I'm doing the timing belt on my son's Legacy Outback. The rad is out, but I don't want to disconnect the A/C condenser so I can't get my electric impact gun on the nose bolt of the crank. How do I get that bolt out and the pulley off? There are 4 holes in the rubber portion of the pulley/dampener that might be usable if I make up a tool to hold the pulley. Anybody got ideas, or better yet have done this before? Thanks in advance.

I usually use the trick that most recommend NOT to do. 22mm socket on a long breaker bar, rest the bar against the ground, inner fender frame rail or alt/ac bracket (some models) and just blip the throttle, making sure that the car won't start.

Or,

If it's a 5 spd, put it in 5th, and have someone stand on the brakes. Use a breaker bar on the bolt.

If it's an auto, remove the square rubber plug on the engine side of the bell housing. The one that gives access to remove the torque converter bolts. Stick a screwdriver or something into a hole on the flex plate. Use a breaker bar on the bolt.

A friend of mine has luck just holding the breaker bar tight against compression/valve springs and twacking (tapping/wacking) the end of the breaker bar with a BFH.

Or you could find the subaru tool that has the pins that is made to hold the crank pulley.

The car is an automatic, so standing on the brakes won't work.The special tool is $50 (found it on Ebay), or so, but I'll bet I can fab up something that will work. Given how everything on this car is rusted, I'll not expect whacking the breaker bar to work. It turned the engine pretty easily anyway. And I won't even try bumping the starter when it's not my car.

Thanks Hocrest.

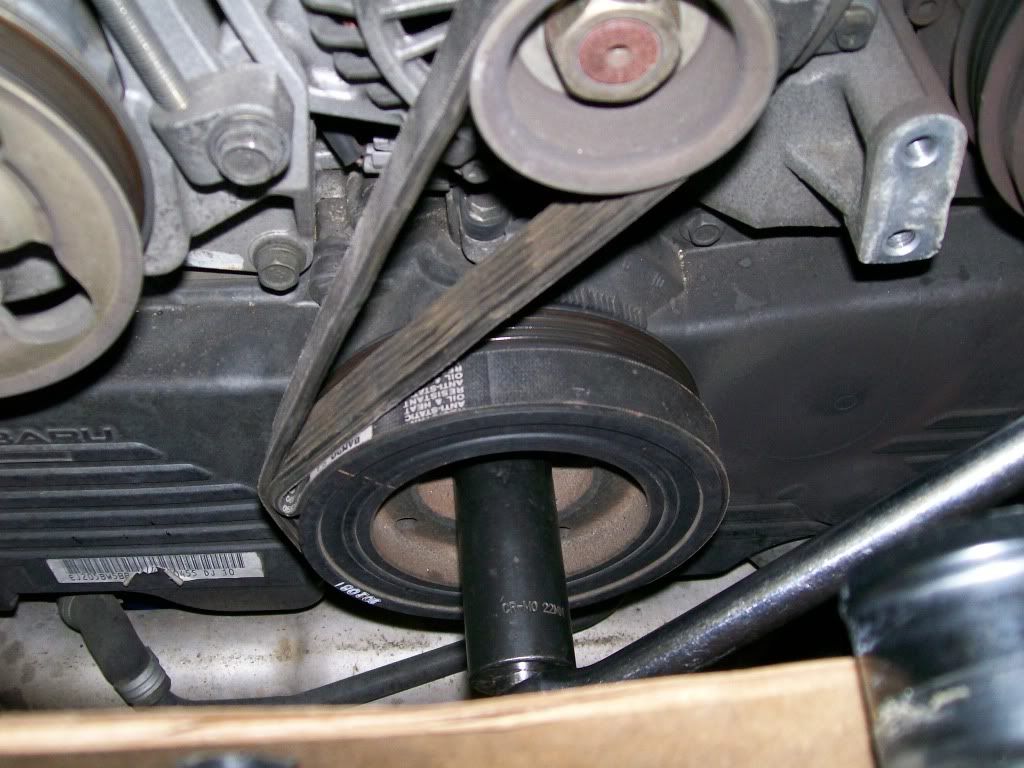

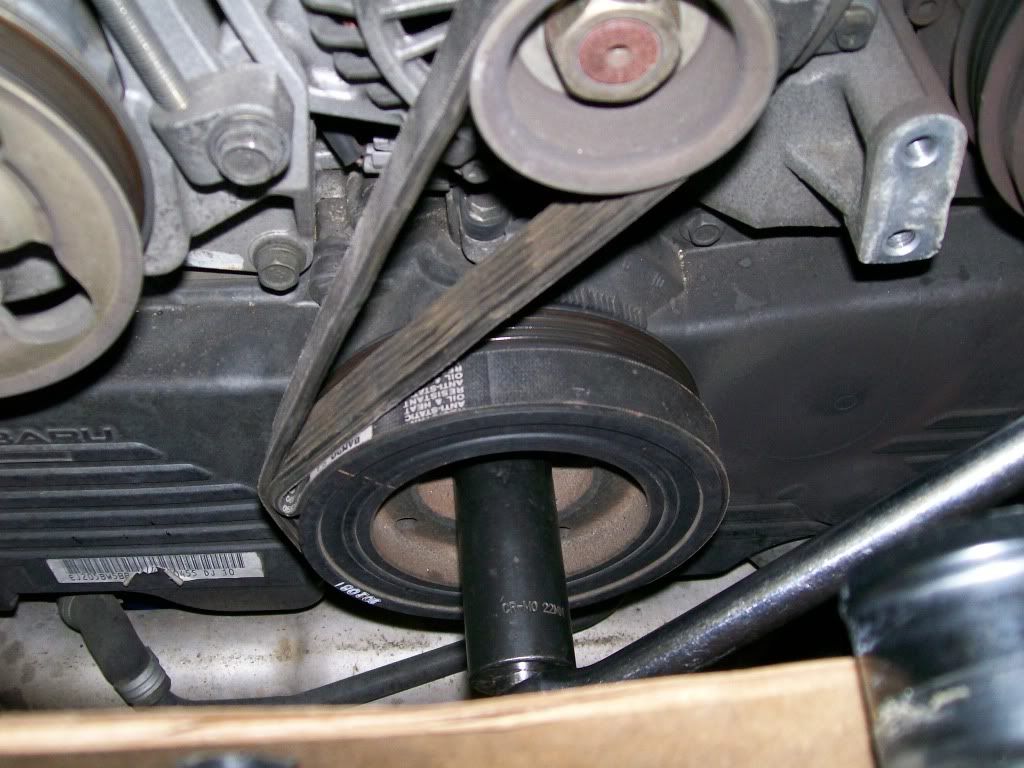

Here's what I found works pretty well : Take an old alternator or A/C belt, loop it over the alternator and the crank pulley and tuck it in on itself to act as a self-tightening strap wrench.

Like so:

Reverse it to put it back on.

Nashco

UltraDork

4/24/12 2:24 p.m.

There should be a small black rubber plug near the top, passenger side of the engine that is removable to access the flexplate/torque converter bolts (near the back of the engine). If you remove that, you can put a pry bar or similar in there to keep the engine from spinning while you use your breaker bar on the crank bolt. That crank bolt (and the pulley) is usually pretty easy to get off on Subies, so it shouldn't be too hard with this method.

Bryce

that belt trick is really handy!

The subaru crank holder tool makes this job super easy though

Yes, the belt trick was useful when I had to replace the t-belt on my old 2.2 Outback Sport. In a parking lot. In Utah. In January. Quick and easy.

You can also make your own crank holder (got this one off of the forester forum somewhere):

Why does my mind always go to welding and grinding to make a tool, when a scrap piece of wood will do just fine ? I like the belt idea ,too.

Tried the belt trick....but the pulley moved any way.

Tried the wooden tool thing.....broke the 3/4 plywood.

Tried sticking a pry bar in the port on the top of the motor... BINGO !!

It worked like a charm.

Thanks for all the suggestions Folks. I love this board.

jstand

Reader

4/25/12 10:18 p.m.

Too late now, but a few other tricks:

Step one: place plywood against a/c condenser to avoid draining a/c system.

Option 1:

On my forester (5spd) I used two deep set 1/4 drive sockets in two of the pulley holes. I placed a long 2x4 across the frame rails, and used a long boxed end wrench over one of the sockets and positioned it so the second socket wedged the wrench against the board. That held it enough to use a breaker bar on the bolt.

Option 2: (not tried on forester, but used on engines ranging from 3.5 hp Briggs up to 4.1L I-6, and various 2 and 4 strokes in between)

- Remove spark plug from #1 cylinder

- Rotate engine in the direction you want to keep it from rotating until it is on

the upstroke with both valves closed (very important if you don't want to bend valves!!!).

- Feed in as much cotton clothes line rope as possible through spark plug hole (if working on 2 stroke, make sure rope doesn't hang out of any ports).

- Continue rotating engine until clothes line rope stops rotation.

- Remove or torque down bolt

- Rotate engine in opposite direction and remove rope.

mrjoshm

New Reader

4/26/12 7:41 p.m.

here is what i did to make changing the timing belt on my subaru easier, obviously late, but whatev

clearly there was this cross bar in the way of my impact gun

so i drilled a hole

fixed forever!

to torque it back on, luckily i got it to the first spec just fine with my torque wrench, and iifc the second spec was an additional quarter turn, which i did with the impact

disclaimer: do not use a non-impact grade extension with an impact

DeadSkunk wrote:

Why does my mind always go to welding and grinding to make a tool, when a scrap piece of wood will do just fine ? I like the belt idea ,too.

That is what I did and bingo, another custom home built tool!

It's fun to see all the crazy ideas people have some up with do deal with that SOB bolt.

When I had to do it on my '01 OBW I couldn't even get it off with a 6 foot breaker bar, so I removed the ignition or ECU fuse, wedged the breaker bar against the frame, and blipped the starter. Done.