Kreb

UltraDork

1/7/17 2:00 p.m.

I can see how in a transverse engine situation one would probably be space limited, but with a conventional IRS diff or longitudinal transaxle, it would see like a logical way to move those heavy rotors to a place where they don't add to the unsprung weight.

I think because then you direct a larger load into the axle CVs under braking making it have to be beefier and negating much of the gains. It probably makes more sense on dirt racers though where huge slicks won't be generating torque in the axle... They just slide.

Service would become much more difficult with everything all tucked in there. Knuckles create a convenient caliper mounting location... just cast a couple bosses and drill them for bolts. Mounting inboard would likely require an additional bracket by the differential.

I remember a Jag setup with inboard braked IRS though.

Ian F

MegaDork

1/7/17 2:13 p.m.

Ease of maintenance, most likely. Granted, IMHO if the mounting was designed right, swapping a rotor out wouldn't be too painful. The 6 bolts attaching the CV to the flange could also hold the rotor on. Remove those bolts, shift the CV out a bit, slide the rotor off.

Another reason - packaging. Big 12" or larger rotors would require additional body and chassis clearance around the diff mounting.

Third reason - torsional packaging - the diff is usually mounted on bushings to reduce the amount of noise and vibration transmitted to the chassis. As a result it moves around a bit when torque is applied. Mount the brakes on the output flanges and either the diff has to be fairly solid mounted in order to not have rotor deflection, or the entire diff/caliper assembly would need to be mounted rigidly to a subframe (which they often are anyway, but often includes the suspension mounting), which would then need to be mounted in a way that didn't transmit NVH to the chassis.

Fourth reason - easier to cool the brakes when they are out by the wheels.

In reply to collinskl1:

I agree. Servicing would be a PITA.

Sonic

SuperDork

1/7/17 2:14 p.m.

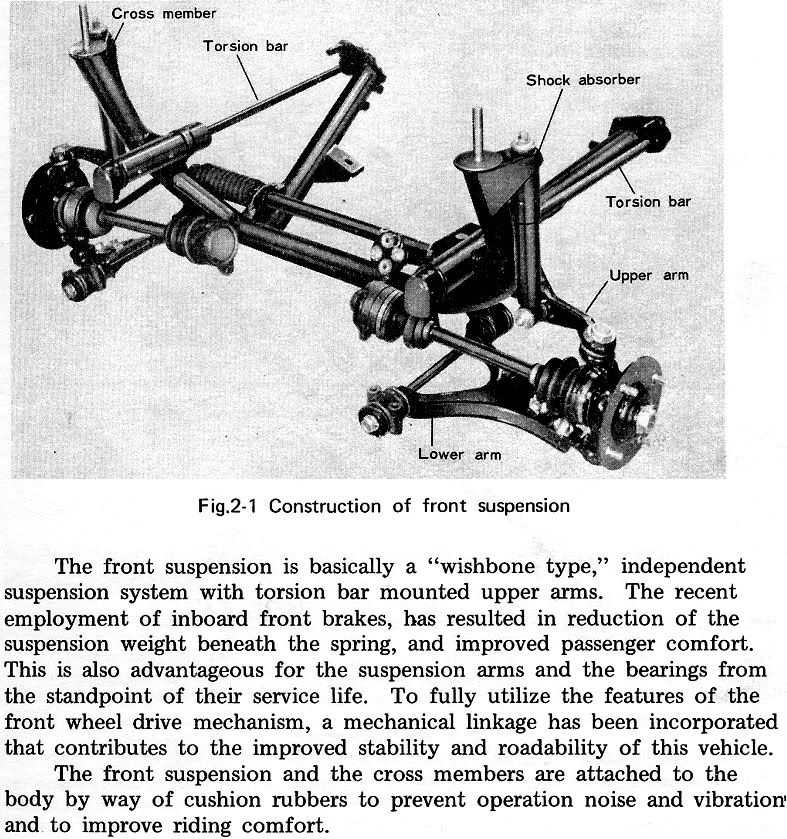

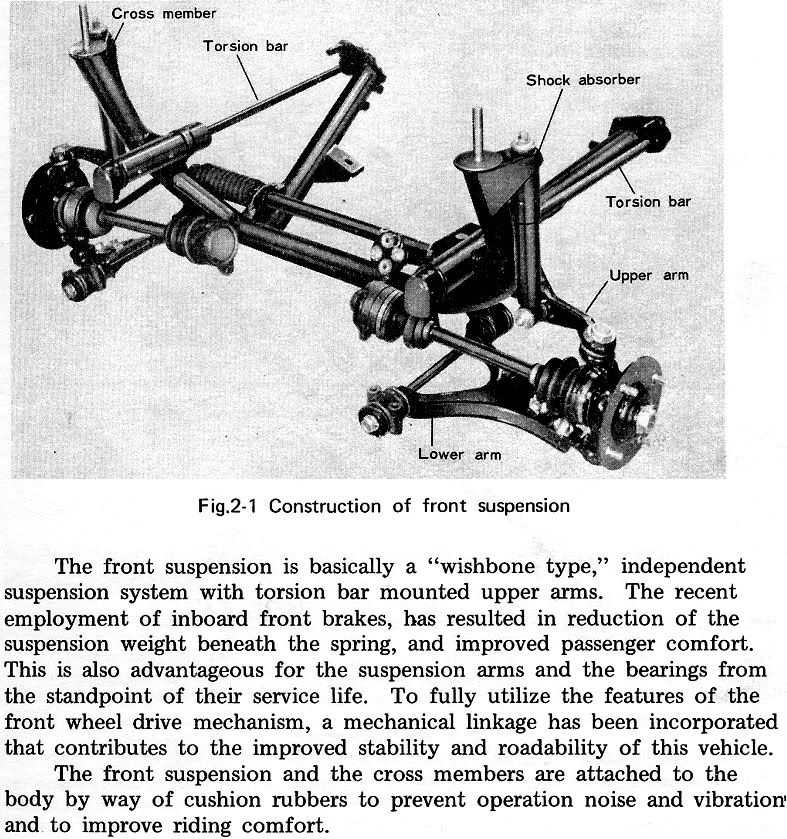

Dealing with the heat in a less ventilated location is also an issue. We dealt with this on our Lemons Citroen SM that has inboard front brakes, bolted to the transmission basically. The factory had some ducts to them even, but they were not all that effective in a racing environment

H1 Hummers (military and civilian) use inboard mounted brakes. As pointed out, it puts stupid strain of the CV axles and allows a lot of "slop" when you come to a stop and a few degrees of rotation between all the moving parts keeps the vehicle rocking back and forth.

AM General did it to accommodate the gear reducing hubs and give the HMMWV silly amounts of ground clearance.

The older versions of the Jaguar IRS had them. They moved the brakes outboard on the later versions, as they determined the inboard brakes were too much of a compromise in cooling and serviceability compared to the small benefits in suspension performance.

And keep in mind, that's a suspension that already had beefy u-jointed axle shafts that act as the upper control arms (in a double A-arm setup).

Stefan

MegaDork

1/7/17 3:41 p.m.

Also, think about what happens if the axles or CV joints fail completely.

No brakes.

On our D-sports racer it had inboard discs; it had a custom made limited slip for chain drive. Sealed limited slip unit with sprocket where ring gear would be. The unit had two large plates on either side that the stub axles and half shafts bolted to. The discs were mounted on a custom hub that the half shafts bolted to. Brake pads changes were easy as being a race car you could get to the calipers. The discs and calipers were Yamaha RD350. Cooling was also not an issue as you can duct air easily on a race car.

For a road car servicing and cooling are an issue. Also if you loose a half shaft you also loose braking to that wheel. What you gain in unsprung weight is not worth it especially considering that there are modern rotors that are very light weight.

IIRC, my Rover 2000TC had inboard rear discs. One of the few things on that car that didn't break. They braked but didn't break.

collinskl1 wrote:

Service would become much more difficult with everything all tucked in there. Knuckles create a convenient caliper mounting location... just cast a couple bosses and drill them for bolts. Mounting inboard would likely require an additional bracket by the differential.

I remember a Jag setup with inboard braked IRS though.

All this. I used to work with a guy who missed being a Jag technician because it was 3-4 billable hours just to inspect the rear brakes.

I have some more good reasons - Ground clearance is a hell of a lot better with outboard brakes, since the rotors are inside the wheel. And you can take use of the brake torque on the upright to get some antis in the suspension under braking. Inboard brakes make that extremely difficult, just like IRS makes getting antisquat extremely difficult compared to a solid axle.

Looking at the fairly heinous suspension design the inboard-braked Jags used, they probably went with inboard specifically to prevent torque on the upright. It was a single stick-like lateral link, with NO trailing link. Camber control was via halfshaft. Basically there was nothing there to really prevent the upright from twisting around.

I have a friend who has a 72 Jag. He said when he bleed the rear brakes he had to do it through an access hole in the rear seat / trunk area!

In reply to Knurled:

They didn't change the layout of the Jag IRS much when they moved to outboard brakes in the mid-late 80s. It still used the halfshaft as a locating link.

Kreb

UltraDork

1/7/17 6:49 p.m.

Thank you for edumacating me.

L-29 Cords are FWD with inboard drum brakes:

I've serviced them a couple times and they are a pain in the ass to get at.

Trans_Maro wrote:

L-29 Cords are FWD with inboard drum brakes:

So were Subaru FFs.

Clearly, the sins of this design are why Subarus from the 80s on have been paragons of ease of service.

rslifkin wrote:

In reply to Knurled:

They didn't change the layout of the Jag IRS much when they moved to outboard brakes in the mid-late 80s. It still used the halfshaft as a locating link.

That isn't the part that gets me, it's that the upright's entire location to the chassis is a single I-shaped control arm, all longitudinal location is down to the beaming strength of that arm and its bushings.

Granted, on the newer cars, it's maybe 3-4" in diameter TUBULAR I-shaped control arm, so it can handle the brakes' twisting forces. But the whole idea of accelerative and braking forces loading that long narrow arm in bending makes me cringe.

This is the same company that made the XJ so flimsy frame-wise that a person could flex the frame by hand enough to change the front wheel camber by half a degree. First time I did a front end check, I was trying to figure out what was loose, then I saw it was the frame flopping around. Ugh. At least seeing that cured me of ever wanting to own a non-Ford Jag. (Doing two engines in X-types and various work on Lincoln LSs cured me of wanting a Ford Jag)

I was kidding earlier. The illuminati are keeping them down.

kb58

Dork

1/7/17 7:54 p.m.

I have a now-old car book around here with a picture of a formula car that took me a while to figure out what I was seeing. The designer added front axles solely to move the brakes inboard to reduce unsprung weight. To this day I have to wonder what that really did for the car's performance.

In reply to Knurled:

That explains why the old Jags ride so well... The XJ40 and newer were much better cars than the old chassis though.

I was told that they are no longer legal on cars sold in the us as a result of safety regs. Cv fails=no brake to that wheel. I imagine that diameter of the rotor is restricted by ground clearance. I always thought they were kinda cool, I also like the ones on the pinion.

sesto elemento wrote:

I was told that they are no longer legal on cars sold in the us as a result of safety regs. Cv fails=no brake to that wheel. I imagine that diameter of the rotor is restricted by ground clearance. I always thought they were kinda cool, I also like the ones on the pinion.

Are those the same safety regs that said the Renault LeCar isn't legal in the US because it only has three lug nuts? (Shhh, don't let the Feds see a Smart!)

The Hummer H1 was sold for many years to civilians until they stopped making Hummers, I don't think it was regulations that stopped that. As pointed out, they had inboard brakes, although the reasons for that were weird. They had portal axles to get the axleshafts higher, which meant the axles turned backwards, so they mounted the Dana 20 diffs upside-down to compensate, so the whole damn drivetrain was really REALLY high. Inboard brakes meant the whole brakes and hydraulics could be tucked up above the undercarriage protection. The fact that the brakes spun 1.8x faster than the wheels did meant they had that much more effectiveness, too, as if the tires were 5/9ths their actual diameter.

Apocryphally, the original HMMWVs had outboard brakes, but in testing, when the trucks would get stuck with a wheel or two off the ground, they would snap axles when people would ride the brakes to get the three Torsen diffs to bias torque to wheels still touching ground. So inboard brakes meant they could act on the diffs directly without overstressing the axles. Make of that what you will.

Having done rear pads and rotors on a XJS without a lift and an E-type with a lift (just made it easier to remove the entire IRS), I think we could have stopped at "PITA to service."