stroker

PowerDork

6/21/23 2:33 p.m.

Per previous thread I bought two RD 400 Yamahas for virtually nothing. The better of the two engines is going to a friend of mine which leaves the worse of the two for me to decide its fate. I think, even if I got the pistons freed up, that the crank is probably rusted and the only real solution is to break the engine down to see if it's economically viable. If not, then I Ebay the useful bits for whatever I can get.

The problem, however, is that the engine has Phillips head screws holding the side covers on the engine cases. Those screw heads are boogered up badly--I can't get them to turn. Any suggestions on how to proceed? Try to cut a single slot with the angle grinder/cutting disc and go from there?

They aren't Phillips screws. They are JIS.

Try a JIS impact driver. You may be surprised with your success.

In reply to Cousin_Eddie (Forum Supporter) :

A Vessel Impacta #2 screwdriver has to be some of the best money I've ever spent.

A JIS driver bit is the correct tool, but in most cases a regular phillips in an impact driver will do the job. If the screw is totally boogered out, use a drill of the appropriate size so that the screw head will pop off, then after removing the side cover you can remove the shank of the screw with pliers or a vise grip.

stroker

PowerDork

6/21/23 3:29 p.m.

Cousin_Eddie (Forum Supporter) said:

They aren't Phillips screws. They are JIS.

Try a JIS impact driver. You may be surprised with your success.

I've been involved with Japanese bikes for more than 50 years--how is this the first I'm hearing of this...?

Not sure Stroker. It's a god send. Once I learned about JIS, I was like I've had JDM cars for how long and I don't have this? It's definitely the right tool for the job.

It's kind of like, "Why does the phillips screwdriver on a Swiss army knife suck?" Because it isn't a phillips, it is an Imperial Cross. Old "made in Hong Kong" tools were the same way.

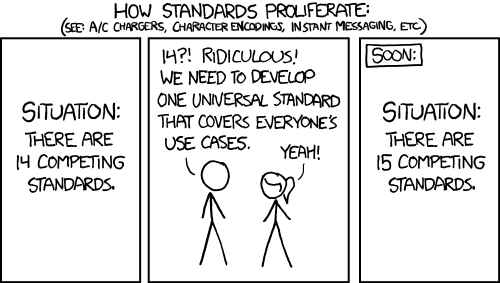

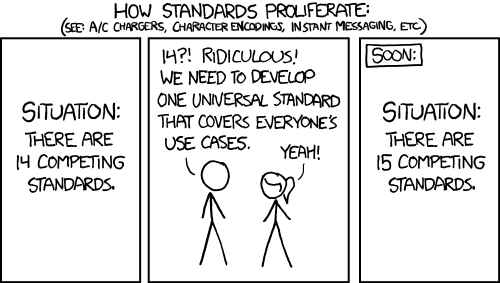

Screw engineers/manufacturers:

Another vote for the Vessel JIS screwdriver. Phillips just don't bite as well into a JIS fastener. Also, putting a little bit of valve-lapping compound in the head of the screw will help the driver bite a little better.

Don't forget about pozi-drive, the third Phillips variant.

Noddaz

PowerDork

6/21/23 6:23 p.m.

Thread sidetrack:

Where does anyone buy replacement bits for the impact driver?

Back to our thead in progress.

Is that why #2 bits seem to strip out construction screws made in China a lot more in the last 20 years?

VolvoHeretic said:

Is that why #2 bits seem to strip out construction screws made in China a lot more in the last 20 years?

No, that's because you don't use Robertson screws.

ShawnG

MegaDork

6/22/23 12:00 a.m.

obsolete said:

In reply to Cousin_Eddie (Forum Supporter) :

A Vessel Impacta #2 screwdriver has to be some of the best money I've ever spent.

This.

I have one, it's a game changer.

Try knocking a bit of the tip off your #2 Phillips driver with a bench grinder. This let's it seat deeper in the jis screw and will be less likely to strip out.

Once you have them all out, replace with Allen fasteners.

Impact screwdriver and a set of all the forms of bits is a game changer.

Noddaz

PowerDork

6/22/23 6:07 p.m.

93gsxturbo said:

Noddaz said:

Thread sidetrack:

Where does anyone buy replacement bits for the impact driver?

Back to our thead in progress.

Snap On has them

Snap On? I can at least see how much those are before I run from the truck while laughing hysterically.

ShawnG

MegaDork

6/22/23 6:14 p.m.

Noddaz said:

93gsxturbo said:

Noddaz said:

Thread sidetrack:

Where does anyone buy replacement bits for the impact driver?

Back to our thead in progress.

Snap On has them

Snap On? I can at least see how much those are before I run from the truck while laughing hysterically.

That's why you strip Phillips heads.

Snap-On makes the best #2 Phillips driver on the planet. I own a few of them.

Trent

PowerDork

6/22/23 7:12 p.m.

Impact screwdriver bits are really one item that you SHOULD buy from either a tool truck or a brand with a great exchange policy. They absolutely will break with repeated use. For the $7 per bit I paid Matco for them they have replaced each of them 6 or 7 times. It is a false economy to spend less on something without a warranty. If Tekton offers the 5/16" impact driver bits, I'd get them from them.

I haven't used the screwdriver/part you smack with a hammer in years. I took the bit off the end, realized it was a standard 3/8" socket and I use it in my low torque impact driver. It just works better. You can really bear down on it and the hundreds of small impacts work better than the huge sloppy hammer generated one. Less chance of damaging the item the screw is stuck in as well.

I suppose we could just have the conversation about how Phillips screws just kinda suck and that Allen head, Robertson and yes even slot head are better at imparting torque to the fastener. Phillips are a torque limiting feature and will cam out under high force by design.