Door speaker adapters for Miata

NermalSnert (Forum Supporter) said:NermalSnert (Forum Supporter) said:Finally got started on the loft ladder after 5 years.

The treads from sawmill run red oak:

Loft ladder assembled and test fitted. Not sure if I want to stain it or just oil it. I like the red tint. The orange strings represent where the bridge goes. That's next....

Got the catwalk framed in. I'm about to gain 224 sq ft of living space.

In reply to NermalSnert (Forum Supporter) :

We are fully expecting to see some red and blue American Gladiator battle gear to see who is king of the bridge

:max_bytes(150000):strip_icc():format(webp)/american-gladiators-8-06032024-dd0bc05c697e447eadd6dcc2ba84dcf6.jpg)

You'all made some awesome stuff. How about it's the late 1930's and my grandfather made this for his bride? It's a spice box.

Simplicity - a hand saw, miter box, a hand drill, some shellac and a box of nails.

In reply to 4cylndrfury :

Har! I got some of the T&G flooring on it this afternoon and walked out to the middle. It's 10' high and 22" wide and feels A LOT higher with no hand rails.

Whipped up some sway bar mounting spacers for my fathers small block vega. The crank pulley interferes with the location of the front bar, but dropping it ~2.5" should do the trick.

The e-brake cable on the Monte Carlo rests lightly on the new exhaust, so I whipped up these little retainers from 3/16” stainless rod

Now it doesn't drive me crazy rattling at stop lights

Buzzgirl and I have been living in a 262 sqft apartment for the last 4 summers. It's lovely and plenty but we only had a miniature kitchenette and we both love to cook. We had a 110 sqft screened in porch out front. After selling my BMW I put half the money back into building us a little kitchen.

Yes, it was a porch so it slopes down. Nothing quite lined up because of that but I made it work.

learned how to do quick and dirty radius on the mill without a rotary table, used a pin through the hole and put it against the side of the vice while keeping the cutting tool in the same yz plane and rotating the part to cut a lot of "facets."

Was then able to clean it to super quick on the grinder.

roughly 10-15 minutes to do both so not too bad

Popular Mechanics magazine had a blueprint and plans for a workbench back in the mid-1950's. My grandfather, my father and I all built one for our basement over various decades. My dad ended up with two workbenches then I ended up with them.

Not needing two workbenches in the basement my grandfathers top became a coffee table. (Sold the box portion on Craigslist)

Nothing crazy here, but a client of mine runs a machine shop and just brought in this giant Matsuura that is so tall that his employees can't reach up to load the machine. I built a three-piece bolt-together step unit to assist in loading.

Yes, I could've spent a lot of time on finish details but, given the use case, that seemed unnecessary. All said, I think this came out pretty well. It sits nice and level and doesn't rock or tilt, and the expanded metal will make it easy to keep the walking surface free of debris. If and when it needs to be moved, it can be unbolted and carried by hand easily.

My wife wanted a swing, so I went over to my buddy's wood shop and we made one out of hickory.

Pictures were before I put the oil finish on and trimmed the rope to length.

Also, not really something I "made", just "made legal again". Got my trailer wired with fresh LEDs and wire. So bright!

Drill template for a mk60 abs. Drew it up in fusion 360. Complete with outline of the abs so I can get it just right before clamping to drill.

Drill template for a mk60 abs. Drew it up in fusion 360. Complete with outline of the abs so I can get it just right before clamping to drill.

In reply to theruleslawyer :

What are you drilling the ABS for? I'm curious and interested to see how the retrofit turns out.

Kendall Frederick said:In reply to theruleslawyer :

What are you drilling the ABS for? I'm curious and interested to see how the retrofit turns out.

Mounting it to a bracket. The bolt pattern on it is weird so I figured this would help me get the holes right. Drilling the bracket, not the ABS.

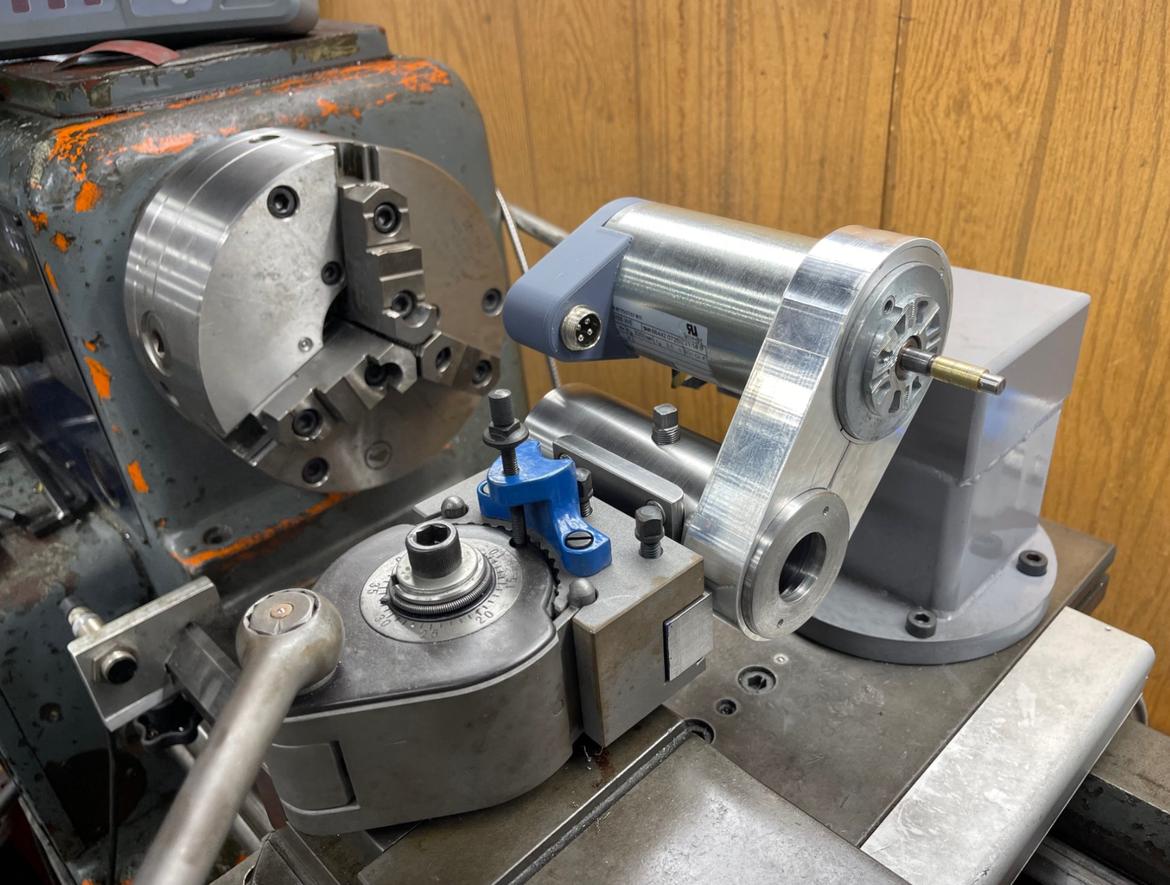

Update on my CNC router. It was designed to handle machining aluminum but I was a bit scared, along with the worry of throwing chips all around the garage. Finally called my own bluff and gave it a try, and it worked really well once feeds and speeds where dialed in. The part is going into a tool post grinder.

You'll need to log in to post.