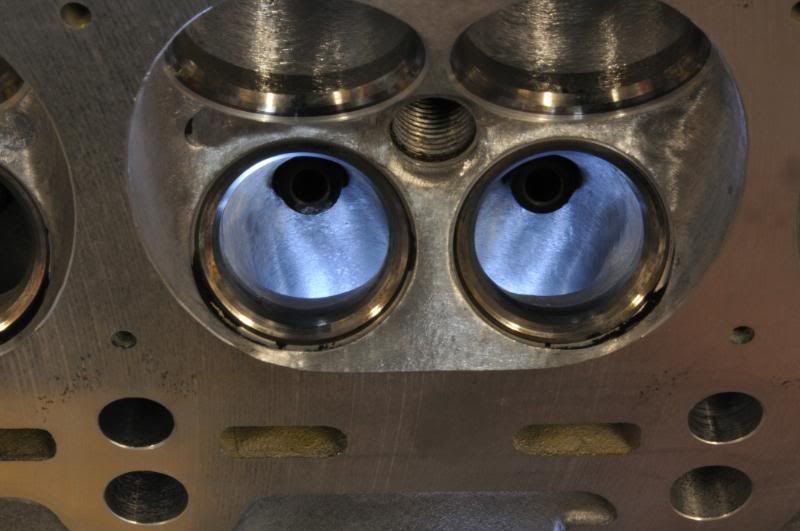

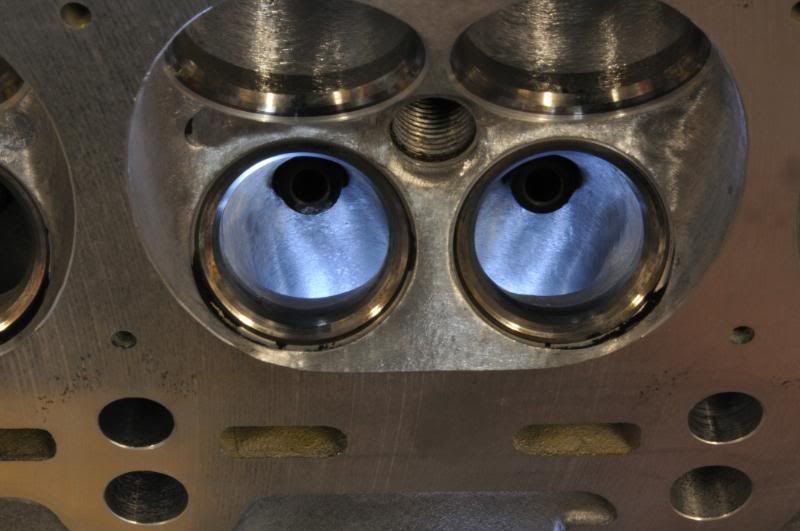

VW ABA head with 1mm oversize valves....... short radius (both intake, and exhaust) are garbage. I did managed to build one on the intake side

As far as the exhaust is concerned - not a great deal of room at the roof, or the floor, but both walls..... yielded very good results

Side draft manifold only required a little bit of core shift adjustment

Just assembly left

I may have told you this before but I love this thread. Looking at those VW heads is it unusual to have the intake and exhaust ports flipped like that?

In reply to Stampie :

VW probably did that to make the intake manifold as compact as possible without having lots of kinks.

Kettering designed V8s (most GMs from the 50s) are IEIEEIEI to make an exhaust crossover for intake manifold exhaust heat easier. This is for fuel economy and smooth drivability with a carburetor and points ignition system.

Stampie said:

I may have told you this before but I love this thread. Looking at those VW heads is it unusual to have the intake and exhaust ports flipped like that?

is it unusual..... not that much... while in this case it is in the chambers, having paired, or in some inline 6's, tripled pairings used to make a casting.... as to why I'm not sure.

My Hemi V8 heads are flipped - in my case it isn't the valves, but plug location

Would you be willing to take on an Audi 5 cylinder head? It's more or less the ABA head, but counterflow instead of crossflow, and one extra cylinder.

I have two that I ported myself, no doubt very poorly, and one "virgin" head that probably needs new guides because it's been to the moon and halfway back. Plus it has 8mm stems and the only good valves anymore are 7mm.

Supposedly there are two different ABA castings, the early one that is not horrible, and the '96-up head that has short turns like the ports were designed with a drill press.

So, heres a question that ive been half ass googling but want to ask the gurus.

Dohc neon head.

Whats the best investment in porting? Bowl blend? Gasket match? Knife edging the port divider?

The head ports look like almost every othe 2 liter twin cam head of the late 90s, so there HAS to be some good information.

oldeskewltoy said:

VW ABA head with 1mm oversize valves....... short radius (both intake, and exhaust) are garbage. I did managed to build one on the intake side

As far as the exhaust is concerned - not a great deal of room at the roof, or the floor, but both walls..... yielded very good results

Side draft manifold only required a little bit of core shift adjustment

Just assembly left

I found that some ABA castings (I think the later castings) have a "hump" in the intake track near the valve guide. Have you come across this before? I had an extra head where I leveled it out a bit, and it did help flow on the bench, but I am wondering if in the future there is something more that can be done to the shape than just lobbing it off.

Honsch

Reader

9/15/21 11:07 a.m.

That hump is for additional swirl for emissions reduction. On the race car, I just remove it.

Pete. (l33t FS) said:

Would you be willing to take on an Audi 5 cylinder head? It's more or less the ABA head, but counterflow instead of crossflow, and one extra cylinder.

I have two that I ported myself, no doubt very poorly, and one "virgin" head that probably needs new guides because it's been to the moon and halfway back. Plus it has 8mm stems and the only good valves anymore are 7mm.

Supposedly there are two different ABA castings, the early one that is not horrible, and the '96-up head that has short turns like the ports were designed with a drill press.

be happy to look/listen, email me.... These were later castings..... although no humps were found in the intake tract

Mr_Asa

PowerDork

9/15/21 12:17 p.m.

I need to find a porting guide for LS cathedral port heads. Probably many out there, I just gotta find a good one.

Dusterbd13-michael said:

So, heres a question that ive been half ass googling but want to ask the gurus.

Dohc neon head.

Whats the best investment in porting? Bowl blend? Gasket match? Knife edging the port divider?

The head ports look like almost every othe 2 liter twin cam head of the late 90s, so there HAS to be some good information.

Bowl blending, setting the bowl/seat diameter to a percentage of the valves diameter. The other 2 just don't matter to the same degree... if at all. Gasket matching can actually be harmful, and knife edge a port divider does little or nothing without the proper port work to support it.

This is actually the 2nd head.... the first head had a hidden crack that revealed itself the moment the new seats were installed

In reply to oldeskewltoy :

Cool. What percentage of the valve am i looking for?

Is cleaning up casting flash and such worthwhile? Youve already saved me HOURS.

Dusterbd13-michael said:

In reply to oldeskewltoy :

Cool. What percentage of the valve am i looking for?

Is cleaning up casting flash and such worthwhile? Youve already saved me HOURS.

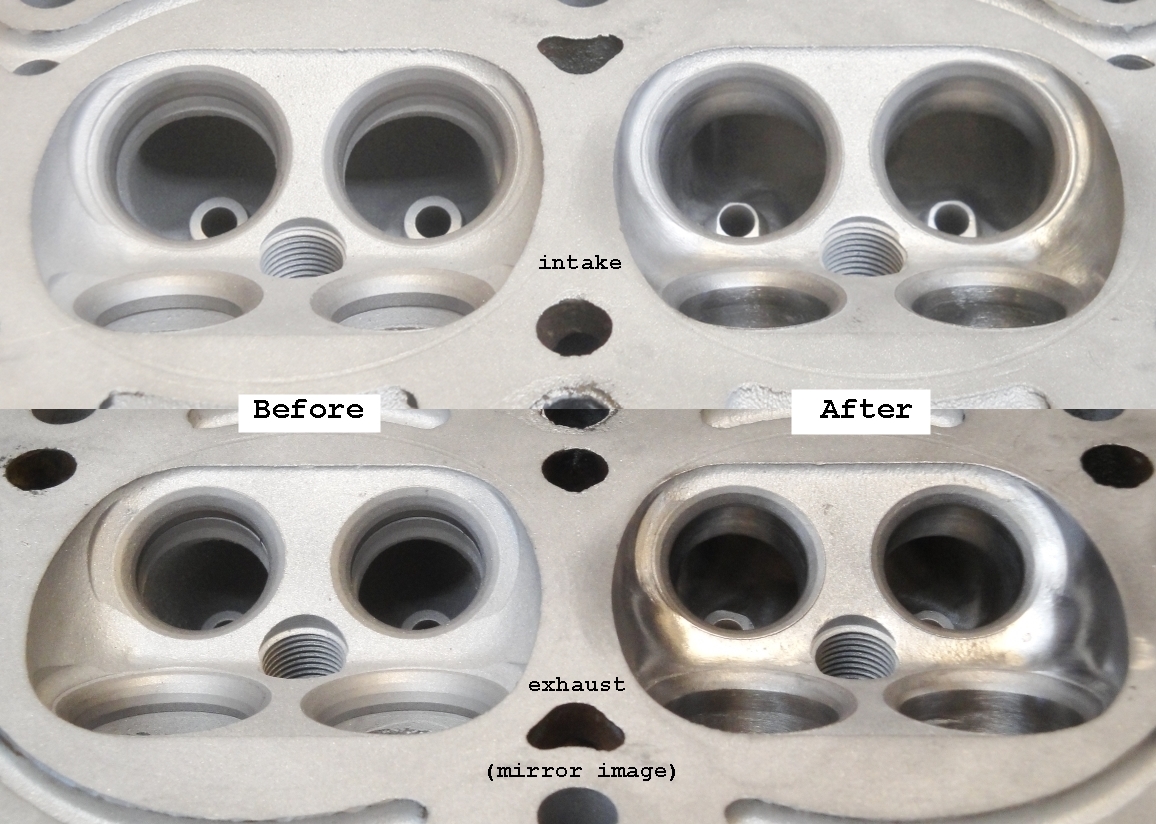

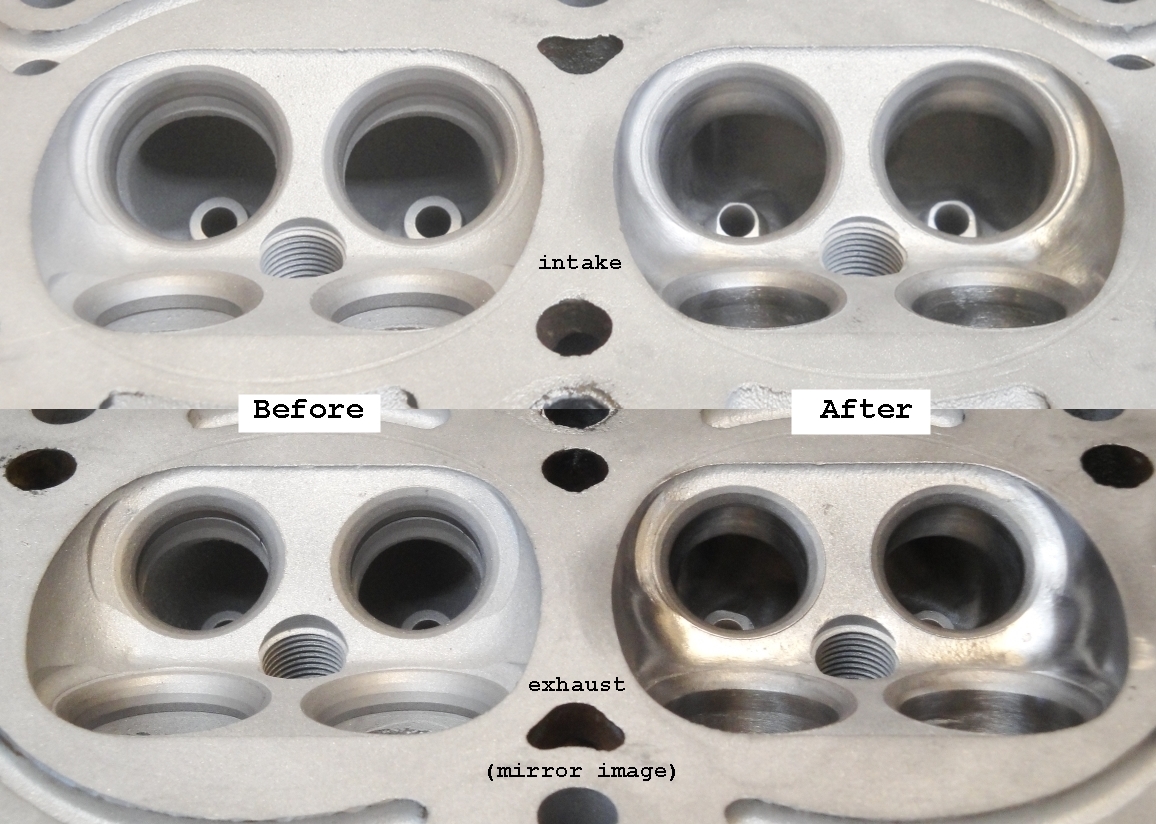

The magic numbers are between 85% and 90%. Measure the valves diameter, multiply by 85%, and that would be the minimum cross section of the seat/bowl. For example 4AGE intake valve is 30.5mm. The bowl/seat throat is about 25.5mm stock, or about 83.7% of the valves diameter. So if you open the 4AG seat/bowl out to 26mm, it is just over 85%. By doing this you also gain enough room in the bowl to remove harmful casting, or machining, as well as improving the shape of the bowl - example

Some heads (Porsche heads listed above) are already at, or near 90%, in which case bowl clean up (removing casting marks), correcting core shift, and a multi angle valve job are about all that can be done... without adding material. Look back (through this thread) at what I do in the bowls.

As to how to do it - setting bowl/seat diameter..... I began with a Dremel, and a couple of sanding drums.....

don't forget an accurate caliper to get your ID throat measurements

mke

Dork

9/15/21 1:39 p.m.

oldeskewltoy said: As to how to do it - setting bowl/seat diameter..... I began with a Dremel, and a couple of sanding drums.....

I bore them in the mill so they are all pretty much exactly the same.

mke said:

oldeskewltoy said: As to how to do it - setting bowl/seat diameter..... I began with a Dremel, and a couple of sanding drums.....

I bore them in the mill so they are all pretty much exactly the same.

nice to have a mill...... but only a few have a mill handy like you do......

but only a few have a mill handy like you do......

In reply to oldeskewltoy :

Thanks!!

Do you mind me picking your brain as i work on this head? I know its how you make your living, so i understand if the answer is "id rather not".

Just trying for free hp for the challenge motor.

Dusterbd13-michael said:

In reply to oldeskewltoy :

Thanks!!

Do you mind me picking your brain as i work on this head? I know its how you make your living, so i understand if the answer is "id rather not".

Just trying for free hp for the challenge motor.

Sure... happy to help where I can..... can I assume your challenger motor is a DOHC Neon?? (edit - found this: http://www.turbo-mopar.com/forums/showthread.php?67557-Porting-a-16v-neon-head)

One other "tool" I've recently gotten are a selection of Pferd small (1/8" shank) flap wheels.

In reply to oldeskewltoy :

Thansk! I had found that thread, but looking at cut up ports made no sense to me, to be honest. Cant really see what im looking at except that walls seem good and thick.

Dusterbd13-michael said:

In reply to oldeskewltoy :

Thansk! I had found that thread, but looking at cut up ports made no sense to me, to be honest. Cant really see what im looking at except that walls seem good and thick.

I found a few photos after the cut-aways that I thought were interesting...

intake side... bowl looks blended, no inclusions (casting marks), and the short side looks adequate

On the exhaust side a similar result, short radius appears to be "softened" with no casting imperfections

While this is ok... I'm not a fan of knife-blading the splitter, especially when there is room in the outer port walls

and finally again this is ok...there might be more room in the port roof and walls but without a gasket on it I can't be sure

When you say the short side looks adequate, what do you mean? The short side is the tight radius bend on the bottom of the port, but what are you looking for to judge good/bad?

oldeskewltoy said:

This is actually the 2nd head.... the first head had a hidden crack that revealed itself the moment the new seats were installed

I think they all crack there. Certainly it seems like at least two are cracked in any given 10v turbo head. I have never seen the crack extend into the ports, though!

I'll be paying closer attention there...

Dusterbd13-michael said:

When you say the short side looks adequate, what do you mean? The short side is the tight radius bend on the bottom of the port, but what are you looking for to judge good/bad?

does this help at all (from an earlier post).....????

Get your Neon head cleaned, and take similar photos.... we can discuss along the way.......

The "king" of the imports, a Acura/Honda K24 RBB2 head....... triple lobe cams on both the intake, and the exhaust

The high lift lobe engagement......

Port work begins.........

one bowl down on the intake side....

both bowls down......

more to come.......

exhaust. I can feel a ridge where the valve seat is more into the port that the aluminum casting on the short side.

intake: looks pinched on the floor, like it could be smoother and rounder by a bit.

intake: looks pinched on the floor, like it could be smoother and rounder by a bit.

Right? This is the neon dohc head we were discussing for my challenge car. Lotta scrubbing....

![]()

intake: looks pinched on the floor, like it could be smoother and rounder by a bit.

intake: looks pinched on the floor, like it could be smoother and rounder by a bit.