Knurled

UltimaDork

2/7/15 7:06 a.m.

oldeskewltoy wrote:

One reason I'm a 4AG fan.... so simple... so easy... just belt, and tensioner, even the water pump is independent

You have to take the motor mount out of the way? My GTI laughs at your follies.

Part of diagnosing the problems with the GTI I bought a couple years ago was finding the timing belt was off a tooth. Wow, I'd forgotten how easy it was to work on the old VWs. You can fit a fist sideways between the engine and chassis rail, the motor mount is behind the engine instead of through the timing belt, and you can access the crank pulley with an extension through the wheelwell if you turn the steering all the way to the right, no need to take the wheel off or jack the car up.

Knurled

UltimaDork

2/7/15 7:10 a.m.

mad_machine wrote:

Question is.. did Porsche follow in their footsteps with tooth design?

Don't know about Porsche, but Audi didn't change from square to rounded teeth until 1990-1991 or so. The actual VIN split is in 1990. When looking up parts for my '90 200 engin, I had to scrape down to find the number stamp on the block to see which belt and water pump I had to order.

OTOH, my '86 VW has had a square belt on it for 80k and it's still fine. The belt problem really is a Porsche thing. They simply did not do a very good job of engineering the belt drive.

Knurled

UltimaDork

2/7/15 7:14 a.m.

carbon wrote: I think it's bull e36m3 and those itallian berkers are just trying to ream you on another service, it doesn't even have valve springs and there are only 4 valves 4! and there are two belts!!!!!!!! The thing doesn't even rev that high. Are you really telling me that belt is worked harder than the one in my 2jz (24v/ one belt)? WTF?

Actually, this makes sense. With the low number of valves per camshaft, let alone cams per belt, the torque loads on each belt are going to be oscillating a lot. The torque loads on an inline six are going to be FAR smoother and more friendly to the belt.

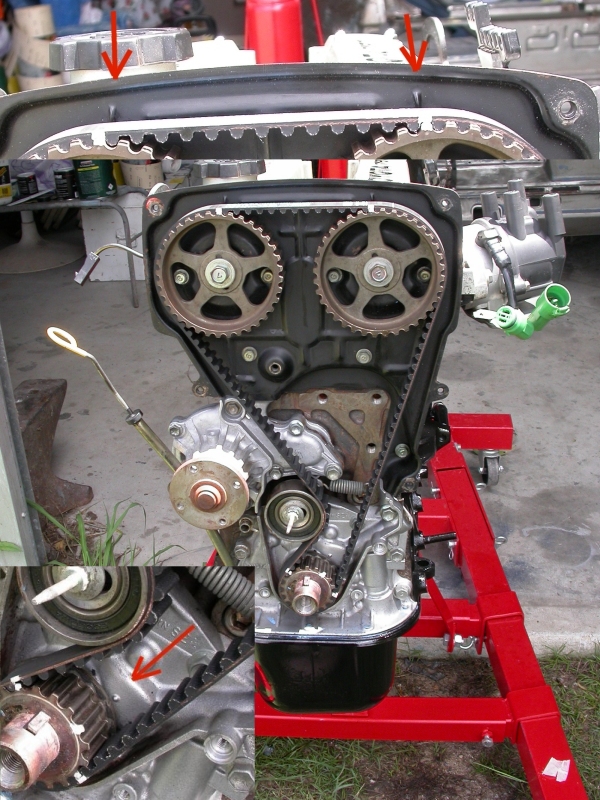

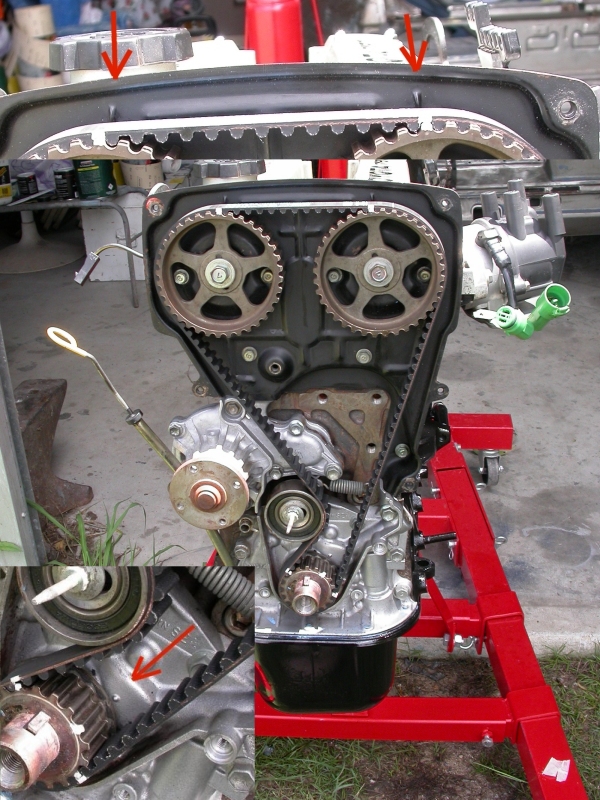

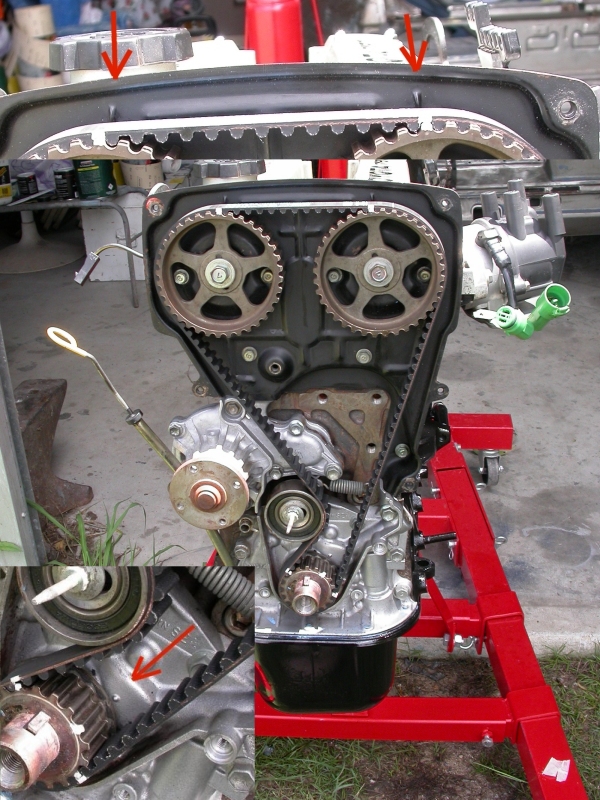

Subaru flat-four engines have the same issues on DOHC models. Manual transmission versions actually have little guides that have to be a certain distance away from the crank and cam pulleys to keep the belt from jumping off, because four cams times boxer engine equals a lot of weird torque spikes/reversals on the belt drive.

Knurled

UltimaDork

2/7/15 7:27 a.m.

turboswede wrote:

In reply to oldeskewltoy:

It was the precursor to the Audi I5 and was used in the Audi 100LS which morphed to the 4000, etc. shares the same bellhousing pattern and there are a few other similarities with VW and Audi engines of the time period.

The bizarre part of that? That engine design was originally from Mercedes.

The Audi I5 shares nothing with that old four except for bellhousing bolt pattern. The old four that the 924 engine was based on had a sane bore spacing and was a pushrod engine.

The Audi I5 engine is a VW four-cylinder in every dimension you can care to measure, with practically everything interchangable. Same deck height, same ridiculously short bore centers (an Audi five is about the same length as a 944 four!), same cylinder head port shapes... in fact you can cut the rear cylinder off of an Audi intake or exhaust manifold and use in on a VW four. Many 5000 turbo exhaust manifolds have been sacrificed to people putting turbos on VWs. (Furthermore, you can use a pair of VW 16v turbo manifolds to put a pair of turbos on an Audi V8!)

My perpetual-build turbo Audi motor's rotating assembly is 80% a friend's old bubble-block based turbomotor, with one new piston ordered to the same spec as the original four.

The main differences between an Audi five an an old VW four are Audi's using a block-mounted water pump and a crank snout oil pump, with the distributor in the head. Oddly enough, the 06A block looks a lot like an Audi five that is short one cylinder. Water pump and thermostat in the same spot.

Streetwiseguy wrote:

Germans are not very good at rubber. Simple as that.

I differ in opinion. Billy boy makes great condoms. German made.

Knurled

UltimaDork

2/7/15 10:25 a.m.

Trackmouse wrote:

Streetwiseguy wrote:

Germans are not very good at rubber. Simple as that.

I differ in opinion. Billy boy makes great condoms. German made.

Kinder durch Freunde!

(The original VWs were known as KdF-Wagens because of the slogan Kraft durch Freude - Strength through Joy. Because people back then were a lot like people today, people would joke about Kinder durch Freunde - children through girlfriends. If German rubber was as bad back then as it is today, you'd get a lot of Kinder durch Freunde no matter how hard you tried...)

Knurled wrote:

carbon wrote: I think it's bull e36m3 and those itallian berkers are just trying to ream you on another service, it doesn't even have valve springs and there are only 4 valves 4! and there are two belts!!!!!!!! The thing doesn't even rev that high. Are you really telling me that belt is worked harder than the one in my 2jz (24v/ one belt)? WTF?

Actually, this makes sense. With the low number of valves per camshaft, let alone cams per belt, the torque loads on each belt are going to be oscillating a lot. The torque loads on an inline six are going to be FAR smoother and more friendly to the belt.

Subaru flat-four engines have the same issues on DOHC models. Manual transmission versions actually have little guides that have to be a certain distance away from the crank and cam pulleys to keep the belt from jumping off, because four cams times boxer engine equals a lot of weird torque spikes/reversals on the belt drive.

That makes sense, but in the ducat's case it doesn't entirely answer the question. It doesn't have valve springs, it's desmodromic so there is a cam to close the valve too. You can spin the cam with your hand easily

Knurled

UltimaDork

2/7/15 10:48 a.m.

In reply to carbon:

Well maybe there's still some weird resonance effects from driving only four "lobes" per cam? Valvetrain still has significant inertia even if there's no valvesprings to muddy things up.

I'm reaching here.

The only person I've known who had a Ducati had to have the the top end rebuilt twice in 6000 miles and the bottom end rebuilt once. While still paying for a $20k bike. So maybe they were just doing their part to reinforce the stereotype that Italian machinery is magically awesome yet frightfully fragile?

carbon wrote:

SEADave wrote:

Just be glad it's not a Ducati - earlier ones had the interval at 10k kilometers, which is about 6,200 miles. Plus there are two belts and you are supposed to adjust the valves at the same time.

EXACTLY….

I was about to comment that the SWMBO's berking monster needs one at that interval, I think it's bull e36m3 and those itallian berkers are just trying to ream you on another service, it doesn't even have valve springs and there are only 4 valves 4! and there are two belts!!!!!!!! The thing doesn't even rev that high. Are you really telling me that belt is worked harder than the one in my 2jz (24v/ one belt)? WTF?

My buddy that owns RSRacecraft found a solution to the failing Ducati belts.

Since Ducati would not share the good stuff with him, he (beat the factory team and) would not disclose the fix.

I think it was heat related.

I think it was heat related.

tjbell

Reader

2/7/15 2:39 p.m.

kanaric wrote:

928 had a timing belt? I don't think i've ever seen a v8 with one

toyota 4.0, 4.7 v8 , audi 4.2 there is probably more but brain fart

The ducati is a 1:1 drive with small sprockets. Big cam torque small sprockets means really high belt loads.

So why isn't the 944 timing belt service interval longer than 30,000 miles?

(All that Ducati information was interesting...)

this just reminds me of why I still like ohv engines. after servicing several different ford timing belts I still prefer the original 2.3 lima for ease of service. Im not cut out for Porsche ownership!

I'd gloat about timing chains being superior but my VR6 is still in the shop from a timing tensioner failure so I'll just look at all the pretty pictures of engines.

You guys are making me love pushrods even more

In reply to noddaz:

That's why I love my Mazda3, wifey's Mazda5 and my three Triumph TR8's. None of this nonsense. Porsche built this in deliberately to make more money of the suckers who bought 944's for no other reasons that they were Porsches.

RXBeetle wrote:

The ducati is a 1:1 drive with small sprockets. Big cam torque small sprockets means really high belt loads.

I think we have a winner!

/goes outside and hugs gear driven valvetrain in Powerstroke. 289k troublefree miles so far.

In reply to noddaz:

Because Porsche didn't have experience with it, over engineered it and after testing it was determined that it was 30k. Period.

Follow up question on this subject then: why do they even manufacture engines with such an innate hand grenade of a failure point? In my Miata if the timing belt ever breaks, I simply coast to a stop and put on a new one. But in my '91 Eclipse and now '07 Passat a failure of a part that wasn't even due for service (DSM assured me the timing belt wasn't ready to be changed for another 10k miles when it munched) or was supposed to EVER be serviced (VAG timing chain buried between engine and transmission). Both failures resulted in bent valves and generally bad mechanical mayhem costing warrantee suppliers big bucks.

Would it really be so hard to make engines non-interference? Couple of releaf cuts in the tops of pistons and no more ticking time bomb.

Knurled

UltimaDork

2/8/15 8:23 a.m.

Gearheadotaku wrote:

You guys are making me love pushrods even more

Timing chains and timing belts and pushrods and valvetrain geometry and tensioners and phasers and this and that and the other...

2 ounces of oil per gallon of gasoline, a stout exhaust system, and me and rotaries are good

Knurled

UltimaDork

2/8/15 8:29 a.m.

KyAllroad wrote:

Would it really be so hard to make engines non-interference?

Yes. To make an engine non-interference, you need to make compromises to the piston or chamber (redundant: the piston is the bottom of the chamber) that hurt emissions, fuel economy, and power. Which is also redundant - a good chamber will reduce emissions and fuel consumption while also increasing power. You can't have that if the valve seats are way up high or you have deep recesses in the pistons.

And VAG is right - the timing chain isn't ever supposed to be serviced. You are simply being irresponsible and unreasonable to want to drive a car mroe than 60k miles. Doing more oil changes is wasteful, and driving a car more than three years old is also wasteful because new cars are cleaner and more efficient. (This is what many people really believe)

oldeskewltoy wrote:

The Fiat TwinCam is not all that different.. but it's one difference might be better.

As you can see, it has an auxiliary "cam gear" that all it does is drive the oilpump, distributer, and fuelpump (on cars with block mounted distributer and fuel pump) that also does a great job of smoothing out the tight radii of the belt as it comes off of the tensioner. Sadly, you cannot see the crank pulley, as it be behind the fanbelt pulley

Knurled

UltimaDork

2/8/15 9:19 a.m.

That looks like the VW setup, with the jackshaft that drives the distributor and oil pump.

Or, for that matter, the Ford "Lima" engine.

Or the Volvo redblock engine, which looks so close to a Lima than you'd think that they were the same engine.

44Dwarf

UltraDork

2/8/15 10:27 a.m.

Long spans between small pulleys and thin belts with varying loads at wicked surface speeds equal short belt life. As a former owner of a 944 and a current owner of a Ducati ST4 916 desmoquattro I really hate belts and there short service lives. Thankfully CA Cycle works has better quality belts for less $$ then factory Ducati belts but they have same shelf life 2 years or XXX miles. Yes there a pain in the ass but not really that hard take your time use the right tools and even a kid can do it.

At least the 944 didn't have to use a vibration meter to set the tension to 100HZ.

The fibers in the belts absorb water along with heat cycles they get weak so it cheaper to keep the short intervals then rebuild motors