bluej

Dork

9/18/13 10:22 a.m.

Hey all, I'd like to get some input/advice on what do for the starter situation for the challenge build I've been working on.

Motor is a gen 3 4.8 chevy. flywheel and trans is an fs5w71c from the s12 using adapters between the crank/flywheel and block/bell.

The nissan flywheel diameter is just under 12" while the smallest stock chevy flywheel/starter combo I've been able to find is the 153 tooth at 12.75" which others seem to have been able to make work with the gen 3.

The nissan starter won't work because the body of the starter interferes with the block when attempting to move it more "inboard".

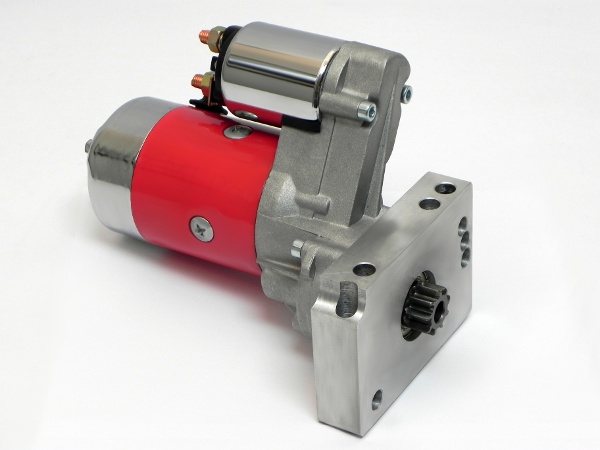

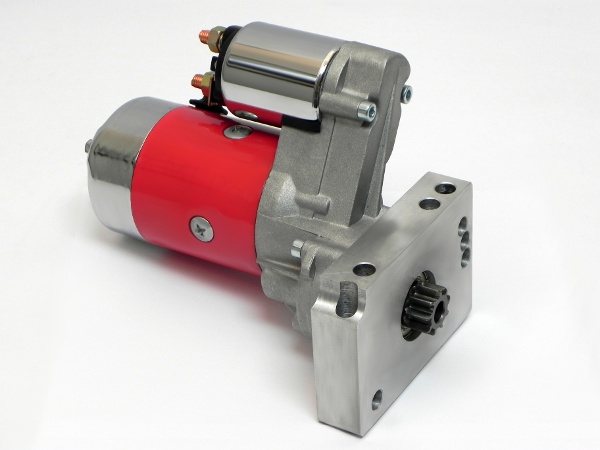

I'm thinking a chevy mini-starter like this: http://www.dbelectrical.com/p-1293-chevy-305-350-454-mini-starter-super-torque-series-st100.aspx with modifications made to that mounting block is the best bet. I know you can pick them up for between $50-$80 between amazon/ebay regularly. The key aspect is that the main body is offset from the gear axis and additionally, the mounting block should be easy to mod/replace:

So my questions are:

(1) Anyone see any glaring issues with the above plan?

(2) Anyone know of a stock starter from anything that has a similar configuration where the starter gear axis is offset like above? I'd much rather be able to put my hands on one before purchasing it and then do so for the ~$20 junkyard cost.

Thanks!

Nashco

UberDork

9/18/13 4:17 p.m.

For a challenge car? Push start it! Free, weight reduction, zero time.

Bryce

bluej

Dork

9/18/13 4:41 p.m.

Heh, I wish it were that easy.  There is not good space for that where the garage is I rent to work on and store the car. It's in the city off a short back alley, mostly gravel, down a hill that's the only exit/entrance.

There is not good space for that where the garage is I rent to work on and store the car. It's in the city off a short back alley, mostly gravel, down a hill that's the only exit/entrance.

Not to mention that It sounds like a huge pain to deal with that when setting up MS engine management for the first time. I was planning to drive it down to the challenge, so it would at least need to be tuned enough to get me started on the drive.

bluej

Dork

9/19/13 8:20 a.m.

Morning bump. First post too long? Did I say something stupid?

why not use a proper LS flywheel and go from there?

this allows you to use any LS starter, which might come in handy if the el-cheapo ebay starter you seem to want to use decides to die in the middle of nowhere on a sunday afternoon and you need to be able to swap in a replacement on the side of the road...

bluej

Dork

9/19/13 9:38 a.m.

In reply to novaderrik:

I'm already all set up with the nissan trans, flywheel, clutch and adapters. That's not changing at this point. I need to make the stuff I've got work.

Most of those starters seem to bolt to a block that's been fabbed to match to the application. Makes sense from a manufacturing standpoint since you only need to fab different blocks and can use the same starter module. Hopefully that means that if the module craps out down the road, I can re-use the adapted mounting block with a new starter module.

I did also ask if anyone was aware of a stock application that has the gear offset. I'd much rather work with an OEM "module" for availability and quality reasons like you mention above. I guess that's really what I was hoping someone here might be aware of.

I've used that type of starter for builds before, it's actually cheaper than some OEM types from advancepepboyszone (looking at you LT1) and shouldn't be a problem to modify or fabricate a new aluminum flange to bolt the electric motor to.