caused by unequal length axles is 99% myth. Their diameters are small so the rotating effect is similarly small. I think most of what people feel as torque steer is when one side breaks traction, it immediately begins pulling less than the side with traction still. On a FWD car, the unequal force from the two front tires causes a steering input. (Imagine with a car in the air pushing forward on both front wheels and then suddenly letting go on one side - the car would steer toward the side you let go on).

Worn components make it worse because the steering input is greater and less controlled, and you can minimize torque steer by intelligently setting up the suspension forces on the front wheel such that pushing forward on the hub does not create a steering input.

TLDR, you are unlikely to feel much if any torque steer if you are driving non-steering wheels, even if you use unequal axles. If you are driving steering wheels with equal length axles, you are still likely to experience torque steer.

Ransom

PowerDork

10/26/18 1:37 p.m.

In reply to Robbie :

I absolutely agree about the non-steering end, and I suspect you're right about the rest as well. It certainly seems like a second-order concern at most.

Torque steer, VS traction. My Maxima had really bad torque steer and very different axle lengths. My subaru could take off on ice with spinning tires, dry pavement or in between with my hands off the wheel and go dead straight, it had four equal length axles. My Mazda 5 doesn't make any appreciable torque yet also has heavy torque steer. I thing it has more to do with suspension and steering design that anything else.

The Maxima could break traction on dry pavement the Subaru only on snow or ice.

What about cars that have an extra support bearing on the long axle side, does that help with torque steer?