Shawn_D

New Reader

4/16/17 8:31 a.m.

Y'all,

While the vehicle in question is not among the usual varieties discussed here, I'm hoping the component in question is something folks can assist with. The vehicle in question is my '57 Chevrolet Bel Air Sport Sedan (4-door hardtop) and the component in question is a rear-steer rack-and-pinion. The '57 was originally owned by my grandfather and was my first car. After ~30 years of questionable maintenance/mods, I've spend the last ~5 years doing/re-doing things right (or at least significantly righter).

About 20 years ago, I bought a Classic Chevy International rack-and-pinion conversion and finally put it on about three years ago. Doing so got rid of 80% of the effort of driving the car, but the width between the inner tie rod pivots is ~26", ~6" wider than the lower control arm shafts, resulting in significant bump steer. Every rack conversion designed for Tri-Fives has this problem. Some conversions for other cars use either: A) a bracket that bridges the rack side-to-side and then places the inner tie rods on it, or B) a "center take off" rack like some Chevy Cavaliers and Hondas have; however, I don't believe there's any room for either of those. Converting to front-steer is not realistic, given the shape of the frame and spindle position, and I ain't gonna do a C4 or F-body subframe swap.

TL;DR So, does anyone know of any rear-steer rack-and-pinions with tie rod pivot widths in the 18"-20" range?

BTW, I'll be entering the '57 in the Skidpad Challenge at The Mitty this weekend.

Thanks in advance, Y'all!

patgizz

UltimaDork

4/16/17 8:49 a.m.

You want power or manual? sweet manufacturing makes lots of stock car racks that are pretty darn narrow. I just happen to have a retired stock car and could check some measurements later

Shawn_D

New Reader

4/16/17 9:01 a.m.

Indeed, Sweet Mfg does, and thanks for the offer! However, the only rear-steer rack they make is 24" and is manual. The steering was already hard enough when it had the original bus-size steering wheel with a slow gearbox, and now that I run 235s with a smaller-diameter steering wheel (and am no longer a teen/20-something who works out all the time), I want a power box.

That is REALLY tiny. You might end up having to get a wider rack and shorten it.

This is basically the same problem that the 1st generation RX-7s have, with the added problem that the inner tie rod needs to be under the engine.

One thing I've always thought would be neat would be to keep the center link and idler arm, install a second idler arm on the driver's side, and install a center takeoff rack to drive the center link. Small-chassis Audis that had struts (basically Audi 80/90/4000 and Fox) had a very tiny rack that looks swappable to me. Might fit in roughly the same place as the hydraulic ram did on Fords, maybe.

Good luck! Keep us posted on what you find.

Shawn_D

New Reader

4/16/17 9:45 a.m.

That's an interesting concept, Knurled. If one were keeping the center link, one could use most any rack and connect it wherever on the center link, even from just one side to the other like a straight-axle drag link.

I certainly will keep Y'all posted on any developments.

Another thing I thought of: A while back someone posted a thread here of someone who was cramming most of an S2000 under an old Hillman. He had to narrow the suspension significantly to fit, I'd like to say 5" was taken out of the crossmember. He kept the S2000 rack but he built a kind of ladder frame that attached to both ends, and the inner tie-rods attached to that ladder frame, so he could get the inner tie rod pivots in closer than the rack would allow. I'll see if I can find it for ya.

Shawn_D

New Reader

4/16/17 9:52 a.m.

That's similar in concept to "A" I mentioned in my original post. If I could install an oil pan with a sump that was about 1.5-2" further aft on the front, there might be enough room. I know early Nova/Chevy II pans have a special cutout on the front of the sump, but that's only big enough for a center link.

Knurled

MegaDork

4/16/17 10:06 a.m.

I was wrong, the superstructure was so the rack could be moved forward to clear the engine since he moved the engine down and back a lot relative to the subframe.

All the same: Here it is

Shawn_D

New Reader

4/16/17 11:26 a.m.

Thanks -- that's pretty interesting! There are some good fabrication ideas I might be able to use.

I'm not well versed in the world of Tri-5's but my thought would be what's wrong with going back to a rebuilt power steering recirculating ball box? Is the bumpsteer bad with those too? Not enough room because of headers or something?

I went through a similar search for a narrow rear steer rack for my W123 Benz. Looking back now, sticking with the box doesn't look like such a bad idea, but I've already modified the car to the point that going back would be just as much work, and I would still need to rebuild the box.

For my Benz I used a center steer rack from a GM J-body, but I had to make some modifications to the setup to get the tie rods to clear the ends of the rack.

You mentioned you may not have enough room for a center take off rack, but I could put some pictures of my setup on here. It may give you some ideas at least?

fanfoy

Dork

4/18/17 11:32 a.m.

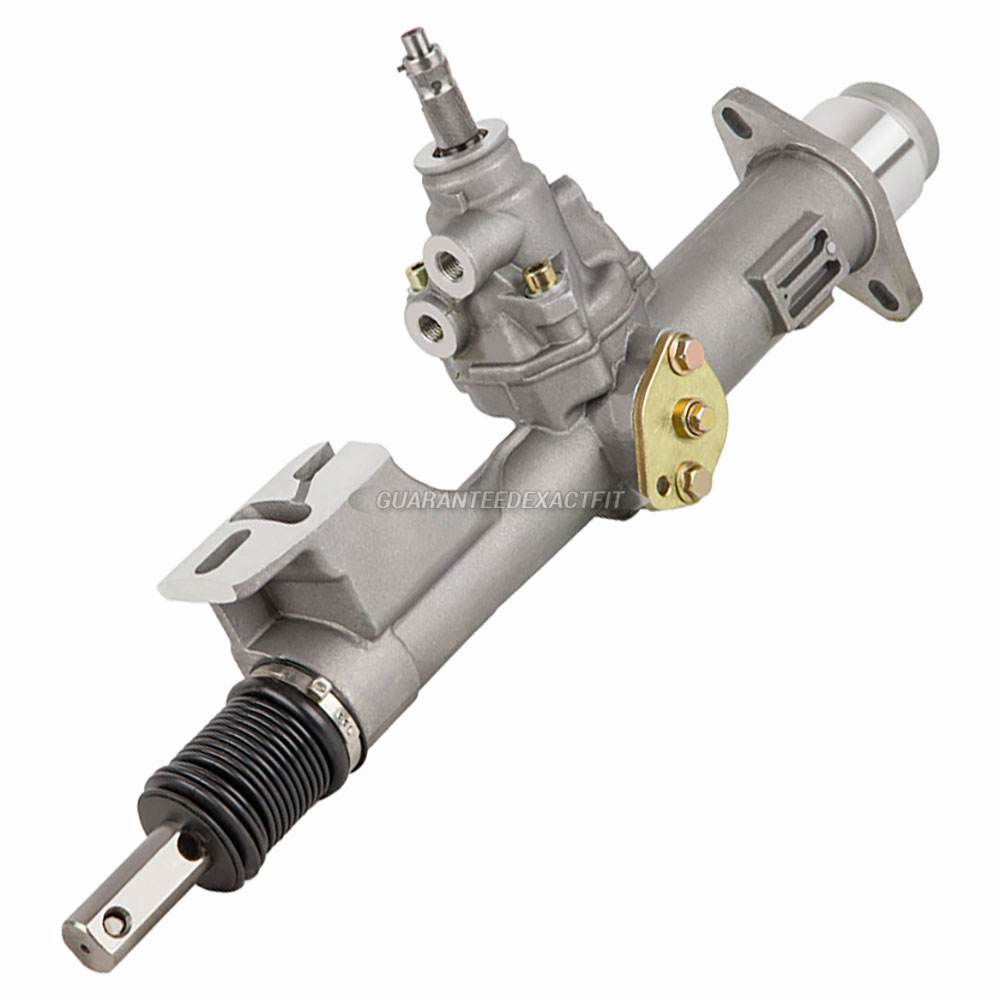

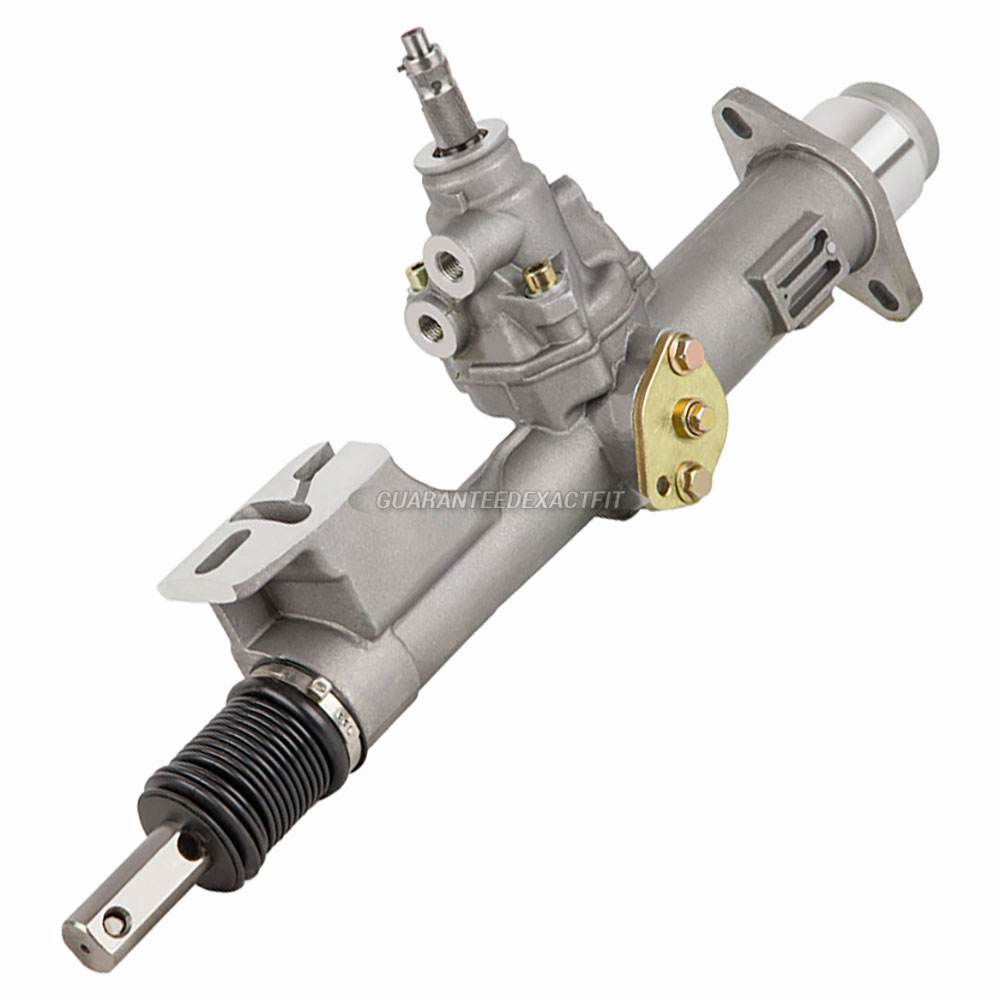

I think you could do something with a up to 2002 Saab 9-3 steering rack:

In reply to fanfoy:

Yep that's the one. if you look at the part number, GM used that rack in a lot of different cars, not just J-bodies.

I had to come up with a "center link" that bolts to the center, to get the spacing of the inner tie rods correct though.

Shawn_D

New Reader

4/18/17 8:25 p.m.

TheRyGuy wrote:I'm not well versed in the world of Tri-5's but my thought would be what's wrong with going back to a rebuilt power steering recirculating ball box? Is the bumpsteer bad with those too? Not enough room because of headers or something?

Bumpsteer is actually excellent with the stock linkage. The problem is the wear-prone drag link arrangement, which uses spring-loaded hemispheres (admittedly, wear for a car driven 1500 miles/year is down on the list of reasons), but worse than that is the idler arm, which uses control-arm-style bushings which rip themselves apart after a few tight turns (there are bearing kits, but they suck). Header clearance really isn't an issue, as there are dozens of options that fit well.

You mentioned you may not have enough room for a center take off rack, but I could put some pictures of my setup on here. It may give you some ideas at least?

There's plenty of clearance ahead of the oil sump to frame, but the problem is that the aft-most part of the lower control arm (the rear of the bushing cross shaft) is maybe only 3" ahead of the vertical part of the oil pan sump. Installing a center take off rack would likely place the inner tie rods far enough forward that the line between them and the steering arms would be thru the control arm. That being said, if you have some pictures handy, that would be great, but don't go take any on my behalf.

fanfoy wrote:I think you could do something with a up to 2002 Saab 9-3 steering rack:

Thanks for the suggestion. It's good to hear a 2nd from TheRyGuy on it.

Rabbits have a narrow rear steer rack as well, power steering is rare but I just gave one to someone on here.

Robbie

UberDork

4/19/17 9:35 a.m.

fanfoy wrote:

I think you could do something with a up to 2002 Saab 9-3 steering rack:

This is what I came in to say. You could build a solid bar in the middle that is 20 inches wide, and attach inner ball joints at its ends.

Gimp

SuperDork

4/19/17 11:19 a.m.

What about the manual rack Pat mentioned earlier, but then using an electric power assist from a Saturn?

http://www.fordmuscleforums.com/all-ford-techboard/538585-100-power-steering-yes-you-can-use-column-electric-power-assist-system-epas.html

fanfoy wrote:

I think you could do something with a up to 2002 Saab 9-3 steering rack:

My 2004 Honda CR-V has a similar style rear steer power steering rack with the inner pivots close together like that. I think that the Civic does to, in similar model years. I'm not sure where you live, but Civic's are everywhere around here, so it might be easier to find than the Saab unit.

Shawn_D

New Reader

4/20/17 9:26 p.m.

chandlerGTi wrote:

Rabbits have a narrow rear steer rack as well, power steering is rare but I just gave one to someone on here.

Thanks, I'll check those out.

Robbie wrote:

This is what I came in to say. You could build a solid bar in the middle that is 20 inches wide, and attach inner ball joints at its ends.

That is how it's done on many rack conversions, but that would still leave me with the problem of not having sufficient fore-aft clearance. I'll probably have to do some measuring and whip up a diagram to explain it, as I probably didn't convey it well enough above. The tie rods are almost certainly going to need to be in line with the rack.

Gimp wrote:

What about the manual rack Pat mentioned earlier, but then using an electric power assist from a Saturn?

http://www.fordmuscleforums.com/all-ford-techboard/538585-100-power-steering-yes-you-can-use-column-electric-power-assist-system-epas.html

As I responded to Pat, unfortunately, the only rack rear steer rack they have is both manual AND 24" wide, which is still too wide.

Waid joined the TriFive.com forums and posted that very same thread! It would take a whole lot of surgery to install one of those, as the area it'd need to go in is quite small and has the brake/clutch structure in the way, which is also the main dash and steering column support.

Swap the spindles L to R,

use a front steer power rack. (Appleton or Sweet)

Problem solved!

Shawn_D

New Reader

4/20/17 10:47 p.m.

bentwrench wrote:

Swap the spindles L to R,

use a front steer power rack. (Appleton or Sweet)

Problem solved!

The spindles are symmetrical and the steering arms are separate, so the spindles could stay right where they are and I could easily fabricate front steer arms, but as I said in the first post: "Converting to front-steer is not realistic, given the shape of the frame and spindle position." I'll elaborate.

In the diagram below, you can see how the front crossmember bows forward. Not counting the projection at the front of it (which supports the radiator and basically the whole front of the front end sheet metal assembly), the front of the bow is roughly in line with the wheel diameter. Even if the front end support projection were not required, an installed rack would be ~3" ahead of the steering arm end, really screwing up the Ackerman and possibly causing a toggle lock problem (see page 72 here). Then I'd have to tunnel through the crossmember to get the steering shaft to the rack.

Shawn_D wrote:

but worse than that is the idler arm, which uses control-arm-style bushings which rip themselves apart after a few tight turns (there are bearing kits, but they suck).

So make a better bearing kit? What sucks about the available ones? Making a better idler arm is probably the easy way out.

Shawn_D

New Reader

4/21/17 12:03 p.m.

BrokenYugo wrote:

Shawn_D wrote:

but worse than that is the idler arm, which uses control-arm-style bushings which rip themselves apart after a few tight turns (there are bearing kits, but they suck).

So make a better bearing kit? What sucks about the available ones? Making a better idler arm is probably the easy way out.

Well, it's not the easy way out when all of that steering gear is gone and a rack has been in for three years!

What sucks about the available ones is that they only do one end of the idler arm (the end fixed to the frame bracket stud) when there are bushings at both ends, are unsealed, and non-greaseable (although I could tap the idler arm for a zerk).

It still leaves one with a track rod featuring spring-loaded cups on one end.

Yes, though, going back to stock-type gear and attempting a better bearing conversion (or getting a lathe and machining some Del-A-Lum style bushings) is indeed an option.

If the situation is as bad as you make it sound the lathe might pay for itself if you can turn out a superior solution. I don't see the big deal with the spring loaded cups, modern ball joints and tie rod ends are built more or less the same way, just sealed up better and miniaturized. Have you actually seen wear issues, or is it just a common sentiment held by people who probably don't leave them looking nasty and pump in grease every oil change until the protective grease/dirt crust starts to move? I had a modern tie rod end with a junk boot like that once that turned into a "how long will it go?" type of experiment, the answer was longer than the few years it served as my daily driver that forded water a few times, water and dirt can't get in if it's always packed full of grease.

I mainly say fix the stock setup because it seems to me that you rarely see people pull out old centerlink steering systems for whatever reason (usually clearance related) and make a rack work better. They either can't get a narrow enough rack, can't put it where it really needs to be without compromising engine placement, or both.

Shawn_D

New Reader

4/21/17 3:21 p.m.

I already have a Taig 2019 CNC mill (4-axis when you include the rotary table) and getting a lathe would be a nice addition, whether I use it for this or not.

I have seen wear issues, but admittedly with the original pieces with 175,XXX miles on them. Until recently, you could not get new replacements. These spring-loaded cups are metal-on-metal and work side-to-side. The fixed ball on the Pitman arm gets egg-shaped, and if you set the clearance for no play while straight, it will bind when you turn; setting the clearance for no binding during turns will leave lots of play straight ahead. Unlike a regular ball-joint-style tie rod on a center link, you'd have to replace the cups and Pitman arm when they wear.

TBH, I think the main reason you don't see folks change out old center link steering systems is because they are accustomed to crappy steering, don't care about handling, and/or the engineering/expense is too much.

![]()