Had issues with my Birkin having a miss, then no start. Eventually figured out it wasn't getting anything from the crank position sensor. Pull the sensor and wiring and it chafed the insulation, probably on a hose clamp. Ford 2 pole cps, shielded wire. Assuming I dont have to have to also extend this after excising the fudged up part, just cut back the bad spots and use a crimpless solder/shrink connection? Leave the shield wire intact and wrap her all back up? If I do have to patch in an extension, extend the shield/drain wire with whatever kind of wire I use to repair the signal wires and just don't bother removing the insulation?

Am I looking at two insulated wires (red and blue) and the bare shield/bonding wire? If so, clean up the 2 insulated wires and make sure they're in good condition before re-wrapping them. If you have to cut and repair, offset your joints to prevent 1 big lump. If you have to add to the shield, it doesn't need to be insulated but it won't hurt if it is. If you do have to cut everything to make a repair, it's a good time to slide something over the wire to protect it before you put it back together.

In reply to djsilver (Forum Supporter) :

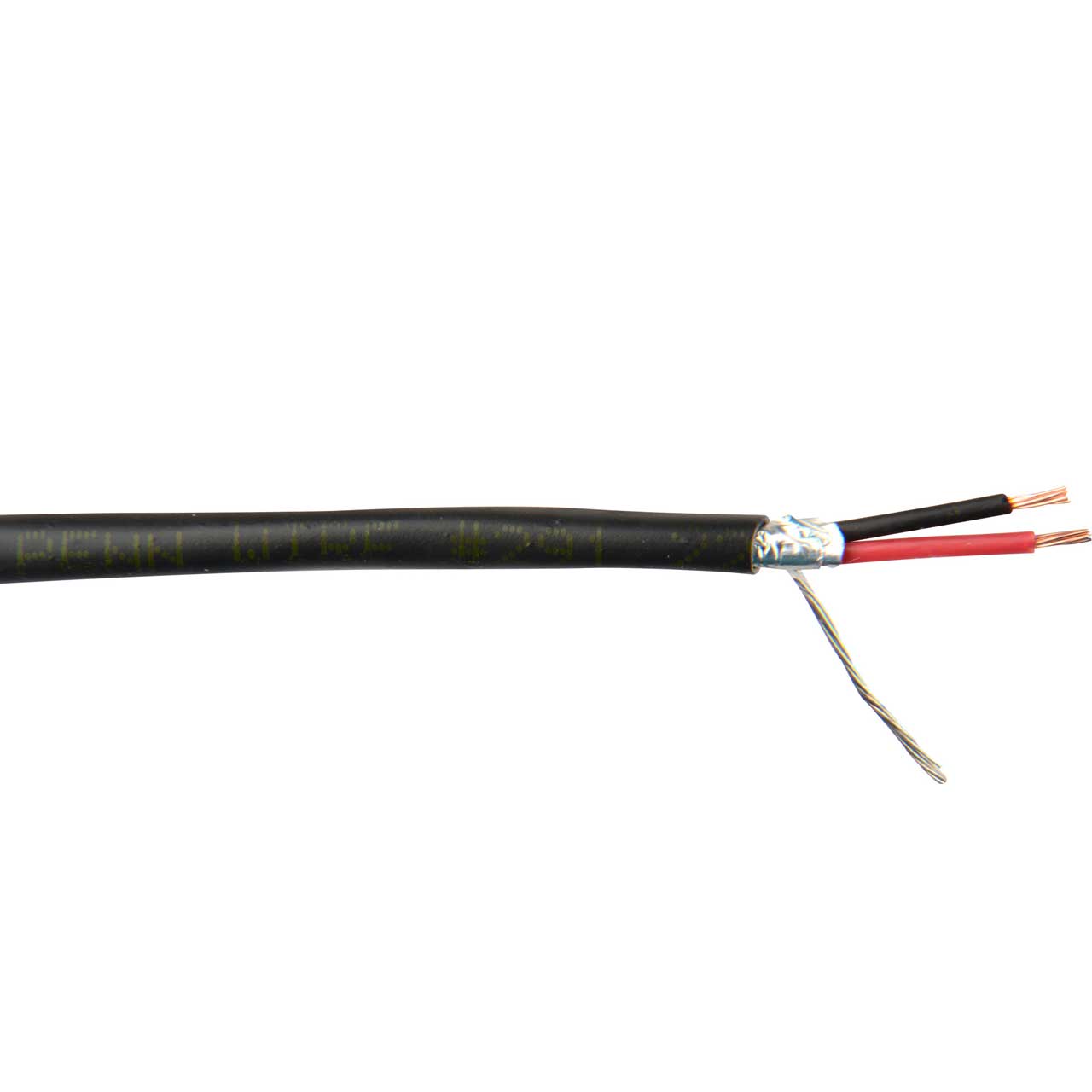

It's red and black, the blue is the inside of the foil shield/whatever thats on there. I know I'm going to lose the shielding in that spot, but I can live it with it. This is probably the best photo of the kind of wiring.

I think I have a roll of that wire I purchased when I was transplanting an edis system in to a Porsche. If you need a couple feet let me know I can drop it the mail.

It's a bit tricky and retain the shielding over the splice. Basically you cut the wire and strip the foil but leave the drain wire exposed at both ends. Splice the signal wires, shrink wrap, etc. Then you take expandable stainless braid and put it OVER the entire repair, and solder the two drain wires at each end of the repair. Then cover the whole thing with adhesive shrink.

You can also do some ugly things with alum foil and tape, but YMMV.

Oh hey, I literally just repaired a 2-wire CPS wire last week. I ended up splicing in a new plug with pigtail, essentially the "extension" method you're describing. I didn't replace any shielding, just did the repairs, heat shrink over both conductor repairs, then braided loom and tape over the pair of sensors wires. I'm missing probably 6" of shielding, but it fired right up. In hindsight I should have wrapped the repaired wires with aluminum foil or something first before the braided loom.

This might help. super simple:

http://www.aeroelectric.com/articles/Shielded_Wire_Splicing/S_Wire_Splice.html

Personally, I would cut out the damaged area if you had enough spare lead, stagger the splices for your two conductors so you dont make a "fat spot", and do the shield wire as shown in the link.

If you wanted to wrap the area with another shield, these solder sleeve splices exist but require $25 a pop, and a heat gun:

But it'll basically solder itself to your old shield ends.